SPM Airius User manual

1

1

Instructions

www. .com information@itm.com1.800.561.8187

2

3

Technical data subject to change without notice.

ISO 9001 certified. © SPM 2022-08. 72258 B Rev.2

Contents

1. Safety 3

1.1 Special conditions for safe use 3

1.2 Marking and list of standards 3

2. Description 4

3. Technical specifications 5

4. Installation of Airius Ex sensor 6

4.1 Screw installation 6

4.2 Glue installation 8

5. Sensor operation 10

5.1 Reset to factory default 10

5.2 Clear settings via SPM Connect app 10

5.3 Setting up Airius with SPM Connect 11

5.4 Setting up vibration measurements in Condmaster Ruby 12

5.5 Setting up vibration measurements in Condmaster.NET 14

6. Maintenance and service 16

6.1 Battery replacement 16

www. .com information@itm.com1.800.561.8187

2

3

1. Safety

This sensor must only be installed, used and maintained

by competent personnel. Such personnel shall have un-

dergone training that included instruction on the various

types of protection and installation practices, the relevant

rules and regulations, and on the general principles of area

classification. Appropriate refresher training shall be given

on a regular basis (see EN 60079-17).

The installation, use and maintenance of this sensor must

comply with the appropriate European, national and lo-

cal regulations, which may include reference to the IEC

standards IEC60079-14, IEC60079-17 and IEC60079-19.

In addition, particular industries or end-users may have

specific requirements relating to safety (or health) and

these requirements should also be met. Instructions and

specifications issued by the manufacturer must be followed.

Warning – Use only SPM 18425 battery.

Immediately remove the sensor from Ex-hazardous areas if

safety is questioned or compromised. Return the product

to SPM Instrument AB for examination.

For configuring the Airius sensor, only certified mobile

devices are allowed to be used in Ex-hazardous areas.

The batteries are classified as dangerous goods, when

transported. Transportation of batteries must be in full com-

pliance with the appropriate regulatory provisions. UN3090

is applicable for the batteries and UN3091 is applicable

when the battery is contained in the sensor.

1.1 Special conditions for safe use

None.

1.2 Marking and list of standards

I M1 Ex ia I Ma

II 1G Ex ia IIC T4 Ga

II 1D Ex ia IIIC T135 °C Da

Ta –40 °C to +85 °C

CML 19ATEX2081

CML 21UKEX2595

IECEx CML 19.0018

Standards are listed in the EU Declaration of Conformity.

Sensor marking.

Battery marking.

www. .com information@itm.com1.800.561.8187

4

5

2. Description

The battery-powered wireless sensor AIR01-EX, which ena-

bles wireless condition monitoring in potentially explosive

atmosphere, measures acceleration in three directions,

and temperature. For remote communication, Wi-Fi and

Bluetooth are used. An external push button and three

RGB-LEDs are local user interfaces.

The product enclosure consists of a metal body and an

ESD-protected plastic lid. To enable battery replacement,

the lid is removable. Screw or glue installation on a machine

is performed with an installation foot. Depending on the

installation foot and place of installation, the metal body

may be earthed or unearthed.

There are different versions of AIR01-EX, specified as

AIR01-xy-EX-Szz, where variations do not affect Ex safety.

The letters ‘xy’ denote measurement performance (e.g.

frequency bandwidth) and ‘Szz’ denote variations of op-

erating software.

AIR01-Ex is a member of the Airius family of wireless sensors.

The Airius sensor is compatible with both Condmaster.NET,

the application providing easy access to measurement

data through a user-friendly interface, and the analysis and

diagnostic software Condmaster Ruby.

The SPM Connect app, downloadable for mobile devices,

is used to configure the parameters required for connection

to Condmaster Entity Server (CES) or SPM Cloud.

www. .com information@itm.com1.800.561.8187

4

5

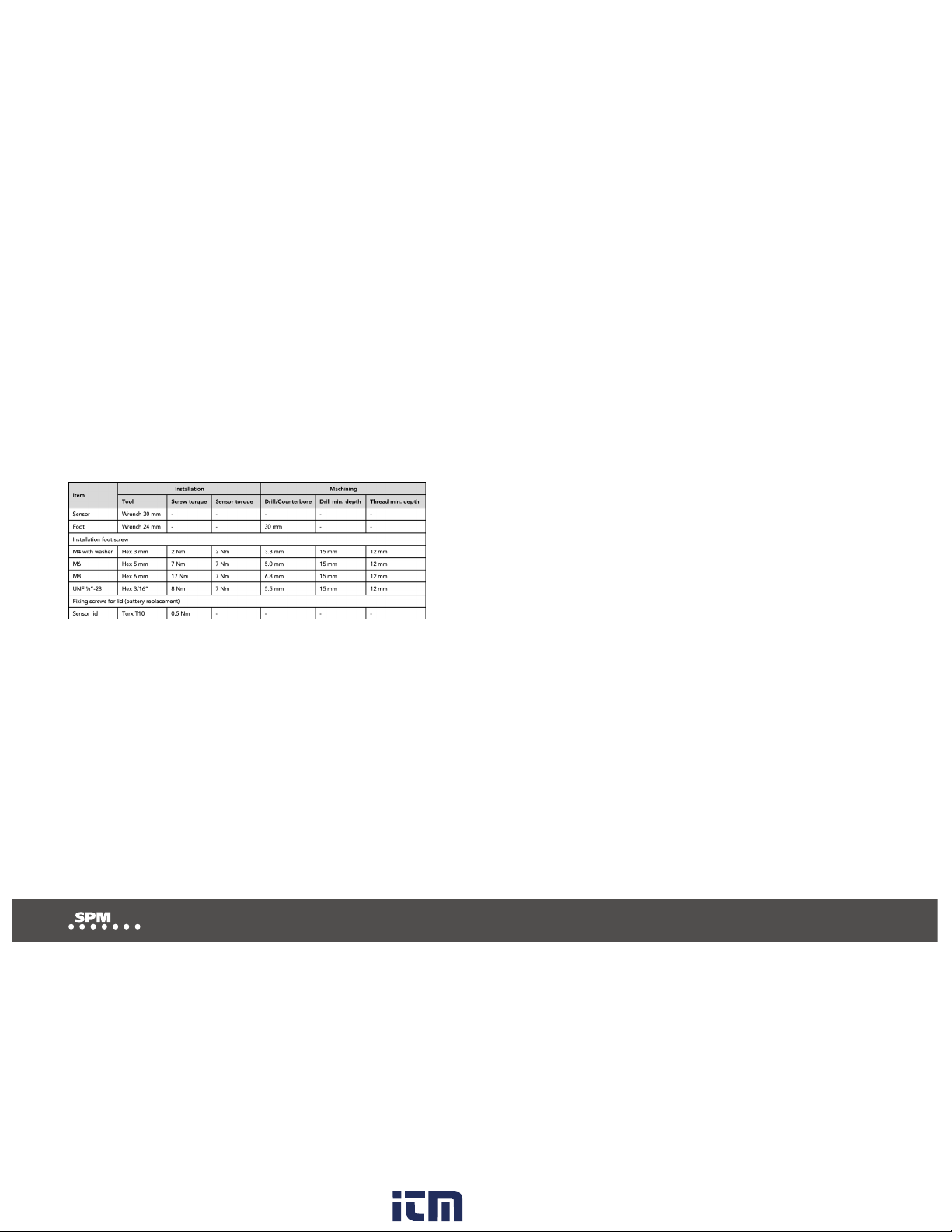

3. Technical specifications

Approvals/Certificates: CE, ATEX, IECEX, UKEX, FCC, Canadian RSS, China

MIIT, Japan MIC, Korean CRM, Taiwan NCC, WiFi Alliance,

Bluetooth SIG

Enclosure: stainless steel body, acid proof; plastic lid, ESD protected

Weight: 215 g

Power supply: replaceable lithium battery, SPM 18425 only

Battery capacity 13 Wh1

Battery shelf life 12 months2

Acceleration measurement: See part numbers:

Range, Resolution

Bandwidth, Resolution

Temperature measurement:

Range –40 °C to +85 °C (–40 °F to +185 °F)

Resolution 0.1 °C

Accuracy +/– 2 °C

Ambient temperatures:

Operational –20 °C to +85 °C (–4 °F to +185 °F)

Ex safety –40 °C to +85 °C (–40 °F to +185 °F)

Storage –40 °C to +85 °C (–40 °F to +185 °F)

Protection class: IP69

Relative humidity: 0 to 100% (non-condensing)

Wi-Fi: 802.11 b/g/n, 2412 MHz-2472 MHz, 19.9 dBm

Wi-Fi Security: WPA/WPA2 PSK/WPA2 Enterprise (PEAP-MSCHAPv2

and TTLS-MSCHAPv2 without certificates)

Bluetooth: v4.2 BLE, 2402 MHz-2480 MHz, 2.7 dBm

Antenna: Internal PCB antenna only, 3.7 dBi

Installation: Installation foot, glue (Loctite 326 and activator Loctite 7646)

or screw (M4, M6, M8, UNF ¼”)

1Battery cell capacity is 13Wh. Affected by ambient temperature, current profile of load and shelf life above

12 months. Active sensor power consumption increases by Radio (Wi-Fi or BL) low signal strength or high

traffic intensity.

Typical capacity cases:

• Four measurements per day for four years, ±0 to +40 °C, RSSI

≥ −70 dB. Sleeping sensor power consumption is increased by

high ambient temperature.

• Eight years of sensor deep sleep only, ±0 to +40 °C.

The sensor calculates the remaining number of measurements

based on; time from manufacture, time spent in configuration

mode (BL), time between measurements, ambient temperature

and Wi-Fi signal strength (RSSI).

2Battery Shelf Life is 12 months. After 12 months the battery ca-

pacity might be reduced. Ongoing long-time tests are performed,

with the aim to prove an expected longer battery shelf life.

Part numbers

AIR01-01-EX Airius Ex sensor, 2/4/8 g, 16 bits,

10-1000 Hz, 800/1600 lines

AIR01-10-EX Airius Ex sensor, 2/4/8/16 g, 16 bits

10-5000 Hz, 800/1600 lines or

Airius Ex sensor, 10/20/40 g, 20 bits

2-1000 Hz, 800/1600 lines

Accessories

18470 Installation kit (installation foot, M4 screw,

M4 washer, M6 screw)

18471 Installation kit (installation foot, M8 screw)

18466 Installation foot, glue installation

Spare parts

100065 Ex spare part kit (battery, lid with

gasket, 4 pcs M3x8 screws)

www. .com information@itm.com1.800.561.8187

6

7

4. Installation of Airius Ex sensor

Installation must only be performed by competent

personnel. There are two methods for installing Airius Ex

sensors, either by screw installation or glue installation.

Position the sensor in such a way that it can optimally

perform measurements while having good Wi-Fi signal

strength.

4.1 Screw installation

1. Drill a screw hole where the sensor should be

placed.

2. Drill a counterbore with 30 mm diameter on the

machine.

3. Align the longest flat side of the installation foot

with the x-axis of the intended measurement direc-

tion.

4. Screw the installation foot onto the machine. See

table for screw torque.

5. Screw the sensor onto the installation foot. See table

for sensor torque.

6. Check that the marking of the sensor aligns with the

intended measurement directions. If the markings

are not aligned with the intended measurement

directions, adjust the installation foot.

NOTE: There are markings for z, x and y on the

sensor, indicating the directions of the measurement.

www. .com information@itm.com1.800.561.8187

6

7

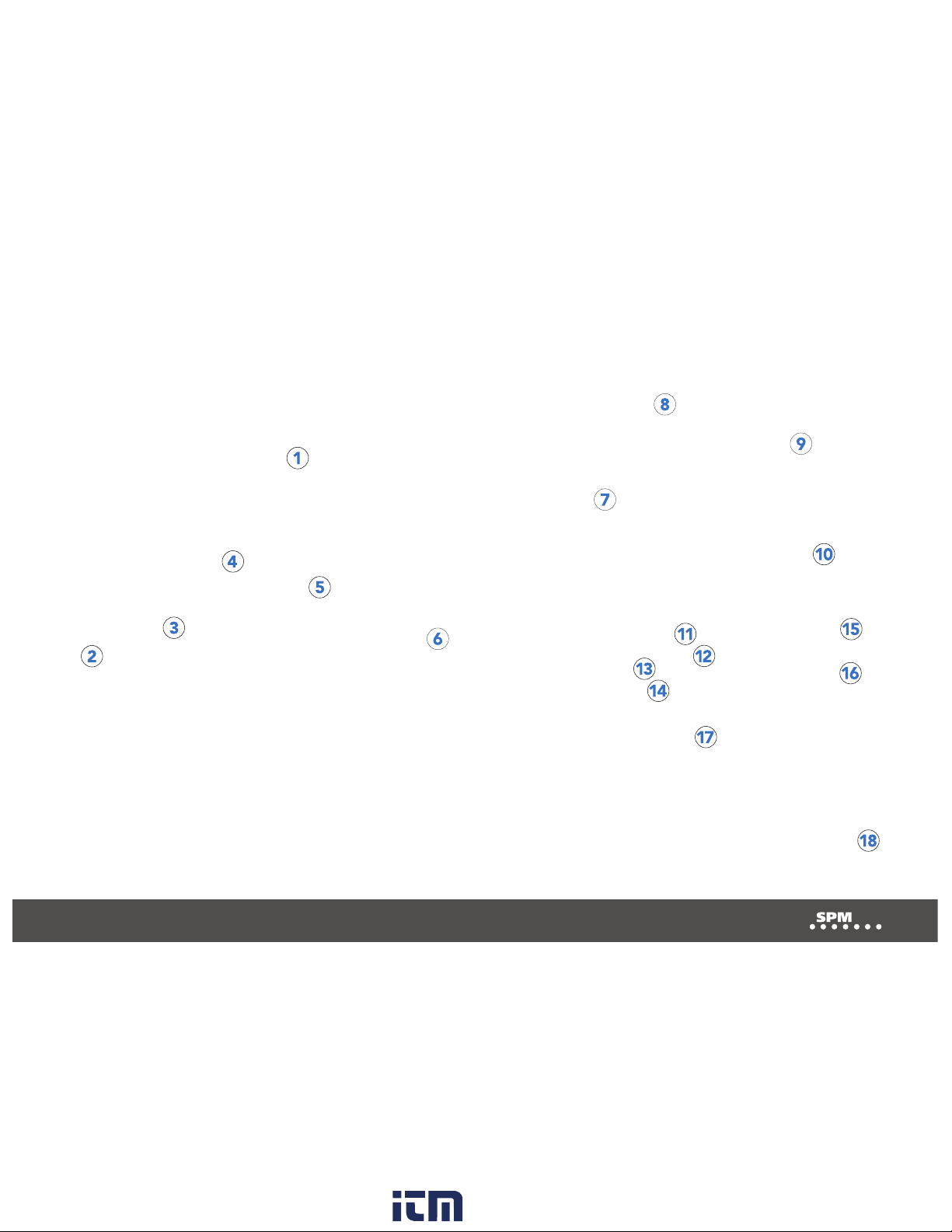

1 2 3

4 5 6

Ø 30 mm

Sensor torque:

M4 with washer 2 Nm

M6 7 Nm

M8 7 Nm

UNF 1/4” 7 Nm

Screw torque:

M4 with washer 2 Nm

M6 7 Nm

M8 17 Nm

UNF 1/4” 8 Nm

www. .com information@itm.com1.800.561.8187

8

9

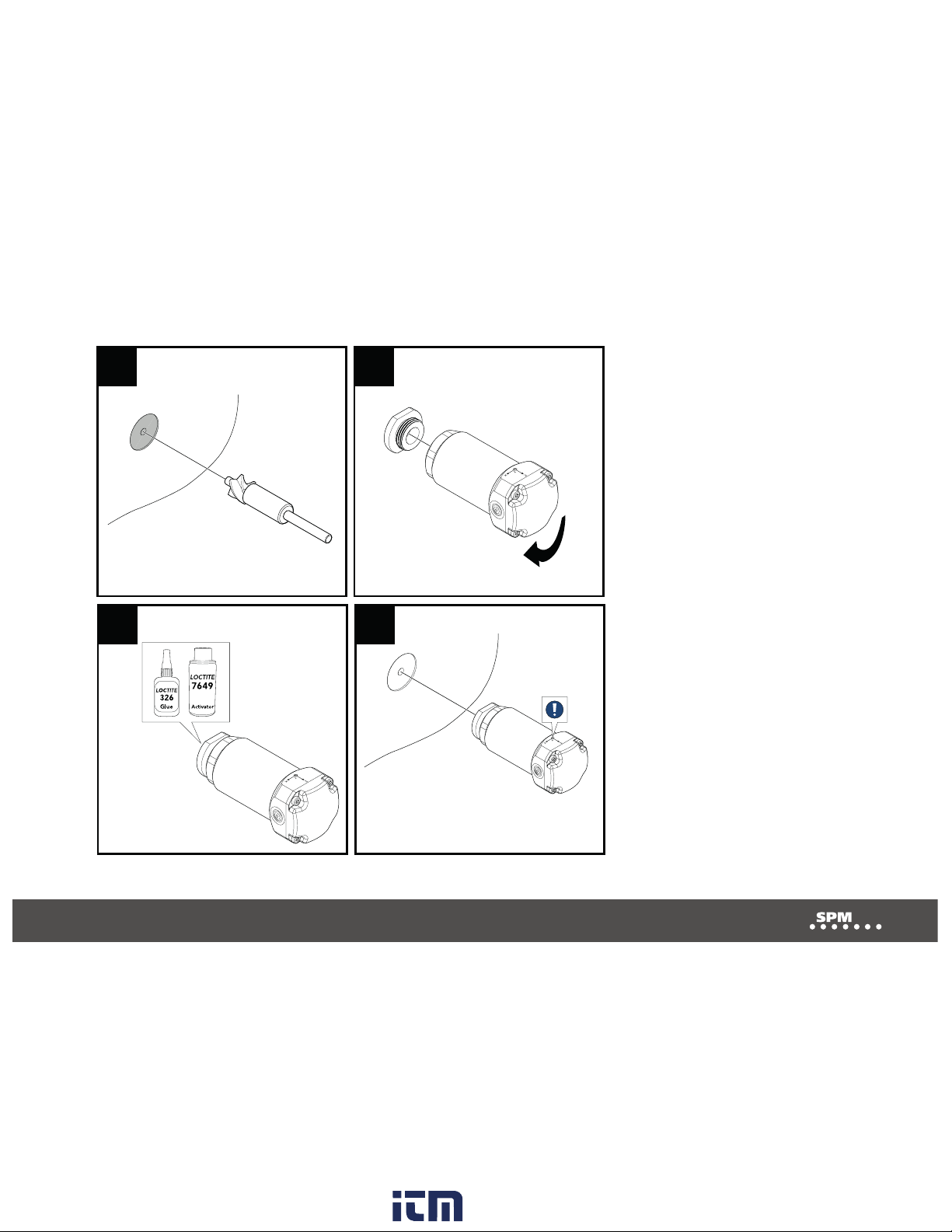

4.2 Glue installation

1. Drill a counterbore with 30 mm diameter on the

machine where the sensor should be placed.

2. Screw the sensor onto the installation foot. Tighten-

ing torque: 7 Nm.

3. Apply glue (Loctite 326) and activator (Loctite 7649)

to the installation foot.

4. Check that the markings of the sensor align with the

intended measurement directions. Press the sensor

onto the flat surface. Hold steady for three minutes.

NOTE: There are markings for z, x and y on the sen-

sor, indicating the directions of the measurement.

www. .com information@itm.com1.800.561.8187

8

9

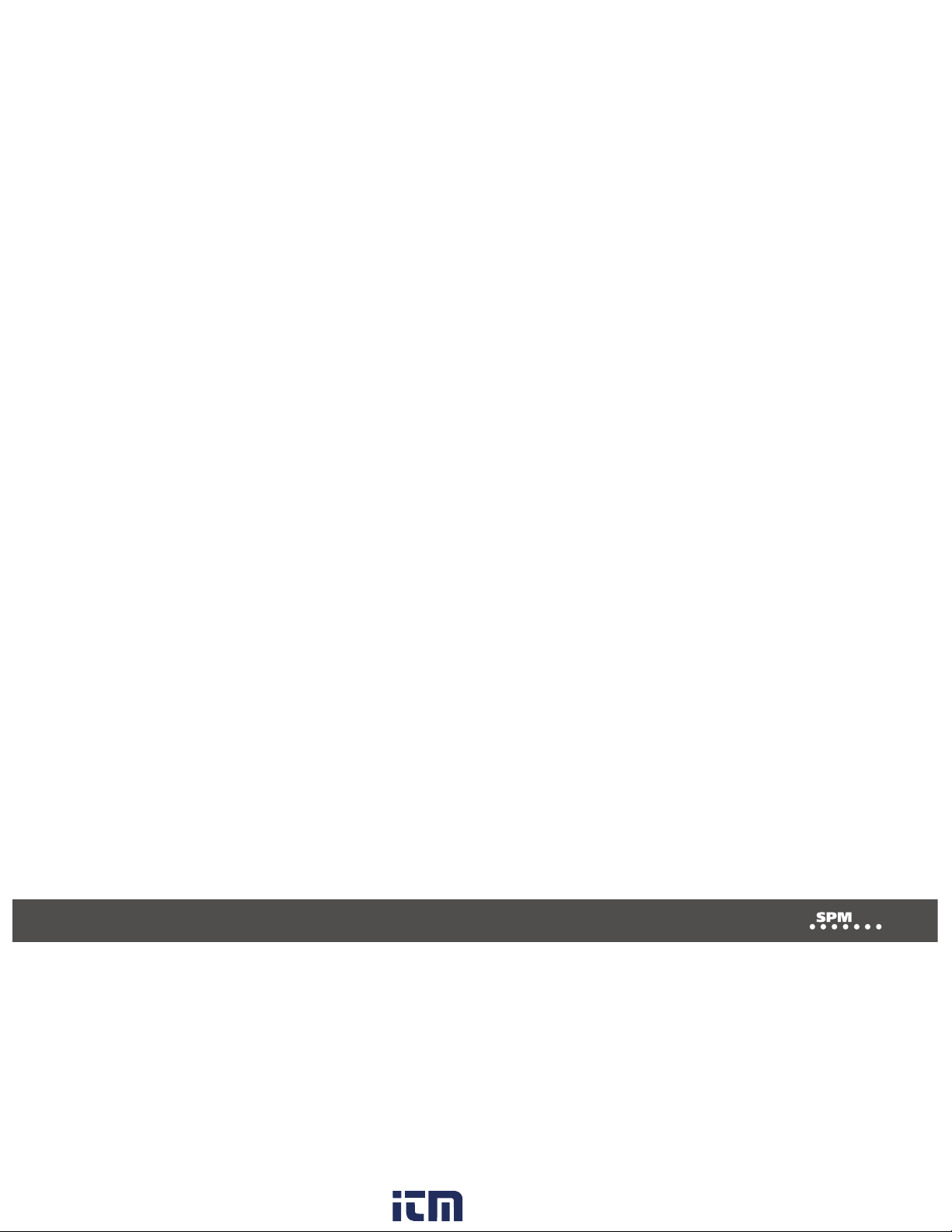

1 2

3 4

Sensor torque: 7 Nm

Ø 30 mm

www. .com information@itm.com1.800.561.8187

10

11

5. Sensor Operation

LED indication and push-button management are shown

in the functional state diagram to the right.

5.1 Reset to factory default

Press and hold the internal push button while the battery

is reconnected. Factory default clears all settings and

reverts to the software installed during factory production.

5.2 Clear settings via the SPM Connect app

Clear settings continue to use the latest software while all

settings are cleared. For more information, see chapter

‘Setting up Airius with SPM Connect’.

Not configured

Not configured

No server

Button

pressed

On

Fast flash

Slow flash

Off

Button pressed

and hold

From any state

E.g. measure and

send data to server.

Set timer.

Recovered/connected

battery

Bad/disconnected

battery

Configured

Configured

Timer expired

Server available

Exit, button pressed,

20 s timeout or connection lost

www. .com information@itm.com1.800.561.8187

10

11

5.3 Setting up Airius with SPM Connect

1. Download the SPM Connect app via App Store or Google Play.

2. Press and hold the button on the Airius sensor until it lights blue.

3. Open the SPM Connect app.

4. Swipe down to search for a sensor. Choose a sensor in the list (A).

5. Select Configure (B).

6. Choose Wi-Fi from the list and enter a password (C). To connect to a hidden

network, select Enter SSID manually.

7. Choose dynamic (”Obtain IP address automatically (DHCP)”) or static IP

addressing (D). If static, enter IP address.

8. Choose SPM Cloud or Condmaster Entity Server (CES), depending on

the method of connection. Enter server address, server port and whether SSL

should be activated or not (E).

9. To create a password for the sensor, select Password protect device (F).

10. Select APPLY (G).

11. To perform a function and connection test, press the button on the sensor.

Immediate green flashing means that the sensor works. When the connection

to the server is successful, the sensor flashes green. The number of flashes

corresponds to the Wi-Fi signal strength (1-3). If the connection is unsuccessful,

the sensor lights red.

12. Follow the steps in ‘Setting up vibration measurements in Condmaster

Ruby’ or ‘Setting up vibration measurements in Condmaster.NET’, depending

on your software.

www. .com information@itm.com1.800.561.8187

12

13

5.4 Setting up vibration measurements in Condmaster Ruby

1. Go to the Graphical Overview tab and select View as tree in the ribbon bar.

2. Expand Components.

3. Right-click Components, choose Create and select Component.

4. Enter component number and name.

5. Select Save.

6. Right-click the created component, choose Create and select Measuring point.

7. Enter Measuring point number and name.

8. Choose a vibration measurement technique (Vibration, 2 or 3 channel vibration, or ISO 10816) and select Add.

9. Choose Online under Instrument, choose settings as desired and select OK.

10. Go to the Online tab, select the Airius sensor and direction (z, x or y) under Address. Select OK.

11. Go to the Settings tab, name the assignment and edit the settings as desired.

12. For settings regarding conditions and filtering of results, go to the Online Advanced tab.

13. Go to RPM and enter fixed or variable speed (as a global value).

14. Select Save.

For further information regarding these steps, see chapter ’Setting up measuring assignments for Airius Ex

vibration sensors’ in the ’Condmaster Ruby User guide’ (72261).

www. .com information@itm.com1.800.561.8187

12

13

www. .com information@itm.com1.800.561.8187

14

15

5.5 Setting up vibration measurements in Condmaster.NET

1. Open Condmaster.NET and log in. If required, choose a database.

2. Select Settings.

3. Select Components.

4. Select Add.

5. Enter the component details.

6. Select Create.

7. Select Measuring points.

8. Select Add.

9. Enter the measurement point details.

10. Select Create.

11. Enter a name for the measuring assignment.

12. Choose a sensor under Measuring device.

13. To edit measuring interval, operational hours or measuring range for the Airius sensor, select Edit device settings.

14. Select the axes (z, x, y) to be measured.

15. Choose frequency range.

16. Choose spectrum unit.

17. Set alarm limit for each condition parameter that should have an alarm limit.

18. Select Create.

For further information regarding these steps, see chapter ’Getting started’ in the ’Condmaster.NET User guide’ (72239).

www. .com information@itm.com1.800.561.8187

14

15

www. .com information@itm.com1.800.561.8187

16

17

6.1 Battery replacement

0.5 Nm

6. Maintenance and service

The installed sensor may only be maintained, inspected

or repaired by competent personnel.

Immediately remove the sensor from Ex-hazardous areas

if the safety is questioned or compromised. Return the

product to SPM Instrument AB for examination.

Battery assembly, lid and screws may be replaced. All

other repair measures may only be performed by SPM

Instrument AB. To clean the external surfaces of the

product, wipe the enclosure with a damp cloth and mild

detergent. Always take necessary ESD precautions when

the sensor is maintained or repaired.

1. Loosen the screws and remove the lid.

Note: Observe the position of the lid.

2. Remove the battery and disconnect the plug.

Note: If the battery is stuck, carefully pull the cables

or use a long thin hook.

3. Connect the plug and insert the new battery.

Warning: Use only SPM battery.

4. Carefully press down the plug and cables below the

top of the battery.

5. Clean the surfaces between the lid and the sensor body.

6. Screw on the new lid with new screws. Tightening

torque: 0.5 Nm.

Note: Ensure the lid protrusion is above the battery.

7. Ensure the battery health indicator is aware of

the battery replacement. For more information, see

chapter ’Setting up measuring assignments for Airius

Ex vibration sensors’ in the ’Condmaster Ruby User

guide’ (72261) or ’Getting started’ in the

’Condmaster.NET User guide’ (72239), depending on

your software.

www. .com information@itm.com1.800.561.8187

16

17

This product must be disposed as electronic waste and is marked with a crossed-out wheeled bin symbol in order to prevent

it being discarded with household waste.

When the life cycle of the product is over You can return it to Your local SPM representative for correct treatment,

or dispose it together with your other electronic waste.

www. .com information@itm.com1.800.561.8187

This manual suits for next models

3

Table of contents

Other SPM Accessories manuals

Popular Accessories manuals by other brands

Samsung

Samsung SIP-1201DD user manual

Sloan

Sloan SJS-1450 Installation & operating instruction manual

Haltian

Haltian thingsee AIR User and installation guide

RTK

RTK MV 5351 Series Installation and operating instructions

Tecsis

Tecsis P3427 instruction manual

PCB Piezotronics

PCB Piezotronics ICP 356A26 Installation and operating manual