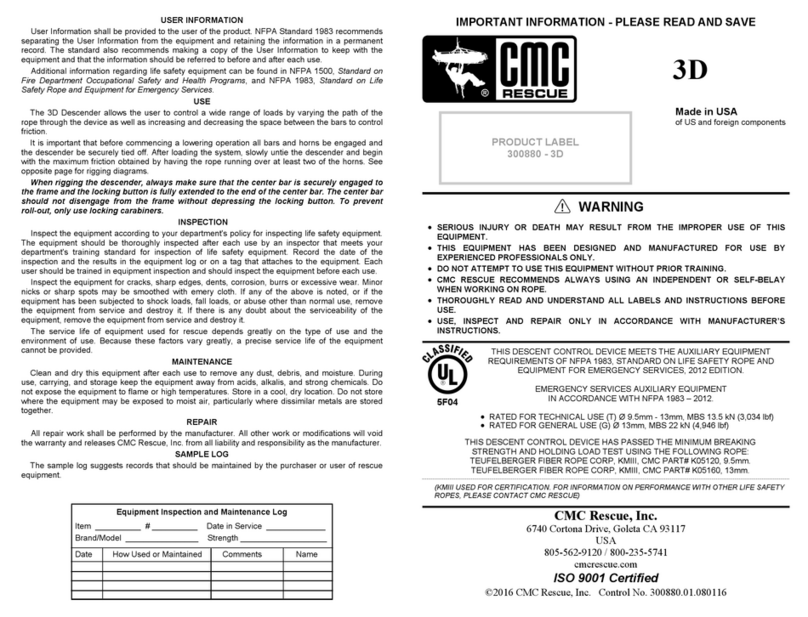

USER INFORMATION

User Information shall be provided to the user of the product. NFPA Standard 1983, incorporated

into the 2022 edition of NFPA 2500 recommends separating the User Information from the equipment

and retaining the information in a permanent record. The standard also recommends making a copy

of the User Information to keep with the equipment and that the information should be referred to

before and after each use.

Additional information regarding life safety equipment can be found in NFPA 1500 and NFPA 1858

and NFPA 1983, incorporated in the 2022 edition of NFPA 2500.

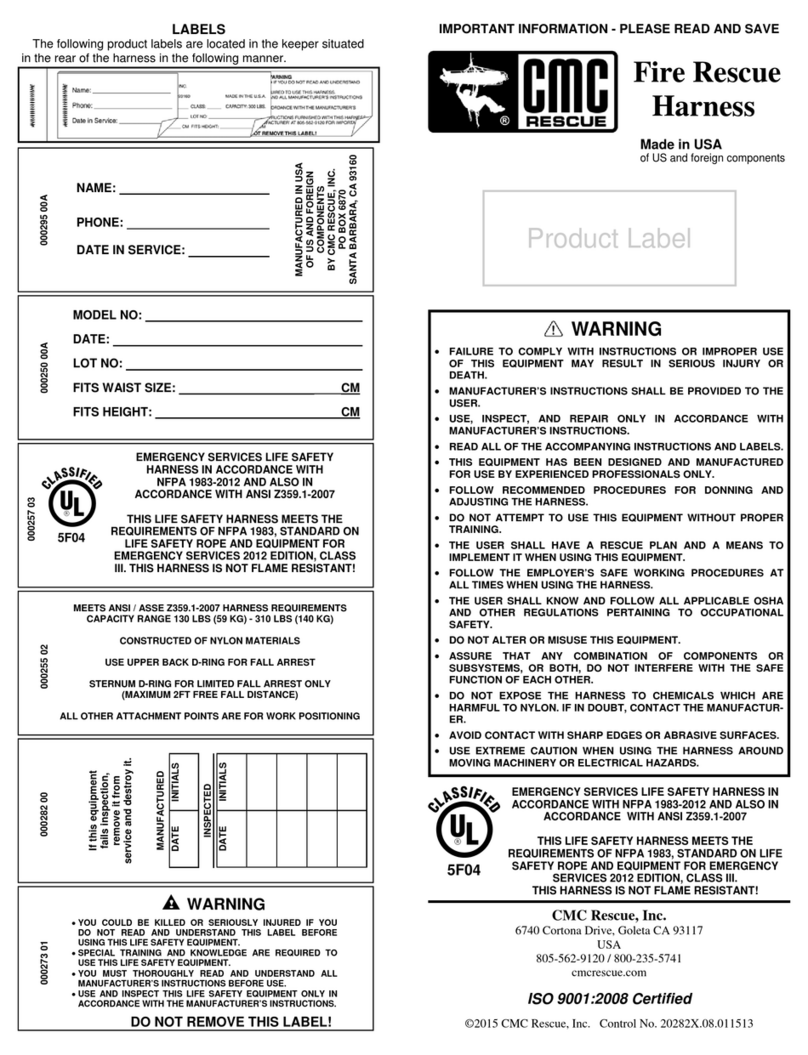

LIFESPAN / INSPECTION / RETIREMENT

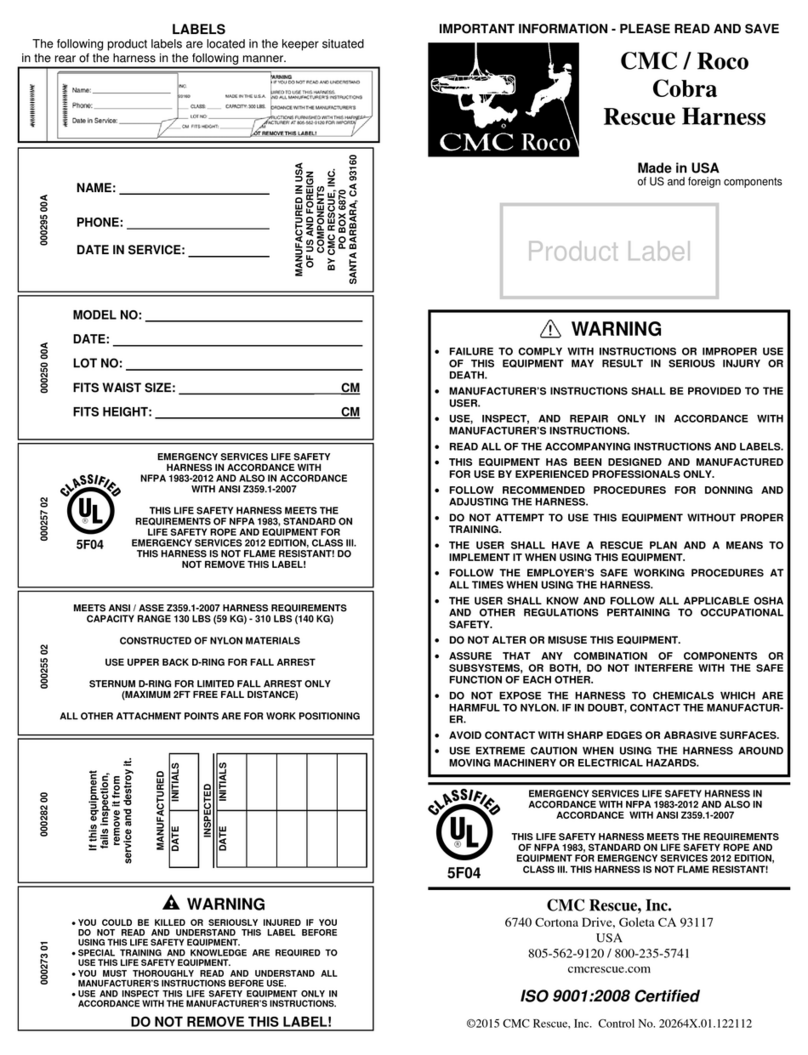

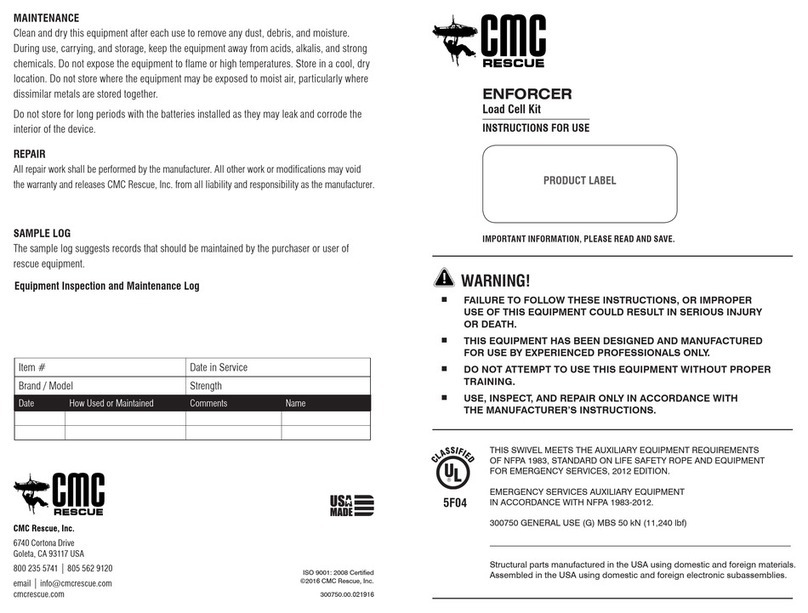

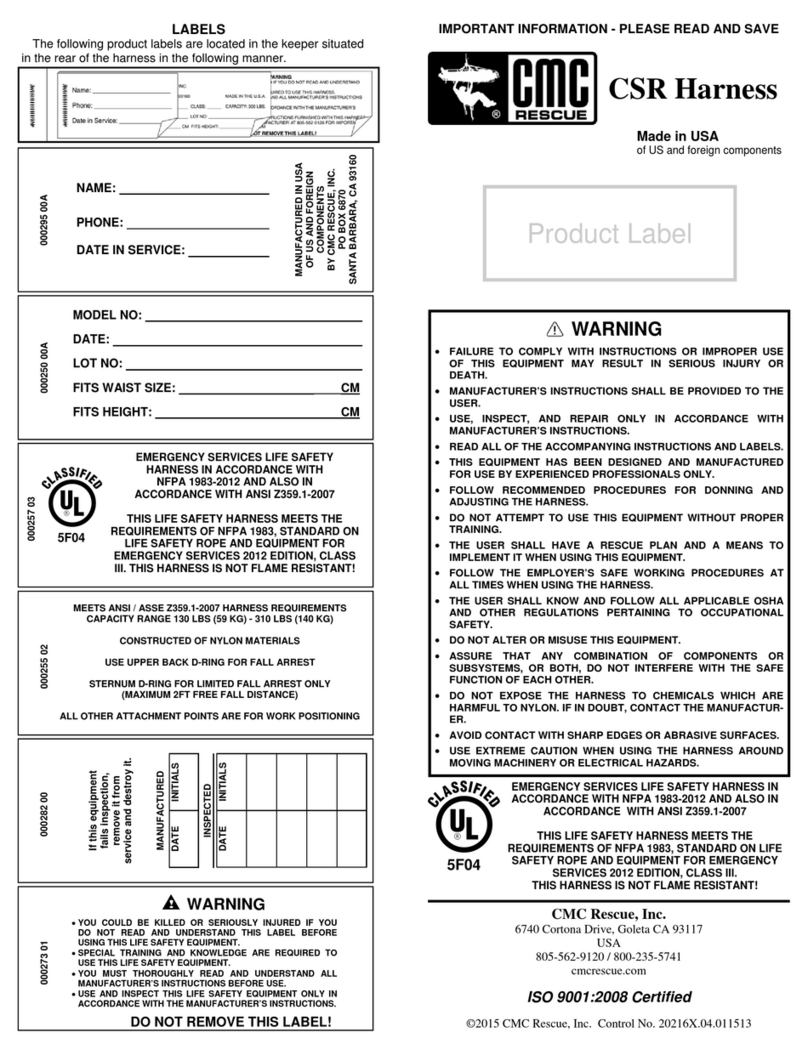

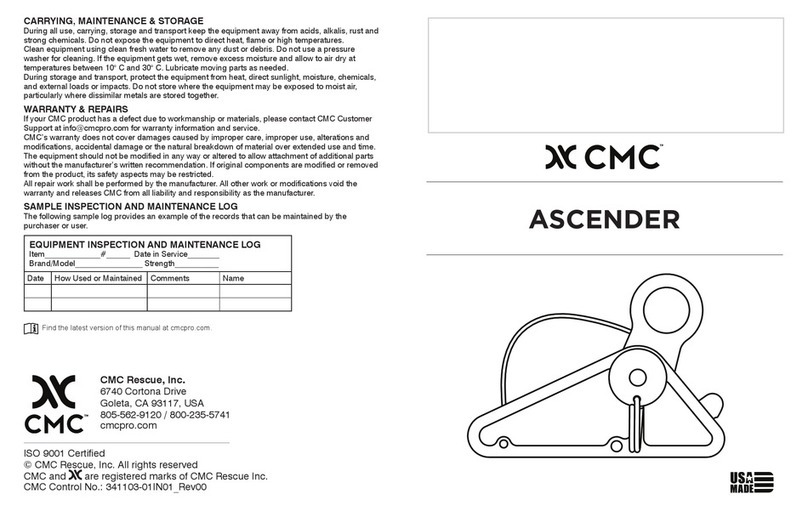

The equipment has a lifespan of 10 years from the date of manufacture shown on the product label.

The type of use, intensity of use, and environment of use are all factors in determining serviceability

of the equipment. A single exceptional event can be cause for retirement after only one use, such as

exposure to sharp edges, extreme temperatures, chemicals, or harsh environments. Any concerns

about its safe use is cause for retirement. Remove retired equipment from service and destroy it to

prevent further use.

The equipment must be retired when:

• It fails to pass inspection.

• It fails to function properly.

• It has illegible product labels or markings.

• It shows signs of damage or excessive wear.

• It has been subjected to shock loads, falls, or abnormal use.

• It has been exposed to harsh chemical reagents.

• It has an unknown usage history.

• You have any doubt as to its condition or reliability.

• When it becomes obsolete due to changes in legislation, standards, technique or incompatibility

with other equipment.

Inspect the equipment according to your department’s policy for inspecting life safety equipment.

CMC recommends a detailed inspection by a competent person at least once every 12 months

depending on current regulations and conditions of use. Record the date, inspector name, and

inspection results in the equipment log as well as any other relevant information to track the usage

history.

Before each use, the user should:

• Conrm the equipment is functioning properly.

• Verify the presence and legibility of the product labels and markings.

• Check soft components for cuts, worn or frayed areas, broken bers, soft or hard spots,

discoloration, or melted bers. Check the stitching for pulled threads, abrasion, or breaks.

• Check hard components for excessive wear or indications of damage such as deformation,

corrosion, sharp edges, cracks, or burrs. Minor nicks or sharp spots may be smoothed with

emery cloth or similar.

• Check for the presence of dirt or foreign objects that can affect or prevent normal operation

such as grit, sand, rocks, and debris.

During Each Use, the user should:

• Conrm all pieces of equipment in the system are correctly positioned with respect to each

other.

• Monitor the condition of the equipment and its connections to other equipment in the system.

• Do not allow anything to interfere with the operation of the equipment or its components.

• Prevent foreign objects from interfering with moving parts.

LIMITATIONS AND PROPER USE

Rescue and work harnesses from CMC are designed to comfortably support the wearer, creating

a safe work platform. Depending on the intended use (rescue, rope access or fall protection)

harnesses are tested to specic standards set by the applicable industry. CMC warns against using

the equipment around moving machinery and electrical hazards. When using this harness, follow

best practices for avoiding high impact falls.

CMC Harnesses are designed for applications in which the wearer uses the harness primarily for

positioning. Always keep the safety line (belay) above the wearer and keep the slack in the safety

line to a minimum. To ensure the safety and comfort of your harness, make sure it is properly sized

and adjusted per the instructions below.

• The ventral front D-ring is a load-bearing attachment point and the primary attachment point for

work positioning.

• The front lift is designed to accommodate a screw link behind the D-ring for connecting a chest

harness or a chest ascender.

• The rear connection loop is a positioning attachment point designed for travel restraint and can

also be used to secure dorsal chest harness connection straps.

• The side connection loops are positioning attachment points and must always be used in pairs.

WARNING: High impact fall situations should be avoided. Always minimize the slack in the

safety line. To prevent roll out, always use locking carabiners when connecting to the D-rings.

PUTTING ON YOUR HARNESS

Loosen the waist strap and leg loops as far as possible, but do not pull the web out of the buckles.

If using the Ranger Quick Harness, the leg loops can simply be opened for easy donning using the

quick-connect buckles.

Hold the harness in front of you. Make sure the D-ring loop is in front and the leg loops are not

twisted. Lower the harness until the leg loops are lying on the ground in the proper position. Step

over the waist belt and into the leg loops.

Pull the harness up around your hips and tighten the waist strap until it is snug and the D-ring is

centered. Next, adjust the leg loops to the desired tightness. In most cases, snug waist and legs

loops provide the best comfort. If using the Ranger Quick Harness, make sure to fully close the

quick-connect buckles.

Time spent practicing donning the harness and adjusting the straps will increase your level of

comfort and your ability to quickly put on and adjust the harness.

A suspension test should be carried out in a safe place prior to putting the harness in service. A

suspension test will verify that the harness is the correct size, has sufcient adjustment, and is of an

acceptable comfort level for the intended use.

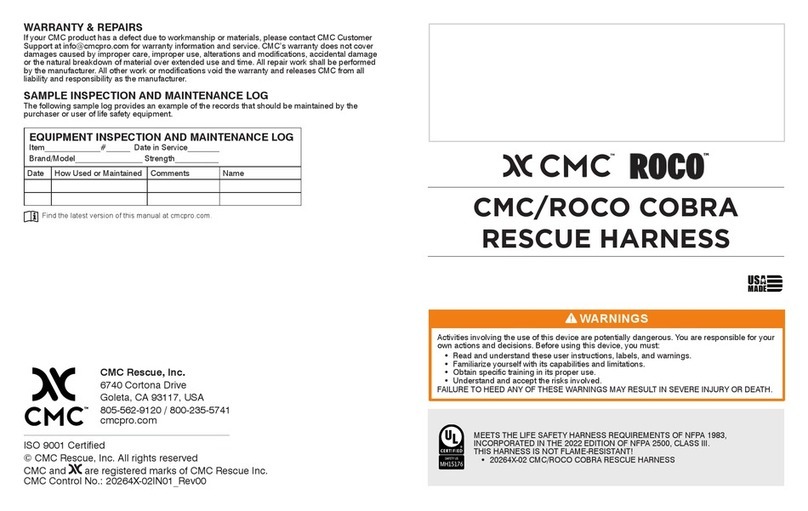

Activities involving the use of this device are potentially dangerous. You are responsible for your

own actions and decisions. Before using this device, you must:

• Read and understand these user instructions, labels, and warnings.

• Familiarize yourself with its capabilities and limitations.

• Obtain specic training in its proper use.

• Understand and accept the risks involved.

FAILURE TO HEED ANY OF THESE WARNINGS MAY RESULT IN SEVERE INJURY OR DEATH.

WARNINGS

MEETS THE LIFE SAFETY HARNESS REQUIREMENTS OF NFPA 1983,

INCORPORATED IN THE 2022 EDITION OF NFPA 2500, CLASS II.

THIS HARNESS IS NOT FLAME-RESISTANT!

• 20238X-02 CMC RANGER HARNESS

• 20239X-03 CMC RANGER QUICK CONNECT HARNESS