IM-F12-31 CH Issue 210

4.3 Procedure for renewing chevron gland seals

For spring-loaded single PTFE chevron gland seals, the gland spring (10) maintains a sealing

force on the packing. If leakage is noted around the stuffing box bush (18) check to be sure the

shoulder on the bush is touching the bonnet. If the shoulder is not touching the bonnet, tighten

the stuffing box nuts (16), until the shoulder is against the bonnet. If leakage cannot be stopped

in this manner, the gland seals will need replacing.

If the leakage comes from the outside diameter of the seals, it is possible that the leakage is

causedbydamagetothestuffing box wall. If performing any of the following procedures, inspect

the valve stem and packing box wall for damage.

4.3.1 Replacing chevron gland seals:

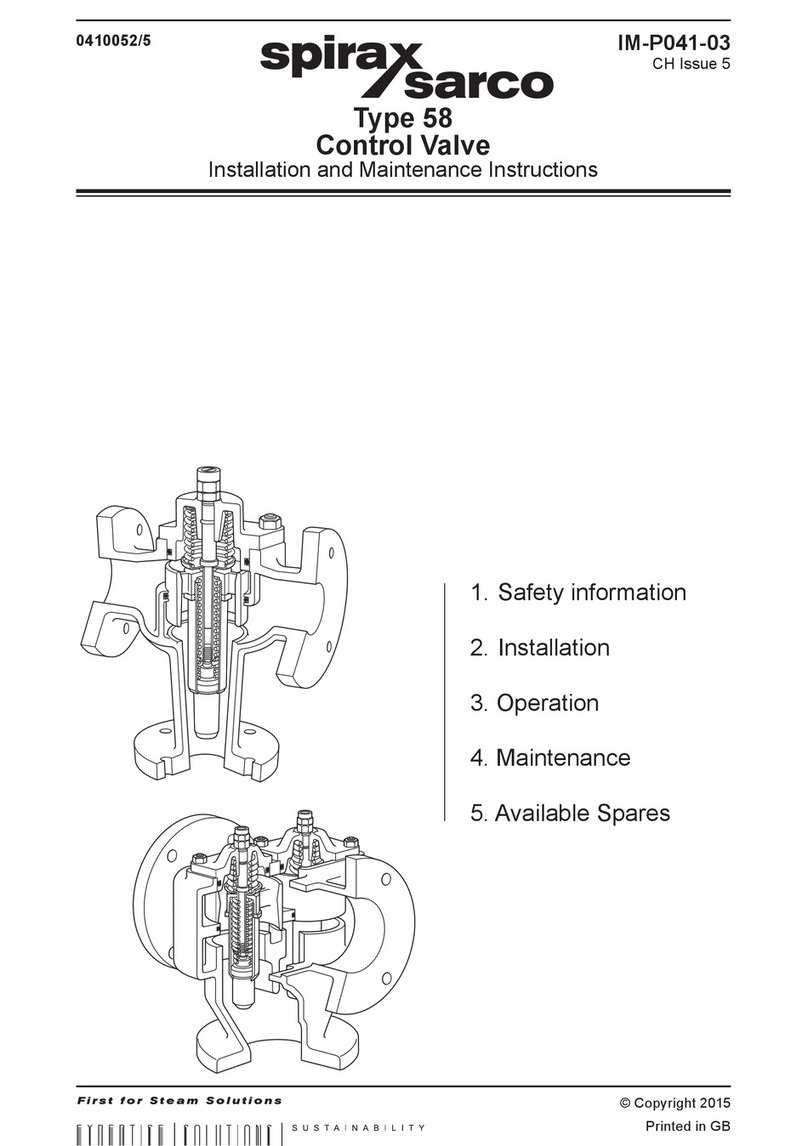

1. Isolate the control valve from the pressure, and release pressure from the valve body.

2. Disconnect the operating lines from the actuator and any leak-off piping from the bonnet.

Disconnect the valve stem (6) from the actuator and then remove the actuator from the valve

by unscrewing the mounting nut (9).

3. Loosen the stuffing box nuts (16) so that the seals are not tight on the valve stem. Remove the

stem lock-nut (8) from the valve stem.

Caution:

When lifting the bonnet (2), be sure that the valve plug and stem assembly remains in the

valve and on the seat. This will avoid damage to the seating surfaces as a result of the

assemblydropping from thebonnet after being lifted partway out. Theparts are also easier

to handle separately.

4. Unscrew the bonnet nuts (14) and carefully lift the bonnet off the valve stem.

5. If the valve plug and stem assembly starts to lift with the bonnet, use a brass or lead hammer

ontheendofthestemandtapitbackdown.Putthebonnetontoaprotectivesurfacetoprevent

any damage to the bonnet gasket surface.

6. Cover the opening in the valve body to protect the gasket surface and prevent foreign material

from getting into the body cavity.

7. Remove the stuffing box nuts (16), stuffing box ring (19), and stuffing box bush (18). Carefully

push out all the remaining packing parts from the body side of the bonnet using a rounded rod or

othertoolthatwillnotscratchthestuffingboxwall.Cleanthestuffingboxandmetalpackingparts.

8. Inspect the valve stem threads and stuffing box surface for any sharp edges which might cut

the packing. Scratches or burrs could cause damage to the new packing. If the surface

condition cannot be improved by rolling with light emery paper, replace the damaged parts.

9. Removethe cover protecting the body cavity and install a new bonnet gasket set(F1, F2 and

F3),makingsurethatthegasketseatingsurfacesarecleanandsmooth.Thenslidethebonnet

over the stem and onto the bonnet studs (13).

Note:

Proper tightening of the bonnet nuts compresses the bonnet gasket set (F1,F2 and F3)

enough to both load and seal the seat ring gasket (F4). It also compresses the outer edge

of the bonnet gasket enough to seal the body-to-bonnet joint.

Ensure that bolting threads are clean, and evenly tighten the nuts onto the studs in a

diagonal pattern. Because of the bolt-up characteristics of spiral wound gaskets, a

tightened nut may loosen an adjacent nut. Repeat the diagonal tightening pattern several

times until each nut is tight and the body-to-bonnet seal is made. When the operating

temperature has been reached, perform this torquing procedure once again.

10. Lubricate the studs (13) and tighten the nuts (14), using proper bolting procedures. (See

Table 1 'Recommended tightening torques', page 18).

11. Tighten the stuffing box nuts (16) until the stuffing box ring (19) sits on the shoulder of the

stuffing box bush (18).

12. Mount the actuator on the valve body assembly and reconnect the actuator and valve stem

accordingtotheprocedureintheappropriateactuatorInstallationandMaintenanceInstructions.