Splash Lab TSL.960 Maintenance and service guide

TSL.960 / TSL.990

deck mounted sensor tap

installation + maintenance

3 Safety and Warnings

4 Box Contents

5 Diagram

6 Technical Data

8 Before You Install

9 Technical Drawing

11 How To Install

15 Commissioning & Operation

16 Troubleshooting

17 Cleaning

18 Maintenance

19 Warranty

Back Cover Contact Details

contents

2TSL.960 / TSL.990 MANUAL

TSL.960 / TSL.990 MANUAL 3

For more information contact:

Tel: +44 (0)161 482 7000

Email: technical@thesplashlab.com

Read and save these instructions

WARNING !

To reduce the risk of fire, electric shock or injury to persons, observe the following:

+ Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer (see back page for more details).

+ Ensure plumbing is installed correctly before activating water supply.

+ All plumbing is to be installed in accordance with applicable codes

and regulations.

TSL.960 / TSL.990

4TSL.960 / TSL.990 MANUAL

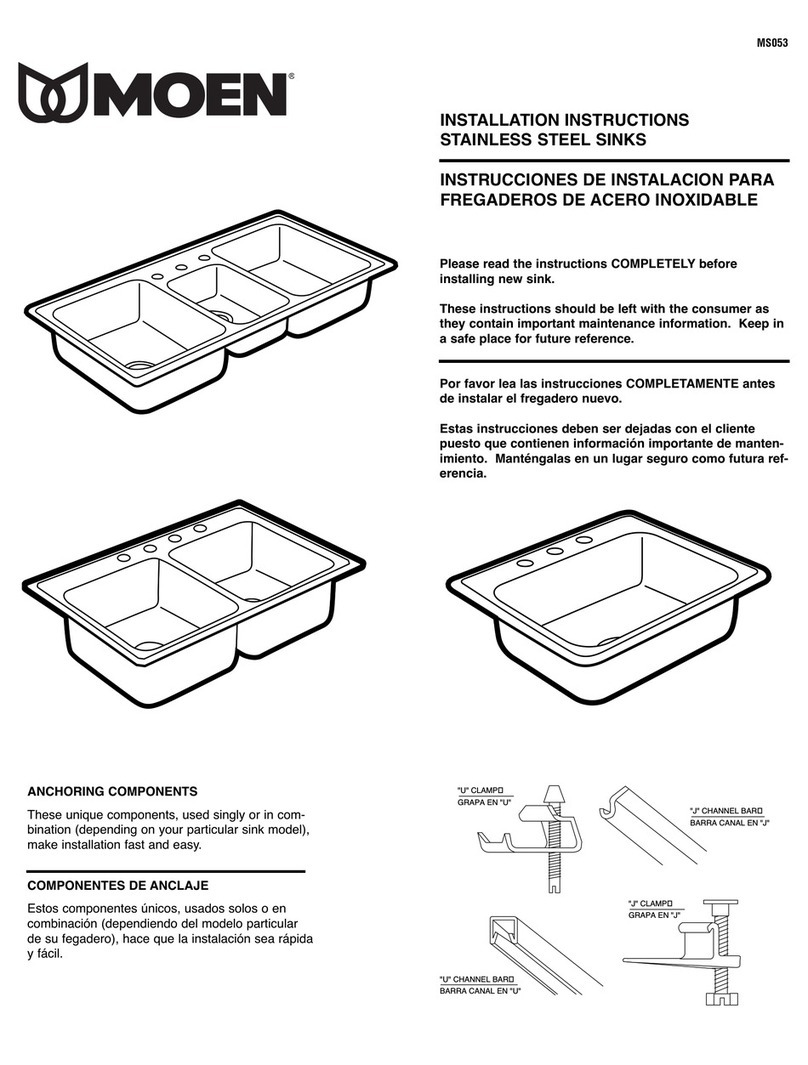

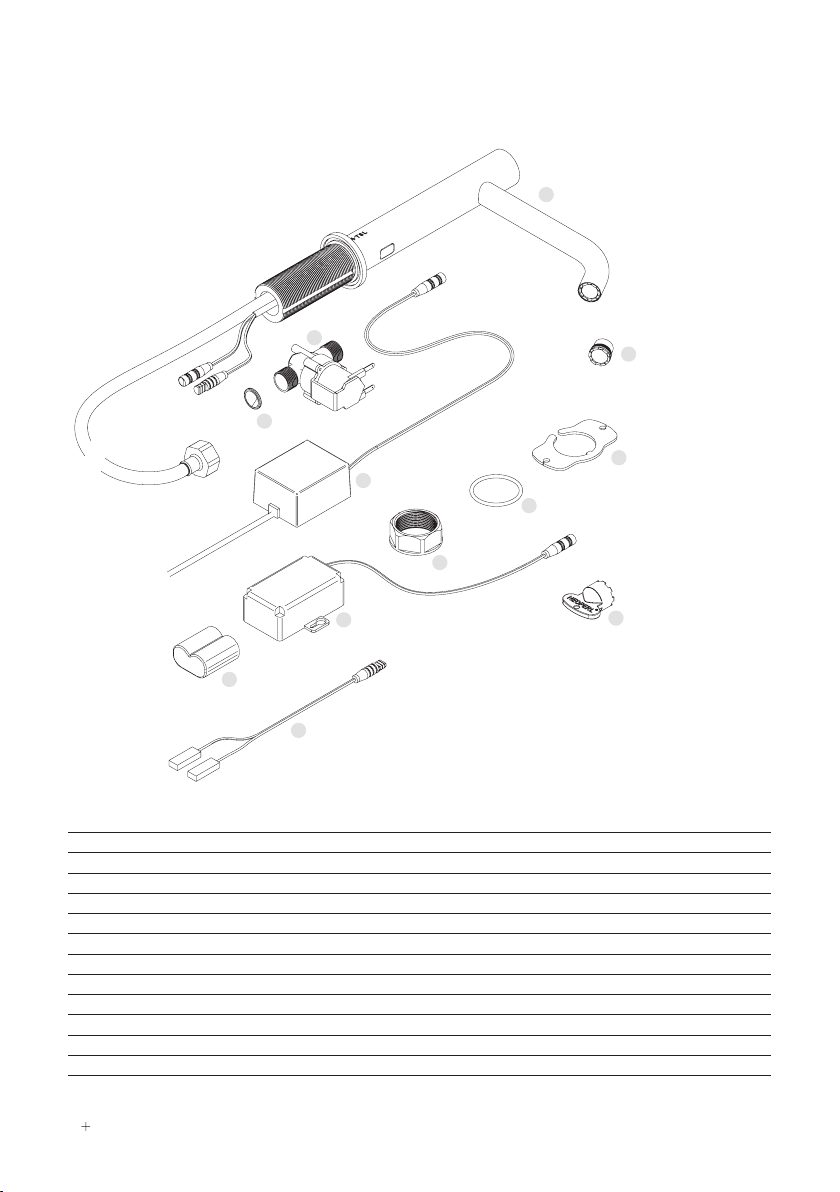

box contents

1

3

4

2

5

7

8

10

11

12

9

6

TSL.960.ELE TSL.990.ELE TSL.960.BAT TSL.990.BAT

1Tap assembly - - - -

2Inline filter / strainer TSLP.08530015 TSLP.08530015 TSLP.08530015 TSLP.08530015

3Solenoid valve TSLP.120030 TSLP.120030 TSLP.120030 TSLP.120030

4Mains power suply unit TSLP.270066 TSLP.270066 - -

5Battery - - TSLP.270030 TSLP.270030

6Battery holder - - TSLP.270029 TSLP.270029

7Backnut TSLP.900.020 TSLP.900.020 TSLP.900.020 TSLP.900.020

8Base O-ring TSLP.104 TSLP.104 TSLP.104 TSLP.104

9Anti-rotation plate TSLP.900.000 TSLP.900.000 TSLP.900.000 TSLP.900.000

10 Aerator - 1.89lpm - Spray pattern TSLP.260063 TSLP.260063 TSLP.260063 TSLP.260063

11 Solenoid connector cable TSLP.120032 TSLP.120032 TSLP.120032 TSLP.120032

12 Aerator key TSLP.260050 TSLP.260050 TSLP.260050 TSLP.260050

TSL.960 / TSL.990 MANUAL 5

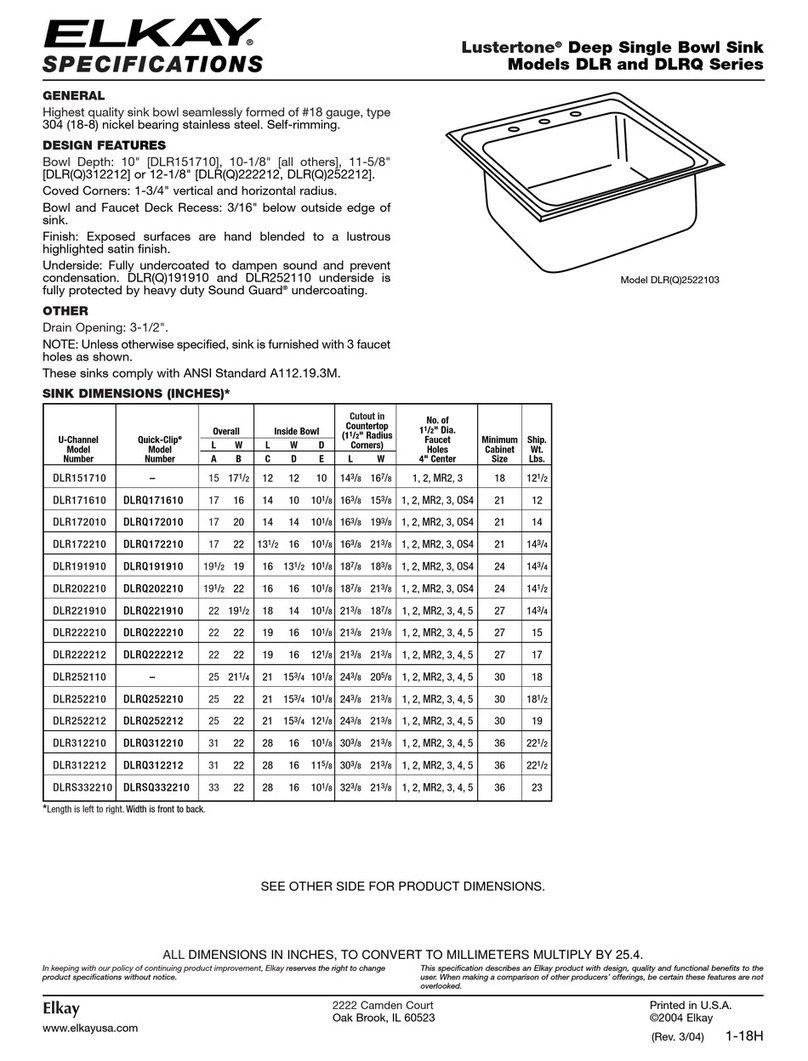

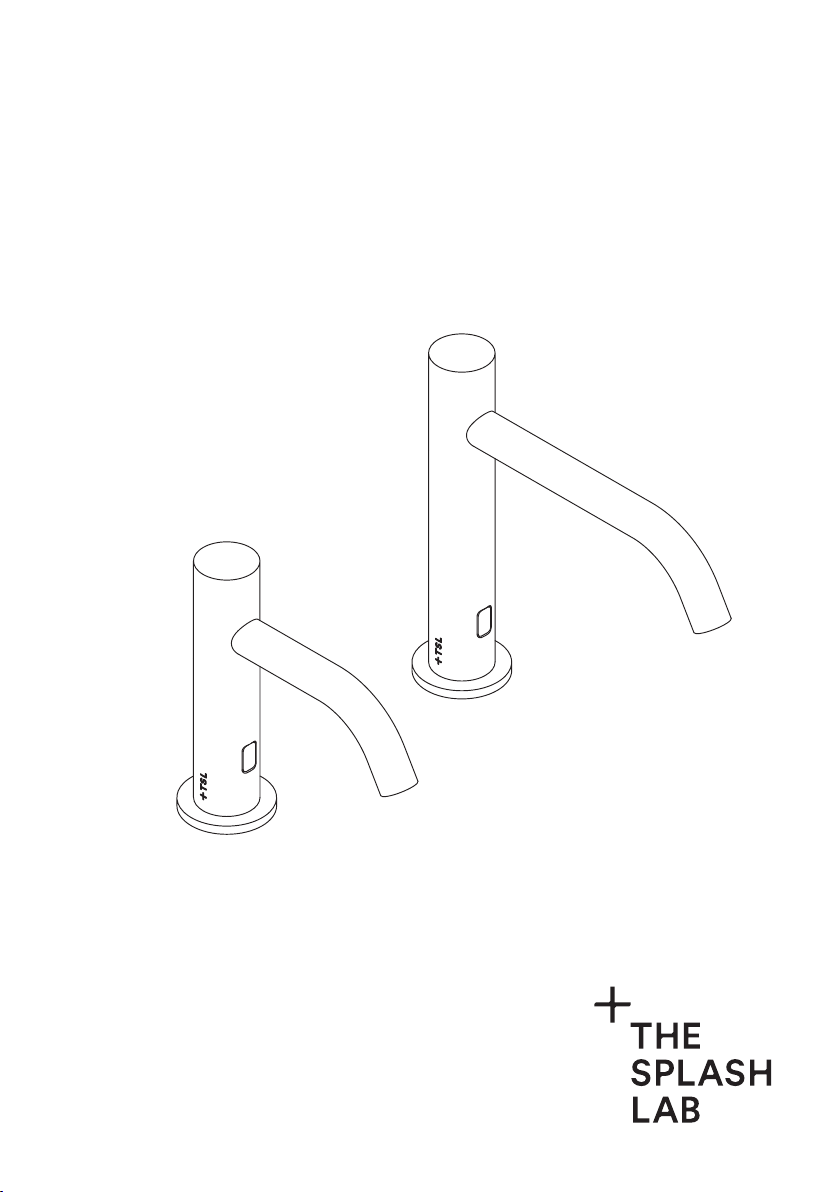

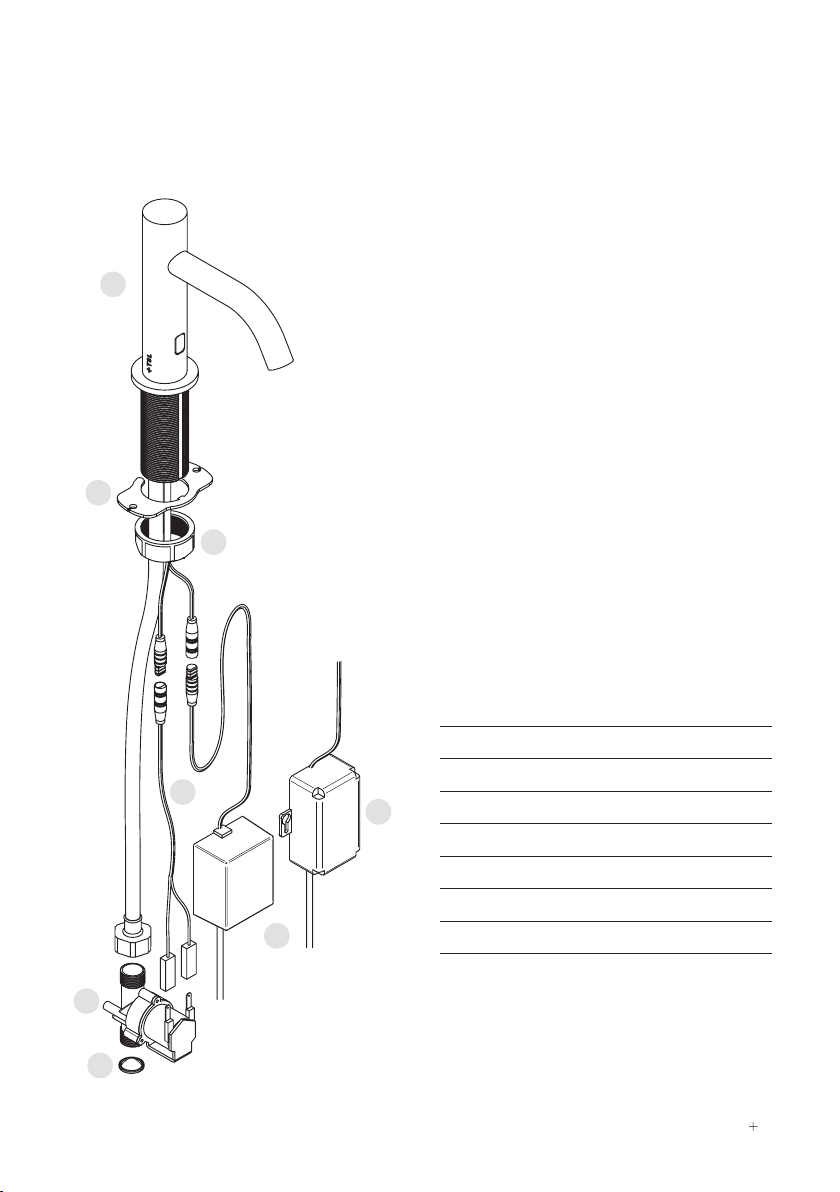

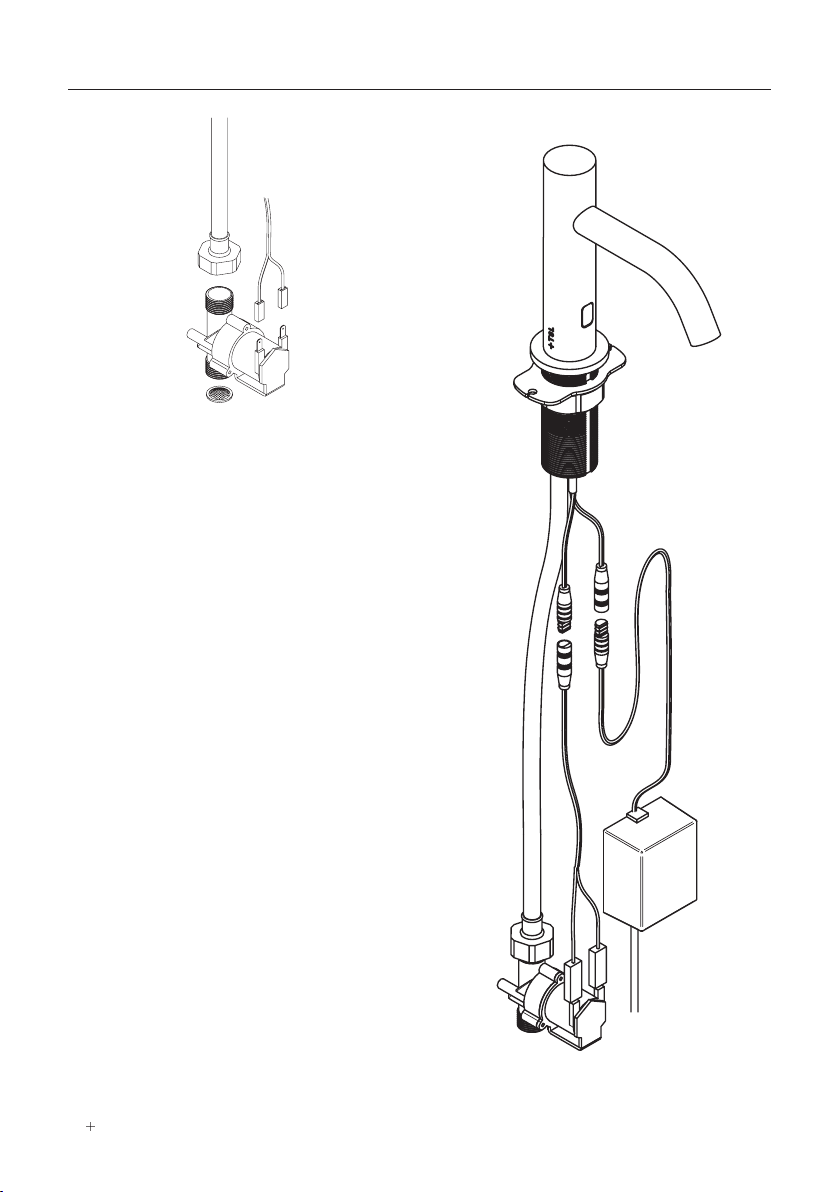

diagram

1 Tap assembly

2 Anti-rotation plate

3 Backnut

4 Solenoid valve

5 Inline filter / strainer

6 Solenoid connector cable

7 Mains power supply unit

8 Battery holder

1

3

4

2

5

7

8

6

6TSL.960 / TSL.990 MANUAL

technical data

Overview

The TSL.990 is a stainless steel deck mounted sensor tap, available in a variety of

coloured finishes, with a sleek and minamalist design.

Codes Power Finishes

TSL.990.CS.BAT Battery Brushed Stainless Steel

TSL.990.CP.BAT Battery Brushed Copper

TSL.990.BK.BAT Battery Brushed Black

TSL.990.BR.BAT Battery Brushed Brass

TSL.990.BZ.BAT Battery Brushed Bronze

TSL.990.CS.ELE Mains Brushed Stainless Steel

TSL.990.CP.ELE Mains Brushed Copper

TSL.990.BK.ELE Mains Brushed Black

TSL.990.BR.ELE Mains Brushed Brass

TSL.990.BZ.ELE Mains Brushed Bronze

Light Reflectance Values

Brushed Stainless Steel 58

Brushed Copper 19

Brushed Black 3

Brushed Brass 40

Brushed Bronze 17

Technical Data: Mechanical

Body Material AISI 304 Stainless Steel

Coating Type PVD (colours only)

Weight 1.4Kg

Aerator Cascade flow

Min/Max pressure 0.5 - 7.5 bar

Flow Rates 3.8l/min [0.5gpm]

Also available as optional extras:

1.35l/min [0.35gpm]

1.89l/min [0.5gpm]

Max Hot Water Temperature 60°C

TSL.960 / TSL.990 MANUAL 7

technical data

Technical Data: Electrical

Power Supply (Battery) 6V CR-P2 Lithium Battery

Power Supply (Mains) 100-240V; 1.5A; 50-60Hz PSU.

Output (Max) 6V; 6W max

Power Consumption < 80A

Solenoid Valve 6V

Water Ingress (PSU) IP67

Cable Lengths Connection to sensor cable - 400mm

Connection to fused supply - 1.5m

Technical Data: Sensor

Sensor Type Infra red

Pre-set Sensor Range 120mm

Maximum Sensor Range 250mm

Comfort Delay 2 seconds

Security Time-out 30 seconds

Operating Temperature 0 to 50ºC

Response Time (max) < 300ms

Compliance

WRAS Certificate 2012304

CE PSU conforms to RoHS, REACH, EN15091

BREEAM Qualities for up to 5 credits as part of water

eciency assessment

8TSL.960 / TSL.990 MANUAL

Access Requirements

It is critical all components which require fixing behind the wall are easily accessible at

all times during installation and routine maintenance.

Front access: If the underside of the wash basin is tiled in, or is fixed onto a vanity

unit, a front hatch or panel(s) must be constructed below the wash basin for ongoing

maintenance access.

Access Requirements

1. A pre-mixed water supply is required that complies with the current local

plumbing regulations.

2. A minimum dynamic water pressure of 0.5bar is required for valve to function.

Gravity-fed installations may require the installation of a booster pump to

achieve the optimum operating pressure.

3. All pipework must be flushed through prior to the tap being connected to

ensure all debris is clear and will not enter the tap. Chlorination of the building

system must also be performed prior to connection of the tap.

4. For mains powered taps, a 3A fused power supply is required. If required,

multiple PSUs can be connected to the mains supply if the fuse is upgraded

accordingly.

before you install

!

Caution

+ The TSL.960 / TSL.990 parts must be put together correctly before

installation.

+ All parts must be installed correctly before powering up the system.

TSL.960 / TSL.990 MANUAL 9

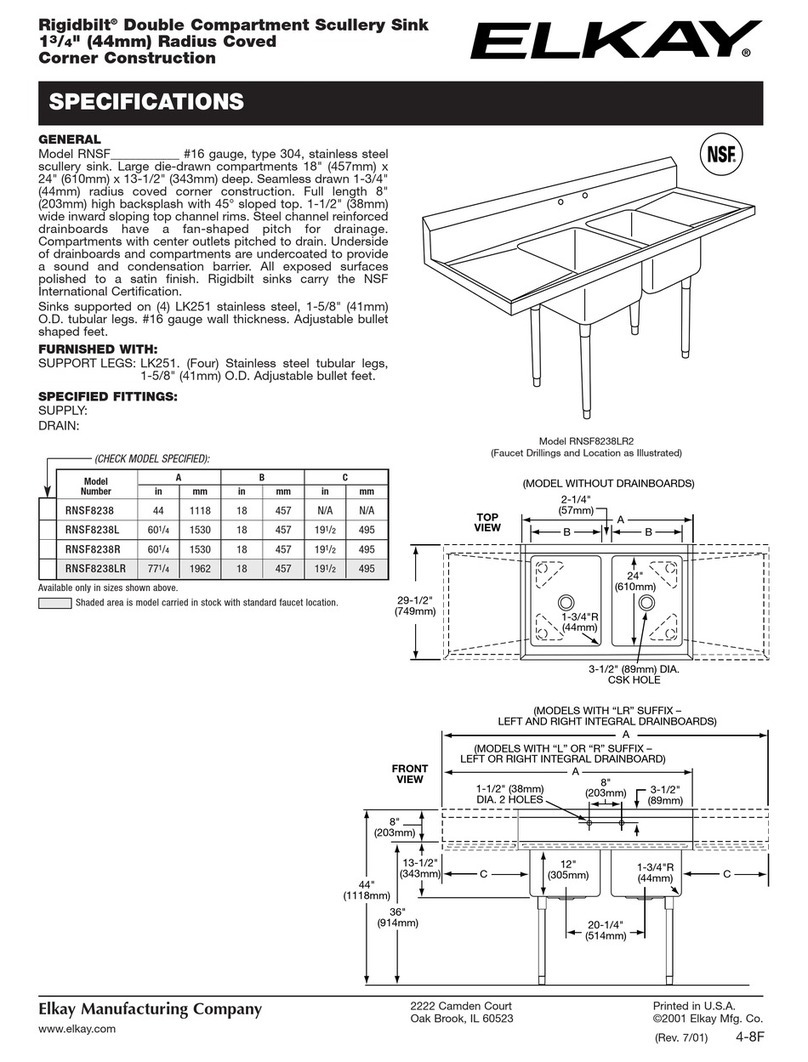

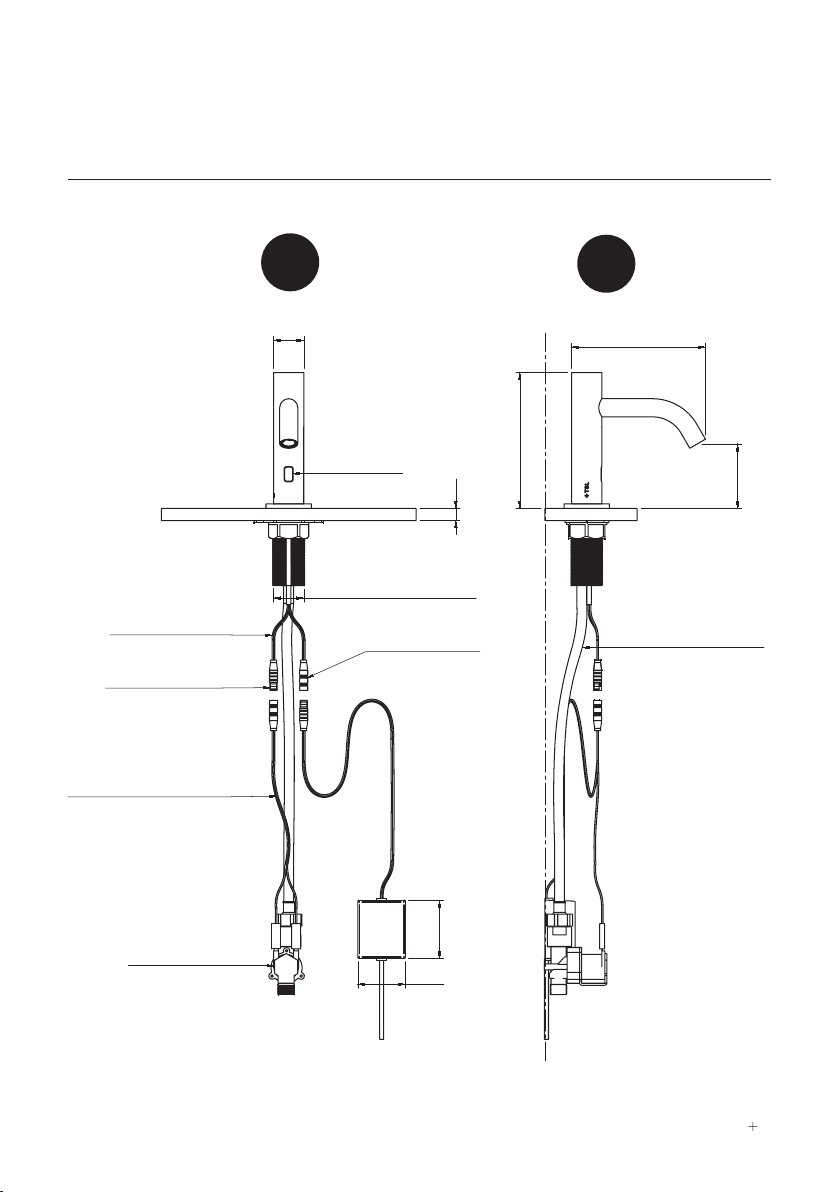

technical drawing

30

12

IR SENSOR

34MM THROUGH HOLE

PSU

58

47

600MM LEAD LENGTH

SENSOR CONNECTOR

TO SOLENOID VALVE

SENSOR CONNECTOR

TO POWER SUPPLY

SOLENOID CONNECTOR LEAD

200MM LEAD LENGTH

SOLENOID VALVE

700MM FLEXIBLE HOSE

135

64

133

TSL.990

SIDE

FRONT

SENSOR CONNECTOR LEAD TO

POWER SUPPLY

10MM MIN 35MM MAX

1

2

" BSP PROVIDED 34MM THROUGH HOLE

SENSOR CONNECTOR CABLE TO

SOLENOID VALVE

IR SENSOR

700MM FLEXIBLE HOSE

POWER SUPPLY

SOLENOID VALVE

135

135

13330

400mm LEAD LENGTH

200mm LEAD LENGTH

600mm LEAD LENGTH

SIDE

FRONT

SENSOR CONNECTOR LEAD TO

POWER SUPPLY

10MM MIN 35MM MAX

1

2

" BSP PROVIDED 34MM THROUGH HOLE

SENSOR CONNECTOR CABLE TO

SOLENOID VALVE

IR SENSOR

700MM FLEXIBLE HOSE

POWER SUPPLY

SOLENOID VALVE

135

135

13330

400mm LEAD LENGTH

200mm LEAD LENGTH

600mm LEAD LENGTH

10 TSL.960 / TSL.990 MANUAL

technical drawing

TSL.960

12

IR SENSOR

34MM THROUGH HOLE

SENSOR CONNECTOR TO

POWER SUPPLY

PSU

58

47

SOLENOID VALVE

SOLENOID CONNECTOR LEAD

200MM LEAD LENGTH

SENSOR CONNECTOR

TO SOLENOID VALVE

175

Ø30

104

175

183

SIDE

FRONT

SENSOR CONNECTOR LEAD TO

POWER SUPPLY

10MM MIN 35MM MAX

1

2

" BSP PROVIDED 34MM THROUGH HOLE

SENSOR CONNECTOR CABLE TO

SOLENOID VALVE

IR SENSOR

700MM FLEXIBLE HOSE

POWER SUPPLY

SOLENOID VALVE

135

135

13330

400mm LEAD LENGTH

200mm LEAD LENGTH

600mm LEAD LENGTH

SIDE

FRONT

SENSOR CONNECTOR LEAD TO

POWER SUPPLY

10MM MIN 35MM MAX

1

2

" BSP PROVIDED 34MM THROUGH HOLE

SENSOR CONNECTOR CABLE TO

SOLENOID VALVE

IR SENSOR

700MM FLEXIBLE HOSE

POWER SUPPLY

SOLENOID VALVE

135

135

13330

400mm LEAD LENGTH

200mm LEAD LENGTH

600mm LEAD LENGTH

TSL.960 / TSL.990 MANUAL 11

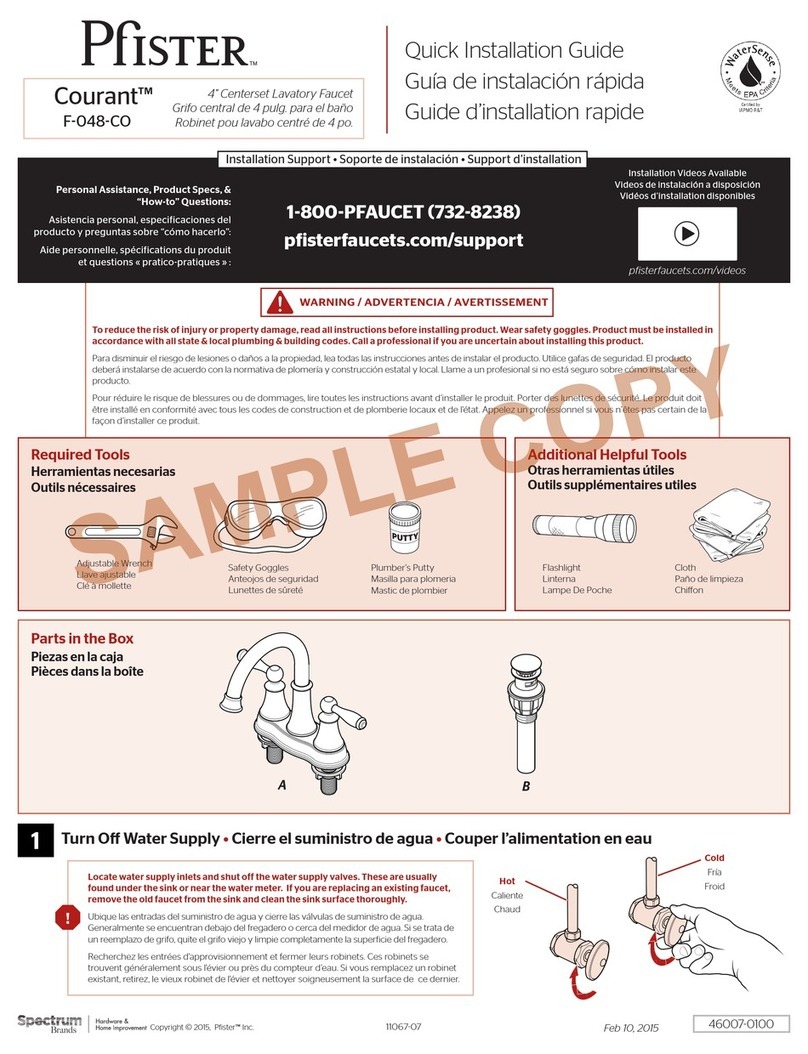

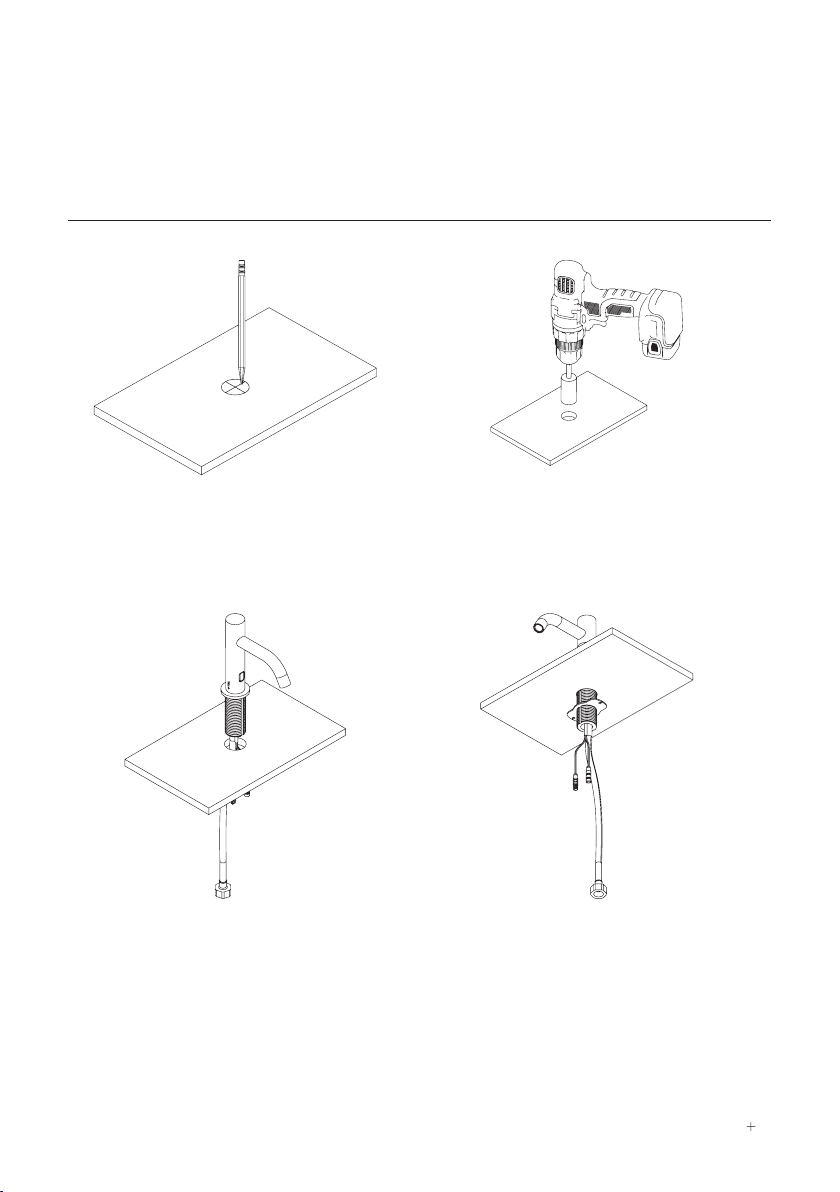

1

Mark tap hole centre onto the surface for

installation.

Tap Installation

2

For countertop fitment, drill 35mm

diameter hole in countertop.

3

Insert the tap through hole in basin or

countertop.

4

Slide the anti-rotation plate and fixing

nut over flexi hose and sensor cable and

onto mounting shank.

how to install

12 TSL.960 / TSL.990 MANUAL

5

Using fixings suitable to your application,

fix the anti rotation plate using the holes

provided.

Tap Installation

6

Slide the backnut over the flexible

hose and sensor leads. Tighten using a

spanner.

7

Position the power supply to the

underside of the unit. Before fixing

into place ensure cables can reach

connector positions.

8

Connect the power supply cable to the

sensor cable.

TSL.960 / TSL.990 MANUAL 13

9

Position the solenoid valve to the

underside of the unit. Before fixing into

place, ensure cables can reach the

connector positions.

Tap Installation

10

Connect the solenoid cable connector

leads to the solenoid valve. observing the

correct polarity of the terminals.

11

Connect the solenoid cable connector to

the sensor connector.

12

Fit the flexible hose nut onto the solenoid

adapter

14 TSL.960 / TSL.990 MANUAL

13

Insert conic filter into inlet side of valve

and connect to water supply. The filter

must be fitted, otherwise the warranty

may be invalid.

Tap Installation

14

Once all nuts are tightened, open the

water inlet and allow water to flow.

WARNING: Ensure all connections are

fully tightened to ensure full seal of the

tap.

15

The product is now ready to be wired into

the spur and tested and commissioned

accordingly.

TSL.960 / TSL.990 MANUAL 15

commissioning

+ Connect the water supply (turn isolation valve on)

+ Turn power supply on and wait 20 seconds

+ Activate the sensor by placing hand within detection range, and water will flow.

Adjusting the sensor range:

The sensor range can be adjusted if required to suit the installation conditions.

1. Disconnect the power supply (battery or mains).

2. Wait a few seconds and reconnect the power supply.

3. Position your hand less than 5cm in front of the sensor whilst the LED flashes.

4. When the LED is contiuously lit (and no longer flashing), position your hand at

the new detection distance.

5. Wait until the LED goes out before removing your hand.

6. When the LED goes out the new detection distance will be set.

operation

The user is to activate the tap by placing their hands within the range of the infra-red

sensor, to cause the solenoid valve to open for a preset time. The valve will close a set

time after the user’s hands have been removed from the detection range.

Problem Cause Solution

Water not flowing Range is too short Increase detection range.

16 TSL.960 / TSL.990 MANUAL

troubleshooting

Range is too long Decrease detection range.

Sensor is dirty or

obstructed. Clean sensor and remove

obstruction.

Tap is in security time-out

mode. Replace batteries or

restore power supply.

Solenoid valve is

incorrectly connected

(polarity reversed).

Reconnect solenoid valve

with correct polarity.

Sensor is detecting

reflections from basin or

another object.

Reduce detection range

or remove object causing

reflection.

Water flow does not stop

when user’s hands are

within range

Debris or scale in solenoid

valve. Remove solenoid and clean

or replace valve.

Cables between PSU and

solenoid are disconnected. Reconnect cables.

Solenoid valve is

incorrectly connected

(polarity reversed).

Reconnect solenoid valve

with correct polarity.

Water supply pressure is

too high. Reduce water pressure.

Slow response time when

opening or closing

solenoid valve

Cable connections loose. Check all connections are

properly fitted together.

Debris or scale in solenoid

valve. Remove solenoid and

clean and replace valve.

Sensor is detecting

reflections from basin or

other object.

Reduce detection range

or remove object causing

reflection.

Water flow reduced Aerator is blocked with

scale or debris. Remove aerator and clean

or replace.

Debris or scale in solenoid

valve. Remove solenoid and

clean and replace valve.

TSL.960 / TSL.990 MANUAL 17

cleaning

+ Take extra care when cleaning decorative surfaces.

+ For surface cleaning of the tap use ONLY soap and water, then wipe dry with a

clean cloth or towel.

+ DO NOT use steel wool or cleaning agents containing alcohol, acid, abrasives or

the like.

+ Use of any prohibited cleaning or maintenance products or substances could

damage the surface of the tap.

+ When cleaning bathroom tiles, the taps should be protected from any splattering

of harsh cleansers.

All grades of stainless steel will stain or discolour if due care and attention is not taken.

The surface must be regularly cleaned to ensure a long service life of the tap.

Use a soft cloth or sponge with a mild solution of soapy water as part of the regular

washroom janitorial routine. Do not use abrasive or cream cleaners as these will

damage the surface finish.

If further information is required, contact The Splash Lab technical team for more

detailed stainless steel care guidelines.

18 TSL.960 / TSL.990 MANUAL

maintenance

1. Shut off the water supply to the tap.

2. Disconnect the solenoid cable from the power supply.

3. Disconnect the solenoid valve from the brass reducing adaptor and the brass

fitting attached to the mains water supply.

4. Remove the filter from the faulty solenoid valve.

5. Re-fit new filter to replacement solenoid valve.

6. Reassemble the parts as shown.

7. Restore the incoming water supply checking there are no water leaks.

8. Reconnect the solenoid cable to the power supply.

Note: the directional flow of water is shown on the solenoid housing with an arrow.

TSL.960 / TSL.990 MANUAL 19

warranty

We believe the future is personal. With a global mindset, we challenge conventional

washroom norms via product innovation to create considered washroom solutions

for corporate, public and hospitality spaces. We use rich raw materials, cutting-edge

automation and considered washroom design to powerfully and positively influence the

lives of people.

Demonstrating our commitment to quality and our belief in the strength of our designs,

we offer the following warranties.

The Splash Lab warrant that its products will be free of manufacturing and material

defects during normal use and environmental conditions as detailed below:

Sensor taps 2 years parts & labour

If a defect is found in normal use, The Splash Lab will, at their discretion, repair, provide

a replacement part or product, or make appropriate adjustments. Damage caused by

accident, misuse, or abuse is not covered by this warranty. Improper care and cleaning

will void the warranty.

Non-operation of the product due to environmental conditions beyond our control,

installation error, incorrect maintenance, water quality, fair wear and tear, incorrect or

inappropriate installation, misuse and abuse is not covered by the warranty.

Proof of purchase (original sales receipt) must be provided to The Splash Lab with all

warranty claims.

The above warranty is valid for goods supplied within the United Kingdom.

For goods supplied outside of the United Kingdom, The Splash Lab will honour the

above stated warranty periods for the parts only.

THE SPLASH LAB DISCLAIM ANY LIABILITY FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

TSL.960 / TSL.990 EUR REV 1-11/06/21

contact

General information

+44 (0) 161 482 7000

Technical support

technical@thesplashlab.com

For further contact information visit:

www.thesplashlab.com

This manual suits for next models

5

Table of contents

Other Splash Lab Plumbing Product manuals

Popular Plumbing Product manuals by other brands

Sterling

Sterling clearwater Amelio AML10 Fitting Instructions and Parts List

Grohe

Grohe GLOUCESTER owner's manual

Kohler

Kohler Mira Moto Installation and user guide

Everpure

Everpure Dual Temp Faucet specification

Felton

Felton REFLEX FUSION PLUS RFSPCSMCL installation guide

Sunlighten

Sunlighten Signature III Assembly instructions