Spinball Sports Wizard User manual

Spinball Two Wheel Pitching Machine

Owner's Manual

CAUTIONS

● This machine is not a toy! Use under adult supervision only

● Machine will throw balls and strikes- batters must stay alert and

always wear a helmet

● Use only regulation sports balls, or balls specifically designed for

machine use

● Hold machine steady when loosening ball joint for adjustments

The machine is not fully balanced on the ball joint and may move

under its own weight if not held in place

● Use a grounded (3 prong) electric outlet only Use a GFCI outlet

when machine is operated outdoors Do not use the machine in

wet conditions

● Do not store the machine with the urethane wheel tread

compressed against the ground Flat spots will develop

● Never use a machine with a bent or deformed aluminum wheel

● Machine operator (person feeding balls into machine) should

stay behind a protective screen

FAST, FREE, FRIENDLY HELP

For assistance assembling or using your machine, please view our

videos online, call us at 618-244-4587, or email us at

info@spinballsports com

ASSEMBLY / SET UP

LEGS Slide the legs into the sockets on the tripod base until the spring

loaded buttons pop up and set the machine upright

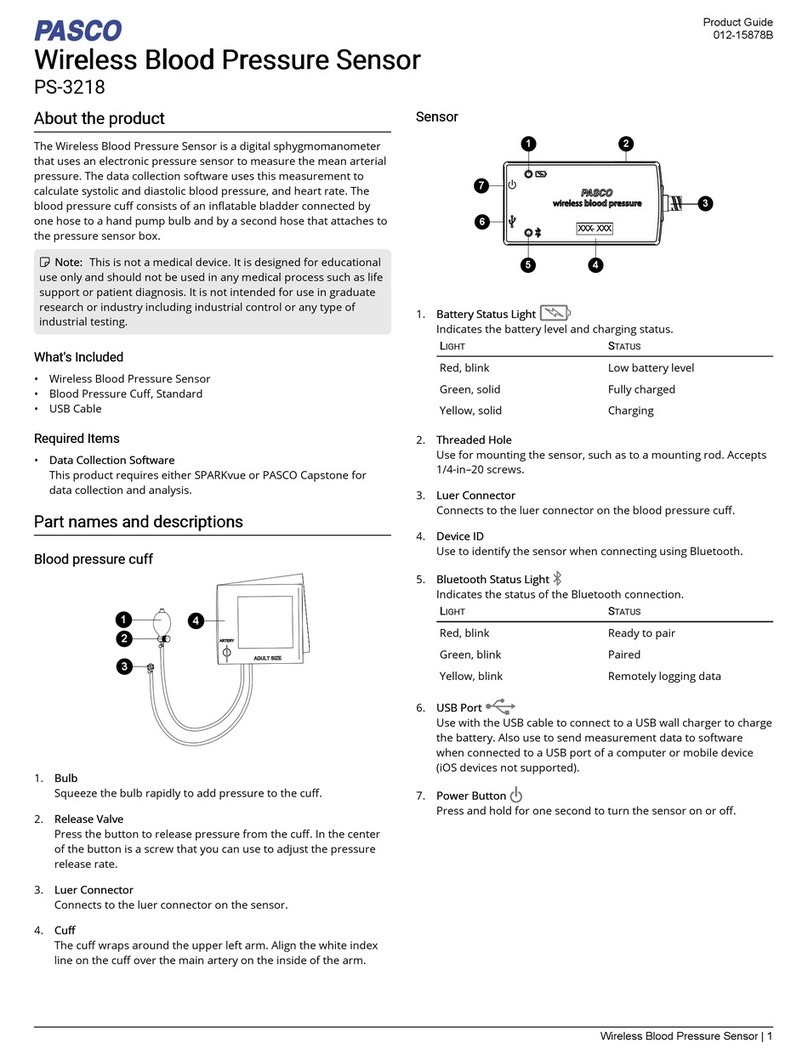

BALL FEEDER TUBES Use the 3" tube for baseballs, tennis balls,

or cricket balls, and the 4" tube for softballs Attach the tube to the

machine using the two included thumb screws Position the feeder tube

to clear the wheels by 1/4 - 1/2" Placing the tube in contact with the

wheels can damage the tube and wheels, and may cause the tube to be

grabbed and thrown Placing the tube too far away from the wheels will

diminish the machine's accuracy See Figures 1 & 2

Figures 1 & 2: Install ball feeder tube as shown. Tube shown in blue.

MOTOR / WHEEL POSITION The gap between wheels is a

critical adjustment to maximize pitch speed and accuracy The optimal

distance between wheels depends on the size and compressibility of the

ball being used Softer, more compressible balls require a smaller gap

than harder balls do Too small of a gap will slow the wheels when

pitches are thrown, producing a loud “thunk” Too large of a gap will not

generate enough squeezing force on the ball, and pitches will be too

slow, without enough spin As a general rule, when the gap is correct,

you should be able to feed a ball through an unpowered machine by

rotating the wheels by hand with a moderate effort

The Spinball Wizard uses a pegboard type system to ease wheel

alignment and spacing A grid of mounting holes provides a fixed number

of positions for motor placement and automatically aligns the motor and

wheel in each of those positions See Figures 5 & 6 for a typical laced

baseball setup

The wheels are moved by removing the four socket (Allen) head cap

screws that hold each motor sled to the frame A 3/16” Allen wrench is

Figure 3: Top motor position numbering system. Motor sled locating pins

shown in position 4 of 6. Motor sled shown in blue for clarity. Hole

numbers are shown to illustrate numbering system only, and do not

actually appear on machine.

Figure 4: Bottom motor position numbering system. Motor sled locating

pins shown in position 3 of 6. Motor sled shown in blue for clarity.

stored in a plastic clip on the back on the machine Be sure to support

the motor / wheel assembly when removing the screws – do not let the

motor fall or hang by its cord Reposition the motor & wheel assembly as

desired, then re-install the four screws (The screws don't necessarily

need to be fully removed during this process - you can just back them off

enough to be able to move the motor )

Table 1 provides guidelines on where to position the motors for various

types of balls Top and bottom motors do not need to be at the same

location, but they should not be more than one setting apart Feel free to

experiment and deviate from these locations to determine the optimal

wheel gap for your particular situation For example, cold weather will

cause both the balls and wheels to harden, requiring a larger wheel gap

than when the same machine is used in hot weather Also, once the

wheels wear down, they will need to be moved closer together to

compensate

Ball Type Top Motor / Wheel

Pin Location

Bottom Motor / Wheel

Pin Location

Soft Dimpled Baseballs

< 85 mph 3 3

Soft Dimpled Baseballs

> 85 mph 3 2

Real Baseballs 4 3

Soft Dimpled Softballs 5 5

Real Softballs 5 6

Table 1: Typical motor wheel location setups for a new machine. A ball

is considered “soft” if you can push your thumb into it 1 16” or more. To

get technical, “soft” is a durometer or 70A or less.

This system is unique to Spinball built pitching machines Adjusting the

wheel gap may seem like extra work, but the improved performance is

well worth the effort

OPERATION

SPEED CONTROLS The wheel speeds are individually controlled

by rotary knobs The actual pitch speed for baseballs will be the average

of the two wheel speeds - see “Throwing Different Pitches” below

Because softballs are heavier than baseballs, they are thrown roughly

15% slower than baseballs A small deadband, where the motor clicks

but doesn't actually turn, is normal below a speed setting of 10-15mph

ADJUSTING MACHINE ORIENTATION The machine is

positioned by use of a single ball and socket joint The joint is locked by

turning the clamping knob clockwise until tight To adjust the machine,

grasp the machine's frame and turn the clamping knob counterclockwise

until the joint is loose enough to move Then rotate the machine to the

desired position and lock the joint in place The best practice is to loosen

the joint just enough that you can adjust the machine with a little effort,

but not loosen it enough that it can flop around on its own For horizontal

adjustments, it is often easier to rotate the entire machine slightly instead

of adjusting the ball and socket joint a tiny amount

THROWING DIFFERENT PITCHES Thrown balls will tend to

curve in the direction they are spinning, and the greater the spin, the

more the curve Spin is imposed on the ball by setting one wheel to turn

faster than the other- the ball will spin & curve away from the faster

wheel By rotating the machine on its ball joint, you can set the curve in

any direction The speed of the pitch will be the average of the wheel

speed settings For example, setting one wheel at 60 and the other at 90

will result in a 75 mph pitch A laminated chart is included for guidance,

but it should only be considered a starting point Please feel free to call

or email us with questions

The most common mistake for new users is to set both wheels to the

same speed to throw a fastball However, if both wheels are set to the

same speed, the ball will have no spin and the pitch will actually be a

knuckleball A fastball has backspin, so the lower wheel must be set to a

higher speed (by 20-40 mph) than the top wheel to throw it

ACCURACY The primary factor behind pitch accuracy is the

consistency of the balls While you can use many types of balls (real or

dimpled / high or low seam / compressible or hard) you can not mix them

in one setup and get consistent results Balls must be dry and in good

condition Dimpled machine balls will be more accurate than leather

baseballs, especially after use Softer balls tend to be more accurate

than harder balls because the wheels grip them better Low seams are

better than high seams (and cause less wear) Rolling the ball into the

feeder tube so that the wheels grab across the seams is better than

along the seams (4 seam is better than 2 seam) The more consistent

the balls are, the more consistent the pitches will be

Another key factor for top accuracy is setting the proper distance

between wheels - see “Motor / Wheel Position” earlier in this manual for

a full discussion

A third factor is the cleanliness of the wheels After use, especially with

new plastic balls (both dimpled and laced), the wheels can accumulate a

residue from the balls The residue is slick and prevents the wheel from

grabbing the ball sufficiently The wheels can be cleaned with solvent

cleaners such as MEK, acetone, or lacquer thinner along with sandpaper

Cheap synthetic leather baseballs wear quickly and leave excessive

residue, so we strongly discourage their use This includes the Wilson

A1010S (Apparently the ‘S’ stands for synthetic )

If pitches seem to wander during use, check that the ball and socket joint

is tight Also check that the entire machine is not moving from recoil

When used on a hard slick flooring surface such as hardwood or cement,

the machine should be set on a carpet scrap or nonslip mat

We have found that Jugs' Pearl brand baseballs are slicker than

standard baseballs, and because of that, they are far less accurate in our

machines than standard baseballs

SPEED The speed dials are very close to actual baseball pitch

speeds, but they are not exact There is no economical way to

compensate for the different types, weights, and conditions of the variety

of balls that might be used The speed settings are, however, very

consistent and repeatable, so that once a machine is set, it will deliver

consistent speed and accuracy

MISCELLANEOUS

WHEEL BALANCING Our wheels are balanced 10X more

accurately than a typical car tire Should your wheels require re-

balancing for any reason we will rebalanced them for you for free

Shipping each way is not covered Bent or deformed aluminum wheels

must be replaced

GENERATORS This machine may be powered by a standard

household outlet or a portable gas generator The machine will pull a

maximum continuous load of 4 Amps (480 Watts) at 120V AC, but we

recommend a generator capacity of 800W minimum Be sure when

selecting a generator that you check the actual electric output power

rating, not the gas engine output, which is often how they are advertised

INVERTERS You can also power your machine with a 12V marine

battery with a 120V AC inverter However, only true sine wave inverters,

which are much more expensive than modified sine wave (MSW) or

square wave inverters, will work 1000W is the minimum recommended

output due to high startup currents

MAINTENANCE If stored outdoors, always keep the machine

covered to protect it from rain Tarps are available at any local hardware

store, but even a large trash bag will work Do not leave the machine

outside during storms High winds can blow the machine over and

damage the wheels and/or motor shafts This is not normal use, and is

therefore not covered by warranty Ball residue may be cleaned from the

wheel tread with sandpaper and / or a solvent cleaner such as lacquer

thinner, acetone, or MEK

WARRANTY If your machine doesn't perform like you expect, please

contact Spinball and we will attempt to diagnose the problem for you If a

part fails during the warranty period and you feel confident you can install

it yourself, we will send the replacement part for free If something goes

wrong during the first 30 days you have the machine, you can also

choose to exchange it for a new one After 30 days, if you need to return

the machine for repairs, you will have to pay for return shipping We will

repair the machine and return the machine back to you at our expense

All components of your machine are covered for non-commercial use for

five years from the date of purchase, but wheels are wear items which

are prorated like car tires For example, if a wheel or motor only lasts 3

years, you will receive 40% off the price of a new one The warranty

does not cover cosmetic issues, normal wear, or misuse of the product

For commercial use, the warranty period is one year Warranties are not

transferable

We don't want anyone to be unhappy with their purchase, so products

may be returned at your expense for any reason within 30 days for a full

refund minus a 15% restocking fee This fee is the lowest in the industry

and covers both our outgoing shipping costs and minor cosmetic damage

to the machine Refunds will be reduced to cover any non-cosmetic

damage

THANK YOU! Thank you for buying from Spinball Sports We hope

you will enjoy your new pitching machine for many years to come If you

have any questions or comments please email us at

info@spinballsports com or call us at 618-244-4587 And thanks again!

Table of contents

Popular Accessories manuals by other brands

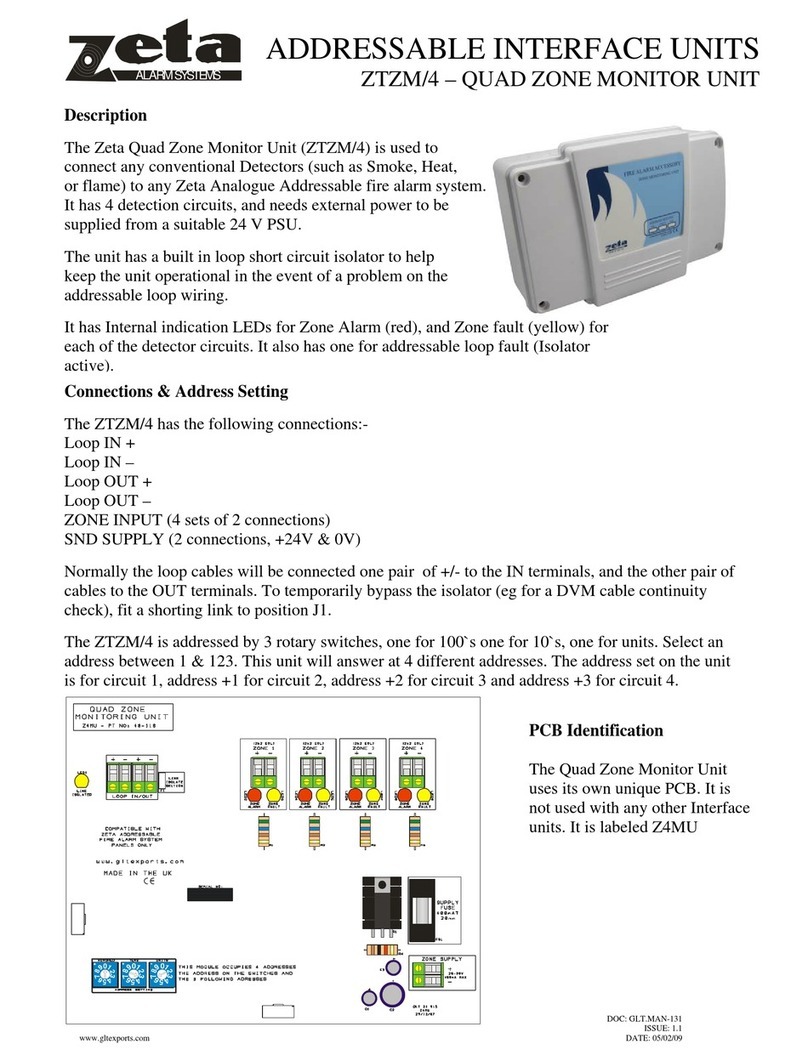

Zeta Alarm Systems

Zeta Alarm Systems ZTZM/4 user manual

Crown

Crown PIP-RPA reference guide

Hitachi

Hitachi Super drive series operating instructions

ADEO CONTROL

ADEO CONTROL SP-C4-1 Installation and use manual

Geemarc

Geemarc CL2 User manuals

Kindermann

Kindermann CablePort desk2 80 Touch Mounting instructions