Spinlock XAS Series Quick start guide

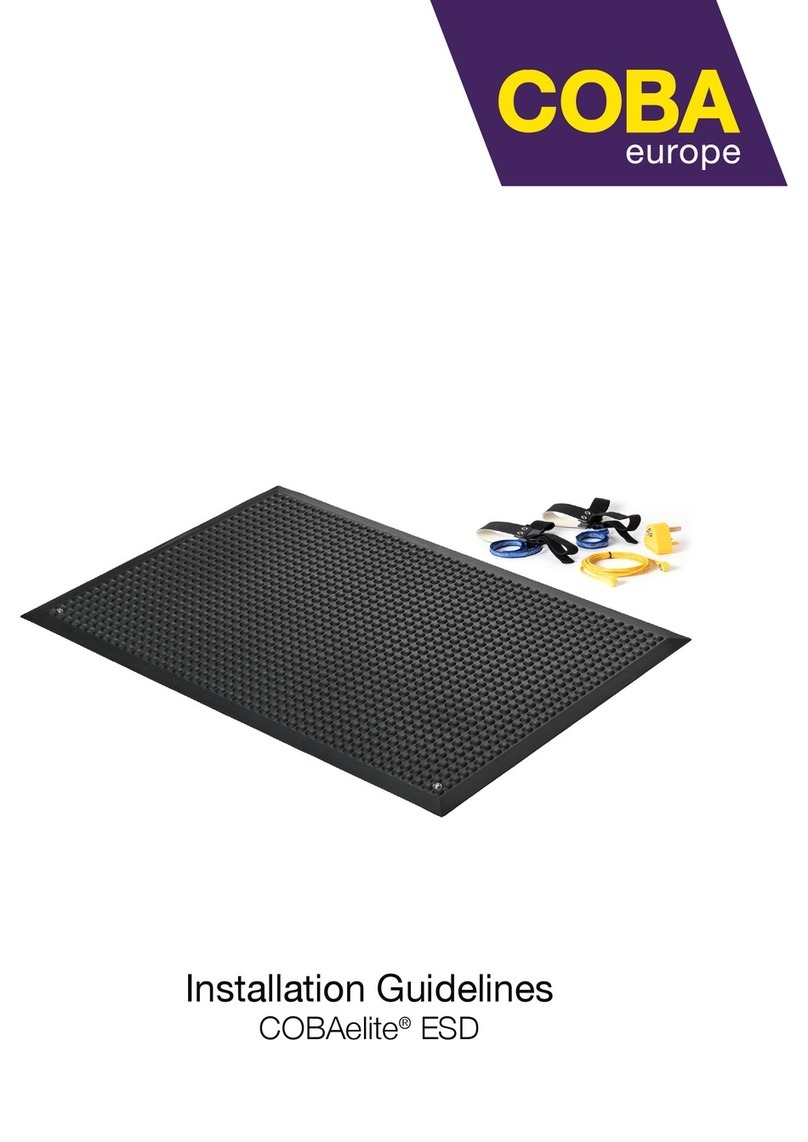

Fig.2

10º MAX

M6 CSK (1/4” CSK)

Description

Effortless multi role clutch for 6-12mm lines and 4-8mm lines.

Safety

Please take care to follow these important safety rules:

•Check that the clutch is correctly specified for your application.

•Check carefully that it is correctly installed before using it for the first time

under load.

•Control release safely by checking snubbing the rope on the winch drum.

•Never flick open the handle when clutch is heavily loaded, sudden

release may cause injury, as well as damage to the rope, rig and clutch.

•Use braided fibre rope only (never use three strand or wire rope).

•Never use the clutch if damaged.

•Never use a clutch with damaged rope.

•Never use cleaning or lubricating solvents, polysulphide or polyurethene

based sealants: they degrade the product.

•Do not modify any part of the clutch.

•Always use hand protection.

Safety warning

This product is designed for use on sailing boats, please consult Spinlock before

using it for any other purpose. The sport of sailing carries a risk of personal

injury. Spinlock accept no liability whatsoever for any claim that may relate

directly or indirectly to the use of this equipment in any manner or for any

application or loading other than advised in current product information published

by Spinlock Ltd.

General guidance

The maximum load achievable in practice is a function of rope diameter and

construction: generally bigger and firmer rope has the better the load holding.

Use

•Open the handle fully forward to thread the line through the clutch.

•With the handle closed,the clutch will hold the rope automatically as the

load is eased from the winch. (Allow for a forward rope ‘run out’ of up to

20mm (1") as the cam engages. Gripping performance on new rope will

improve with use).

•Manual lockdown function. If required, you can achieve increased load

holding by lifting the handle until vertical, then locking it down firmly onto

the tensioned rope before easing the load from the winch.

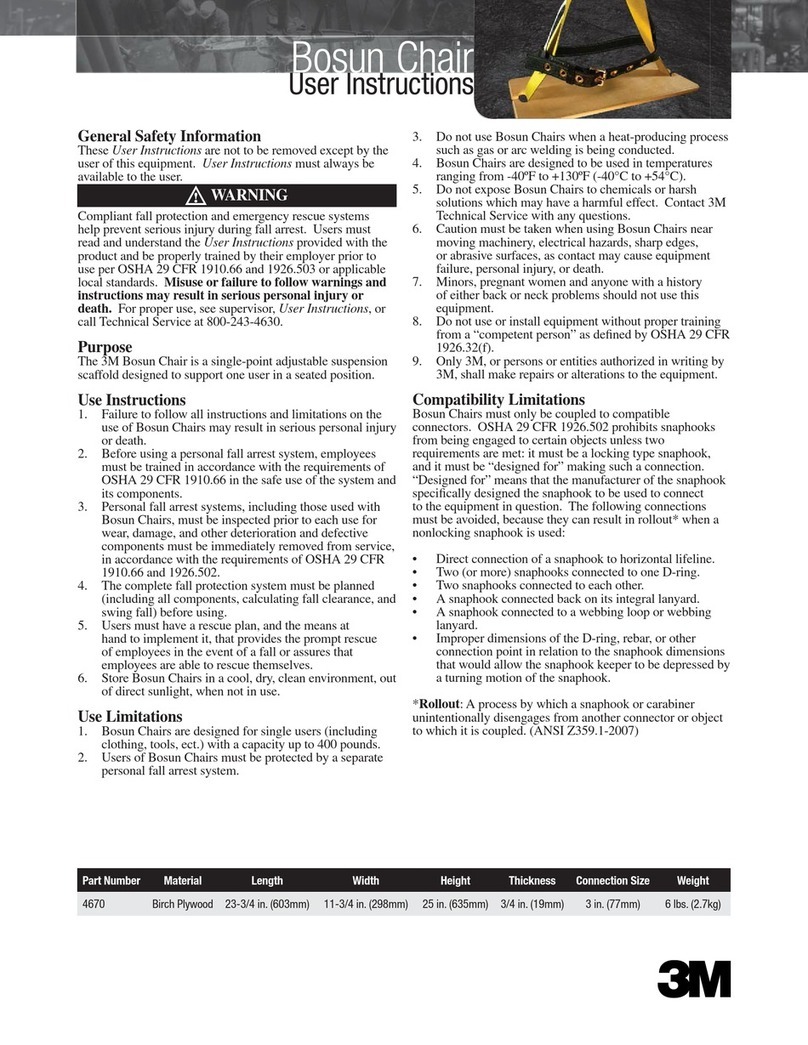

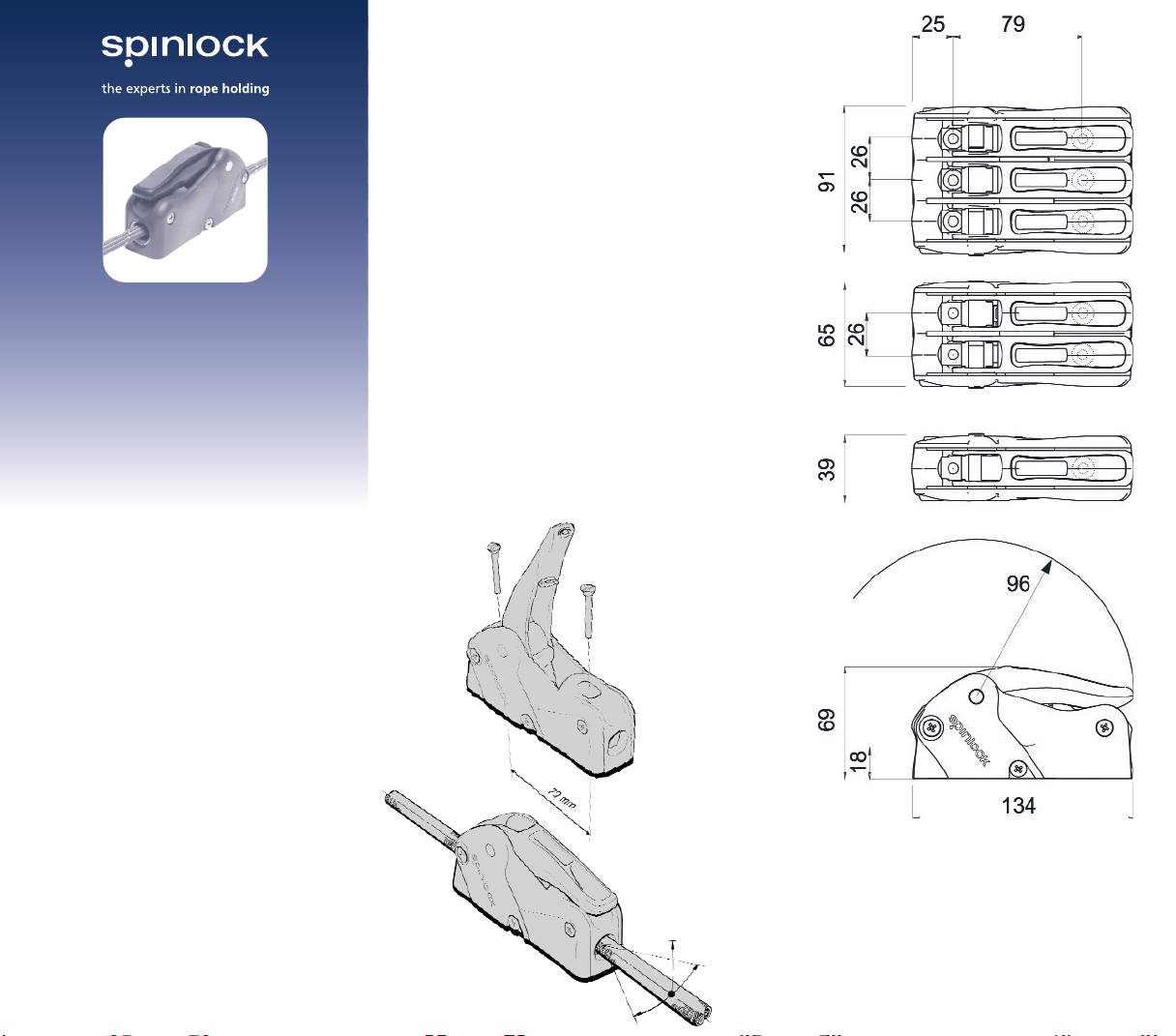

Installation

•Decide the most efficient clutch layout before marking out and drilling

6.5mm (1/4") holes.

Note: take care to check template hole centres against product

•Install clutch forward of the winch with the handle opening towards the

load (Fig. 1).

•Keep the rope deflection angle as small as possible. In a bank of clutches,

try to ensure that the most heavily loaded lines have the least deflection.

•The angle of the line from the clutch up to the winch drum, should not

exceed 10º (Fig. 2). You can reduce this angle by increasing clutch to

winch distance or raising the clutch using a wood or delrintm pad.

•Insert stainless steel M6 (1/4") csk fasteners using full nuts and washers.

•Apply silicone sealant around the thread of the fasteners to ensure a

watertight seal and easy removal.

•Ensure that the clutch is securely fitted to the deck.

•Extra reinforcement is needed for foam sandwich deck installations:

please consult your local boatyard.

•For side mounting use conversion kit XAS-SMNT.

•Rinse the gripping area of new rope in water before use.

Maintenance

This Powerclutch is made from the best quality materials for durability and low

maintenance in a harsh marine environment.

•Flush regularly with fresh water and apply a silicone spray or grease

when dry.

•Never use mineral oil or solvent based lubricants like "WD40". The

wrong lubricants will degrade and weaken the moulded composite

components and can cause sudden structural failure. They will also

degrade the bearing properties of composite bushes.

Quality assurance

This Powerclutch has been intensively tested on all diameters and

specifications of rope in co-operation with international rope manufacturers and

drawing on more than 30 years of ropeholding design experience.

Fig.1

powerclutch XAS

Installation and use

5 year manufacturer’s warranty subject to

published Spinlock terms and conditions.

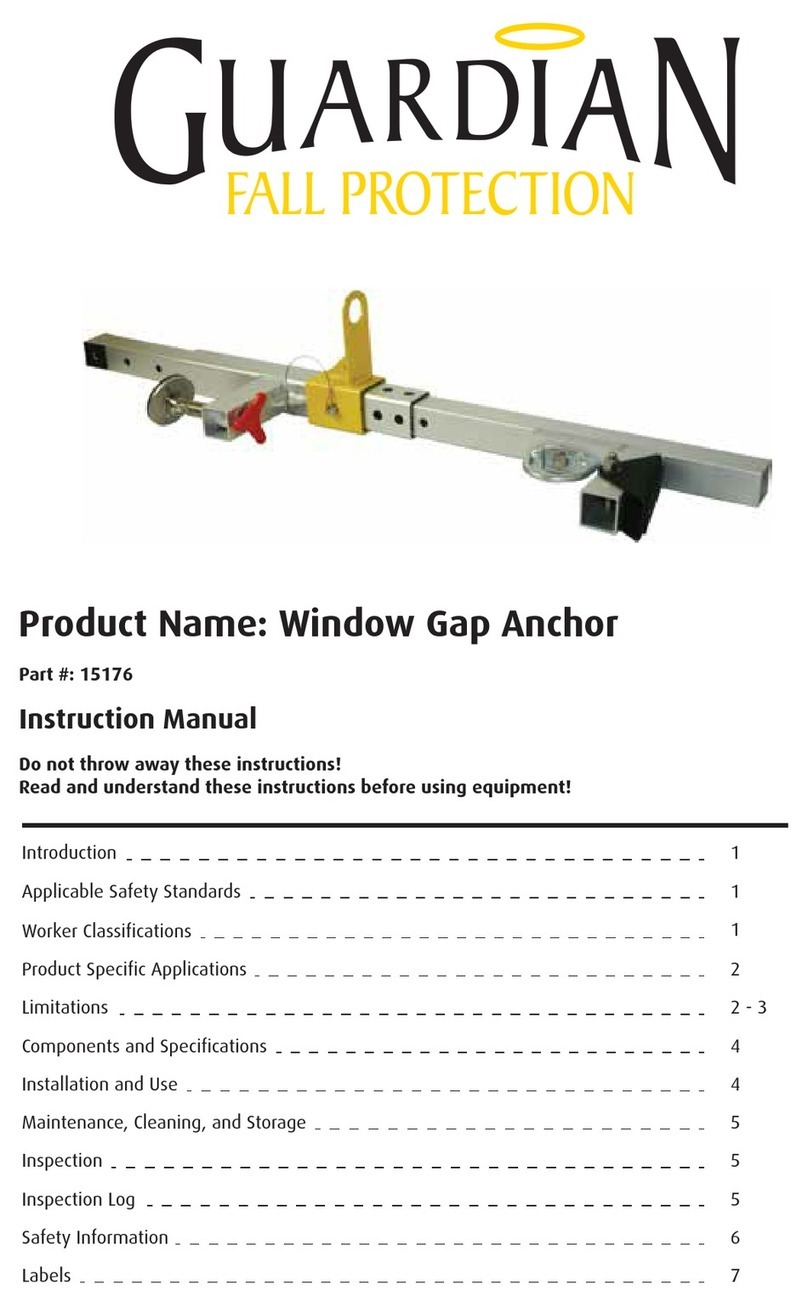

LINE DRAWINGS - NOT TO SCALE

Model Line Dia Max SWL

(each line) Fasteners

XAS0612/1 6-12mm (1/4-1/2”) 575kg (1250Ibs) 2 X M6 CSK (2 X 1/4” CSK)

XAS0612/2 6-12mm (1/4-1/2”) 575kg (1250Ibs) 4 X M6 CSK (4 X 1/4” CSK)

XAS0612/3 6-12mm (1/4-1/2”) 575kg (1250Ibs) 6 X M6 CSK (6 X 1/4” CSK)

XAS0408/1 4-8mm (5/32-5/16”) 450kg (990Ibs) 2 X M6 CSK (2 X 1/4” CSK)

XAS0408/2 4-8mm (5/32-5/16”) 450kg (990Ibs) 4 X M6 CSK (4 X 1/4” CSK)

XAS0408/3 4-8mm (5/32-5/16”) 450kg (990Ibs) 6 X M6 CSK(6 X 1/4” CSK)

SIZE

SAME HOLE SPACING AS THE XA CLUTCH

TEMPLATE FOR SINGLE XAS UNIT

WINCH END

SPECIFICATION TABLE

TEMPLATE - ACTUAL

To Install

(XAS-SMNT, XAS..../HP or

XAS..../HS)

(XAS model only)

•Pass the 3 machine screws M5, 85mm long

through the body (if assembling an XAS-SMNT

the unit is reversible and pre-assembled products

can be changed from Port to Starboard. Fasten

the base fairing to the clutch using the 2

countersunk screws)

•Plan layout of deck before marking out holes for

installing the clutch with the handle opening

away from the winch

•Ensure deck has adequate strength

•Drill the 3 Ø5.5mm holes (Ø9/16”) through the

deck (see dimensions below)

•Use some silicone sealant around the fasteners to

ensure a good seal and then bolt the clutch down

To replace Handle

(XAS-HDL)

(XAS model only)

•Carefully remove handle pivot pin with suitable

punch

•Lift handle and remove from cam

•With new handle upright, locate in cam and

rotate to closed position. Check handle is

engaged with cam and the spring is mounted

on springarm. The springarm must be

through blue pivot in rear moulding

•Align holes and tap pivot pin into place

•Revolve cam slightly if necessary

To replace Handle Insert

(XAS-TAG)

(XAS model only)

•Open handle and remove handle insert screw

•Gently ease out the handle insert from the end

nearest handle pin

•Locate new insert and replace screw

•Do not overtighten

Safety Warning

This product is designed for use on sailing boats,

please consult Spinlock before using it for any other

purpose.

The sport of sailing carries a risk of personal injury.

Spinlock accept no liability whatsoever for any claim

that may relate directly or indirectly to the use of this

equipment in any manner or for any application or

loading other than advised in current product

information published by Spinlock Ltd.

General Guidance

The maximum load achievable in practice is a function

of rope diameter and construction: generally the

bigger and firmer the rope, the better the load

holding.

Service

To help ensure a long working life for every Spinlock

product we supply easily installed parts and

performance upgrades through Spinlock stockists

worldwide.

To replace Side Moulding

(XAS-SIDE)

(XAS model only)

•A side moulding can be replaced without

removing the clutch from its mounting surface. It

is easier if the mounting screws are loosened

•Remove three fastening screws from side

moulding

•Remove damaged side moulding. (gently ease the

side off using a screw driver, alternatively remove

handle pin from the damaged moulding with

suitable punch)

•Carefully replace the side mouldings and snap

together ensuring all parts are located correctly

between mouldings

•Replace three fastening screws

•Re-tighten mounting screws

To replace the Base

(XAS-BASE0408)

(XAS and XA models)

•Remove clutch from mounting surface

•Remove three fastening screws from side

of clutch

•Remove the port side moulding. (gently ease the

panel off using a screw driver, alternatively

remove handle pin from the port moulding with

suitable punch)

•Remove forward and rear mouldings, sliding

spring arm from the hole in the blue pivot in rear

moulding

•Remove base from mouldings

•Slide new base into forward and aft mouldings.

•Push blue pivot moulding into place – from port

side of rear moulding, ensuring spring is trapped

on spring arm

•Locate springarm in cam through hole in

port side

•Replace side moulding ensuring all parts are

located correctly between both side mouldings

•Replace three fastening screws

•Replace clutch on mounting surface

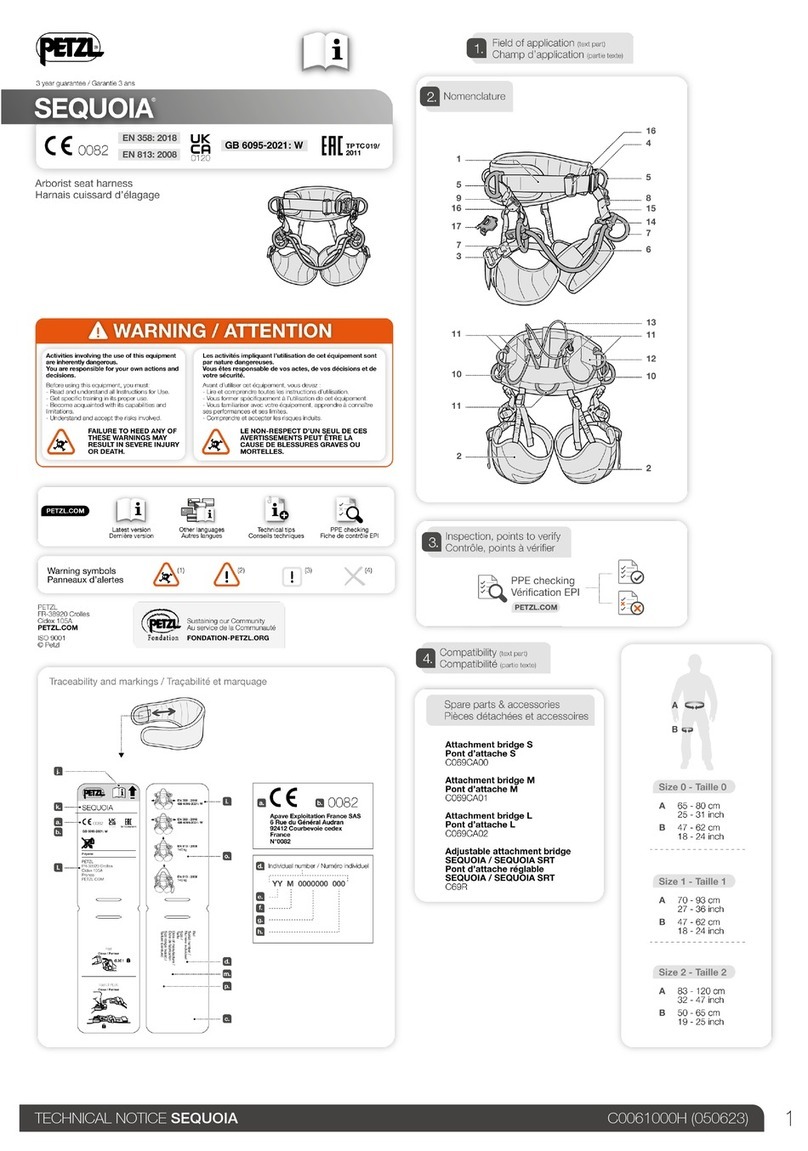

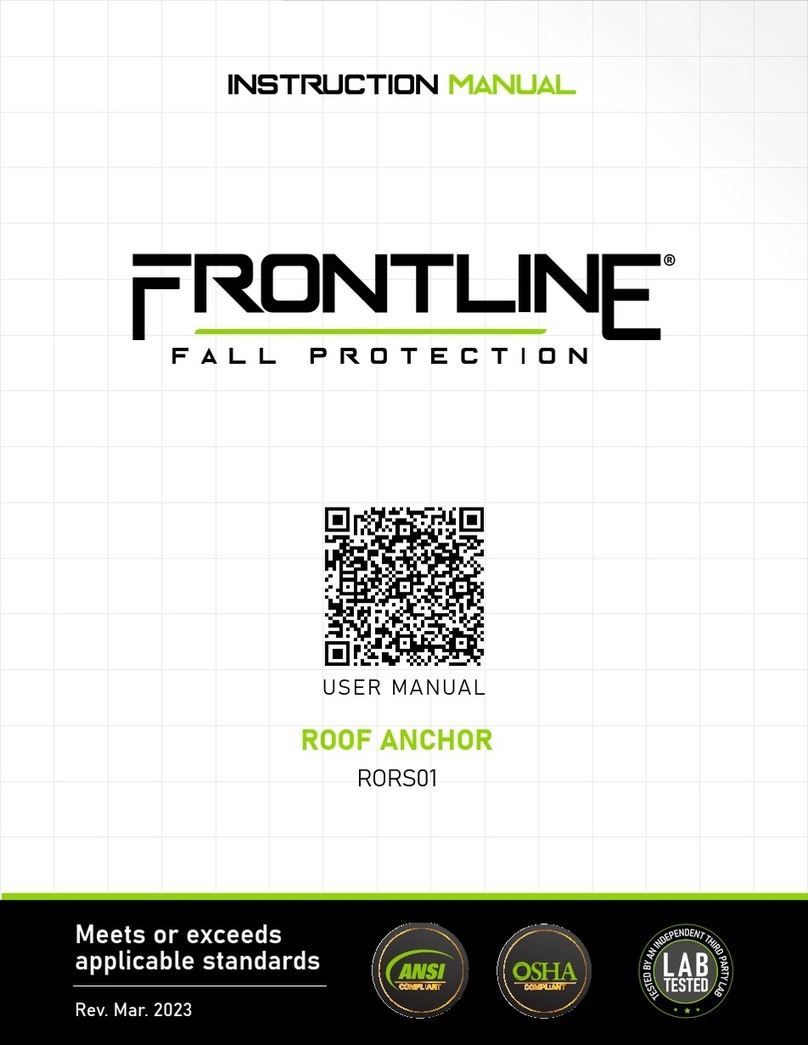

To Replace the Cam

(CAM-XAS)

(XAS and XA models)

•Remove handle pivot pin with suitable punch

•Lift handle and remove from cam

•Withdraw cam and springarm

•Remove springarm from the cam and insert

•Place cam insert in new cam. Note the arrow

shaped hole in insert must point upwards

when used in an XAS assembly and downwards

when used in XA products (see Fig. 1)

•Reassemble the spring onto springarm and into

port side of the cam

•Place springarm and cam into body with

springarm through blue pivot in rear moulding

•With handle upright, locate in cam and rotate to

closed position. Check handle is engaged

with cam and the spring is mounted on the

springarm

•The springarm must be through blue pivot

in rear moulding

•Align holes and tap handle pivot pin into place

Fig. 1

FOR USE IN XAS

NOTE ARROW POINTS UP

ARROW

FOR USE IN XA

NOTE ARROW POINTS DOWN

52.5 52.5

XAS Safety

Please take care to follow these important

safety rules:

•Check that the clutch is correctly specified for

your application.

•Check carefully that it is correctly installed

before using it for the first time under load.

•Control release safely by checking snubbing

the rope on the winch drum.

•Never flick open the handle when clutch is

heavily loaded, sudden release may cause

injury,

as well as damage to the rope, rig and clutch.

•Use braided fibre rope only (never use three

strand or wire rope) Never use the clutch if

damaged.

•Never use a clutch with damaged rope

•Never use cleaning or lubricating solvents, or

polysulphide-based sealants : they degrade

the product.

•Do not modify any part of the clutch.

•Always use hand protection

5 year manufacturer’s warranty subject to

published Spinlock terms and conditions.

Learn more about sailing cleats on our website.

This manual suits for next models

6

Other Spinlock Safety Equipment manuals

Spinlock

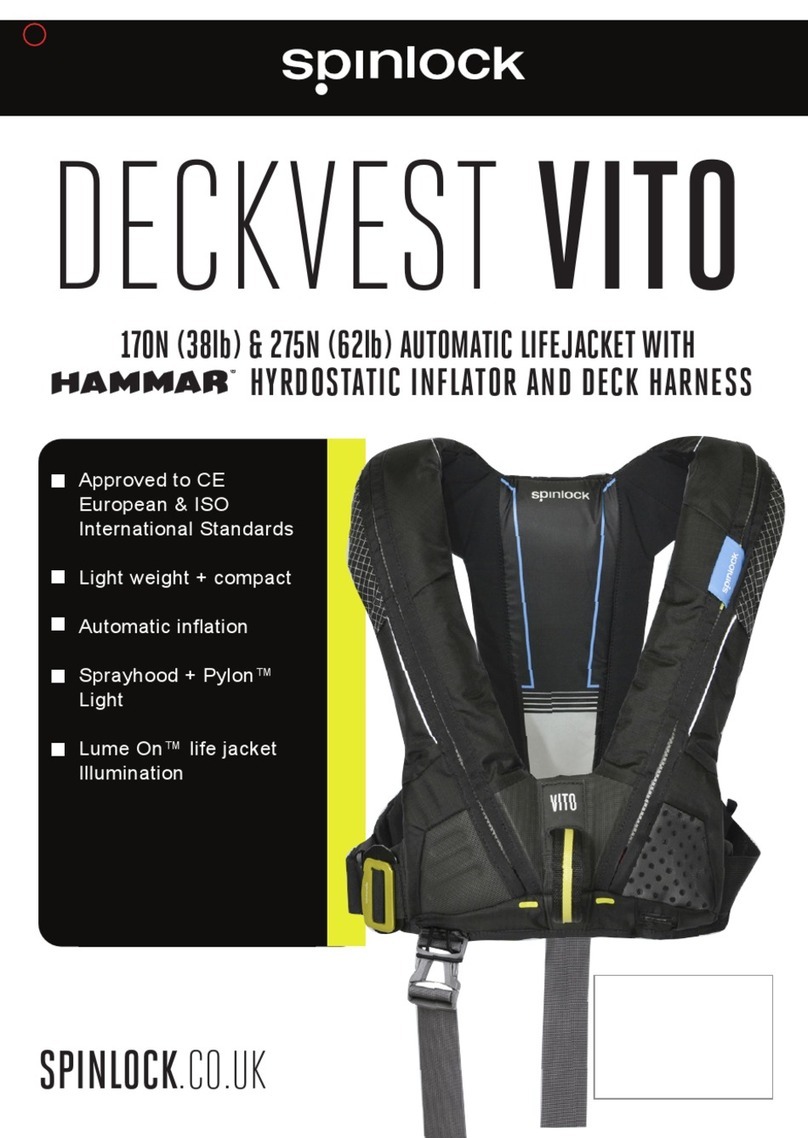

Spinlock 170N User manual

Spinlock

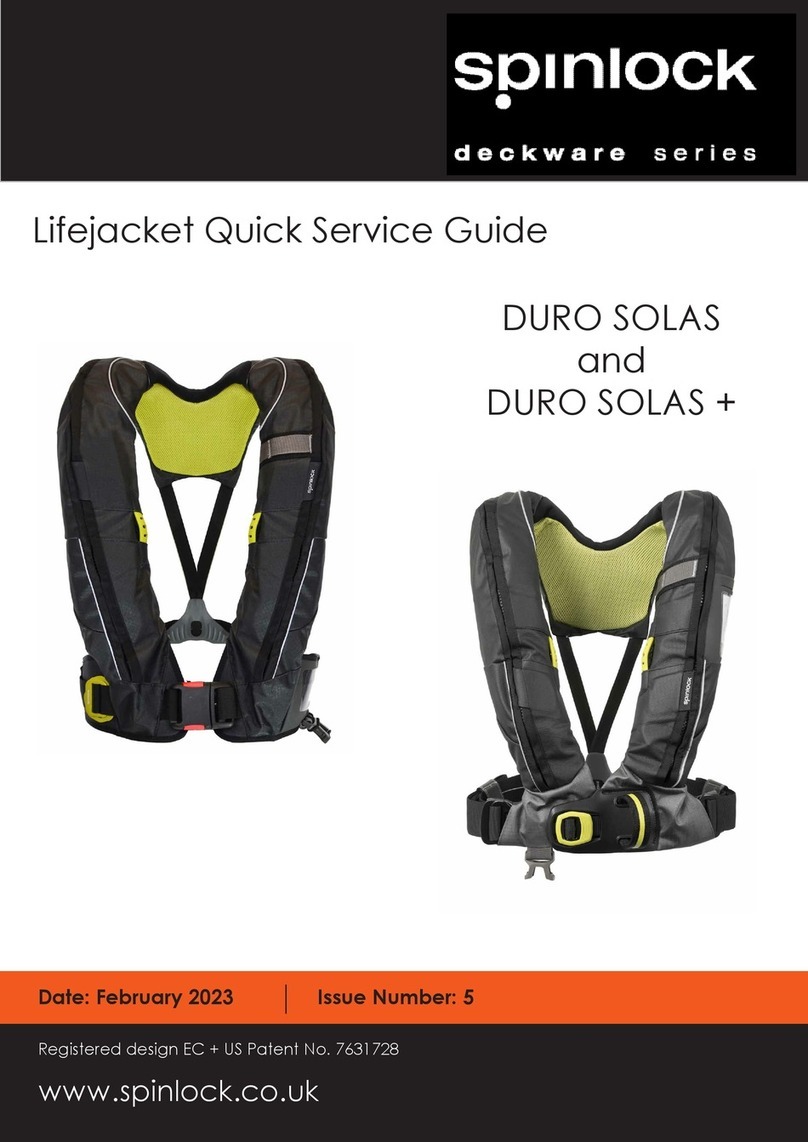

Spinlock DURO SOLAS User manual

Spinlock

Spinlock Deckvest LITE User manual

Spinlock

Spinlock deckvest 5D User manual

Spinlock

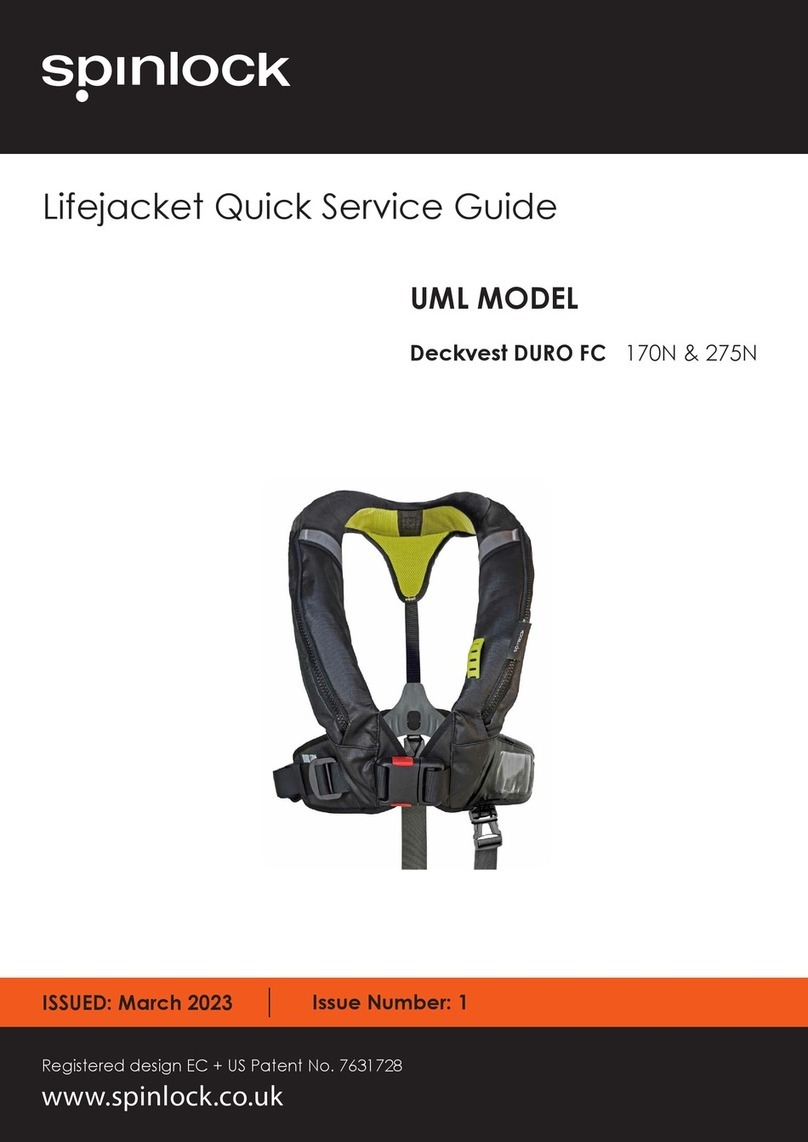

Spinlock Deckvest DURO FC 170N User manual

Spinlock

Spinlock DECK PRO User manual

Spinlock

Spinlock MAST PRO User manual

Spinlock

Spinlock DECKVEST LITE User manual

Spinlock

Spinlock LOAD-SENSE User manual

Spinlock

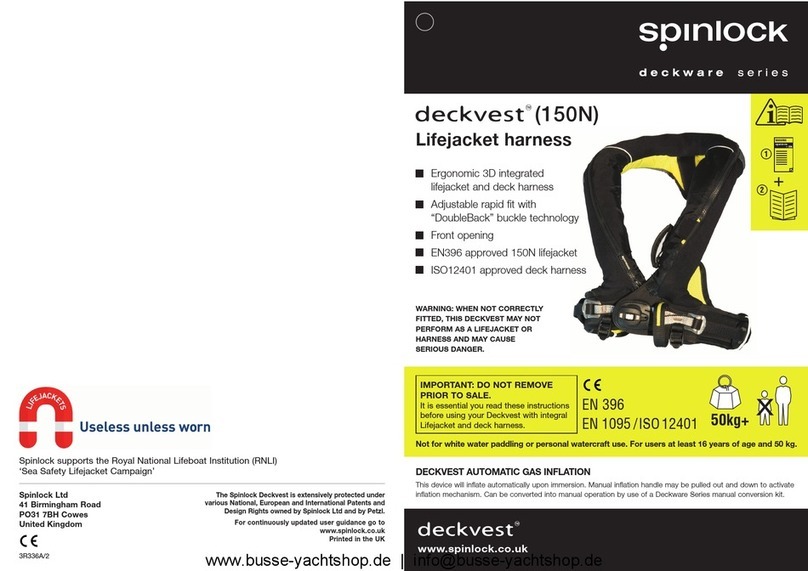

Spinlock deckware Series User manual