SPEX 8200 Planetary Mill User manual

Operating Manual

1

1300-87075-1A

8200 Planetary Mill

High-Energy Planetary Ball Mill

Operating Manual

2

1300-87075-1A

Copyright © 2022 by Spex

All rights reserved. No part of the work may be reproduced or transmitted in any form or by any means, elec-

tronic or mechanical; including photocopying and recording, except as may be expressly permitted by the 1976

Copyright Act or in writing from the publisher. Requests for permission should be addressed in writing to Spex,

65 Liberty Street, Metuchen, NJ 08840.

Operating Manual

3

1300-87075-1A

Contents

1.0 Introduction..............................................................................................................................................5

1.1 Disclaimer..................................................................................................................................................................5

2.0 Specifications .........................................................................................................................................6

3.0 Unpacking ...............................................................................................................................................7

4.0 Setting Up................................................................................................................................................8

4.1 Electrical Connection.............................................................................................................................................8

4.2 Standard Safety Features ...................................................................................................................................8

4.3 CE Safety Features ...............................................................................................................................................8

4.4 General Safety .......................................................................................................................................................9

5.0 Touch Screen Display ...........................................................................................................................9

5.1 Logo Screen.............................................................................................................................................................9

5.2 Control Panel...........................................................................................................................................................9

5.3 Changing Settings ............................................................................................................................................... 11

5.4 Saved Protocols ................................................................................................................................................... 11

6.0 Loading the Grinding Jar.................................................................................................................... 13

7.0 Locking the Grinding Jar in the Clamp ............................................................................................ 14

8.0 Balancing the Jar ................................................................................................................................. 14

8.1 Adjusting the counterweight ............................................................................................................................. 14

9.0 Operation............................................................................................................................................... 16

9.1 Mixing and Grinding............................................................................................................................................. 16

9.2 Operating the Door ............................................................................................................................................ 17

9.3 Running the Planetary Mill ................................................................................................................................ 17

9.4 Emptying and Cleaning the Grinding Jar...................................................................................................... 18

9.5 Safety Recommendations................................................................................................................................. 19

10.0 System Settings.................................................................................................................................20

10.1 Run History ..........................................................................................................................................................20

11.0 Maintenance......................................................................................................................................... 21

11.1 Technical Support ................................................................................................................................................ 21

12.0 Error Messages................................................................................................................................... 21

12.1 Door Error ............................................................................................................................................................. 21

12.2 Motor Rate Error................................................................................................................................................22

12.3 Motor Home Error............................................................................................................................................. 22

12.4 Latch Error .......................................................................................................................................................... 22

Operating Manual

4

1300-87075-1A

13.0 Troubleshooting................................................................................................................................. 23

14.0 Warranty .............................................................................................................................................. 24

14.1 Product Specifications...................................................................................................................................... 24

14.2 To Arrange a Return Shipment...................................................................................................................... 24

15.0 Instrument Disposal.......................................................................................................................... 24

16.0 Contact Us .......................................................................................................................................... 25

Operating Manual

5

1300-87075-1A

1.0 Introduction

The Spex 8200 Planetary Mill grinds samples with a mechanical motion rotating the jar in one direction while

the platform, planetary wheel (often referred to as the sun wheel) is rotated in the opposite direction. The

mechanical milling is performed at a 2:1 ratio causing the jar to rotate twice for every single rotation of the sun

wheel. As the jar is moved, the relative centrifugal force is transferred to the grinding balls causing them to move

in a circular motion, into each other and against the jar wall, grinding the sample. Generally, the grinding jar and

grinding balls are made from the same material.

The 8200 Planetary Mill is used for pulverizing rocks, minerals, sand, cement, slag, ceramics, glass, and other

brittle to hard samples.

Functionally described as a high-shearing or a high-energy ball mill, the 8200 Planetary Mill is capable of rapidly

rotating a jar in a circular motion several hundred times a minute. This multipurpose mill is capable of rapidly

reducing hard and brittle samples to analytical fineness, blending powders or making emulsions.

The 8200 Planetary Mill also features a touch screen display, sleek modern design, forced-air cooling, a safety

interlock, and a choice of hardened steel or stainless steel grinding jars and media, which are purchased

separately.

The jar, containing the sample and grinding media, is secured in the clamp and moved energetically in a circular

motion. The circular motion is combined with the rotating movement of the sun wheel, so that the jar appears

to be resembling a planetary movement as it moves. During each rotation of the jar, the balls impact the sample

and the walls of the jar, both milling and mixing the sample. Because of the amplitude and velocity of the clamp’s

movement, each ball develops high centrifugal forces, enough to pulverize the toughest rocks, minerals and

ceramics.

1.1 Disclaimer

While many materials can be safely ground and/or mixed in the 8200 Planetary Mill, some materials pose

hazards and are not appropriate for use with the Planetary Mill. Reactive materials can generate heat and

pressure and are not suitable for use in a closed vessel such as the Planetary Mill jar. Spex is available to oer

guidance to our customers. However, users are responsible for knowledge and understanding of the potential

hazards of the material with which they are working.

Grinding jars do not provide an airtight seal. Purging a jar with an inert gas prior to grinding will not ensure

exclusion of oxygen.

Operating Manual

6

1300-87075-1A

2.0 Specifications

Type of Mill Planetary ball mill, high-energy ball mill

Grinding Containers Canister type jar with multiple balls

Display Touch screen

Grinding Mechanism Grinding balls of hardened steel or stainless steel

Capacity One 500 mL jar or one 250 mL jar

Clamp Speed Adjustable range: 300 to 600 rpm

Clamp and Sun Wheel Motion Circular. Clamp and sun wheel rotate in opposite directions at a 2:1 ratio

Electrical Specifications CE approved. 115 V/230 V, 50/60 Hz

Power Cord 115 V/60 Hz model: 3-prong grounded plug supplied

230 V/50 Hz model: 2-prong European plug supplied

Circuit Breaker Same as ON/OFF switch

Safety Features Door locks while running. Interlock prevents mill from running if door is not

closed. Manual door release latch on top of the unit.

Run Timer Maximum 99 hours (1 cycle), maximum 20 hours (2 – 5 cycles)

Motor

1 ⁄ HP

Maximum speed: 3500 rpm

Maximum power: 220 V

Environment

For indoor use only at a maximum altitude of 6,600 ft (2000 m). Operate at

ambient conditions between 40 ºF (5 ºC) and 104 ºF (40 ºC), with maximum

relative humidity 80% below 88 ºF (31 ºC) decreasing linearly to 50% at

104 ºF (40 ºC). Main supply voltage fluctuations up to 10% of nominal voltage

(115 or 230 volts AC RMS). Pollution degree 1: none or only dry, conductive

pollution occurs.

Weight 250 lb (113 kg) (empty without jar)

Dimensions 21 in x 22 in x 15 in (54 cm x 56 cm x 38 cm)

Operating Manual

7

1300-87075-1A

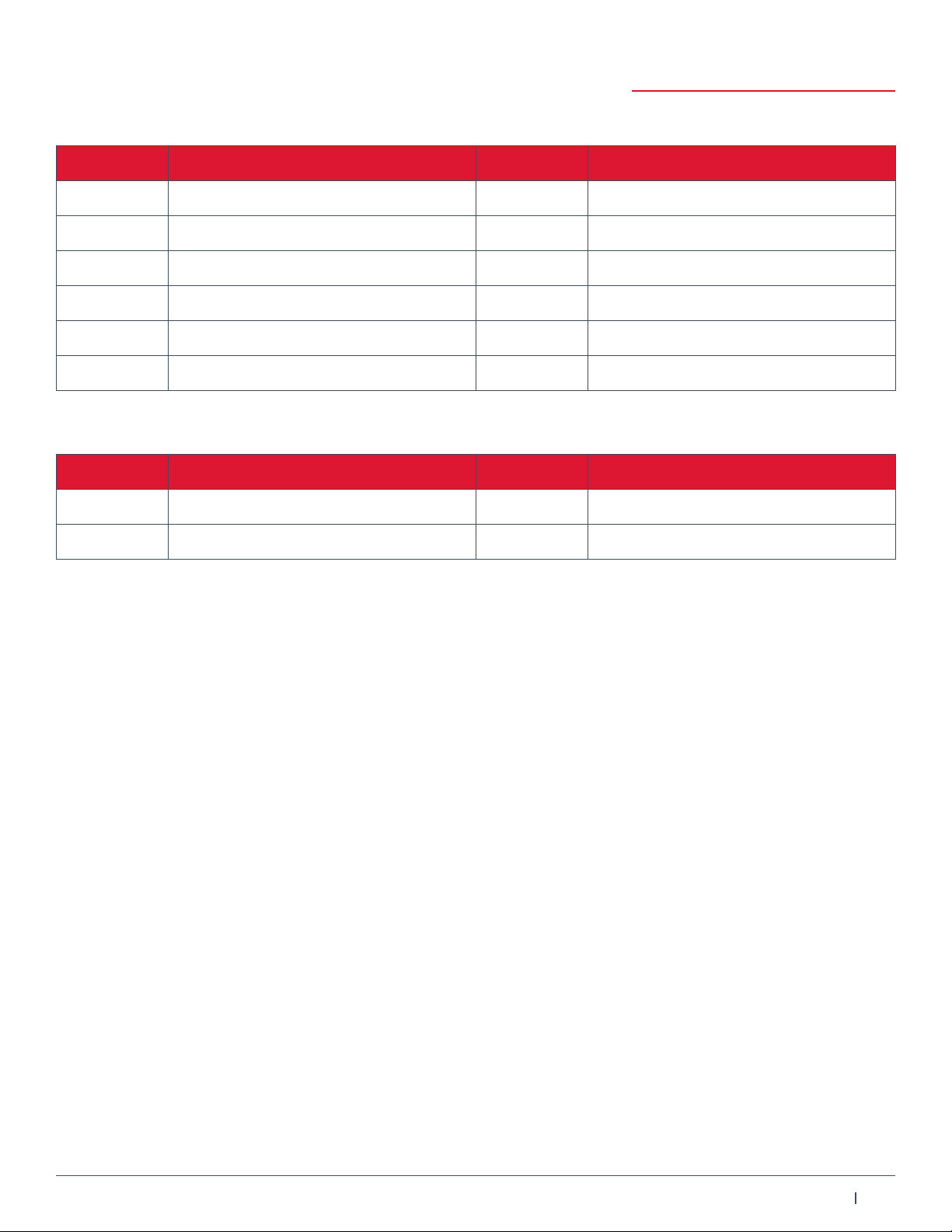

Table 1. Grinding Jars and Grinding Balls Available

Part # Description Part # Description

8211 Hardened Steel Grinding Jar, 250 mL 8227B-30 Stainless Steel Grinding Balls, 30 mm

8221 Hardened Steel Grinding Jar, 500 mL 8227B-40 Stainless Steel Grinding Balls, 40 mm

8217 Stainless Steel Grinding Jar, 250 mL 8221B-10 Hardened Steel Grinding Balls, 10 mm

8227 Stainless Steel Grinding Jar, 500 mL 8221B-20 Hardened Steel Grinding Balls, 20 mm

8227B-10 Stainless Steel Grinding Balls, 10 mm 8221B-30 Hardened Steel Grinding Balls, 30 mm

8227B-20 Stainless Steel Grinding Balls, 20 mm 8221B-40 Hardened Steel Grinding Balls, 40 mm

Table 2. Jar Sieves and Jar O-Rings

Part # Description Part # Description

8240 Jar Sieve for 250 mL Jar 8211S O-Ring for 250 mL Jar

8245 Jar Sieve for 500 mL Jar 8221S O-Ring for 500 mL Jar

3.0 Unpacking

At the factory, the Planetary Mill is adjusted and tested for proper operation, and carefully packaged for

shipping, Upon receipt, carefully inspect the exterior of the packing crate. If there is any visible damage, notify

Spex and file a claim with the carrier immediately.

To unpack the Planetary Mill, loosen and remove the eight wing nuts on the lower edge of the crate (two on

each side) and lift the crate sleeve o the base (this is a 2-person job). Remove loose items from the crate.

Remove any protective plastic cover from the mill. Remove the four hexagonal shipping feet from the bottom of

the crate, unscrewing the hex head screw using a 9/16 in wrench.

CAUTION: The Planetary Mill weights about 250 pounds (113 kg). Be sure to have a mechanical hoist or lifting

equipment on hand when moving the unit.

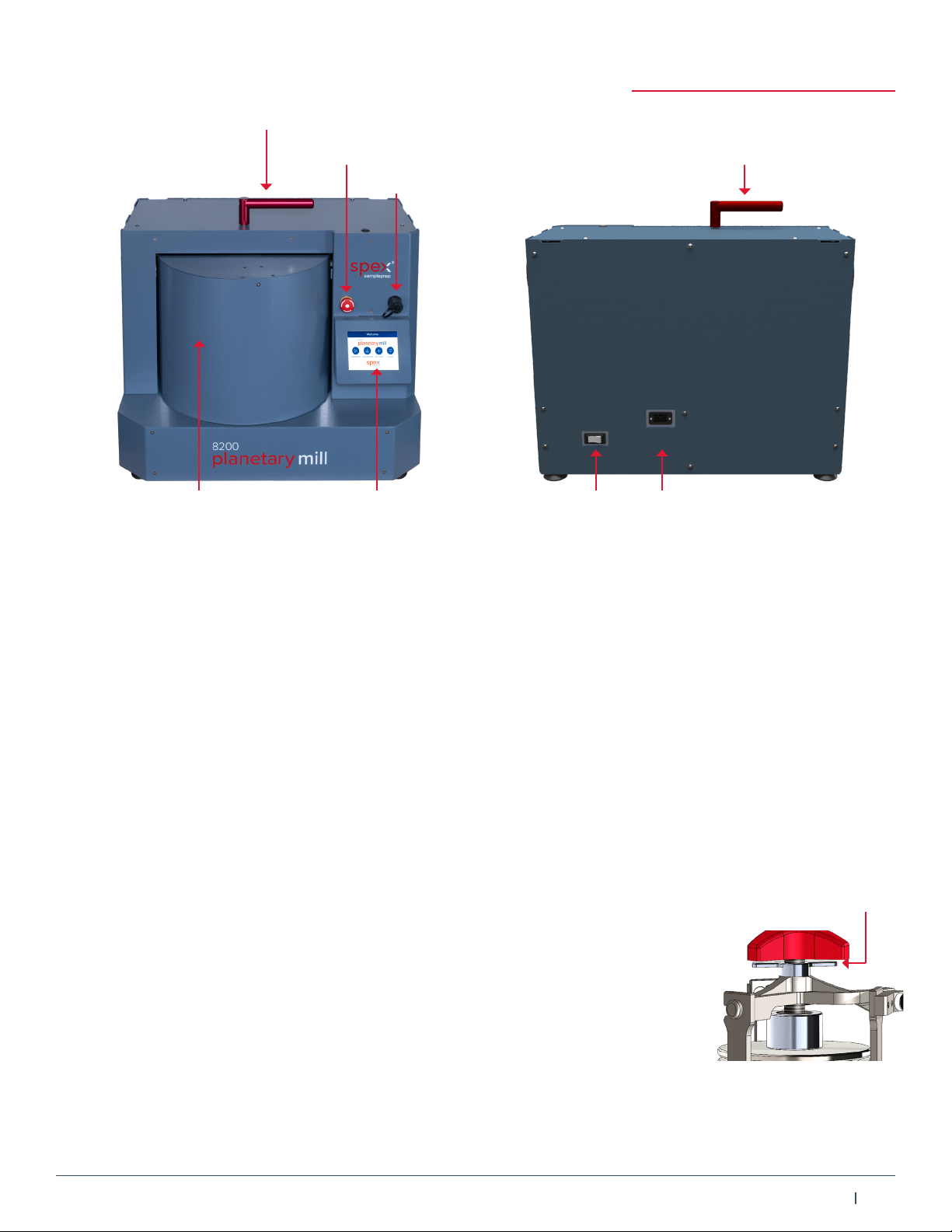

Follow a logical sequence of steps as you inspect the unit (Figures 1 and 2). For example:

1. Inspect the outside of the cabinet for any visible damage.

2. Inspect the electrical input module and on/o switch for any visible damage.

3. Ensure that the door mechanism is working properly (Section 9.2).

4. Open the door and inspect the interior of the Planetary Mill.

5. Check that the clamp has not been damaged.

6. Inspect the accessory pack. Compare with the packing list.

If everything seems to be in proper order, store the crate and packaging materials in case there is a need to

return the unit for service or repair.

Operating Manual

8

1300-87075-1A

Figure 1. Planetary Mill (front view) Figure 2. Planetary Mill (back view)

Door Handle

Door Handle

Emergency Stop

USB

Control Panel On/O

Switch

Electrical

Inlet

Door (closed)

4.0 Setting Up

The 8200 Planetary Mill weighs 250 lb (113 kg). The door rotates to open and close from left to right with the

handle atop the mill. The electrical input module/power cord receptacle is located on the rear of the Planetary

Mill cabinet towards the bottom (Figure 2). The power on/o button is on the rear next to the electrical inlet. The

manual door release latch is located on the top of the unit at the top right. The touch screen control panel is

axed to the front side of the unit. Above the display of the control panel is an emergency stop button (in red)

and a USB port (black screw-o knob) to export run history or upgrade system software (Figure 1).

4.1 Electrical Connection

The on/o switch (controlling power to the motor and timer), is located at the back of the unit. To turn on the

power, press down-left the bar ( | ) side of the switch. Before plugging in the mill, set the power to o by pressing

down right the circle (O) side of the on/o switch, then plug the power cord into the mill’s power inlet. Plug the

mill into a standard 3-prong grounded electrical outlet; the AC input module and the on/o switch (which also

serves as a circuit breaker) are on the back of the cabinet.

4.2 Standard Safety Features

Clamp Locking Tab: The clamp is opened and closed by a knob on the end of

its threaded shaft. Whenever the clamp is closed on a jar, lock the clamp by first

tightening the locking tab clockwise against the clamp Y-bar (the locking tab is on

the shaft between the knob and the clamp Y-crossbar). When opening the clamp, first

loosen the locking tab.

4.3 CE Safety Features

CE directives require that electricity to the motor and timer be interrupted whenever the door is open, and that

the clamp must stop completely before the door can open.

Safety Interlock: Cuts o power to the motor when the door is open. DO NOT disconnect or damage this switch.

Locking Tab

Operating Manual

9

1300-87075-1A

Time-Delay Rotary Latch: Keeps the door closed while the mill is running, and for 5 seconds after the end of the

run. The Time Delay Rotary Latch, on the right side panel, is powered by an internal motor to engage the latch

actuator in the door. When the mill is started, the Time Delay Rotary Latch locks the door immediately and there

is a delay before the motor starts. When the timer reaches zero at the end of a run, the motor stops, the timer

displays RUN COMPLETE, and the latch stays locked for 5 seconds. At the end of 5 seconds, the latch unlocks

and the timer resets.

NOTE: Never try to force open the door before the Time Delay Rotary Latch unlocks.

4.4 General Safety

CAUTION: Every eort has been made to ensure the 8200 Planetary Mill operates at a moderate

noise level. The intensity of noise is directly impacted by the type if grinding jar, number of balls, size

of balls and sample hardness. Ear protection is recommended.

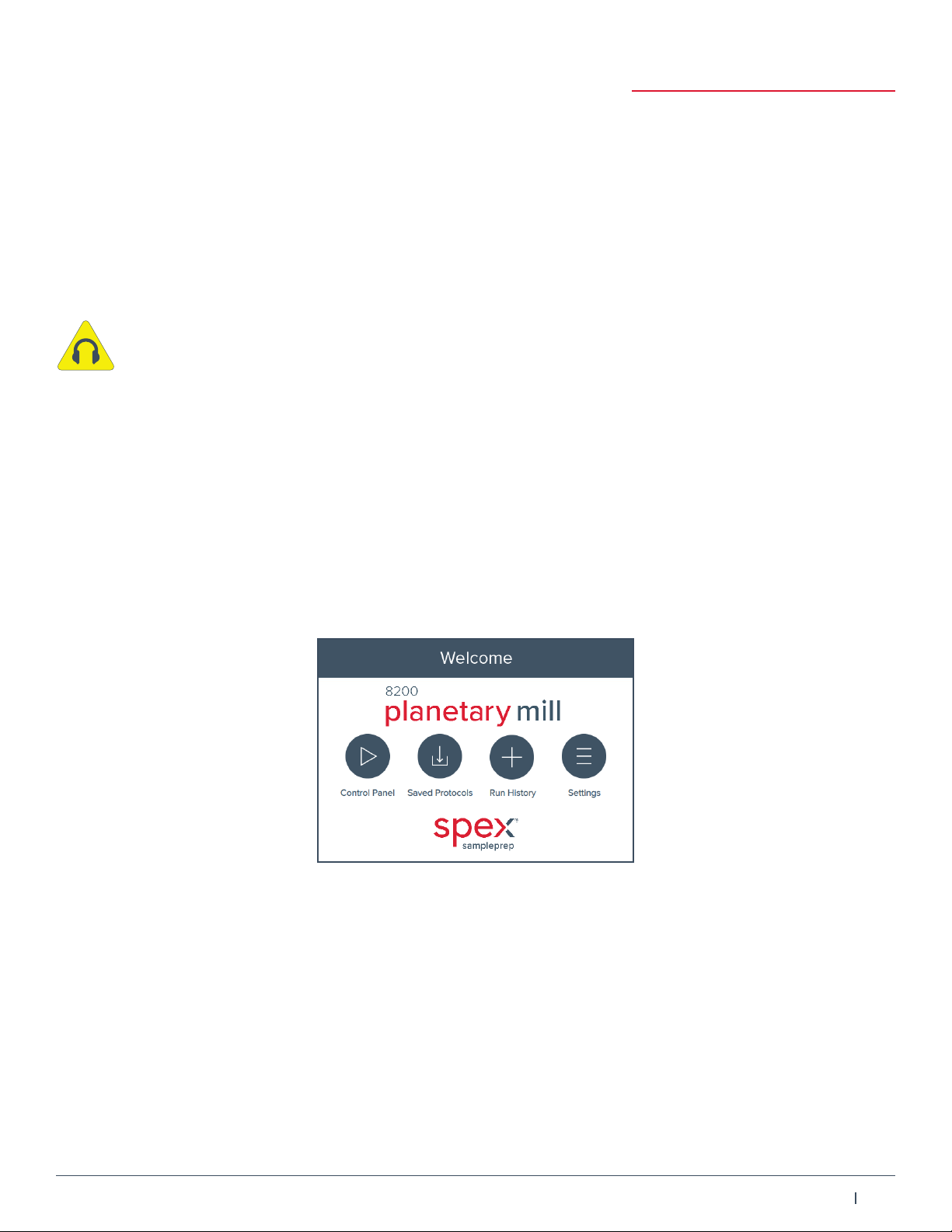

5.0 Touch Screen Display

The 8200 Planetary Mill is programmed and operated through a series of touch screen displays. Transition

between screens, and all programming and operating commands, are done by touching the screen with a

fingertip or stylus. Do not use a sharp point as this can damage or deface the screen.

5.1 Logo Screen

When the power is switched ON at the front of the mill, “Please Wait” appears during start-up as the software

loads. Then the Spex logo is displayed and a brief animated representation of the Planetary Mill logo. After the

animation has finished, the screen will switch to the Home screen (Figure 3). From the Home screen, the Control

Panel, Run History and Settings can be accessed by touching the buttons displayed.

Figure 3. Home Screen

5.2 Control Panel

The Control Panel displays the programmed run parameters, and the Date and Time at the bottom right of the

screen (Figure 4). Changes to the run settings are made from this screen.

To recall stored run protocols, touch the Store/Recall button located at the bottom right of the screen (see

section 5.4 for more information on Saved Protocols).

The Home screen icon can be found on all screens (e.g. Control Panel) positioned at the top right of the screen.

Touching the Home icon allows the user to return to the Home screen.

Operating Manual

10

1300-87075-1A

Figure 4. Control Panel

The following sequence of events will occur from the current settings in Figure 4. Note: Reverse directional

motion is o. Turning on the reverse motion (and running for 2 or more cycles) will reverse the planetary wheel

(opposite direction), causing the jar to rotate in the opposite direction. Reversing the motion can improve the

eciency of the grind, allowing the balls to scrape the wall of the jar to remove caked material.

1. Cycle 1 – unit runs for 2 minutes at a rate of 600 rpm.

2. Rest time – the unit is inactive for 30 seconds allowing the sample to dissipate the frictional heat from the

grinding balls.

3. Cycle 2 – unit runs for another 2 minutes at a rate of 600 rpm. Note: If reverse was on (active), the

planetary wheel would reverse every other cycle.

4. The run protocol is complete after Cycle 2.

In the Control Panel, to change the settings of a selected field such as, Run Time, Cycles, Rest Time, and Speed,

press the (+) or (–) buttons on the Control Panel screen. The (–) buttons decrease the number displayed on and

the (+) buttons increase the number displayed.

5.2.1 Starting a Programmed Run

To run the program displayed on the Control Panel screen, touch the Run button. The Planetary Mill can be

stopped, paused and restarted in the middle of a grinding program from the button selections on the right of the

screen.

Figure 5. Run Screen

Home Icon

Operating Manual

11

1300-87075-1A

During the Run Time stage, the Time counts down the time for the preprogrammed run in 1 second increments.

To pause program, touch the Pause button. To continue the program, touch the Resume button (appears when

paused). To abort the program, touch the Stop button. To start a new program, touch the Run button.

5.2.2 Stopping or Pausing a Run

To stop a program, touch the Stop button on the Run screen (Figure 5), the button will dim or turn a muted red

and the program will end. If the Run button is touched after the program has stopped, then the entire program

will start over.

To pause during a grinding program, touch the Pause button. Note: The Pause button will have a dimmed or

muted yellow appearance for a few seconds after the Run button is touched which indicates it is inactive.

After 5 seconds it will turn a brighter yellow indicating it is active. The run will hold the settings at that

moment (elapsed time, cycle, etc.). At this point, the door to the sample area can be opened. To resume the

program, close door and touch the Resume button. This will restart the program at the point at which it was

paused. Alternatively, pressing Stop will end the program.

5.3 Changing Settings

To change parameters (run time, rest time, cycles, and rate), touch the plus (+) or minus (–) buttons on the

Control Panel screen (Figure 4). Touching the plus increases the parameter, while touching the minus decreases

the parameter. Tap or hold the plus or minus buttons until the desired number is reached. The changes will

appear in the area between the arrows (Figure 4). The maximum run time is 99 hours for 1 cycle. If running 2–10

cycles, the maximum run time per cycle is 10 hours. The minimum rest is 15 seconds per cycle for 2–10 cycles. To

run a program with the new settings, touch the Run button.

Note: If the run parameters are changed to a protocol and not saved then (MOD) will appear to the right of the

protocol name at the top center of the screen.

5.4 Saved Protocols

The Saved Protocols screen is shown in Figure 7. Up to 20 protocols can be saved for simple and fast recall,

increasing productivity, and reducing operator error.

A saved program retains the settings for number of cycles, run time, rest time between cycles, and rate. Be sure

to adjust the rate to the desired setting after recalling a stored program.

Figure 7. Saved Protocols Screen

The Default protocol recalls the last programmed run setting that was not saved. The Default protocol can be

changed without saving the new settings, as described in section 5.4. At the top left on the Saved Protocols

screen is the back arrow button. Touching the back arrow button returns the user to the previous screen.

Operating Manual

12

1300-87075-1A

5.4.1 Recalling a Protocol

To recall a stored program, touch the Store/Recall button on the Control Panel screen (Figure 4). In the Saved

Protocols screen, select the protocol to highlight the box. Then touch Select to send protocol to the Control

Panel screen.

5.4.2 Storing a New Protocol

To store a new program, touch the Store/Recall button on the Control Panel screen (Figure 4). In the Saved

Protocols screen, touch the Add button as shown in Figure 7. This will bring up the Keyboard screen, a simplified

version of the standard keyboard for a computer.

Figure 8. Keyboard Screen

The Clear key deletes whatever has been entered in the label box. Touching the Done key enters the label

shown in the box.

Touch the Save button to save the label shown in the box. The label will appear as the name of the program on

the Saved Protocols screen (Figure 7).

The Cancel key does not change anything on the screen, but returns the display to the Saved Protocols screen.

To run the newly saved protocol, touch the protocol to highlight the box. Then touch Select to send the protocol

to the Control Panel screen. Review the parameters and touch the Run button to initiate the protocol.

5.4.3 Edit a Protocol

To edit a saved protocol, touch the protocol name to highlight the box on the Saved Protocol screen (Figure 7),

then touch the Edit button. From the Edit Protocol screen, change the name by touching inside the box. This will

bring up the Keyboard screen, follow the instructions listed in the Storing a Protocol section 5.4.2. The run time,

rate, rest time, and cycles can also be adjusted in the Edit Protocol screen.

Operating Manual

13

1300-87075-1A

Figure 9. Edit Protocol Screen

5.4.4 Delete a Protocol

To delete a saved program, touch the protocol name to highlight the name on the Saved Protocols screen

(Figure 7). Then touch the Delete button. A pop-up window opens confirming to delete this protocol. Touch Yes

to delete the protocol or touch No to keep the saved protocol.

Figure 10. Delete Confirmation Screen

5.4.5 Modify a Recalled Protocol

Once a saved protocol is recalled to the Control Panel screen, the user can modify the parameters by using the

left and right arrows. If the protocol is modified, (MOD) will appear next to the protocol name, e.g. Shale Rock

(MOD).

6.0 Loading the Grinding Jar

Before using a planetary mill grinding jar, check to make sure that it is clean and that the O-ring is in good

condition. The sample should be crushed to proper feed size before it is loaded into the jar, approximately ⁄-

inch to ⁄-inch for the steel jars.

Place the sample in the grinding jar FIRST, then the grinding balls and apply the cover (firmly seated). Do not

overload the grinding jar. Recommended sample amounts for 500 mL jar (100 g to 225 g) and for

250 mL (50 g to 100 g). Additional information on grinding and mixing is in Section 9.1.

Operating Manual

14

1300-87075-1A

7.0 Locking the Grinding Jar in the Clamp

Lock the Clamp Assembly before running the unit. It is essential that samples are securely locked into

the clamp assembly before operation.

The clamp locking knob is the most critical component of the Planetary Mill, as it must be carefully adjusted to

hold the jar firmly in place. The rotation motion of the clamp is extremely vigorous. The jar must be held securely

in the clamp during operation to prevent damage and leakage.

The clamp base has two dierent size pins, designed to specifically fit in the two holes on the bottom of the jar.

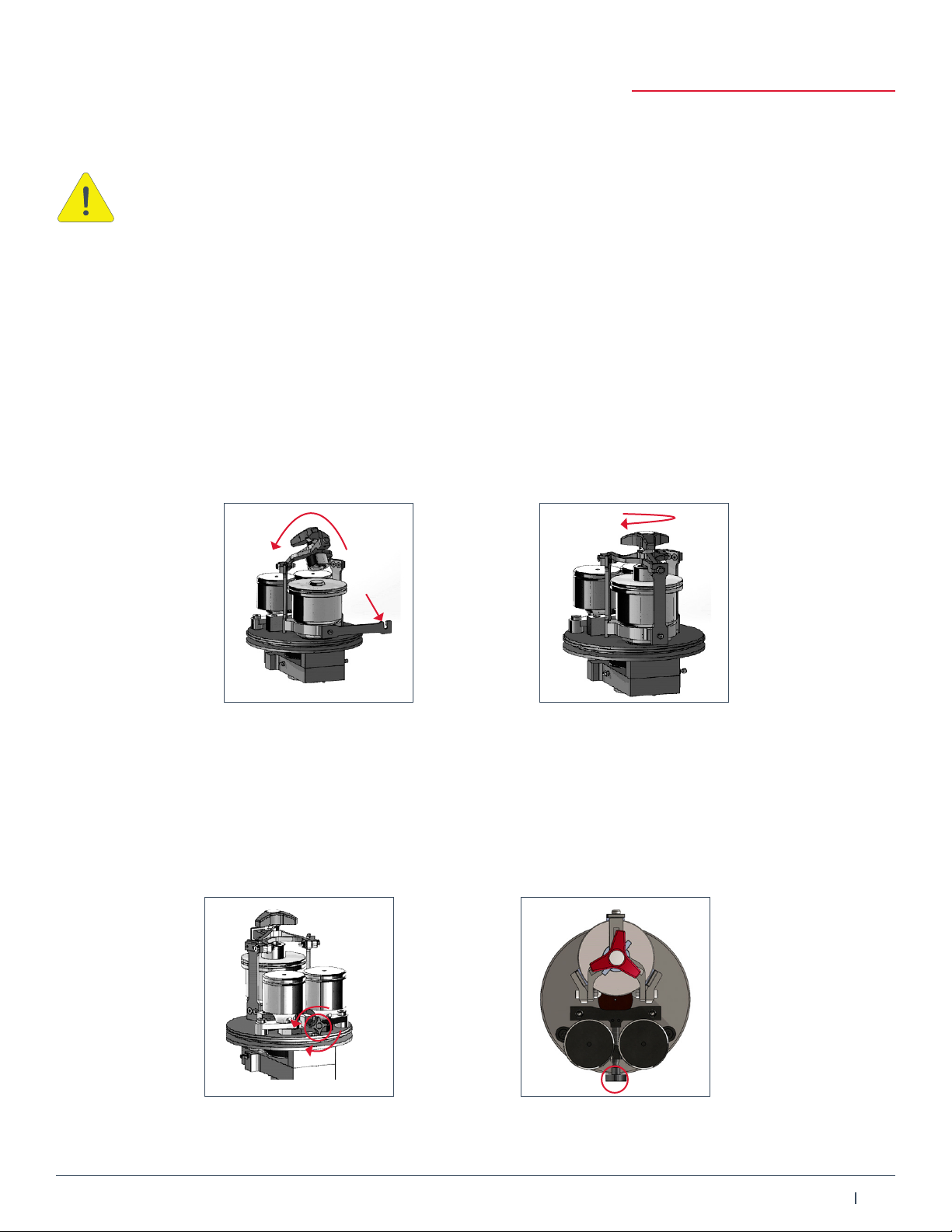

To place a jar in the clamp, loosed the locking tab on the threaded shaft, and unscrew the locking knob with a

few turns (counter-clockwise). Rotate the moveable arm clockwise (downward) unclasping it from the Y-cross bar,

lift the locking knob assembly upward as shown in Figure 11. When placing the jar in the clamp, make sure the

pins are fitting in the proper holes. Once the jar is seated in the clamp base it should not be able to twist.

To lock the jar in the clamp, lower the locking knob assembly, rotate the moveable arm counter-clockwise

(upward) to engage the arm opening into the Y-cross bar pin (Figure 12). Turn the locking knob clockwise to

secure the jar and tighten the locking tab by turning clockwise.

Figure 11. Opening the Clamp Figure 12. Locking the Clamp

8.0 Balancing the Jar

8.1 Adjusting the counterweight

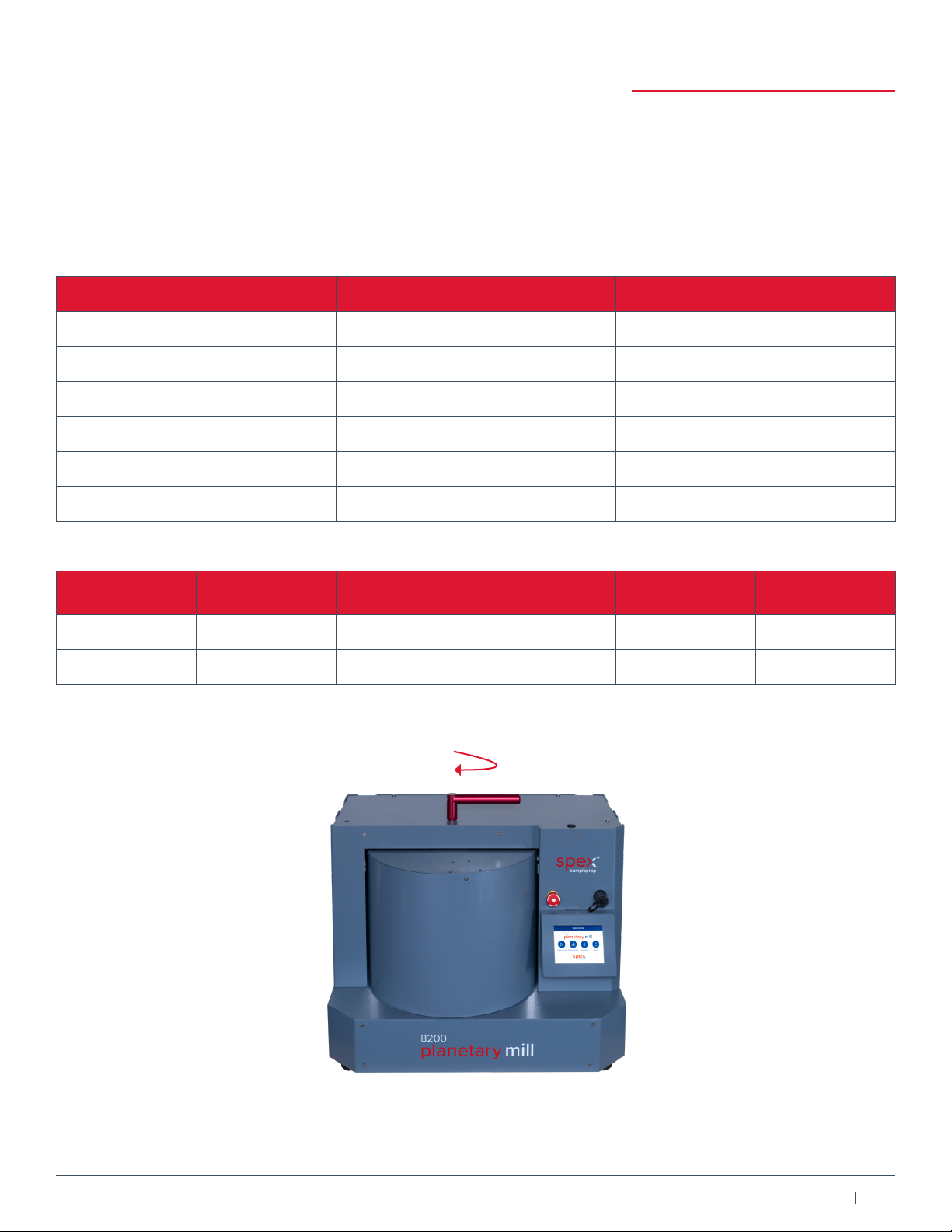

The counterweight is set at the manufacturing facility to balance the stainless steel 500 mL jar with eight 30 mm

stainless steel balls. Turning the knob (Figure 13) clockwise increases the counterweight. Furthermore, turning

the knob counter-clockwise decreases the counterweight.

Figure 13. Counterweight Figure 14. Counterweight (top view)

Operating Manual

15

1300-87075-1A

Note: If the counterweight is not properly balanced, the unit may vibrate or shake vigorously. If this occurs,

turn the unit o by pressing the Stop button on the touch screen or hitting the red Emergency Stop button (red

button above the display).

The mill will not run if the Emergency Stop button is pushed in. To disengage the Emergency Stop button, turn it

clockwise until the button pops out.

Table 3. Weight of jars and stainless steel balls.

Description Jar Weight with Lid Ball Weight per Ball

Stainless Steel Grinding Jar, 500 mL 9.9 lb –

Stainless Steel Grinding Jar, 250 mL 7.2 lb –

Stainless Steel Grinding Balls 40 mm – 0.575 lb

Stainless Steel Grinding Ball, 30 mm – 0.242 lb

Stainless Steel Grinding Ball, 20 mm – 0.070 lb

Stainless Steel Grinding Ball, 10 mm – 0.0089 lb

Table 4. Suggested number of balls per grinding jar based on sample weight.

Stainless

Steel Jar

Sample

Weight

40 mm Stainless

Steel Balls

30 mm Stainless

Steel Balls

20 mm Stainless

Steel Balls

10 mm Stainless

Steel Balls

500 mL 100 – 225 g 4 8 20 100

250 mL 50 – 100 g – 4 10 50

After the sample jar is loaded and secured into the clamp mechanism and the counterweight properly adjusted,

close the door. Grasp the handle and rotate clockwise to slide the door to the closed position (Figure 15).

Figure 15. Closing the Door

Operating Manual

16

1300-87075-1A

9.0 Operation

Before operating the Planetary Mill, make sure it is plugged in and turned on. The power cord inlet is located on

the rear of the cabinet. The white on/o button is located on the rear of the cabinet (Figure 2).

The following steps outline a standard operating cycle:

1. Load sample and balls in grinding jar

2. Firmly place lid on the grinding jar

3. Clamp the jar in place

4. Confirm balance setting and close the door

5. Set the timer

6. Set the number of cycles

7. Set reverse option to on or o

8. Set the pause time

9. Set the run speed

10. Press the green Run button to start a run

11. When the run is complete, open the door

12. Unclamp the jar

9.1 Mixing and Grinding

For samples that cake during mixing, a slurry with water or alcohol may be helpful. Water may be removed

afterwards by drying the sample in the jar in a very low temperature oven. If caking is due to static charge, a

small amount of cellulose (10%) can be added to the jar. Dry grinding is the simplest approach and most often

used.

If a sample is not being ground fine enough, the user can decrease the amount of sample, increase grinding

time, use a denser grinding medium, and/or add a grinding aid or liquid. Wet grinding keeps the sample from

caking and will give a smaller final particle size, but there are hindrances; an extra drying step is required, the

fluid used for wet grinding must be chosen carefully not to alter the sample or attack the jar, all have gaskets and

are watertight.

None of the jars are inherently gas-tight. Limited results can be achieved by loading and unloading the jar in a

glove box under inert gas.

CAUTION: Always use grinding balls that match the material of the jar (e.g. hardened steel balls for a hardened

steel jar, stainless steel for stainless steel, etc.). This will limit contamination.

9.1.1 Grinding Hints

For any grinding jar, the smaller the initial sample size, the finer it can be ground in a given time. Unless a sample

cakes during grinding, the longer it is ground, the finer it will get. Particle size can almost always be lowered

further by reducing the sample size or lengthening the grinding time, or both.

Operating Manual

17

1300-87075-1A

Dry grinding is relatively ecient for most brittle materials, but at small particle sizes (below 50 microns) there is

a tendency for particles to agglomerate or cake. There are many grinding aids to prevent caking. Water, alcohol,

solvents, and other liquids can be added to create slurries whose medial particle size after grinding can be well

below 10 microns, but for most analytical techniques the liquid must be removed before analysis.

9.2 Operating the Door

To close the cabinet, grasp the handle and rotate clockwise to slide the door to the closed position (Figure 16).

The door must remain closed during a run.

To open the cabinet, grasp the handle and rotate counter-clockwise to slide open the door to its open position.

Figure 16. Door Operation

9.2.1 Manual Door Release Latch

To open the cabinet if the power to the Planetary Mill fails, insert the manual key tool into the hole atop the

cabinet, (right side) index lever to release and rotate the red door handle at the same time to open the door.

9.3 Running the Planetary Mill

Press the green Run button to initiate a programmed run. The screen will display a countdown of the time

remaining in a run as shown in Figure 17. The Planetary Mill will stop automatically at the end of the run. When

the grinding program has ended, the screen will display Run Complete. Touch the screen to return to the

Control Panel.

Figure 17. Run Screen

Manual Door Release

Operating Manual

18

1300-87075-1A

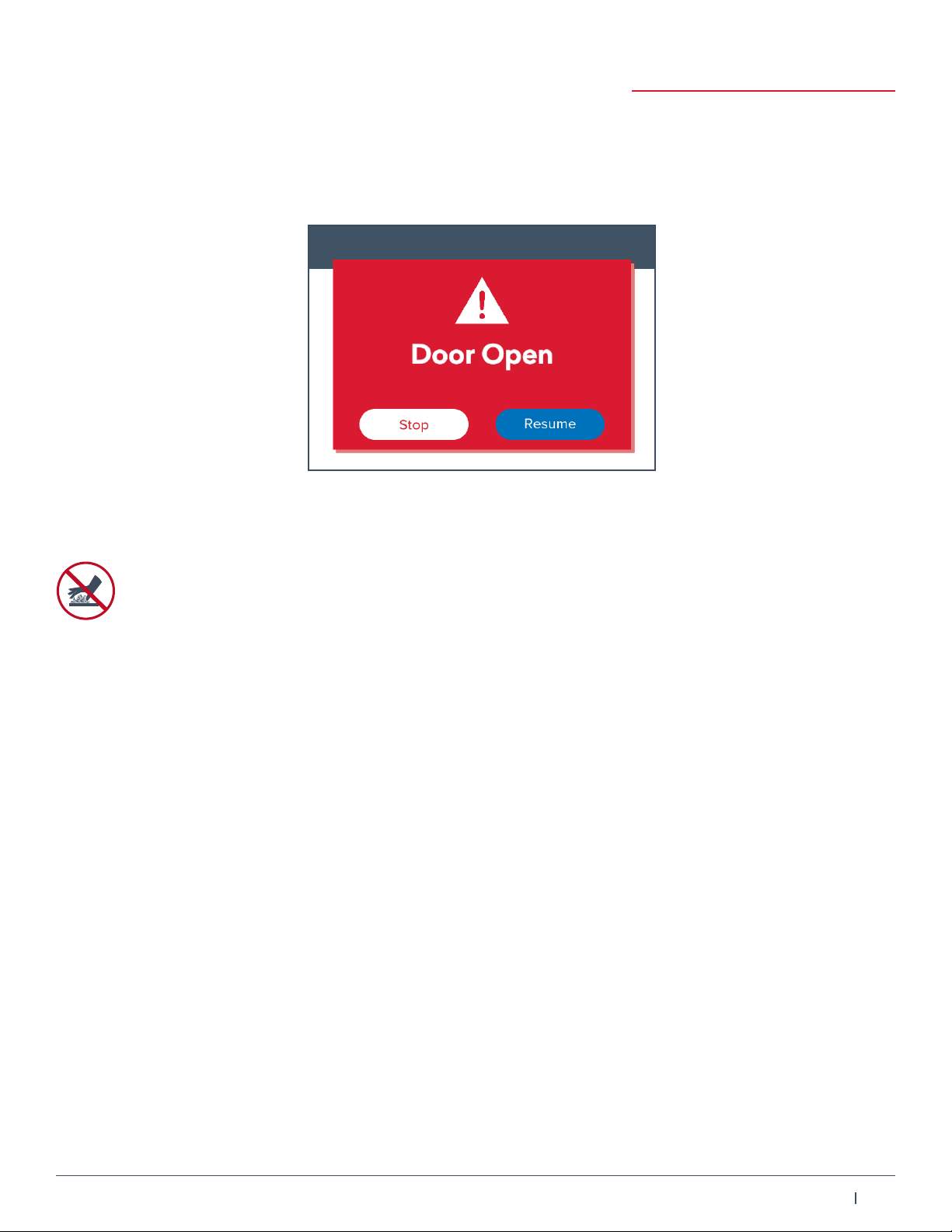

To stop the Planetary Mill during a run, press the Stop button on the screen. If the door lock fails and the door

opens, the screen will display a Door Open message as shown in Figure 18. The timer will maintain the time

remaining in the run. To restart, close the door and press the green Resume button to finish the run. To abort the

run and restart the timer, press the red Stop button. The Door Open message will disappear once the door is

closed.

Figure 18. Door Open Message

9.4 Emptying and Cleaning the Grinding Jar

CAUTION: The jar can become extremely hot after grinding. If the run time is longer than 5 minutes,

it is recommended to allow the jar to cool for 10 to 20 minutes before opening. Carefully pry open the

jar using the opening tool. Tip: If jar is too warm to touch, use gloves that are heat resistant.

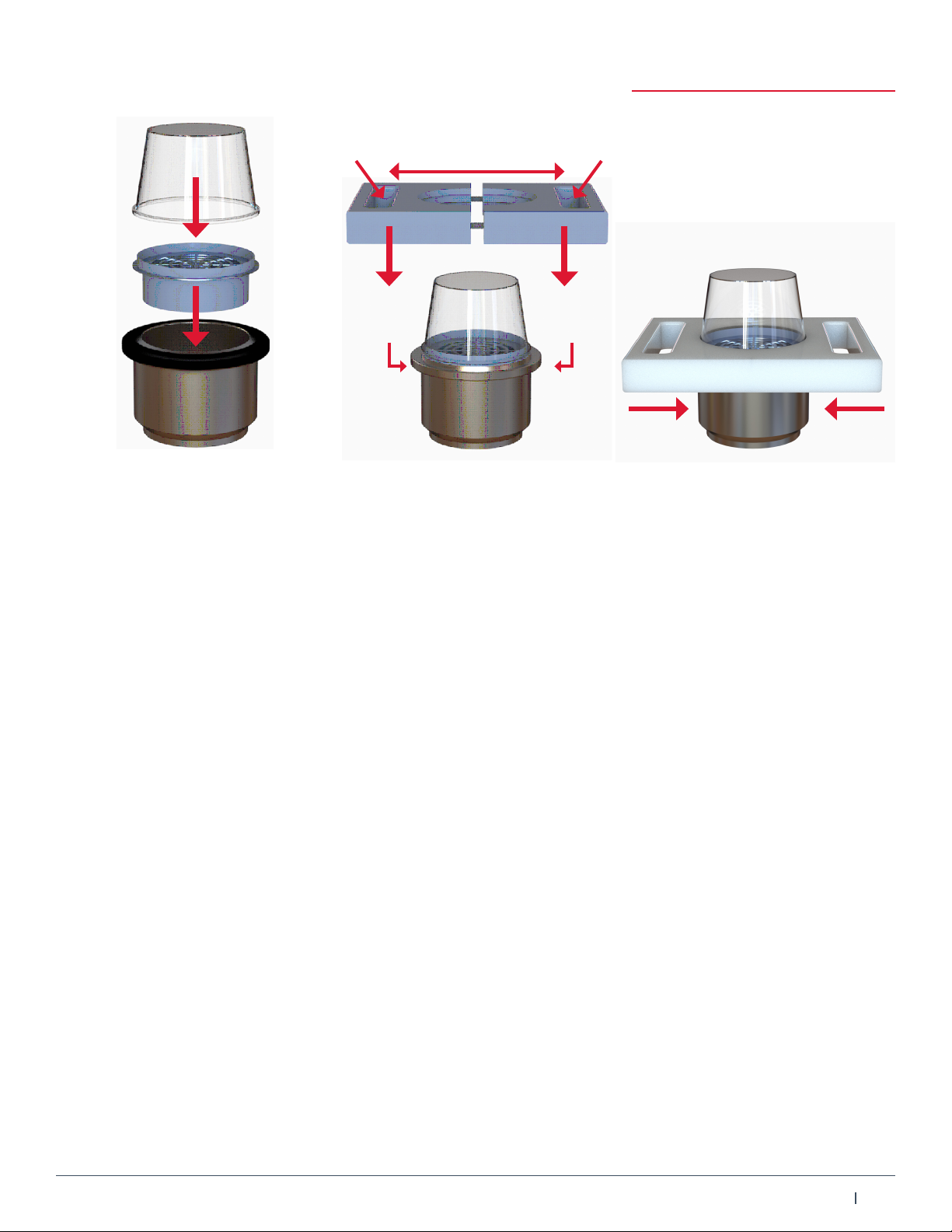

The 500 mL grinding jar can be emptied by using the sieve attachment to separate the grinding balls from the

ground sample. Follow the steps below to attach the sieve and sample collection jar to the grinding jar.

1. After the jar is cool to the touch, remove the lid using the lid opening tool.

2. Scrape (with spatula) any loose powder on the lid into the retain container.

3. Insert the sieve into the jar and place the retain container on top, as shown below.

4. Slide the sieve handle mechanism over the jar and retain container, locking them together.

5. Firmly grasp and invert the assembly (flipping over), and gently tap on the benchtop to shake loose the

powder into the retain container.

6. Remove the sieve handle and carefully lift grinding jar o of the retain container.

7. Remove the sieve containing the grinding balls.

8. Scrape (with spatula) any loose powder from the jar into the retain container.

9. Apply jar lid and label (with sample ID).

Operating Manual

19

1300-87075-1A

Step 3.

Insert Sieve and Container

Retain

Container

Grasp Here Grasp Here

Sieve

Jar

Step 4.

Slide on Sieve Mechanism

Step 5.

Grasp Firmly and Flip

Warning: Finely pulverized sample always presents a respiratory hazard; a dust mask or other protection

should be worn when working with it.

Grinding jars should be cleaned after use. Methods include wiping with a damp paper towel, blowing out with an

air hose, rinsing with water or alcohol, etc. Most of these methods are not very eective, and blowing the dust

out of a jar with an air hose certainly causes a respiratory hazard. We recommend a 3-minute period of grinding

with a mixture of clean quartz stone, hot water, and soap or laboratory detergent. The residue is easily and

safely washed out of the jar, which then may be dried.

Technicians who are particularly concerned about cross-contamination may adopt the “grind and discard”

technique. After sample A has been ground and the grinding jar nominally cleaned, a portion of sample B is

ground and discarded, and the jar cleaned again. Now it should be possible to grind a portion of sample B

without contaminating it with sample A.

If a cleaned grinding jar will not be used immediately, store in a plastic bag. Hardened steel grinding jars should

always be dried and stored carefully, as they are prone to surface rusting.

9.5 Safety Recommendations

The Planetary Mill is intended for use only by qualified and trained personnel. For questions about the operation,

maintenance or service of the 8200 Planetary Mill, contact us at +1.855.GET.SPEX or +1.732.623.0465.

Every eort has been made to ensure that the Planetary Mill is safe to operate. However, the safety protection

provided by the unit may be impaired if the Planetary Mill is operated in a manner other than what is

described in this manual. In addition, the Planetary Mill should only be used with accessories provided by, or

recommended by, Spex and must be used in the intended manner. Use of accessories not recommended by

Spex may negatively aect the safety protection provided by the unit and may void the warranty.

Do not use the 8200 Planetary Mill with hazardous materials for which the unit was not designed. Be aware

of the hazards of the materials that are being used, particularly in the event of a spill. For instance, use of a

flammable liquid could create a fire hazard if a sample is spilled.

Operating Manual

20

1300-87075-1A

10.0 System Settings

To access the Settings screen, touch the icon o the Home screen (Figure 3). The firmware can be upgraded,

diagnostics viewed/exported, and files exported (run history, protocols), and protocols imported. Time display

can also be changed from 12-hour to 24-hour, and time and date can be entered or changed (Figure 19). Touch

inside the window to change the date or time. A pop-up window opens to enter the time or date. Touch the Set

button to confirm the change. Select 12- or 24-hour time, which will be displayed on the Run screen. Touching

the back arrow button returns the user to the previous screen.

Figure 19. Settings Screen

10.1 Run History

To recall the run history, go to the Home screen and touch the Run History button. The date, time, user, run

label, and run protocol data are stored on this screen (Figure 20). The run history can be exported to computer

devices via the USB port located on front of unit. Note: The Export History button will have a dimmed or muted

appearance which indicates it is inactive. After a flash drive or USB cable (connected to computer device)

is inserted into the port, the button will turn brighter indicating it is active. To export run history, touch the

Export History button at the bottom right of the screen. To clear run history or delete run history permanently

from data storage, touch the Clear History button at the bottom left of the screen. To return to the Home screen,

touch the back arrow at the top left of the screen.

Figure 20. Run History

Table of contents