Serai CR/41 User manual

INSTALLATION OF THE CONTROL PANEL CR/41

Place the device near the gate, in order to have the minimum lenght of the cables for connection with the system.

We suggest to place the control panel under a cover or in a place with two lateral walls, to protect it against the

weather conditions. Moreover fix it at 1,5m height so to be far from children.

WHERE PLACING THE CONTROL PANEL

The control panel is supplied from factory with the opening towards the left side. It is possible to change the opening,

please follow the below instructions:

Insert a screwdriver in the hole for the hinges-fixing in the

back side (as shown in the picture) and pull the cover,

pressing the fixing “tooth” (picture 1)

Fig.1

Insert a screwdriver in the hole for the hinge-fixing which is in

the front side of the cover and pull the hinge pressing the

“tooth” (picture 2)

Fig.2

DAL 1965

Install the hinges on the right side of the back cover,

insert them with the fixing “tooth” towards the indoor

part of the cover until the click (picture 3)

Fig.3

COVER OPENING: TOWARDS THE RIGHT SIDE

Pag. 1/10

CR/41 I E 01 10 02072007

ATTENTION: This operation has to be made before the

fixing on the wall.

!

E R A IS

GATE OPENERS DEPARTMENT

DAL 1965

CABLES’ PASSAGE

For the entry of the cables, in the lower part of the cover, holes are already prepared for the glands PG11 and PG

13,5

Cable passage

!ATTENTION: close tightly all the entries to avoid insects

passage and so possible damages.

Pag. 2/10

CR/41 E

WALL FIXING OF THE CONTROL PANEL

We suggest to install the device near the gate, in order

to have the minimum lenght of the cables for the

connection with the whole system.

The control panel has to be fixed with the holes for the

passing of the cables downwards

NO NO YES

Ø 6 ÷ 8 mm

aaaaaa

aaaaaa

aaaaaa

aaaaaa

aaaaaa

aaaaaa

OPENING AND CLOSING OF THE BOX

Advices for generical spaces connections, according to Italian Law ( CEI 64-8 ).

1.Predispose at the bottom of the system an omnipolar disconnecting switch with

distance between contacts of 3 mm or more. On alternative choice it is possible to use

a magnetothermic switch of 10A.

2.Make any kind of connections with no power supply on the system, or with the

disconnecting switch on “ open “ position ( symbol “0” ). Particularly, the control panel

must never be supplied during the wiring, nor when inserting the expansion cards.

3.During the installation use following wires.

- For control panel, motors and electric lock power-supply: 1,5mm² for max. lenghts of

19m, section 2.5mm for lenghts up to 31m

- For the flashing light: section 0.75mm² for max. lenght of 3m, section 1.5mm² for

lenght up to 19m

- For low voltage lines and current, such as photocells, command buttons,

electromechanical key, sensitive edge and other safety devices: section 0.5mm² for

max. lenght of 50m, section 0.75mm² for lenght up to 100m.

2

When you open the box, control that the hinges exit from their

location in order that the cover can remain open during the

electrical connections.

Close carefully the cover, the hinges have to be correctly

inserted.

Close the cover with the screws.

DAL 1965

DAL 1965

Pag. 3/10

CR/41 E

F1

F2

ON

SW1 SW2

345 6 78

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9 DL8

DL10

1 2 910 11121314 15161718 19 20 21 22

272526

2324

28 29

OPEN

CLOSE

COMMON

230V~ ±10%

50/60Hz

FN

FLASHING-LIGHT

230V~

COURTESY LIGHT

230V~

OPEN

CLOSE

COMMON

M2M1

PED

NC

NC

CLOSING

PHOTOCELLS

RECEIVERTRANSMITTER

OPENING

PHOTOCELLS

RECEIVERTRANSMITTER

NC

NC

NO

NC

NO

PEDESTRIAN

START

STOP

ELECTRIC-LOCK

12 Vac 15VA max

EX. SERAI M/83/1

24 Vac

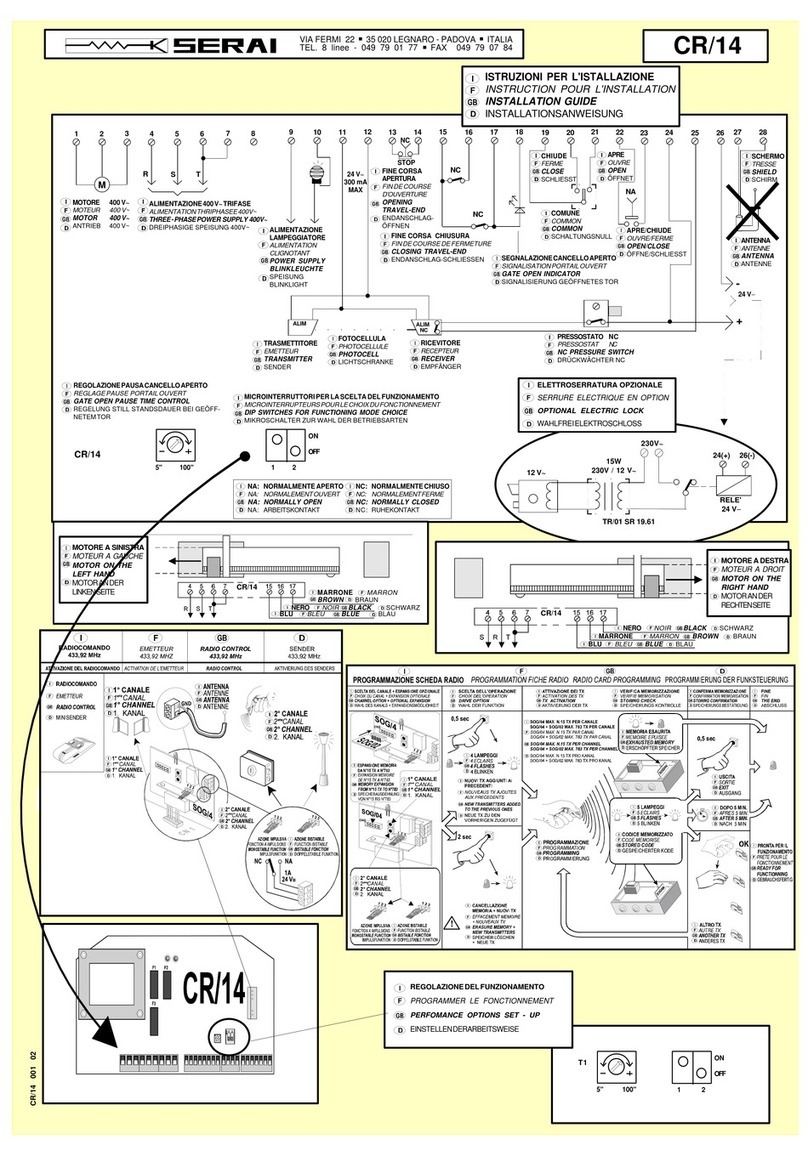

CONNECTION DIAGRAM

CLAMPS CONNECTIONS DESCRIPTION

21 - 22 POWER SUPPLY Entry for electronic card power supply 230Vac 10% 50/60 Hz

±

11 - 12 FLASHING LIGHT Output for flash-light power-supply (230Vac - ), for lamps without

the inside electronic - for ex. SERAI RZ/20F -

max 50W

12 - 13 COURTESY LAMP Output for courtesy lamp (230Vac- ): switched-on for 90 sec. after the STOPmax 100W

14 - 15 - 16 MOTOR M1 Output for motor M1 power-supply (14=common, 15=opening, 16=closing) for

single wing or pedestrian opening (the wing to which is connected the electric lock)

26 - 27 PHOTOCELL

POWER-SUPPLY Output for power supply 24Vac ( ) for accessories such as photocellsmax 500mA

6

OPENING

PHOTOCELL /

SENSITIVE EDGE

8 - 9 NOT USED Make a short-circuit on the common with jumpers.

5CLOSING

PHOTOCELL

2

4

PEDESTRIAN

OPENING

Entry for the pedestrian opening (contact NO). With DIP1 SW1 OFF it opens

only the wing connected to M1. With DIP1 SW1 ON it opens the wing for 7 sec.

STOP

Entry for the STOP (contact NC): when pressed the working of the motors is

interrupted, if pressed during the pause time when the gate is open, the

automatic reclosure is canceled.

3START

OPENING

Entry for the start drive (contact NO) opening and closing with step-by-step

function.

With DIP4 SW2 OFF: entry for photocell activated in opening and

closing phase (contact NC). If obscured during opening the gate

stops until the photocells remains obscured. During closing the gate

stops and reverses the movement.

With DIP4 Sw2 ON: entry for sensitive edge (contact NC).

Entry for photocells activated only in closing phase (contact NC). If

obscured during the closing phase it stops the gate and reverses

1 - 7 - 10 COMMON

ENTRIES

Common clamps of the entries

17 - 18 - 19 MOTOR M2 Output for motor M2 power-supply (17=common, 18=opening, 19=closing)

for motor with delayed opening (gate with 2 wings)

25 - 26 ELECTRIC LOCK Output for electric-lock 12 Vac 15 VA max

23 - 24

ANTENNA

INTEGRATED

RECEIVER

Entry for the connection of the antenna to the integrated receiver

(23= 24= )SHIELD ANTENNA

28 - 29

OPEN GATE

SIGNAL

Output 24Vdc (28 , 29 ) for the connection of the open-

gate signal.

+ -

ATTENTION: to connect lamps with absorption more than

50mA, it is necessary to use an additional outside relay.

max 50mA

DELAY

IN OPENING

SET BREAK WORK

ABC

Com

+24

20 NOT USED

spia

12Vac

RX

TURN OFF POWER SUPPLY

BEFORE WIRING-UP

ADDITIONAL

RELAY

24Vdc - max 50mA

2928

LIGHT

POWER SUPPLY

LIGHT

FUSES:

F1 = 2A 250V~

-

F2 = 5A 250V~

-POWER SUPPLY

ACCESSORIES 24V-

230V-

SW1= Dip-switches to set the control panel

A= Push-button to enter into programming

(SET)

B= Push-button to program the times

(BREAK)

C= Push-button to program the times

(WORK)

POWER= Trimmer to adjust the motor force

SW2= Dip-switches to set the control panel LIGHT 24Vdc

max 50mA

CR/41 E

DAL 1965

Pag. 4/10

ELECTRICAL CONNECTION OF THE MOTOR

Connect the motors to the control panel using cables with 1,5mm

CABLE LIGHT BLUE : Common

CABLE BROWN : Open/Close - Capacitor

CABLE BLACK: Open/Close - Capacitor

CABLE YELLOW-GREEN : Ground

The following indications have to be respected (CEI 64-8):

- Connect the cable yellow-green to a good ground system

- Install at the bottom of the system, an omnipolar switch with at least

3mm as opening distance between the contacts.

² section.

Respect the colour of the cables as follows:

YELLOW GREEN =

GROUND CONNECTION

LIGHT BLUE =

COMMON

BLACK=

OPEN/CLOSE

BROWN=

OPEN/CLOSE

SI 12,5 µF

450V

NO

!

Fig 13

ATTENTION: the high

temperatures cause

different expansions

in all materials,

including the material

of our products. For

this reason we

recommend to control

the motor force

adjusting each winter

and summer in the

beginnig of each

season.

differencies in the

summer and winter

GROUND CONNECTION BETWEEN MOTOR AND THE HOUSE

MOTOR FORCE ADJUSTMENT

The setting of the motor force is made by changing the voltage through the trimmer “Power” in the control panel

CR/41.

The installation has to be carried out in the full respect of the current Laws concerning the gate automaton.

Please consider that the responisibility of the system and its working respecting the “standards” is of the

installer.

F1

F2

ON

SW1 SW2

345 6 78

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9 DL8

DL10

1 2 910 11121314 1516171819 20 21 22

272526

2324

SET BREAK WORK

A B C

Com

+24

spia

RX

CABLES

YELLOW-GREEN

OF MOTORS

CONNECTION

CLAMP

CABLE

POWER-SUPPLY

230 V~

CABLE

MOTOR 2

CABLE

MOTOR 1

CABLE

YELLOW-GREEN

HOUSE SYSTEM

DAL 1965

Pag. 5/10

CR/41 E

DIP-SWITCH SET-UP

DIP-SWITCH

SET-UP

DESCRIPTION

FUNCTION

- One-wing gate: it drives only the oputput indicated as M1

- Double-wing gate: it drives the outputs M1 and M2 (M2 is the wing

which has the delay in opening)

KIND OF

GATE

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

SLOW-DOWN

SET-UP

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

- Slow down speed: HIGH

- Slow down speed: LOW

- Final push activated: at the end of the closing, the motors receive

full power for 2 sec. in order to hook better the electric lock.

- Final push not activated

FINAL PUSH

IN CLOSING

- Kick-back activated: the electric lock is activated for a short closing

phase against the stop blocks and it is released after the start of

M1.

- Kick-back not activated: the electric lock is activated when M1

start and released immediately after the movement.

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

ELECTRIC LOCK

KICK BACK

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

STARTING

ACCELERATION

- Starting acceleration activated: when the motors start, they

receive full power-supply for 2 sec.

- Starting acceleration not activated: when the motors start, they

receive the power-supply as the voltage set with the trimmer.

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

SLOW-DOWN

SET-UP

- Slow-down not activated

- Slow-down activated

!

ATTENTION:

The set-up of the dip-switches has to be made with no power-supply to the control panel. When the

control panel is switched on, the set-up is confirmed and activated.

We suggest, after the dip-switch set-up, to program the working time (see Control panel

programming).

!

ATTENTION: During the slow-down the force decreases and so the speed depends from the

characteristics of the motor and the gate.

A SLOW-DOWN SPEED TOO MUCH LOW MAY PREVENT THE REGULAR WORKING

OF THE WING.

SW1 SW2

!

ATTENTION: When the motors MT/30/2 and MT/38/1 arrive against the stop blocks, there are

some vibrations - not dangerous - which may cause noise.

To avoid this noise the slow-down must be deactivated (dip2 SW2 ON).

DAL 1965

Pag. 6/10

CR/41 E

- A start impulse during the opening stops the gate.

- Another impulse closes the gate.

STE-BY-STEP

FUNCTION

NOT ACTIVATED

DURING

OPENING

- A start impulse during the closig stops the gate for 2 sec. and

opens it automatically.

- A start impulse during the opening is not considered. A start

impulse during the pause with the gate opened closes the gate.

DURING

CLOSING

2 s

start start

start

start

DURING

OPENING

DURING

CLOSING

THE SENDING OF

AN IMPULSE

DURING THE

GATE

MOVEMENT

DIP-SWITCH

SET-UP

DESCRIPTION

FUNCTION

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

- A start impulse during closing stops the gate for 2 sec. and opens

it automatically.

2 s

start

ENTRY

FOR

OPENING

PHOTOCELL

OR

SENSITIVE EDGE

1 2 3 4 1 2 3 4

1 2 3 4 1 2 3 4

- Function “sentive edge” activated: the entry to clamp 6 reverses the

motion of 10cm during opening or closing.

- Function “opening photocell” activated: the entry to clamp 6 stops

the motion during the opening, while reverses the motion during the

closing.

THE MEANING OF EACH LED

LED

FINE CH

FINE AP

FOTO AP

FOTO

STOP

PED

START

ON OFF

FUNCTION

Inside photocell

External photocell

STOP button

PEDESTRIAN button

Open/Close button

Opening Photocell free

Closing Photocell free

STOP button not pressed

Pedestrian button pressed

Open/Close button pressed

Correct connection of

8-10 clamps The Jumper on 8-10 clamps is missing

Fotocellula Apertura oscurata

(presenza di un ostacolo)

Fotocellula Chiusura oscurata

(presenza di un ostacolo)

STOP button pressed

Pedestrian button not pressed

Open/Close button not pressed

DL10 Programming It is used during the programming

DL8 Motor M2 Different brightness according to

the voltage to the motor M2

No power-supply to motor M2

DL9 Motor M1 Different brightness according to

the voltage to the motor M1

No power-supply to motor M1

Correct connection of 9-10

clamps The Jumper on 9-10 clamps is missing

STEP-BY-STEP

FUNCTION

ACTIVATED

SW 2SW 1

DAL 1965

Pag. 7/10

CR/41 E

CONTROL PANEL PROGRAMMING

It is important to follow carefully step by step the programming, if mistakes happen during this phase it is necessary

to make a new programming from the beginning.

To quit the programming switch on and off the control panel.

Before proceeding with the programming it is necessary to control that all electrical and safety devices are

connected (push-button, photocells, flashing light, etc...)

Check their correct functionning and if necessary:

All LED for the NC entries must be (stop, photocells etc...)

All LED for the entries NO must be (start, pedestrian)

ON

OFF

A jumper must be placed on the normally closed (NC) entries not usedATTENTION:

PROGRAMMING OF THE WORKING TIME AND THE SLOW-DOWN FOR A DOUBLE-WING GATE (DIP1 SW1

OFF)

Control panel ON, gate closed. Press one time the button A (SET) to enter into programming. LED DL10 starts

flashing. The programming phase begins.

Press one time the push-button B (BREAK) to make motor M2 starting. The time that you wait from the beginning

of the opening of M1 and the pressing of B (BREAK) is the delay of opening of the second wing. This time is max

15 sec. If you do not press any button after 15 sec. The motor M2 starts automatically the opening.

While the two wings are opening, adjust the power of the motor turning the trimmer POWER.

ATTENTION: - if the trimmer POWER is set two “low”, the gate may not open. We suggest to make this

setting starting with the trimmer turned to the MAXIMUM and decreasing the power while the wing is

opening.

- The high differences of temperature between summer and winter cause different

expansions in all materials, including the material of our products. For this

reason we recommend to control the motor force adjusting each winter and

summer in the beginnig of each season.

ATTENTION: - If you want to change some of the above adjustment it is necessary to repeat

the programming from the beginning.

- During programming the slow-down is set only in the closing phase but

During the standard working it is used also in the opening phase.

Press one time push-button C (WORK): the motor M1 starts the opening (M2 remains still).

When the wing of motor M1 arrives against the stop blocks wait for 3-4 seconds and after press one time button

C (WORK). Motor M1 switches OFF.

When the wing of motor M2 arrives against the stop blocks wait for 3-4 seconds and after press one time button

C (WORK). Motor M2 switches OFF.

When the two wings are completely open and the motors are not supplied, press one time button B (BREAK) to

start the closing phase of motor M2 (M1 remains still).

Press one time the push-button C (WORK) to make also motor M1 starting. The time that you wait from the

beginning of the closing of M2 and the pressing of C (WORK) is the delay of closing of the wing. This time is

max 15 sec. If you do not press any button after 15 sec. The motor M1 starts automatically the closing.

During the closing, press B (BREAK) when you want that the motor M2 starts the slow-down (we suggest at

least from the stop blocks). Motor M2 starts the slow-down.50cm ATTENTION: DO NOT consider this point if

the slow-down is not activated (DIP2 SW2 ON)

During the closing, press C (WORK) when you want that the motor M1 starts the slow-down (we suggest at

least from the stop blocks). Motor M1 starts the slow-down.50cm ATTENTION: DO NOT consider this point if

the slow-down is not activated (DIP2 SW2 ON)

When the wing of motor M2 arrives against the stop blocks wait for 3-4 seconds and after press one time button

B (BREAK) Motor M2 switches OFF.

When the wing of motor M1 arrives against the stop blocks wait for 3-4 seconds and after press one time button

C (WORK). Motor M1 switches OFF and control panel quit automatically from programming. It is ready for

functionning.

DAL 1965

Pag. 8/10

CR/41 E

Control panel ON, gate closed. Press one time the button A (SET) to enter into programming. LED DL10 starts

flashing. The programming phase begins.

While the wing is opening, adjust the power of the motor turning the trimmer POWER.

ATTENTION: - if the trimmer POWER is set two “low”, the gate may not open. We suggest to

make this setting starting with the trimmer turned to the MAXIMUM and

decreasing the power while the wing is opening.

- The high differences of temperature between summer and winter cause different

expansions in all materials, including the material of our products. For this

reason we recommend to control the motor force adjusting each winter and

summer in the beginnig of each season.

ATTENTION: - If you want to change some of the above adjustment it is necessary to repeat

the programming from the beginning.

- During programming the slow-down is set only in the closing phase but

during the standard working it is used also in the opening phase.

Press one time push-button C (WORK): the motor M1 starts the opening.

When the wing of motor M1 arrives against the stop blocks wait for 3-4 seconds and after press one time button

C (WORK). Motor M1 switches OFF.

When the wing is completely open and the motor is not supplied, press one time button C (WORK) to start the

closing phase.

During the closing, press C (WORK) when you want that the motor M1 starts the slow-down (we suggest at

least from the stop blocks). Motor M1 starts the slow-down.50cm ATTENTION: DO NOT consider this point if

the slow-down is not activated (DIP2 SW2 ON)

When the wing of motor M1 arrives against the stop blocks wait for 3-4 seconds and after press one time button

C (WORK). Motor M1 switches OFF and control panel quit automatically from programming. It is ready for

functioning.

PROGRAMMING OF THE PAUSE TIME WITH OPEN GATE (AUTOMATIC RECLOSURE)

Control panel ON, gate closed. Press one time the button A (SET) to enter into programming. LED DL10

starts flashing. The programming phase begins.

Press one time B (BREAK) - flashing light ON - the control panel starts to count the time for the pause

when the gate is open, one flashing = 1 second.

Press B (BREAK) when you want to fix the time choosen for the pause, the control panel memorize the

time from the first and the second pressing of B (BREAK).

It quit automatically from programming.

If you do not press any button, after the maximum time of 120 sec. the control panel quit the programming

memorising 120 sec.

ACTIVATE THE AUTOMATIC RECLOSURE (MAX 120sec.)

Press and keep pressed B (BREAK) until LED Dl10 switches OFF.

Control panel quit automatically from programming.

The automatic reclosure is deactivated.

DEACTIVATE THE AUTOMATIC RECLOSURE

Control panel ON, gate closed. Press one time the button A (SET) to enter into programming. LED DL10

starts flashing. The programming phase begins.

PROGRAMMING OF THE WORKING TIME AND THE SLOW-DOWN FOR GATE WITH ONLY ONE WING (DIP1 SW1 ON)

LEARNING OF TRANSMITTER CODE

The control panel has an incorporated two-channel receiver at 433,92 Mhz which allows to remotely drive the gate

through transmitters at dip-switches - OG/02 and OG/04 - and also self-learning transmitters OG/62, OG/64,

OG/52, OG/54, OG/82/1 and OG/84. The first channel of the receiver works like a start, while the second channel

works like “pedestrian” start.

ERASING OF THE STORED CODES

Keep pressed the button A (SET) for about 10sec. Until the LED DL10 switches off.

!ATTENTION: - before using a transmitter, it is compulsory to program it

- the max number of codes is 32 for the START function and 32 for the

PEDESTRIAN function (different combination are not possible: for ex. 40 start + 24

pedestrian NOT POSSIBLE).

Some examples of the possible combinations:

32 self-learning transmitters- example A: OG/62, OG/64, OG/28, OG/48, OG/52,

OG/54, OG/82/1 or OG/84 as (for ex. the left push-button)+

OG/62, OG/64, OG/28, OG/48, OG/52, OG/54,

OG/82/1 or OG/84 as (for ex. the right push-button)

- example B: OG/62, OG/64, OG/28, OG/48, OG/52,

OG/54, OG/82/1 or OG/84 as (for ex. the left push-button) +

OG/02, OG/04 as (it is not necessary to program

the other OG/02 or OG/04 since it is enough to set the dip-switches in the

same position) + OG/62, OG/64, OG/28,

OG/48, OG/52, OG/54, OG/82/1 or OG/84 as (for ex. the right

push-button) + OG/02, OG/04 as (it

is not necessary to program the other OG/02 or OG/04 since it is enough

to set the dip-switches in the same position)

start 32 self-

learning transmitters

pedestrian

31 self-learning transmitters

start 1 dip-

switch transmitter start

31 self-learning transmitters

pedestrian

1 dip-switch transmitter pedestrian

!

DAL 1965

Page 9/10

LEARNING OF THE START CODE

- Control panel ON, gate closed. the button A (SET) to enter into programming. LED DL10 starts

flashing. The programming phase begins.

- Press the button in the transmitter (for ex. the left button) and keep it pressed until LED DL10 switches OFF. The

control panel has memorised the code and it quit automatically from programming.

- Repeat the same step if you need to program other transmitters.

Press one time

LEARNING OF THE PEDESTRIAN CODE

- Control panel ON, gate closed. the button A (SET) to enter into programming. LED DL10 starts

flashing. The programming phase begins.

- the button A press the button in the transmitter (for ex. the right button) and keep them pressed

until LED DL10 switches OFF. The control panel has memorised the code and it quit automatically from

programming.

- Repeat the same step if you need to program other transmitters.

Press one time

Keeping pressed

12 3 4 56 7 8910

12 3 4 5 6 7 8 9 10

!

CHANGE THE FACTORY SET-UP

TO AVOID NOT WANTED DRIVES

DIP-SWITCH SET-UP ONLY FOR TRANSMITTERS OG/02 AND OG/04

Only in the event that the dip-switches transmitters OG/02 or OG/04 are used, it is necessary to change the dip-

switch set-up before the programming, in order to change the factory set-up.

ATTENTION:before proceeding with the programming or the erasing of the transmitters it is

necessary to disconnect temporarily the antenna to avoid that the receiver during these phases

acquires other signals which may cause the uncorrect functionning of the system.

Connect the antenna as soon as finished.

CR/41 E

CR/41 E

CONTROL PANEL TECHNICAL DATA

Power-supply: 230Vac ±10% 50/60Hz

Motor power-supply: 2 motors single phase 230Vac, 200W+200W

Accessories power-supply: 24Vac, 500mA

Flashing-Light power-supply: 230Vac, max 50W

“Courtesy lamp” power-supply: 230Vac, max 100W

Electric lock power-supply: 12Vac 15VA

Adjustment of the motor working time: from 0 to 120sec.

Adjustment of the pause time: from 4 to 120sec.

Adjustment of the 2nd wing delay in opening + closing: from 0 to 15sec.

Working temperature: -20°C ÷ +70°C

Protection degree: IP54

Dimensions and weight: 270x212x118mm, 1,7Kg

INCREASING THE NUMBER OF TRANSMITTERS

If it is necessary to store more than 32 transmitters on the integrated receiver, you have to replace the existing receiver

with the SOG/4A (to have 40 transmitters) and eventually the expansion card SOG/2A (to reach 794 transmitters). After

this replacement it is necessary to program again all the transmitters, see the SOG/4Ainstructions.

OUTPUT

2nd CHANNEL:

AUXILIARY

COMMAND

ANTENNA

NC

C

NA

Output channel 2 (contact

relay)

Max vcoltage =

Max current =

Install an additional relay

if necessary, according to the

specific application

24Vac/dc

1A

ELECTRIC LOCK

LAMPS

OTHER AUTOMATIC

SYSTEMS

ALTRO

F1

F2

ON

SW1 SW2

345 6 78

SOG/4

POWER

+

-

ON

PED START STOP FOTO FOTO AP FINE CH FINE AP

DL9 DL8

DL10

1 2 910 11121314 15161718 19 20 21 22

272526

2324

28 29

SET BREAK WORK

A B C

Com

+24

spia

RX

TAKE OUT THE

INTEGRATED

RECEIVER

INSERT THE

RECEIVER SOG/4A

OUTPUT 1st CHANNEL:

START COMMAND

OF THE

CONTROL PANEL

PEDESTRIAN

COMMAND

ON CR/41

-CLAMPS 1-2-

TURN-OFF POWER SUPPLY

BEFORE ANY WIRING UP

VIA ENRICO FERMI, 22

35020 LEGNARO - PADOVA

I T A L I A

TEL +39 049 79 08 58

FAX +39 049 883 05 29

international

international

E-MAIL [email protected]

WEB www.serai.com

E L E T T R O N I C A P A D O V A

I

D A L 1 9 6 5

Table of contents

Other Serai Control Panel manuals

Popular Control Panel manuals by other brands

GAS

GAS Gasmaster Installation, operation and maintenance manual

Halma

Halma SENSITRON MULTISCAN++ PK-32 manual

XFP

XFP XFP501E/X Engineering manual

Siemens

Siemens SINUMERIK MCP-S Series Equipment manual

LOVATO ELECTRIC

LOVATO ELECTRIC FFLRA200 installation manual

INSBUD

INSBUD IB-TRON 4000 SOL instruction manual