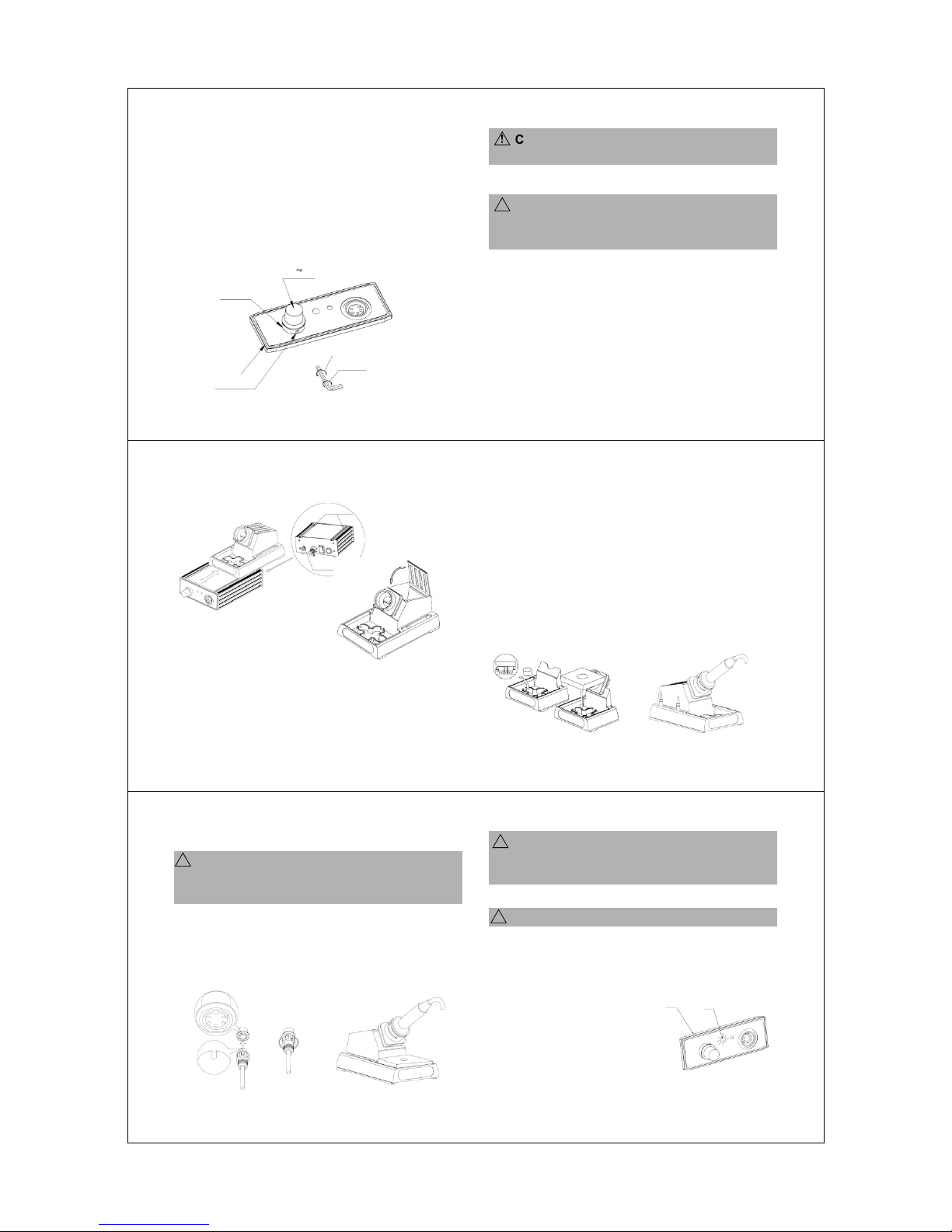

Care and Maintenance of Soldering Iron

1. Working Temperature

A low temperature will slow the rate of flow of solder.

A high temperature will burn the flux in the solder, which

in turn will emit a heavy white smoke resulting in a dry

joint, or damage to the soldered components or parts.

When the Tip working temperature is set within the

correct parameters suited to the particular solder

being used, a good joint is assured. The most common

solder alloy used in the electronic industry is 60% tin,

40% lead. The typical working temperature of the solder

is detailed below but it can vary from manufacturer to

manufacturer.

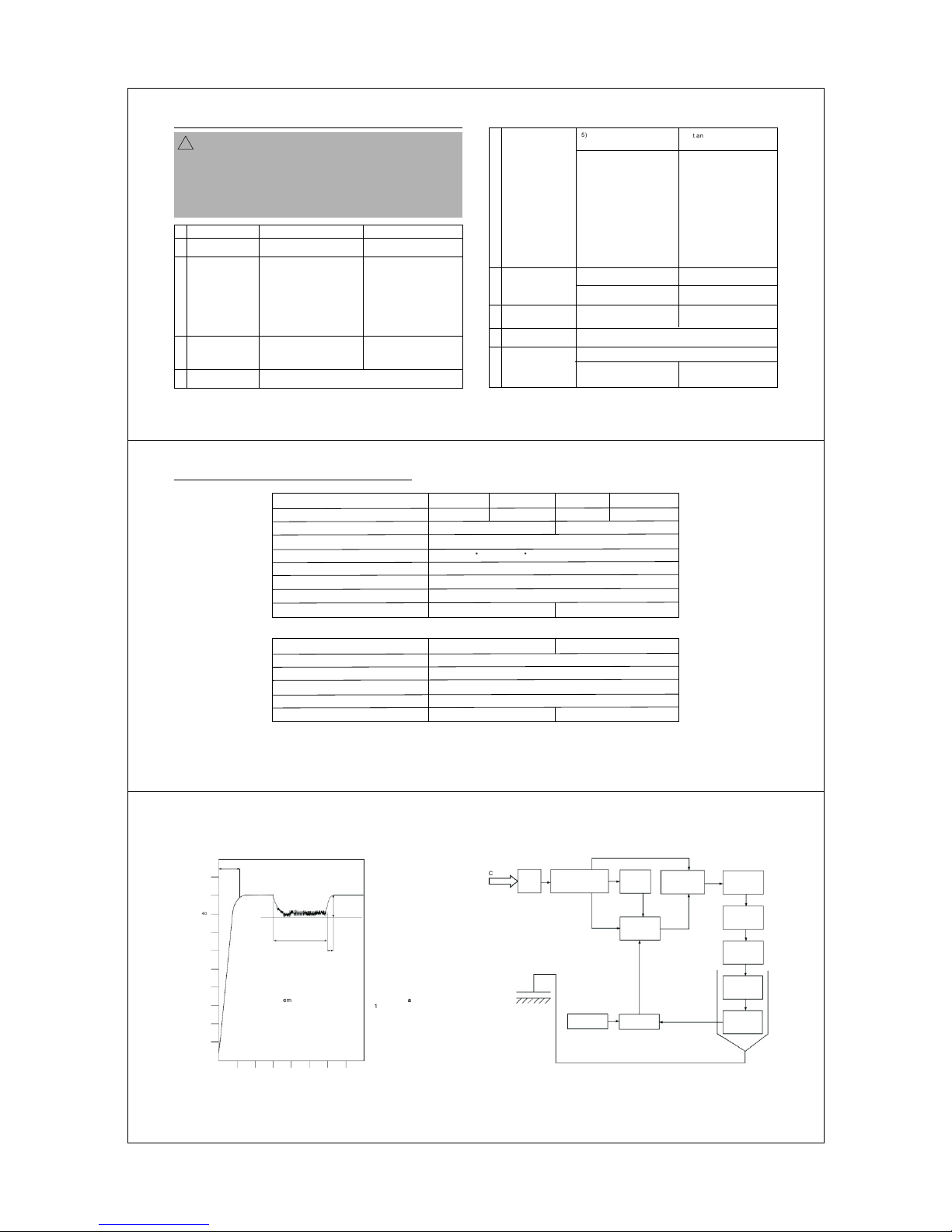

Melting Point

Normal operation

Production line operation

Desoldering operation for small joint

Desoldering operation for large joint

The temperature above ( ) should not be used

for normal soldering functions, but can be used for short

period of time when excessive heat is required.

770 F 410 C

2.Use and Care of Tips

Tip Temperature

When Not in Use

Before Use and After Use

High soldering temperature can degrade the Tip.

Use the lowest possible soldering temperature.

The excellent thermal recovery characteristics of

this system ensures efficient and effective

soldering even at low temperature. This also

protects the soldered items from thermal damage.

Clean the Tip regularly with the supplied Cleaning

Sponge, as oxides and carbides from the solder

and flux can form impurities on the Tip. These

impurities can reduce the Tip’s heat conductivity

or result in defective joints.

Wipe the Tip clean and coat the Tip with fresh solder.

This helps prevent Tip oxidation. Always keep the

11.

419 F (215 C)

608 F (320 C)

716 F (380 C)

608 F (320 C)

752 F (400 C)

Tip tinned before returning to Holder, switching off or storing

for any period of time,wipe only before using.

When using the Soldering lron continuously, be sure to

loosen the Tip and remove all oxides at least once a week.

This helps prevent seizure and reduction of the Tip

temperature.

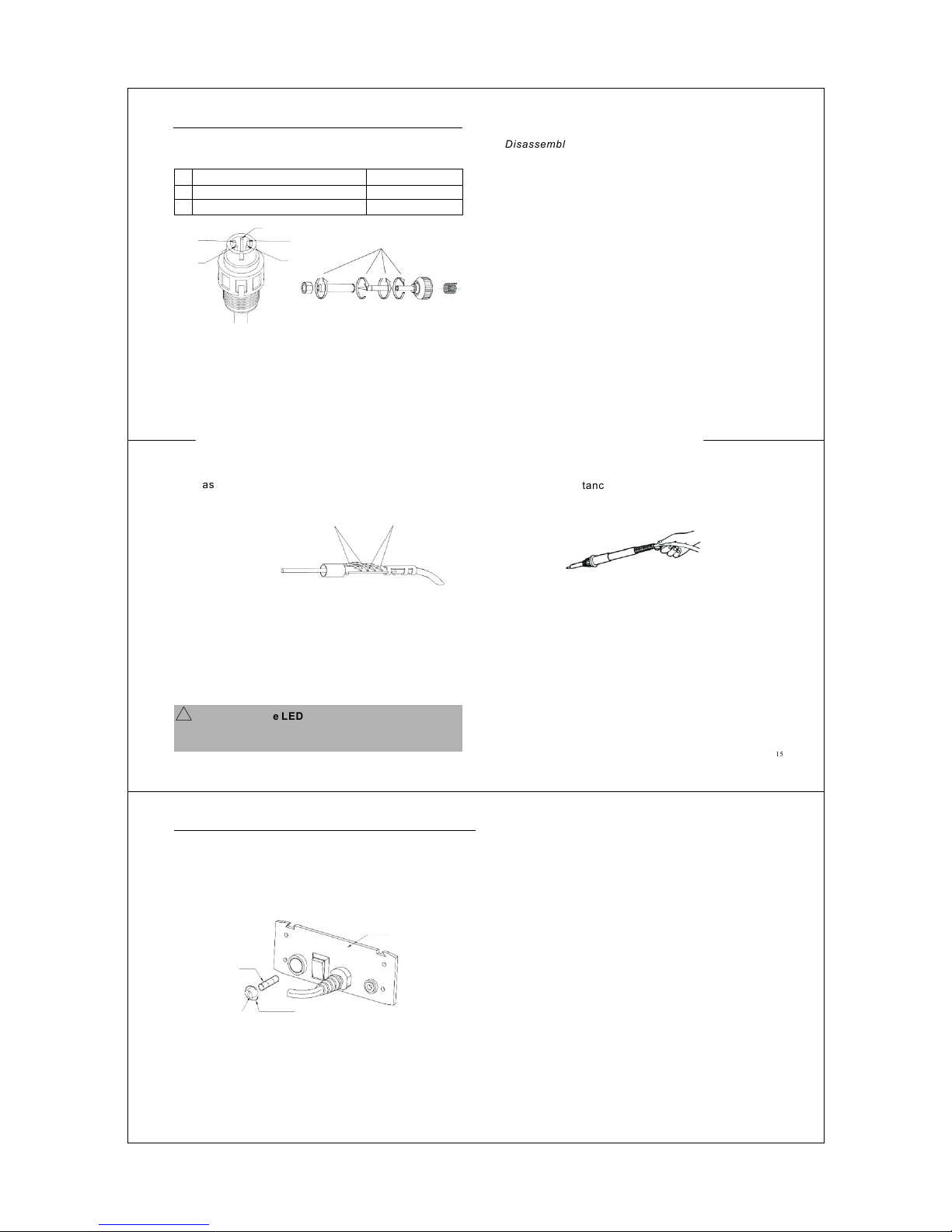

Set the temperature to ( ).

When the temperature stabilizes, clean the Tip with the

Cleaning Sponge and check the condition of the Tip.

If black oxides appear on the solder-plated portion of the

Tip, apply new solder (containing flux). Wipe the Tip on the

Cleaning Sponge. Repeat until the oxides are completely

removed. Coat with new solder.

If the Tip is deformed or heavily eroded, replace with a new

one.

If any oxide film does form, this can be cleaned by carefully

rubbing with a 600-800 frit fine emery cloth, isopropyl

alcohol or the equivalent, then wrap rosin-core solder

around the newly exposed surface and reheat, flood the

482 F 250 C

Maintenance

tinned area with rosin-core solder after wrapped rosin-

core solder melted.

1.

2.

3.

5.

6.

!CAUTION

Do not

Do not

Do not

Never

keep lron set at high temperature for long period

of time as this will break down the surface of the Tip.

give any excessive pressure on a Tip or rubbing a

Tip on a joint during making a joint, it does not improve

heat transfer but only damages the Tip.

use fluxes containing chloride or acid, use only

rosin or resin activated fluxes.

remove Tip oxides with files.

12.

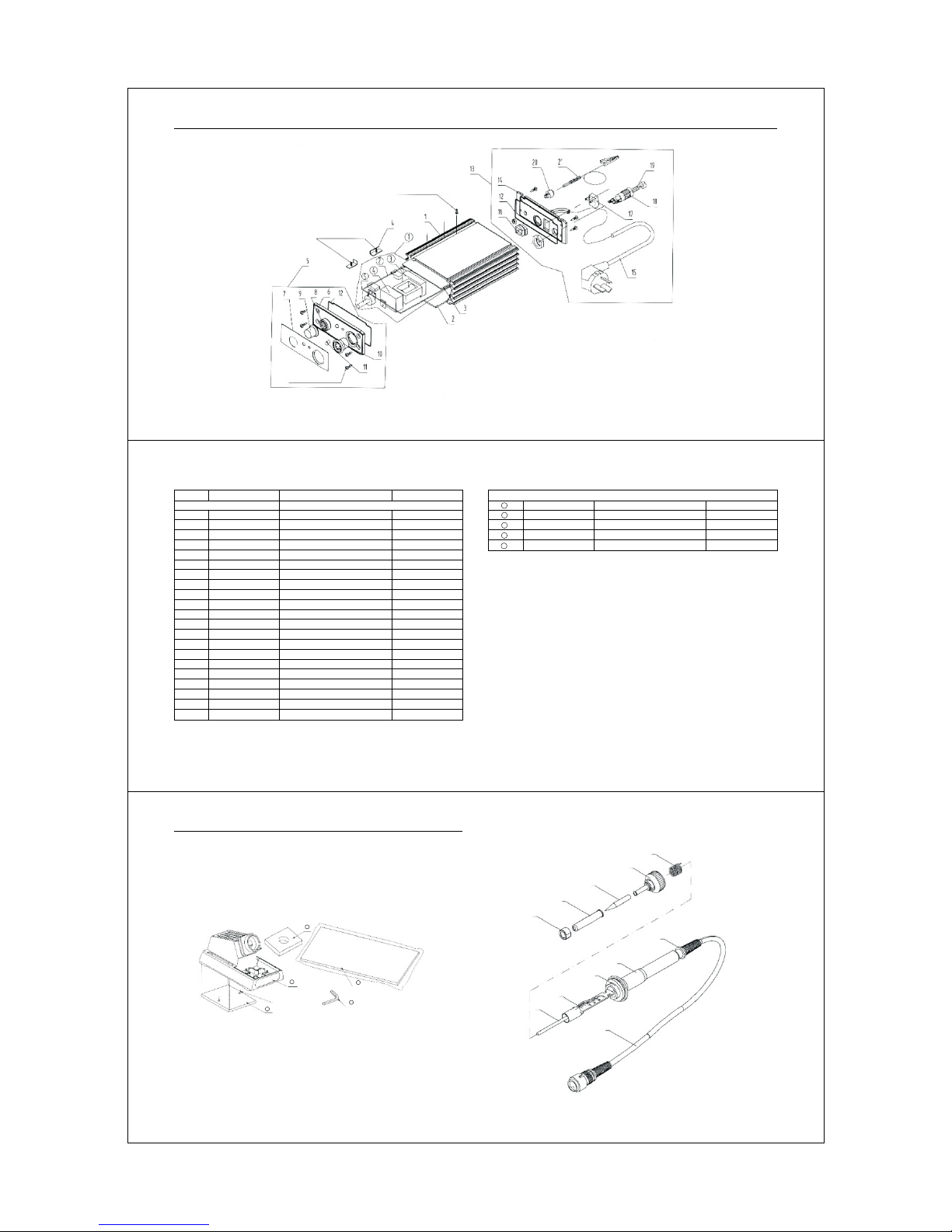

Calibrating lron Temperature

CAUTION: The Soldering System should be

recalibrated after changing the lron, or replacing the

Heating Element or Tip.

!

The initial temperature calibration of this Soldering

System has been set at the factory in accordance with

various industrial standards. No further calibration is

necessary by the user within about 6 months after first

use if no part change is needed.

1. Tools Required

1) Digital thermometer with leads and alligator clips

or digital thermometer equipped with surface

contact sensor specifically for Soldering lron

temperature measurement.

2) Test Tip fitted with thermocouple or SGT-710B

standard Tip for ceramic Heater.

3) 2.3-3mm (3/32” ) small flat screwdriver.

4) Multimeter

2. Steps of Calibrating lron Temperature

1) Connect the Cord Assembly Plug to the

Receptacle on the Control Base. (See Figure 11)

Set the Temperature Control Knob to

().

Remove the CAL Pot Plug on the Front Panel

(See Figure

and turn on the Power Switch.

Wait until the temperature stabilizes. Use a

small flat (-) or philips (+) screwdriver to adjust

the screw (through the CAL hole behind the

Front Panel at the Base) until the Tip

thermometer indicates the temperature to be

( ). Turn the CAL Screw slightly

clockwise to raise the temperature or

counterclockwise to lower the temperature.

Reposition the CAL Pot Plug.

750 400

750 400

2)

3)

4)

5)

!CAUTION: The

Soldering System

should be recalibrated

at the factory or service

agent if the 200

temperature scale

needs to be set.

(Figure 14)

Front Panel

CAL

Clockwise

Counterclockwise

CAL Pot Plug

13.