Spitronics Simulator 3 User manual

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 1 of 11

Table of Contents

1.

Introduction .......................................................................................................................................... 2

2.

Hardware Setup .................................................................................................................................... 2

2.1.

Connecting Instructions ................................................................................................................. 2

3.

Inputs and Outputs ................................................................................................................................ 3

3.1.

LED Indicators : ECU ................................................................................................................... 3

3.2.

Turning Kno s : ECU.................................................................................................................... 3

3.3.

Up and Down Buttons ................................................................................................................... 4

4.

Program Button ..................................................................................................................................... 4

5.

Connecters ............................................................................................................................................ 4

5.1.

DB44 ............................................................................................................................................ 4

5.2.

12V DC Power Jack ...................................................................................................................... 4

5.3.

6Way ............................................................................................................................................ 4

5.4.

8Way ............................................................................................................................................ 5

6.

Signal Simulating .................................................................................................................................. 5

7.

Changing Programs ............................................................................................................................... 5

8.

Programming the Simulator .................................................................................................................. 6

9.

Testing a Spitronics TCU ...................................................................................................................... 6

9.1.

LED Indicators : TCU ................................................................................................................... 7

9.2.

Turning Kno s : TCU.................................................................................................................... 7

10.

Simulator Harness ............................................................................................................................. 8

11.

Trigger Ta le .................................................................................................................................... 8

11.1.

Crank Gears .................................................................................................................................. 8

11.2.

Distri utors ................................................................................................................................. 10

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 2 of 11

1. Introduction

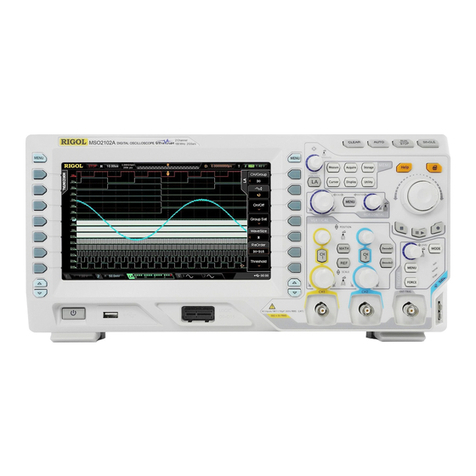

The Spitronics Simulator is a diagnostic tool designed to help you test Spitronics products.

The Spitronics simulator is compatible with:

- Spitronics ECU’s EMU, TITAN, VENUS, PLUTO, PLUTO2, SATURN MERCURY and MERCURY2

- TCU’s TITAN, NEPTUNE, NEPTUNE2, MERCURY and MERCURY2

- Firing modules F10, F11 and all newer modules

- Idle control1/2 TYPE 1 and 2

- Selective non Spitronics management units with the correct harness for the simulator.

Please read through the manual to make sure you follow the correct setup requirements.

2. Hardware Setup

Important!

ECU’s is automatically grounded through the 12 way connector, do not apply a separate

ground to the unit, unless testing an old EMU or a TITAN TCU

Power is supplied to the simulator through the 12V jack that is fitted to the simulator either

through the 12V power supply sold with the unit or battery.

2.1. Connecting Instructions

1. Connect the power supply to the 12V jack on the simulator.

2. Connect the unit (MERCURY, VENUS etc.).

3. Make sure the green power (PWR) LED on the simulator comes on when power is

applied. Also the units LED’s will switch on and this will signify that the unit is

powered up.

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 3 of 11

3. Inputs and Outputs

3.1. L D Indicators : CU

The L D's will indicate all simulated outputs:

Relay = Fuel Relay E-Relay = Electronic Relay

P7 = Positive Coil Driver 7 P8 = Positive Coil Driver 8

P5 = Positive Coil Driver 5 P6 = Positive Coil Driver 6

P3 = Positive Coil Driver 3 P4 = Positive Coil Driver 4

P1 = Positive Coil Driver 1 P2 = Positive Coil Driver 2

GP1 = General Purpose Output 1 RPM = RPM Output

N1 = Negative Injector Driver 1 N2 = Negative Injector Driver 2

N3 = Negative Injector Driver 3 N4 = Negative Injector Driver 4

N5 = Negative Injector Driver 5 N6 = Negative Injector Driver 6

N7 = Negative Injector Driver 7 N8 = Negative Injector Driver 8

GP2 = General Purpose Output 2 5V = Monitor the Units 5V Output

PWR = Power TRIG = Simulator Trigger

3.2. Turning Knobs : CU

The Turning knobs simulates all inputs:

TPS = Throttle Position Sensor RPM = Engine Revolutions per minute

POT = Potentiometer Cam1 = Cam Sensor Degrees

MAP = Manifold Absolute Pressure Sensor Cam2 = Cam Sensor Degrees

Altitude = Altitude Pressure Sensor Speed = Road Speed

Water = Water Temp Sensor Lambda = Exhaust Gas Sensor

Air = Air Temp Sensor Fuel Pressure = Fuel Pressure Sensor

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 4 of 11

3.3. Up and Down Buttons

These two buttons are mainly for TCU testing to simulate the up and down shift buttons.

The buttons are connected to the DB44 and can be used for other purposes as well.

4. Program Button

The program button is not only there to put the simulator in the correct program, it can be

used to change the RPM speed to simulate high and low speeds as well as removing RPM

from the unit to test startup or fuel relay. If the simulator is set on 0 RPM and the power is

removed for a very short time and put back on again the PRM’s will still be 0 and the unit

will switch the fuel relay driver on and then off again if there is still no RPM’s to simulate

fuel pump prime when the key is turned on.

5. Connecters

5.1. DB44

The DB44 connecter connects to the MERCURY and VENUS harnesses that will connect

to the specific unit you want to test.

5.2. 12V DC Power Jack

The Power Jack for applying power to the Simulator.

5.3. 6Way

The 6Way connecter connects to your programmer so you can update your simulator’s

firmware if there are new features available. Be sure to never upload incorrect firmware

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 5 of 11

into the simulator as it will lock the internal processor. Once the processor is locked the

simulator will have to be sent back to Spitronics to be repaired.

5.4. 8Way

The 8Way is for future use

6. Signal Simulating

The simulator is capable of simulating more than 30 different triggers Crank and TDC (Top

Dead Center) position sensors as well as two Cam sensors can be simulated and can be

selected by the program button located on the simulator. The simulator program can be

changed via the program button located on the simulator.

7. Changing Programs

Note

When programming the Simulator, two rapid flashes signifies a zero

1. Switch the simulator off.

2. Hold the button in while turning the power on to enter program mode.

3. Release the button and press once, the green trigger LED will indicating the current

mode of the simulator. If the simulator is in the correct mode and do not want to

change the mode, simply just switch the power off and on again to retain that mode.

4. Enter the new program: press the program button on the simulator to enter a

program

Note

Press the button 5 times in succession to enter a zero in the first character. Press the

button 10 times to enter a zero in the second character.

4.1 Example1: To enter program 09 to simulate a 36-1 trigger, enter a zero by

pressing the button 5 times, then the simulator will confirm a zero by flashing

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 6 of 11

back twice fast, enter a 9 by pressing the button 9 times, the simulator will then

flash the program back at you to confirm the correct program. The simulator is

now in program 09.

4.2 Example2: To enter program 12 to simulate a 60-2 trigger, enter a 1 by pressing

the button once, when the simulator has confirmed a 1 by flashing back once,

enter a 2 by pressing the button twice, the simulator will then flash the program

back to confirm the correct program. The simulator is now in program 12.

5. The simulator power off automatically, just press the power on again to apply the

changes.

8. Programming the Simulator

The simulator firmware can be updated as new versions are released. In most cases the

new firmware will activate more triggers to be simulated and new features.

Important!

Remember to hold the power button down when connecting to the simulator with the

firmware programmer, the unit has a relay build in so as soon as you connect the relay

will disconnect the power and the simulator will not have power to program.

Important!

Do not attempt to upload any non-simulator related firmware onto the simulator, the

simulator may be damaged and will have to be send back to Spitronics to be repaired.

9. Testing a Spitronics TCU

Important!

Note that when testing a TCU unit on the simulator that the inputs and output will work

different from an ECU. This is because the TCU has less inputs and outputs than the ECU.

When testing a TCU, put the simulator in mode 45, with this mode you can change the

engine speed and road speed individually to simulate what happens on a motor car while

driving. The TCU has positive outputs so the positive (Red) LED’s will be used to display the

solenoids.

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 7 of 11

When testing a TCU or a Neptune TCU use the NEPTUNE harness. (Sold separately)

When testing a Mercury TCU use the MERCURY TCU harness. (Sold separately)

9.1. L D Indicators : TCU

The L D's will indicate all simulated outputs:

Relay = Fuel Relay (Mercury TCU only) E-Relay = Electronic Relay (Mercury TCU only)

P5 = Solenoid 5 / Line Pressure P6 = Solenoid 6 / Lockup

P3 = Solenoid 3 P4 = Solenoid 4

P1 = Solenoid 1 P2 = Solenoid 2

GP1 = GPO1 (Mercury TCU only) RPM = Speedo Output (Mercury TCU only)

N1 = Line Pressure 1 (Mercury TCU only) N2 = Line Pressure 2 (Mercury TCU only)

N3 = Line Pressure 3 (Mercury TCU only) N4 = Line Pressure 4 (Mercury TCU only)

N5 = Line Pressure 5 (Mercury TCU only) N6 = Line Pressure 6 (Mercury TCU only)

GP2 = GPO2 (Mercury TCU only)

PWR = Power TRIG = Simulator Trigger

9.2. Turning Knobs : TCU

The Turning knobs simulates all inputs:

TPS = Throttle Position Sensor RPM = Engine Revolutions per minute

POT = Profile Switch Cam1 = Not Used

MAP = Reverse logic / Shifter Cam2 = Not Used

Altitude = Not Used Speed = Road Speed

Water = Oil Temp Sensor (Mercury TCU only) Lambda = Not Used

Air = Not Used Fuel Pressure = Not Used

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 8 of 11

10. Simulator Harness

Note

The simulator has a series of different harnesses for different applications, make sure

you have the correct harness.

11. Trigger Table

11.1. Crank Gears

Program Trigger

Program 01 ……………….………..8-1 Gear - 16 Pulse/Rpm

(1. 8 Teeth Crank Pulse with 1 Tooth Slot)

Program 02 ……………….……….12-1 Gear - 12 Pulse/Rpm

(1. 11 Teeth Crank Pulse with 1 Tooth Slot)

Program 03 …………….………….12+1 Gear - 60 Pulse/Rpm - Magnetic

(1. 12 Teeth Crank Pulse with 1 TDC Tooth

Program 04 ……………….……….12+Home Gear - 12 Pulse/Rpm

(1. 12 Tooth Crank Pulse)

(2. 1 Tooth Cam Home Pulse)

Program 05 ……………….……….18-1 Gear - 18 Pulse/Rpm

(1. 17 Teeth Crank Pulse with 1 Tooth Slot)

Program 06 ………………….…….24-1 - 24 Pulse/Rpm - Magnetic

(1. 23 Teeth Crank Pulse with 1 Tooth Slot)

Program 07 ……………….……….24-2 Gear - 24 Pulse/Rpm

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 9 of 11

(1. 22 Teeth Crank Pulse with 2 Tooth Slot)

Program 08 ……………………….30-2 Gear - 30 Pulse/Rpm

(1. 28 Teeth Crank Pulse with 2 Tooth Slot)

Program 09 ………….…………….36-1 Gear - 36 Pulse/Rpm

(1. 35 Teeth Crank Pulse with 1 Tooth Slot)

Program 10 ……………………...36-2 Gear - 36 Pulse/Rpm

(1. 34 Teeth Crank Pulse with 2 Tooth Slot)

Program 11 ………………………...60-1 Gear - 60 Pulse/Rpm

(1. 59 Teeth Crank Pulse with 1 Tooth Slot)

Program 12 ………………………...60-2 Gear - 60 Pulse/Rpm

(1. 58 Teeth Crank Pulse with 2 Tooth Slot)

Program 13 ………………………...Suzuki 3Cyl 36-4 Gear - 36 Pulse/Rpm

(1. 36 Teeth Crank Pulse with 2x2 Tooth Slots)

Program 14 ………………………...Colt V6 - 18 Pulse/Rpm - Hall Sensors

(1. 3 Pulse Crank Gear)

(2. 4 Pulse ID Cam Gear (3 Small 1 Large))

Program 15 ………………………...Subaru 6&7 Tooth - 36 Pulse/Rpm

(1. 6 Pulse Crank Gear "Weird 6 Tooth")

(2. 7 Pulse Cam Gear "Weird 7 Tooth")

Program 16 ………………………...Subaru 36-6 Gear Pulse/Rpm

(1. 30 Teeth Crank Pulse with 3x2 Tooth Slots)

Program 17 ………………………...Mazda 4+Home - 8 Pulse/Rpm

(1. 4 Tooth Crank Gear)

(2. 1 Tooth Cam Home Pulse)

Program 18 ………………………...Fiat 4Cyl 1.8L 16V 6&3 - 36 Pulse/Rpm - Magnetic Crank Hall

Cam

(1. 6 Tooth Crank Gear)

(2. 3 Tooth Cam Home Pulse - 1 Small 2 Large)

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 10 of 11

Program 19 …………………………18-6 TDC Home Gear - 18 Pulse/Rpm

(1. 12 Teeth Crank Pulse with 3x2 Tooth Slot)

(2. 1 Tooth Cam Home Pulse - 180°)

11.2. Distributors

Program Trigger

Program 30 ………………………...TEST Program

(1. Crank Pulse)

(2. TDC Pulse)

(3. Cam1 Pulse)

(4. Cam2 Pulse)

Program 31………………………….24+TDC - 12 Pulse/Rpm

(1. 24 Teeth Distributor Pulse)

(2. TDC Distributor Pulse)

Program 32 ………………………...Nissan 4Cyl - 30 Pulse/Rpm - Hall Sensors

(1. 4 x Progressive Slots Smaller)

Program 33………………………....Nissan 6Cyl - 45 Pulse/Rpm - Hall Sensors

(1. 6 x Progressive Slots Smaller)

Program 34 ………………………...Nissan V8 - 45 Pulse/Rpm - Hall Sensors

(1. 4 x Progressive Slots Smaller + 4 x Intermediate Pulses)

Program 35 ………………………...Ford Slots 8Cyl - 60 Pulse/Rpm - Hall Sensors

(1. 8 Slots 1 Large 7 Small (Positive Edge))

(Channel 2 Inverted (Negative Edge))

Program 36 ………………………...Daewoo Matiz 60-6 30 Pulse/Rpm - Magnetic

Spitronics Simulator3 Manual

Spitronics Simulator3 Manual Ver 1.0 Page 11 of 11

(1. 60-2-2-2 Distributor Pulse)

(2. Home Pulse)

Program 37 ………………………...Honda 4Cyl - 12 Pulse/Rpm - Hall Sensors

(1. 4 Slots)

(2. 1 Pulse Home)

Program 38 ………………………...Hyundai 4Cyl 16 Valve 1600 18 Pulse/Rpm - Hall Sensors

(1. 4 Pulse Timing)

(2. 2 Pulse TDC)

Program 39 ………………………...Mazda 4Cyl 12 Pulse/Rpm - Hall Sensors

(1. 4 Pulse Distributer)

(2. 2 Pulse Home)

Program 40 ………………………...Alfa 4Cyl - 76 Pulse/Rpm - Hall Sensors

(1. 4 Slots - First 2 Large then 2 Small)

Program 41 ………………………...Spitronics 4 Slots - 12 Pulse/Rpm - Hall Sensors

(1. 4 Slots - 1 Large 3 Small)

Program 42 ………………………...Spitronics 6Cyl - 45 Pulse/Rpm - Optic

(1. 6 Slots 1 Large 5 Small)

Program 43 ………………………...Nissan SR20 4Cyl - 12 Pulse/Rpm - Hall Sensors

(1. 4 Slots)

(2. 1 Pulse Home)

Program 44 ………………………….Mitsubishi 6Cyl Dizzy - 18 Pulse/Rpm - Hall Sensors

(1. 6 Pulse Trigger)

(2. 2 Pulse Home (1 Small 1 Large))

Program 45 ………………………….Gearbox Test Program - Hall Sensors

(1. Crank Pulse)

(2. Speed Pulse)

Table of contents