Sporlan Superheat User manual

May 2020 / Bulletin 100-50-5.1

Superheat Control

Installation and Operation Instructions

Controller v. M.2

Page 2 – Bulletin 100-50-5.1

1. Installation .............................. 3

2. Setup.................................. 4

Superheat Control with Display .............. 4

Superheat Control without Display ............ 5

Factory Reset ........................... 5

3. Setpoint Menu Operation ................... 5

4. System Operation ........................ 5

Refrigeration ............................ 5

Chillers and Air Conditioners ................ 6

Control Features ......................... 6

System Parameters ....................... 7

5. Display Networking ....................... 9

Multiple Controllers ...................... 10

Junction Box Fabrication .................. 10

6. Controller Networking . . . . . . . . . . . . . . . . . . . . 10

Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

RS-485 Connection Requirements. . . . . . . . . . . 11

7. PID Tuning ............................. 11

8. Troubleshooting ......................... 12

Troubleshooting Recommendations .......... 12

Sensors ............................... 12

Alarms ................................ 12

APPENDIX A

Setup Menu ............................ 15

APPENDIX B

Process Values ......................... 16

APPENDIX C

Setpoint Parameters ..................... 17

APPENDIX D

Accessories ............................ 19

APPENDIX E

Technical Specifications ................... 19

APPENDIX F

Controller Status ........................ 19

APPENDIX G

Miscellaneous Displays ................... 19

APPENDIX H

Wiring Diagram ......................... 20

APPENDIX I

Sensor Installation ....................... 21

APPENDIX J

MODBUS Memory Map ................... 22

APPENDIX K

BACnet Map ........................... 24

APPENDIX L

2K Temperature Sensor Specifications........ 32

APPENDIX M

3K Temperature Sensor Specifications........ 33

APPENDIX N

10K Temperature Sensor Specifications....... 34

Terms of Sale with Warranty Limitations......... 35

Contents

⚠WARNING – USER RESPONSIBILITY

Failure or improper selection or improper use of the products described herein or related items can cause death, personal injury and property damage.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further

investigation by users having technical expertise.

The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance,

endurance, maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry

standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or

authorized distributors.

To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user,

the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the

components or systems.

For safety information see the Safety Guide at www.parker.com/safety or call 1-800-CParker.

OFFER OF SALE

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its

acceptance are governed by the provisions stated in the detailed “Offer of Sale” available at www.parker.com.

FOR USE ON REFRIGERATION and/or AIR CONDITIONING SYSTEMS ONLY

For more information about our products visit us at www.sporlan.com.

Bulletin 100-50-5.1, May 2020 supersedes Bulletin 100-50-5.1, August 2016 and all prior publications.

Introduction

The Sporlan Superheat Control is a standalone

controller for refrigeration and air conditioning sys-

tems. The controller operates an electronic expan-

sion valve to control superheat. It may also be used

to control room temperature. The controller may be

networked into a building automation system and

offers several communication protocols. It is avail-

able with or without display for aftermarket or OEM

use. A remote display unit is optional.

Features

• Superheat or room temperature control

• 4-digit LED display with easy to use input knob

• OEM version available without display

• Optional remote display unit

• Optional display networking between controllers

• BACnet or MODBUS communication protocols

• One bi-polar or uni-polar step motor driver

(30ohm/coil minimum)

• One mechanical relay output (for liquid line sole-

noid or piloting a compressor relay)

• Four temperature inputs (Sporlan surface or air

sensor)

• One pressure input (Sporlan pressure transducer)

• One digital input (for external switch or relay)

Bulletin 100-50-5.1 – Page 3

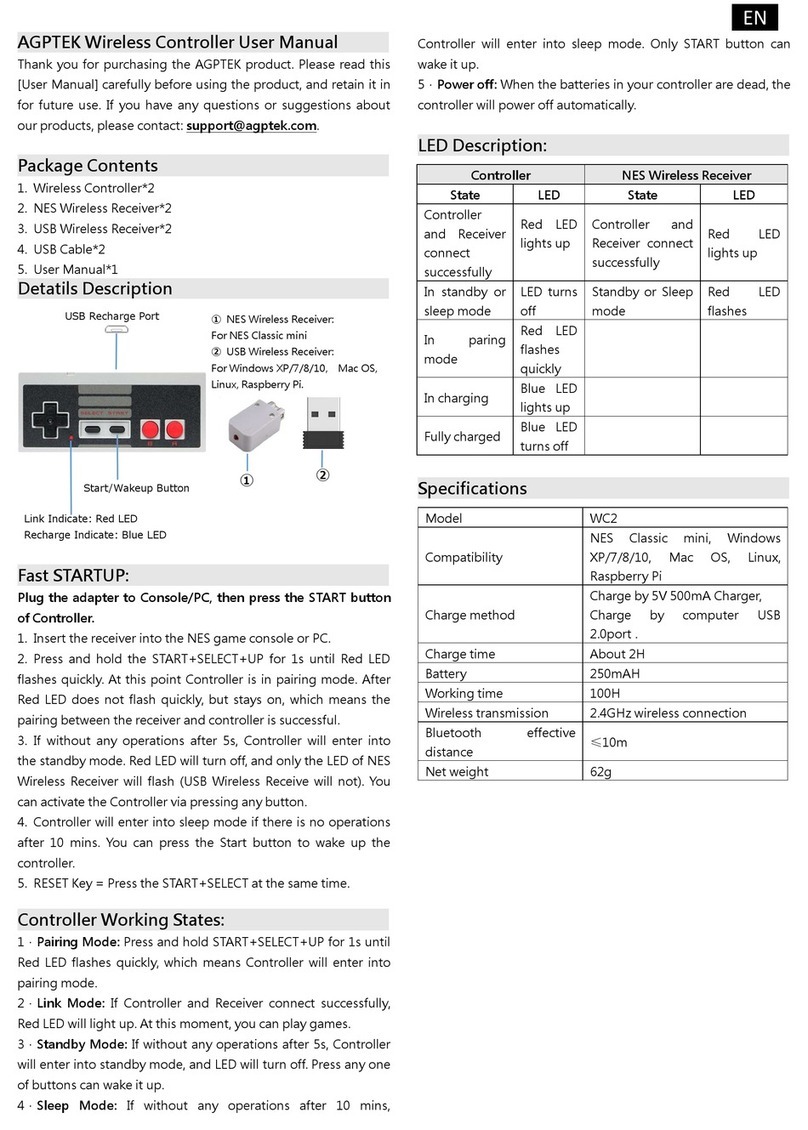

1. Installation

Refer to Appendix H - Wiring Diagram and Appendix I -

Sensor Installation

TOOLS REQUIRED:

• Small flat screwdriver for terminal connections

• Phillips and flat screwdrivers

• Cordless screwdriver

• Needle-nose pliers

• Wire cutters

• Scotch-BriteTM pad

• Two #8 x ½” self-tapping screws to mount DIN rail

1. Mount the controller in a rain-tight, protected location

using the supplied DIN Rail. To leave enough working

space, the suggested mounting area is 10 inches high

and 5 inches wide. The minimum depth is 3 inches. See

Figures 1 and 2.

Superheat Control

with display

Item Number 952567

Superheat Control

without display

Item Number 952569

Kelvin IId

Remote display unit

Item Number 952568

Figure 2 - DIN Rail Detail

1.5”

.25”

4.0”

3.25”

Figure 1 - Recommended Mounting Clearance

2. Connect the suction temperature sensor wires to ter-

minals 31 and 32. Sporlan temperature sensors are not

polarized.

3. Connect the pressure transducer wires to terminals 33,

34, and 35. Sporlan has used transducer cables with two

wire color combinations; see Table 1. Maximum torque

on screw terminals is 3.5 in-lbs.

4. Connect the optional room temperature sensor wires to

terminals 29 and 30. Sporlan temperature sensors are not

polarized.

5. Connect terminals 27 and 28 to a digital input. A short

or a closed contact from an external relay will close the

valve for pump down. See Section 4 - System Operation.

6. Connect the Sporlan EEV wires to terminals 5, 6, 7, and 8.

7. Connect power wires to terminals 1 and 2. Transformer

requirements are 24 volts AC/DC at 40 VA, Class II.

The Sporlan supplied DC power supply is 100-250

VAC/24 VDC, P/N 953444.

8.

NOTE: Sensor leads may be extended to 100 ft. (30.5 m)

with 18 awg wires and Scotchlok™ UR connectors for

long-term integrity. Belden wire is preferred; Transducer

Cable Belden 9493, Temperature Sensor Belden 9409.

WARNING: Route and secure cables away from

hot surfaces, high voltage lines, and moving

components.

NOTE: The Sporlan Superheat Control should be installed

only by a qualified professional. All other system compo-

nents (valves and sensors) should be supplied by Sporlan

to ensure compatibility and proper operation. There are

no user-serviceable components inside the Superheat

Control. Opening the case will void the warranty.

WARNING: Use caution when working around

high voltage components. Safety covers should be

used for personal safety on high voltage panels.

2. Setup

SUPERHEAT CONTROL WITH DISPLAY

The Superheat Control has preset setpoints for most system

parameters. Basic system parameters will be verified through

the setup menu. If additional parameter setpoints need to be

changed, follow the steps in this section and in Section 3 -

Setpoint Menu Operation.

Enter values for six system variables following the steps

below. Refer to Appendix A - Setup Menu. The EEV is closed

upon power-up and the system will not operate until complet-

ing setup. The controller will display the firmware versions

for the display and the controller. It will then display the first

variable to set.

CONTROLLER

TERMINAL

OLD PIGTAIL

LEADS

NEW HERMETIC

CABLE

+5VDC 35 Red Black

Signal 33 Green White

Ground 34 Black Green

Table 1 - Pressure Transducer Wire Colors

Page 4 – Bulletin 100-50-5.1

1. Set StEP, Step Motor Stroke. Press and then turn the

SELECT knob to select the correct number of steps for

the EEV being used. See Table 2 for a list of Sporlan

EEVs. Default is 2500. Press the SELECT knob again to

save the value. The next variable is displayed.

2. Set reFr, Refrigerant. Select the actual refrigerant used

in the system, following the steps above. Default is

R-404A.

NOTE: Verify the actual refrigerant used in the system.

3. Set tt4P, Temperature Sensor Type. Select 2K, 3K, 10K

or 98.6K; see pictures below. Default is 2K.

4. Set Pt4P, Pressure Sensor Type. Select Absolute or

Gauge (sealed), following the steps above. Default is

Gauge.

5. Set Un_t, Temperature Units. Select Fahrenheit or

Celsius. Default is Fahrenheit.

6. Set Un_p, Pressure Units. Select PSI or Bar. Default is

PSI.

Setup is now complete. The Superheat Control will begin

controlling superheat, and will display SvpH. The controller

is now in the Process Values Menu (Appendix B). Rotate the

SELECT knob to view the values.

Table 2 - Electric Expansion Valves

SPORLAN MODEL NUMBERS STEPS

SEI-.5, SEI-1, SER-1.5, SEI-2, SEI-3.5, SEI-6,

SER-6, SEI-11, SER-11, SER-20 1596

SER-AA, A, B, C, D, F, G, J, K, L 2500

SEI-30 3193

SEI-50, SEH-100, SEH-175 6386

ESX, OEV, SEV, SEV-C and CEV 500

3K Surface Sensor

2K Air, Surface

or Well Sensor

10K Air Sensor

(Green orYellow)

3K Air Sensor

(Black)

10K Surface Sensor

(Blue, Orange, or Red)

98.6K Surface Sensor

Bulletin 100-50-5.1 – Page 5

NOTE: Not all refrigeration systems are designed alike.

See Section 7 - PID Tuning to adjust the settings accord-

ing to the specific needs of the system.

SUPERHEAT CONTROL WITHOUT DISPLAY

To set up a Superheat Control without display that is con-

nected to either a Kelvin IId(remote display unit) or a

Superheat Control with display, first go to Section 5 -

Display Networking to establish a network connection.

Then follow the directions in this section and in Section 3 -

Setpoint Menu Operation.

FACTORY RESET

It may be desired to set all of the setpoints of the control

back to the factory defaults. Should that need arise, the user

can perform this function by doing the following steps:

1. With the controller powered off, press and hold the knob

on the display.

2. Power on the controller while the knob is still depressed.

3. The knob may be released once “FrSt” is seen on the

screen.

The controller will now require the user to complete the

setup process before continuing.

3. Setpoint Menu Operation

See Appendix C - Setpoint Parameters. All setpoints must be

verified prior to system startup for proper system operation.

It may be necessary to adjust these parameters for a specific

system. Details on advanced features can be reviewed in

Section 4 - System Operation.

1. To enter the Setpoint Menu: Press the SELECT knob

for 5 seconds. Enter the password “111 ” and press the

SELECT knob again.

2. To view a parameter, rotate the SELECT knob to the

desired parameter and press the knob. The default value

will display.

3. Turn the SELECT knob to change the value and then

press the SELECT knob to enter the value and return to

the Setpoint Menu.

4. After all desired parameters are set, turn the SELECT

knob to “ESC” and press the knob to save and implement

all changes. Observe the system for proper operation.

NOTE: The Setpoint Menu times out after 60 seconds of

inactivity and you will lose all changes entered.

The Superheat Control is now operational and displaying the

Process Values Menu (Appendix B). To view system param-

eters while in operation, turn the SELECT knob and scroll

through the menu. Select the desired parameter. For example,

to view system superheat, turn the SELECT knob to SvPH.

After a few seconds, the actual system superheat will be dis-

played. See Appendix B – Process Values for a description of

each variable.

Pressing the SELECT knob at any time will display the

Controller Display Address CAdr.

4. System Operation

The Sporlan Superheat Control can be configured as a stand-

alone superheat controller or a refrigerated space tempera-

ture controller. The controller can be used in refrigeration

systems, chillers, or air conditioning systems. The Superheat

Control should not be used inside of a conditioned space that

exceeds product specifications (See Appendix E - Technical

Specifications).

The controller, by default, is designed to control superheat

in refrigerated spaces that use evaporator pressure regula-

tors (EPRs). In all applications, it is recommended to use a

normally closed solenoid valve upstream of the electronic

expansion valve to ensure positive shutoff of refrigerant flow

during power loss.

REFRIGERATION

Superheat control on cases with EEPR (pre-

ferred method): The Superheat Control will regulate

the refrigerant flow entering the evaporator to achieve the

superheat setpoint. The EEPR is typically controlled by a

system level controller and provides consistent evaporator

temperatures based on the discharge air setpoint (set through

the system controller). This combination provides greater sta-

bility in control, increased efficiency of the evaporator coil,

and accurate case temperatures.

Superheat control on cases with liquid line sole-

noid or suction stop solenoid valves:

Some applications in refrigeration that typically use mechani-

cal expansion valves also use a solenoid valve upstream

(liquid line) or downstream (suction stop) of the TEV to

control case temperature. The system controller closes and

opens the solenoid valve to meet cut-in and cut-out tempera-

tures. If the Superheat Control is used on these systems in

conjunction with an EEV, a digital input must be connected

to the Auxiliary Temperature Sensor terminals (27 and 28 in

Appendix H – Wiring Diagram). Since refrigerant flow is a

critical part of the Superheat Control scheme, the controller

must be tied into the liquid line solenoid or suction stop sole-

noid when flow is stopped. This input allows the controller to

respond to major flow variations upstream or downstream of

the EEV.

Case temperature control using cut-in / cut-out:

The Superheat Control can be used as a thermostat by con-

necting a room temperature sensor to T2, terminals 29 and 30,

and setting C_n and Cvt to the desired cut-in and cut-out

temperatures, respectively. For optimum control, the room

sensor must be located inside the case as specied by the

refrigerated case manufacturer. Connect a normally closed

liquid line solenoid valve to terminals 19 and 20. The solenoid

valve should be wired so that the Superheat Control is cutting

one leg of the supply voltage. Terminals 19 and 20 may also

pilot a compressor relay in place of the liquid line solenoid on

smaller standalone systems. Note relay ratings specied in the

wiring diagram located in the appendix. The controller will

maximize the efciency of the evaporator coil by regulating

Page 6 – Bulletin 100-50-5.1

the EEV to control superheat until the cut-out temperature is

reached. The solenoid valve and EEV will then close until the

temperature rises to the cut-in temperature. Once the valves

close and refrigeration stops, the Superheat Control will

display FF. During refrigeration mode, the controller will

display C. During defrosts, the system master controller

must provide a digital input/short to terminals 27 and 28. The

Superheat Control will close the EEV and display pdn for

pumpdown. A standard dry contact relay can be used. A mini-

mum relay on and off time can be set for the solenoid valve.

See rnt and rF features under the Parameters Section.

CHILLERS AND AIR CONDITIONERS

Superheat control - Single evaporator:

The Superheat Control may be used on single evaporator

chillers or air conditioners. The default control scheme is

optimized for quick pull down (coil temperature) and stable

holding loads. If the controller is used on systems with major

transient conditions (impulse heat loads) it may be necessary

to adjust the PID control scheme parameters. See Section 7 -

PID Tuning.

Superheat control - Dual evaporator:

On some systems, it may be necessary to control two

independent evaporator coils. This setup will consist of a

Superheat Control with display and a Superheat Control

without display. A network must be established between the

two controllers; see Section 6 – Controller Networking. The

display can be used to set up both controllers and to review

parameters from each evaporator coil.

CONTROL FEATURES

Pumpdown

Closing or shorting terminals 27 and 28 (T3) places the con-

troller in pumpdown mode and closes the EEV. A standard

dry contact relay can be used. During pumpdown signal, the

Superheat Control will open terminals 19 and 20 (relay),

which can be used to pilot a solenoid valve or compressor.

During this time, the controller will shut down the control

scheme and prepare for restart. This ensures maximum con-

trol efficiency and system stability.

Manual Valve Positioning

The Superheat Control can be used to manually position the

EEV via a local or remote display. To access manual valve

control, navigate to the Setpoint menu, scroll to SPS and press

the SELECT knob. Once this is selected, the controller no

longer controls the superheat or case temperature setpoint. The

display will show the actual valve position, from 0% to 100%

open once the SELECT knob is pressed. To open the valve,

turn the select button clockwise. To close the valve, turn the

select button counter-clockwise. To end manual valve control,

press the SELECT knob to go back to the Setpoint menu. At

this point, the controller will resume normal operation.

The controller has an internal timeout function and after

60 minutes of inactivity, normal operation will resume. For

troubleshooting purposes, the timeout may be disabled us-

ing the Stepper Timeout Override (Stt) feature. This may

be accessed through the Setpoint menu and placed in the n

position to override the timeout. It should be noted that the

setpoint parameter menu must be exited before changes are

saved. The valve position shown under SPS will blink when

the timeout is disabled.

If manual valve control is needed without viewing system

parameters use the following steps:

1. Through the display, press and hold the SELECT knob

until E PASS appears.

2. Enter “111 ”by turning the knob.

3. Scroll to SPS feature and hold down the SELECT knob

until the position on the display starts blinking (10 sec-

onds). This will override the time out feature.

4. To move the valve, rotate the SELECT knob. The con-

troller will remain in manual mode until the SELECT

knob is pressed.

If manual valve control is needed while viewing system

parameters use the following steps:

1. Through the display, press and hold the SELECT knob

until E PASS appears.

2. Enter “111 ”by turning the knob.

3. Scroll to Stt feature and press SELECT knob.

4. Turn selection to .

5. Push the SELECT knob and scroll to ESC.

6. Press the SELECT knob; the controller is now locked in

manual mode.

7. To manually move the EEV press and hold the SELECT

knob until E PASS appears.

8. Enter “111 ”by turning the knob.

9. Scroll to Sp feature and press SELECT knob.

10. Rotate the knob to move the EEV. The position on the

display is shown % open and will be blinking while in

manual control.

11. To exit manual valve control, use the steps above and

select FF under Stt; exit parameter setpoint menu to

save changes and continue automatic control.

Manual valve control through MODBUS:

1. Enable the feature by writing a 1 to the “Manual Valve

Enabled” coil using the ‘Write Single Coil’ function. See

Appendix J – Modbus Memory Map.

2. Manually move the valve by writing the position, tenths

of a percent, to the “Manual Valve Position” holding reg-

ister using the ‘Write Single Register.’ Each time a write

is sent to the controller, the manual timeout feature resets.

Manual valve control through BACnet:

1. Enable the feature by writing a 1 to the “MANUAL_

VALVE_CONTROL” binary value object’s present value

property. See Appendix K – BACnet Map).

2. Manually move the valve by writing the position, in tenths

of a percent, to the “MANUAL_VALVE_POSITION” ana-

log value object’s present value property. Each time a write

is sent to the controller, the manual timeout feature resets.

NOTE: Use caution and monitor superheat while in manu-

al valve mode. To avoid floodback, start with the valve in a

low position. Never leave the system unattended while in

manual mode.

Bulletin 100-50-5.1 – Page 7

SYSTEM PARAMETERS

Addr (Address) – The MODBUS or BACnet network address

must be set on each Superheat Control if they will be installed

on a network. No two controllers may have the same address

on the network. The Superheat Control has been designed

to have addresses for both the controller and the display. It

should be noted that this parameter, Addr, is for the controller,

not the display.

vd (Baud Rate) – Baud rate refers to the number of signal

changes that occur per second via the communications line on

the network. The MODBUS or BACnet baud rate must be set

to the same rate as the master controller or other devices on

the network.

_S (Bleed Step Position) – The EEV will be placed in the

bleed position to allow for refrigerant equalization in the sys-

tem after the unit is signaled to shut down via a short across

terminals 27 and 28. The bleed position works in conjunction

with _d, bleed delay feature. The default bleed position is

0%. See below for more information.

_d (Bleed Delay) – The bleed delay feature works with

the _S, bleed step position feature. Once the system gets a

signal to shut down via a short across terminals 27 and 28, the

EEV will close to 0% then dwell for the bleed delay time, in

seconds, before moving to the bleed delay position for system

pressure equalization. The default bleed delay time is 0 sec-

onds. See below for more information.

Bleed System Equalization (_S, _d)

Use of an EEV can dramatically improve efciency of a re-

frigeration or air conditioning system. By accurately control-

ling the system’s superheat, the EEV achieves full utilization

of the evaporator coil surface area. A drawback to the use

of EEVs with some compressors is the need for off-cycle

pressure equalization of high to low system pressure. Speci-

cally, when the system is off the compressor is not cycling

refrigerant and the EEV is closed. This keeps refrigerant from

owing through the system. This condition can cause high

backpressure on the discharge side of the compressor, and

hence, a hard start condition. Setting a Bleed Step Position,

_S, allows a small amount of liquid refrigerant to pass

through the EEV while the system is off. Normal industry

practice is to set a bleed to equalize the system in 3-5 min-

utes. The Superheat Control also allows the delay of the bleed

process by setting the Bleed Delay parameter, _d.

Cdr (Controller Display Address) – The display address

must be set when viewing multiple Superheat Controls through

a single display. If a display network is not used between

controllers, the Cdr must remain at default values. No two

controllers may have the same address on the network. The

Superheat Control has been designed to have addresses for both

the controller and the display. It should be noted that this pa-

rameter, Cdr, is for the display, not the controller. See ‘Display

Networking’ section for more information.

C_n (Cut In Temperature) – The cut in feature may be used

if case temperature control via cut in/cut out is desired. It is

used with the Cut Out feature, Cvt. The Superheat Control

will start the system once the case temperature rises to the cut

in temperature setpoint. The refrigeration mode will remain

on until the case temperature falls to the cut out temperature

setpoint. To activate this feature, adjust the cut in temperature

setpoint to the desired value. See ‘System Operation’ section

for further description.

Cvt (Cut Out Temperature) – The cut out feature may be

used if case temperature control via cut in/cut out is desired.

It is used with the Cut In feature, C_n. The Superheat Control

will stop the system once the case temperature falls to the cut

out temperature setpoint. The refrigeration mode will remain

off until the case temperature rises to the cut in temperature

setpoint. To activate this feature, adjust the cut out temperature

setpoint to the desired value. See ‘System Operation’ section

for further description.

CAP (Calibration Pressure Sensor) – The Superheat Con-

trol has adjustable calibration offsets for the pressure sensor.

By default, it is set to 0. This parameter may be adjusted to

compensate any error with the pressure sensor.

Ct1 (Calibration Temperature Sensor T1 Suction) – The

Superheat Control has adjustable calibration offsets for the

temperature sensors. By default, it is set to 0. This parameter

may be adjusted to compensate any error with the temperature

sensor.

Ct (Calibration Temperature Sensor T2 Room) – The

Superheat Control has adjustable calibration offsets for the tem-

perature sensors. By default, it is set to 0. This parameter may

be adjusted to compensate any error with the temperature sensor.

Ct (Calibration Temperature Sensor T3) – The Superheat

Control has adjustable calibration offsets for the temperature

sensors. By default, it is set to 0. This parameter may be ad-

justed to compensate any error with the temperature sensor.

Ct4 (Calibration Temperature Sensor T4) – The Superheat

Control has adjustable calibration offsets for the temperature

sensors. By default, it is set to 0. This parameter may be ad-

justed to compensate any error with the temperature sensor.

d (Derivative Control Gain) – The derivative gain is part

of the PID control scheme. In general the derivative gain ef-

fects the speed of the electronic valve in response to the rate

of change in superheat error. The derivative gain is sensitive to

noise and if set too high the valve may overreact and system

oscillations may occur. The derivative gain is generally set to 1

for most systems. See PID tuning section for more information.

dnd (Dead Band) – This feature provides a smoother opera-

tional range around superheat setpoint. For tighter superheat

control, the dead band may be decreased. The Superheat

Control has +/- 2°F and +/- 1°F options.

d_n (Delay On) – This feature sets a delay time before en-

ergizing terminals 19 and 20 after the EEV reaches the Delay

Percent Open position set by d_St. It may be used on small

single compressor systems to position the EEV prior to start-

ing the system. If the Superheat Control gets a signal to start

the system (remove dry contact/short across terminals 27 and

28), it moves the EEV to the Delay Percent Open position, en-

ergizes the relay terminals 19 and 20 after the Delay On time

has been met. Delay On time is in seconds and starts when the

EEV is at the Delay Percent Open position. Terminals 19 and

20 can be used to pilot a compressor relay.

Page 8 – Bulletin 100-50-5.1

d (Delay Off) – This feature sets a delay time before

de-energizing terminals 19 and 20 after the EEV reaches 0%

position. If the Superheat Control gets a pumpdown signal to

shut off the system (dry contact/short across terminals 27 and

28), it closes the EEV and waits for system pumpdown by the

specied Delay Off time, then de-energizes the relay terminals

19 and 20. Delay Off time is in seconds and starts when the

controller receives a pumpdown signal or enters ‘OFF’ mode.

Terminals 19 and 20 can be used to pilot a compressor relay.

d_St (Delay Percent Open) – This feature is used in con-

junction with delay on, d_n, and is used to help equalize

system pressure prior to starting smaller, standalone systems.

The EEV position will move to the percent open position for

the time set by d_n.

HCP (Max Valve Capacity) – The maximum valve capacity

feature can be used to limit the EEV opening. This may be

used to compensate for an improper, oversized EEV. If set too

low however, system superheat may become too high.

H_P (Maximum Operating Pressure) – This feature can

be used on various systems to limit the suction pressure. The

Superheat Control limits the amount of suction gas going to

the compressor by closing the EEV when pressure is within 3

psi of the maximum operating pressure setpoint.

PA (High Pressure Alarm) – The high pressure alarm can

be deactivated. The alarm, by default, is turned on to alert

against high system pressure. For certain low pressure systems,

it may be necessary to turn this feature off to avoid nuisance

alarms during system off time. With the alarm deactivated, the

Superheat Control will still continue to take action and attempt

to reduce system pressure by regulating the EEV when high

pressure is detected. It should be noted that superheat control

takes priority as a safeguard.

5d (High Superheat Alarm Delay Time) - The high super-

heat alarm trigger may be delayed by adjusting the High Su-

perheat Alarm Delay time. Decreasing the setting will trigger

the alarm sooner. Increasing the setting will extend the time

before an alarm is triggered. The setting is in minutes.

5HF (High Superheat Failsafe) - When the High Superheat

Failsafe is placed in the ‘on’ position, the EEV will close

to 0% position after the High Superheat Alarm Delay time

(h5hd) has passed. The EEV will remain at 0% until the con-

troller is manually repowered, This setting is ‘off’ by default.

(Integral Control Gain) – The integral gain is part of the

PID control scheme. In general the integral gain affects the

electronic valve response over a given time period to bring

the steady state error to zero. See PID tuning section for more

information.

_P (Low Operating Pressure) – This setting can be used

in smaller systems to aid in startup. If the EEV is not open

enough during start up (superheat above setpoint and pres-

sure below the low operating pressure setpoint) the Superheat

Control will automatically open the EEV to equalize system

suction pressure to maintain mass ow and keep the system

running. It will go back to superheat control when suction

pressure rises above _P setpoint. It should be noted that

superheat control takes priority as a safeguard.

Sd (Low Superheat Alarm Delay Time) - The low super-

heat alarm trigger may be delayed by adjusting the Low Su-

perheat Alarm Delay time. Decreasing the setting will trigger

the alarm sooner. Increasing the setting will extend the time

before an alarm is triggered. The setting is in seconds.

SH (Low Superheat Integral) – The EEV response to low

superheat can be adjusted by increasing the low superheat

integral. By increasing this number, the EEV will close faster

when superheat falls below 2°F. In general, if low superheat

conditions exist for more than 3 minutes in normal opera-

tion, increase the low superheat integral. It is recommended

that the low superheat integral be adjusted slightly above the

normal PID integral to help safeguard against low superheat

conditions.

net (Network Communication Protocol) – The Super-

heat Control offers MODBUS and BACnet communication

protocols. The Superheat Control has been designed follow-

ing industry standard specications. For system set-up and

implementation, reference the following documents:

MODBUS – www.modbus.org

MODBUS Serial Line Protocal and Implementation Guide

v1.02

MODBUS Application Protocal Specification v1.1b3

BACnet – ANSI/ASHRAE Standard 132-2012

nPAr (Network Parity) – An even or odd parity bit is used for

error checking when transmitting a string of binary code via

MODBUS and BACnet. A check bit is added to the end of the

string. The Superheat Control also offers a “no parity” selec-

tion to meet the BACnet standard. It is important to congure

the Superheat Control and the master controller with the same

network parity. The following chart shows an example.

8 BITS

OF DATA

COUNT OF

“1” BITS

9 BITS INCLUDING PARITY

EVEN ODD

00000000 0 000000000000000001

10100010 3 101000101101000100

11010010 4 110100100110100101

11111110 7 111111101111111100

P(Proportional Control Gain) – The proportional gain is

part of the PID control scheme. In general the proportional

gain effects the speed of the EEV in response to the superheat

error. If the proportional gain is too low, the valve may be too

slow to respond. If it is too high, the valve may overreact and

system oscillations may occur. See PID tuning section for

more information.

Prn (Pressure Sensor Range) – The pressure sensor range

must be congured to properly measure suction pressure.

Suction pressure is used to calculate superheat and establish a

minimum and maximum operating pressure, set by _P and

H_P respectively. The Superheat Control offers several pres-

sure range options based on system design and refrigerant

pressure. When Avt is selected, the Superheat Control will

automatically set the pressure range based on the following

refrigerant criteria:

Bulletin 100-50-5.1 – Page 9

R-410A: uses 0-300 psig

R-744 (Subcritical): uses 0-500 psig

All other common refrigerants: 0-150 psig

Ensure that this setpoint matches the corresponding pressure

sensor used on the system.

Ptp (Pressure Sensor Type) – The pressure sensor type,

such as gauge pressure, must be set correctly to properly mea-

sure suction pressure. Ensure that this setpoint matches the

corresponding pressure sensor used on the system.

rer (Refrigerant Type) – The system refrigerant type must

be set up in order to calculate and maintain superheat. The

Superheat Control has a list of commonly used refrigerants.

rnt (Relay On Time Minimum) – The amount of time, in

minutes, that the output of the relay terminals 19 and 20 must

remain on after it is energized. See below for more detail.

rFt (Relay Off Time Minimum) – The amount of time, in

minutes, that the output of the relay terminals 19 and 20 must

remain off after it is de-energized. See below for more detail.

On standalone systems, the rnt and rFt feature may be

used to prevent compressor short cycling when the Superheat

Control is used as a thermostat and Cut In/Cut Out tempera-

ture control is desired. The parameters C_n and Cvt must be

set as the temperature control range along with installation of

the room sensor, T2, to terminals 29 and 30. The minimum on

and off relay parameters should be set according to the com-

pressor manufacturer recommendations. When the Superheat

Control receives a pump down or call for defrost from the dry

contact at T3 temperature sensor input, terminals 27 and 28,

the system will not execute the procedure to pump down until

the minimum relay time has expired.

WARNING: The default setting for the Minimum

Relay On and Off time is 0 minutes. For a stand-

alone system these values may be adjusted to

prevent compressor short cycling.

NOTE: Use caution. An oversized compressor can cause

low case temperature during Minimum Relay On Time

cycle set by rnt.

SHSP (Superheat Setpoint) – The superheat setpoint is the

control variable. The Superheat Control uses system suction

pressure and temperature to calculate and maintain superheat

for a given refrigerant type.

SPS (Stepper Position) – The EEV position is shown on the

display real time in percent open. The position may also be

read through MODBUS or BACnet.

Stt (Stepper Timeout Override) – When the Stepper Time-

out Override is placed in the ‘on’ position, the system will

remain in manual valve mode indenitely and the standard 60

minute timeout will be disabled. It should be noted that the

setpoint parameter menu must be exited before changes are

saved. The valve position shown under SPS will blink when

the timeout is disabled. See Advanced Features section for

more information on manual valve mode.

NOTE: Use caution and monitor superheat while in manu-

al valve mode. To avoid floodback, start with the valve in a

low position. Never leave the system unattended while in

manual mode.

Step (Stepper Valve Type/Stroke) – The electronic valve

type must be set correctly to match the valve that is used on

the system. The type refers to the valve stroke, which typi-

cally is 2500 or 6386 steps.

SvPS (Supermarket Mode) – Supermarket Mode may be

used on large refrigeration systems; typically on controllers

that are used in refrigerated case line ups. This mode has a

unique algorithm to improve both case temperature pull down

and steady state control. If the Superheat Control is used on

standalone systems or systems with quick transient changes

in load, it is recommended to turn this mode off and manually

tune the PID parameters for the system. See PID tuning sec-

tion for more information.

ttp (Temperature Sensor Type) – The temperature sensor

type, such as 3K, must be set correctly to properly measure

temperature and calculate superheat. The Superheat Control

offers several types of temperature sensors; however, all

temperature sensors must be of the same type per controller.

Ensure that this setpoint matches the corresponding tempera-

ture sensor used on the system.

Un_P (Unit Type Pressure) – The pressure sensor units, such

as PSI, must be set correctly to properly measure and display

suction pressure.

Un_ (Unit Type Temperature) – The temperature sensor

units, such as Fahrenheit, must be set correctly to properly

measure and display temperature.

5. Display Networking

A Kelvin IIdremote display unit can be connected to another

Superheat Control in order to set up that controller, view that

controller’s process values, and change setpoints.

To network a Superheat Control without display with a

Kelvin IId(remote display unit):

1. Connect the two controllers with a Cat-5 Ethernet cable.

2. The remote display unit will access the Superheat Control.

3. Set up the Superheat Control (Section 2 - Setup).

To network a Superheat Control without display with a

Superheat Control (with display):

1. Connect the 2 controllers with a Cat-5 Ethernet cable.

2. The Superheat Control with display must have its CAdr

parameter (Display Address) set to 1-99 to enable display

networking. Navigate to “End” in the process variables

display of the Superheat Control with Display and press

the SELECT knob to select a different controller on the

display network. (Controller should display “c”)

Note: “End” is not available if “CAdr” is 0.

3. Turn the SELECT knob to nd the Superheat Control

without display (2is default for the Superheat Control

without display), and press the knob to connect.

4. After a connection is established the display should

switch from “----” to the rmware version of the

Superheat Control with display followed by the setup

screen (if the controller has not been set up as described

in Section 2).

Page 10 – Bulletin 100-50-5.1

The local controller is listed as c. To view a different

controller on the display network, rotate the SELECT knob to

CAdr and then press and release the knob. Rotate the knob to

select the address of a controller. Once the address is selected

it will take a moment to boot up. Setpoints on any control-

ler can be changed as described in Section 3 - Setpoint Menu

Operation.

The CAdr of a Superheat Control without display can also be

set through Modbus.

Multiple Controllers

The CAdr of a Superheat Control without display, display

address 3-99, must be set individually using a Kelvin IIdor

through Modbus.

Three or more controllers can be networked through the

use of a special junction box that is easily fabricated. The

controllers are wired to the junction box using the RJ-45 jacks

and Cat 5 Ethernet cable (see Figure 3 - Display Network-

ing). Superheat Controls can connect to any junction box

ports. Unpowered remote display units (Kelvin IId) should be

connected to specially wired ports designated for the remote

display, shown in red in Figure 4.

Junction Box Fabrication

Category 5E junction boxes can be sourced from L-com.

• Model SMM45-6W can connect 6 controllers (1 remote dis-

play and 5 Superheat controllers with or without displays).

• Model SMM45-12W can connect 12 controllers.

Junction boxes may be daisy-chained to extend the number of

Kelvin II Controls on the network. Kelvin IIdremote displays,

being unpowered, must be connected to an energized port (red

Figure 3 - Display Networking Figure 4 - Wiring the Powered (Red) Jacks

Kelvin IId

Superheat Control

with or without

Display

Superheat Control

with or without

Display

Superheat Control

with or without

Display

Superheat Control

with or without

Display

Junction Box

jacks in Figure 3), with a powered controller plugged into the

other red jack. If all the networked controllers are powered

models, no special wiring (red jacks) is necessary.

To wire a junction box, punch down all blue and blue/white

wires. To wire a pair of energized (red) jacks, punch down

brown and brown/white wires between 2 jacks. See Figure 4.

6. Controller Networking

The Sporlan Superheat Control can communicate with a

Modbus RTU communication master or BACnet MSTP mas-

ter via RS485. See Appendix J - Modbus Memory Map and

Appendix K - BACnet Map.

The serial settings are:

• 9600 baud (default), 19200 baud, 38400 baud

• 8 data bits

• 1 stop bit

• Even parity (default), odd parity, no parity

Scaling

For better precision, scaling is used for Bar or Celsius units.

PSI and Fahrenheit are whole numbers and have no scaling.

Celsius values transferred via Modbus are 10X. For example,

a value of 45 will be transferred for the superheat when the

actual superheat temperature is 4.5°C. Remember this when

changing a setpoint.

Bar values transferred via Modbus are 100X. For example a

value of 1034 will be transferred for the Maximum Operating

Pressure when the actual pressure is 10.34 Bar. Remember

this when changing a setpoint.

Bulletin 100-50-5.1 – Page 11

Figure 5 - RS-485 Wiring

Controller 1

GND

RT

RT

Communication

Master

A B

B

Controller n

RT- Termination

resistor

B

A

Controller n-1

GND

B

A

AGND

Setup

The Sporlan Superheat Control can be networked to com-

municate process variables back to a master controller. This

information can be used for verifying system performance or

updating individual setpoints via RS-485 and PC interface.

Data can be accessed remotely through the master controller.

For further information on remote monitoring, see the docu-

mentation for the master controller.

Prior to connecting the network, each controller must be

assigned a separate address on the Modbus or BACnet net-

work, Addr. Refer to Section 3 – Setpoint Menu Operation to

enter the Setpoint menu. Once in the Setpoint menu, scroll to

Add and assign each controller on the network an individual

Communication

Master Figure 6 - Daisy Chain

Network Configuration

address. Note that no two controllers can have the same

address. Default address for each controller is ‘1’.

NOTE: Add is the controller’s RS-485 address and CAd is

the controller’s display address.

RS-485 Connection Requirements

See Figure 5 - RS-485 Wiring.

Wire Type: Use Belden 8760 or equivalent

Maximum Number of Network Nodes: 100

Maximum Run Length: 4000 ft

Recommended Network Configuration: Daisy Chain, a

single continuous transmission line from one end to the other.

Other configurations involving triple-lug connections, such as

star, are not recommended. See Figure 6.

Noise Reduction: Termination resistance (RTin Figure

5) is recommended to reduce reflections and noise on the

data transmission lines. Place the resistance at the extreme

ends of the cable, with the resistance value matching the

characteristic impedance of the transmission line (typically

120 ohms for twisted pair cables).

Shielding prevents noise from EMI sources. If the cable is

shielded, connect the shield to earth ground at one end only.

NOTE: Do not connect shield to RS485 GND.

Keep RS485 wiring away from high voltage AC lines to

reduce noise and data errors on the communication lines.

RS485 communication cable should be placed perpendicular

to AC lines at any intersection.

Grounding: Connect a third conductor to RS485 GND (ter-

minal 13) to prevent ground potentials between nodes. This

conductor should be included in the shield of the twisted pair

cable to prevent noise. NOTE: Do not connect RS485 GND

to earth ground.

Third Party Controllers: To avoid nuisance “network

errors”, the use of third-party controllers on the same RS485

network with Sporlan controllers is not recommended.

Refer to the documentation supplied with the communication

master for additional RS485 network requirements.

7. PID Tuning

If temperature pull down is satisfactory, then the default

control scheme (supermarket mode) should be used. The PID

values may be adjusted if superheat is not stable. If super-

heat is oscillating around setpoint at steady state conditions,

reduce PID settings to half of existing values. If pull down is

not satisfactory, then the Superheat Control can be configured

into a standard PID scheme that can be fully adjustable. This

feature can be accessed by entering the Setpoint Parameters

Menu as described in Section 3. Go to parameter SvPS, super-

market mode, and change its value to FF.

NOTE: Only experienced professionals should access

this feature. System stability and performance may be

improved by adjusting PID.

The Superheat Control is factory programmed with default

Proportional–Integral–Derivative (PID) settings that will

Page 12 – Bulletin 100-50-5.1

provide efcient control. It may be necessary, however, to

ne tune the PID settings in applications where systems expe-

rience rapid transient conditions (such as frequent “impulse”

changes in loading or mass ow rates).

In most instances, adjustments to the PI setpoints are ad-

equate. If tuning is needed, see Section 3 - Setpoint Menu

Operation to enter the PID setpoint menu. The following

guidelines should be followed:

• p (Proportional Coefcient) - Increase value to

increase valve response to superheat.

• (Integral Coefcient) - Increase value to increase

valve response to superheat over a given time period.

• d (Derivative Coefcient) - Increase value to increase

valve response to rate of change in superheat.

•

• When PID adjustments are made, allow adequate time for

the system to respond to the changes.

When the superheat is oscillating to extremes, the Propor-

tional and/or the Integral value may be too high. If superheat

is slow to react to a transient system change, then the Propor-

tional and/or the Integral value may be set too low.

NOTE: Not all refrigeration systems are designed alike.

Use caution when tuning PID setpoints.

8. Troubleshooting

Troubleshooting Recommendations

As with any refrigeration component troubleshooting, actual

system conditions should be verified with a gauge set and a

calibrated temperature sensor (i.e verify actual superheat and

refrigerant condition). This system information is valuable in

determining whether it is component related or system related.

For systems or applications that experience light loads on

the Superheat Control circuit, it is important that the heat

exchanger and refrigerant lines are sized correctly. This will

ensure proper oil return and will minimize the effects of oil

logging in the heat exchanger. Many heat exchanger manufac-

turers recommend a hot gas bypass for loads below 50%.

Sensors

Failed sensors will trigger an alarm. An alarm code will show

which sensor is mis-wired, disconnected, or faulty. The alarm

will persist until the problem is corrected.

Failed temperature sensors may read extremely low or

innite resistance when tested with an ohmmeter. Readings

should be taken with the sensor disconnected from the Super-

heat Control. A missing or disconnected temperature sensor

will read 60 on the controller.

Temperature sensor output can be checked by measuring the

DC voltage across the sensor wires and consulting the tables

in Appendices L, M, N.

Pressure transducers must be installed tight enough to

depress the valve stem in the tting. Failure to do so will

result in erroneous pressure readings and possibly leaks.

Pressure transducers should be tested while connected to the

controller and powered. Test at the controller terminals. Volt-

age between terminals 34 and 35 should be 4.8 - 5.2 volts DC.

Voltage between 33 and 34 should be between 0.5 and 4.5

volts DC. See Table 1 - Pressure Transducer Wire Colors.

To test the accuracy of the transducer, use a gauge set to obtain

the actual system pressure. For volts-to-pressure conversion,

measure the voltage between terminals 33 and 34. Identify the

pressure transducer used and nd the correct range Prn in

Table 3. Substitute the measured voltage (v) into the formula

in the PSI column. The result should be within 3 psi of the ac-

tual system pressure shown on the gauge set. If not, check the

transducer for proper installation, correct Schrader valve, and

verify the pressure range identied on the transducer.

To test the transducer cable, disconnect the cable from the

transducer and check for 4.8 - 5.2 volts between terminals +

and –. See Figure 7 - Pressure Sensor Cable.

Alarms

The Superheat Control will display A when the system

detects a fault. The alarm feature noties the user on the dis-

play and through MODBUS or BACnet (when used). During

alarm, a voltage difference will occur across terminals 11/12

to support an external alarm relay. Note: Terminal 11 is not

part of the controller’s ground. See Table 4 for a list of alarms.

LABEL COLOR Prn PSI

Green 150 (v-.5) x 37.5

None / Silver 300 (v-.5) x 75

Yellow 500 (v-.5) x 125

Pink 652 (v-.5) x 163

Table 3 - Pressure Transducer Specifications

Figure 7 - Pressure Sensor Cable

S

–

+

+Black

–Green

S White

Bulletin 100-50-5.1 – Page 13

Troubleshooting

SYMPTOM CHECK

Will not power up Wiring terminals for power at transformer and controller

Supply voltage (see Appendix E - Technical Specifications)

Superheat below

setpoint

PressureTransducer Range (correct transducer set up in controller; 0-300, etc)

PressureTransducer Type (correct transducer set up in controller; gauge/sealed vs absolute)

Temperature Sensor Type (correct sensor set up in controller; see Appendix I - Sensor

Installation)

Temperature Sensor wiring (ensure sensor locations are not mismatched)

Foam insulation on piping and sensors

Superheat above

setpoint

Liquid condition entering expansion valve

PressureTransducer Range (correct transducer set up in controller; 0-300, etc)

Temperature Sensor Type (correct sensor set up in controller; see Appendix I - Sensor

Installation)

EEV (correct valve set up in controller; 1596, 2500 steps, etc)

EEV sizing (if EEV position in controller is at 100% when symptom exists, EEV may be

undersized)

Heat exchanger sizing

Proper system refrigerant charge

Oil return (oil logging in heat exchanger)

Liquid line filter (clogging or excessive pressure drop)

No Superheat Wiring terminals (power) at transformer and controller

Proper system refrigerant charge

PressureTransducer Range (correct transducer set up in controller; 0-300, etc)

PressureTransducer Type (correct transducer set up in controller; gauge/sealed vs absolute)

Temperature Sensor Type (correct sensor set up in controller; see Appendix I - Sensor

Installation)

Temperature Sensor wiring (ensure sensor locations are not mismatched)

Foam insulation on piping and sensors

Superheat unstable Wiring terminals (power) at transformer and controller

Wiring terminals (sensors) at controller

Sensor locations

Sensor operation (See additional information under Section 8 - Troubleshooting)

Proper heat exchanger flow direction

Stability of head pressure control valves (upstream of EEV)

Stability of suction pressure control valves (downstream of EEV)

Stability of rack controller (verify compressors are not short cycling)

Controller PID setting (See Section 7 - PIDTuning)

No Communication Wiring at controller and master communication board

Addresses of controllers (see Section 6 - Controller Networking)

Communication errors Wiring terminals at controller and master communication board

Network wiring from controller to master communication board (see Section 6 -

Controller Networking)

Proper network wire grounding (see Section 6 - Controller Networking)

Termination resistors (see Section 6 - Controller Networking)

Network parameters in controller and master communication board (baud rate, parity,

etc; see Section 6)

Third-party controllers on Control network

Setpoints not saved ESC must be set within 60 seconds of changes being made

Page 14 – Bulletin 100-50-5.1

ALARM DESCRIPTION CAUSE SYSTEM ACTION

PSA Pressure Sensor

Alarm

1. Voltage across terminals 33 and 34 less

than 0.3VDC

2. Voltage across terminals 33 and 34 greater

than 4.6VDC (System pressure greater than

operating range of transducer, set by P)

Note: If HPA is set to , then PSA for high

pressure will not activate.

Opens terminals 19 and 20 and

closes EEV (pumpdown) until proper

pressure input returns. Alarm is

generated and a voltage difference

will occur across terminals 11/12 (for

use with an external alarm relay)

tSA vt Temperature

Sensor Alarm

Voltage across terminals 31 and 32 is outside

of the normal range of the thermistor.

Normal ranges: 2K = 0.36VDC to 4.5VDC

3K = 0.39VDC to 4.9VDC

10K = 0.3VDC to 4.6VDC

98.6K = 0.36VDC to 4.8VDC

Note: Display will show 60 if temperature

sensor is not installed.

Opens terminals 19 and 20 and

closes EEV (pumpdown) until proper

temperature input returns. Alarm is

generated and a voltage difference

will occur across terminals 11/12 (for

use with an external alarm relay)

SHA Low Superheat

Alarm

System operates less than 2°F superheat for

the delay time set by Sd.

Will use 5Hparameter to close the

EEV quicker. Alarm is generated and

a voltage difference will occur across

terminals 11/12 (for use with an ex-

ternal alarm relay). Normal operation

will resume and alarm will clear once

system superheat reaches 2°F.

HSHA High Superheat

Alarm

System operates more than 2°F above SHSP

(setpoint) for the delay time set by 5d.

If 5HF is set to : No system

response. Alarm is generated and a

voltage difference will occur across

terminals 11/12 (for use with an exter-

nal alarm relay).

If 5HF is set to n: EEV drives to 0%

position. Alarm is generated and a

voltage difference will occur across

terminals 11/12. Note: A power cycle

is required to resume normal opera-

tion if h5HF is set to ‘on’ and the sys-

tem goes into high superheat alarm.

Table 4 - Alarm Actions

Bulletin 100-50-5.1 – Page 15

DISPLAY DESCRIPTION OPTIONS

StEp Valve Type

Display Readout Description

156 1596 Step Bipolar Valve

1 3193 Step Bipolar Valve

500 2500 Step Bipolar Valve

66 6386 Step Bipolar Valve

500 500 Step Unipolar Valve

rEFr

RefrigerantType

NOTE: Select the actual

refrigerant used in the system.

Display Readout Description

r R-22

14 R-134a

40 R-402A

404 R-404A

40 R-407A

40C R-407C

410 R-410A

41 R-417A

4 R-422A

4d R-422D

r50 R-507A

r44 R-744

45 R-245FA

re5 R-E5

4 R-438A

401 R-401B

40 R-408A

50A R-508A

50 R-508B

40 R-407F

44 R-434A

444 R-444B

44 R-448A

450 R-450A

44 R-449A

45 R-452A

51 R-513A

dr R-DR2 (R-1336MZZ)

r R-32

45 R-452B

14 R-1234ZE

14 R-124

45A R-458A

45A R-453A

tt4p Temperature SensorType

Readout Description

tp 3KThermistor

tp 2KThermistor

tP 98.6KThermistor

tP10 10KThermistor

Pt4p Pressure SensorType

Display Readout Description

AS Absolute PressureType

AU Gauge (Sealed)

PressureType

Un_t Temperature Units

Display Readout Description

FAH Fahrenheit

CES Celsius

Un_p Pressure Units

Display Readout Description

PS Pounds per square inch

A Bar units

Counterclockwise

Clockwise

Default values are highlighted.

APPENDIX A - Setup Menu

Page 16 – Bulletin 100-50-5.1

APPENDIX B - Process Values

PROCESS DESCRIPTION RANGE

End End display session with controller Controller display address CAD must be reset *

SvPH Superheat (tout-tsat) 0 to 165°F (0 to 91.6°C)

SvcP Suction Pressure Depends on pressure sensor range and type

-14.7 to 652 PSI (-1.01 to 44.95 Bar) Max. range

tSAt Saturation Temperature -60 to 150°F (-51.1 to 65.6°C)

tvt Suction Temperature -60 to 150°F (-51.1 to 65.6°C)

CtP Case / RoomTemperature -60 to 150°F (-51.1 to 65.6°C)

PSn EEV Position (% of max stroke) 0 to 100% Open

S Auxiliary Temperature 1

or Pumpdown State

-60 to 150°F (-51.1 to 65.6°C) if input is within range for a valid

temperature reading.

Otherwise:

Display Description

C Cool Mode - High Resistance or open

on T3

Pdn Pumpdown Mode - Low Resistance or

short on T3

S4 Auxiliary Temperature 2 -60 to 150°F (-51.1 to 65.6°C)

rEA Relay Status

Display Description

dEn Relay is de-energized (open)

En Relay is energized (closed)

Stt System State

Display Description

SEtU Setup Mode

FF Off Mode

C Cool Mode

Pdn Pumpdown Mode

StP Manual Valve Override Mode

AS Controller Alarms

Display Description

nnE No Active Alarms

PSA Pressure Sensor Failure

tSA Suction Temp Sensor Failure

SHA Low Superheat Alarm

HSHA High Superheat Alarm

*If the controller display is alternating between Ctr, and either a number 1-99 or c, then scroll to cand press the

SELECT knob to view the local controller attached to this display. Press and hold the SELECT knob for approximately 5

seconds and enter password 111 when prompted. Scroll to CAD(Controller address) and set it to 0. Exit the setpoint menu.

NOTE: The controller’s default menu is the Process Values Menu.

Bulletin 100-50-5.1 – Page 17

PARAMETERS

ESC Escape and save settings -

SHSP Superheat Setpoint

Change to desired Superheat Setpoint

5 to 45°F (2.7 to 25°C)

Default is 10°F (5.5°C)

rEFr

Chosen at

Setup

RefrigerantType

Change to desired RefrigerantType

r R-22

14 R-134a

40 R-402A

404 R-404A

40 R-407A

40C R-407C

410 R-410A

41 R-417A

4 R-422A

4d R-422D

r50 R-507A

r44 R-744

45 R-245FA

re5 R-E5

4 R-438A

401 R-401B

40 R-408A

50A R-508A

50 R-508B

40 R-407F

44 R-434A

444 R-444B

44 R-448A

450 R-450A

44 R-449A

45 R-452A

51 R-513A

dr R-DR2 (R-1336MZZ)

r R-32

45 R-452B

14 R-1234ZE

14 R-124

45A R-458A

45A R-453A

d_n Delay On 0 to 60 seconds Default is 0

d Delay Off 0 to 60 seconds Default is 0

d_t Delay Step Position Open of Valve 0 to 100% Default is 0%

_t Bleed Step Position of Valve % 0 to 15.0% Default is 0.0%

_d Bleed DelayTime 0 to 9999 seconds Default is 0

_p Low Operating Pressure

Values depend on pressure sensor range

and type. Set Prn first, then EXIT, then set

this value.

-14.7 to 485 psi (-1.03 to 9.30 Bar) max.range

H_p Maximum Operating Pressure

Values depend on pressure sensor range

and type. Set Prn first, then EXIT, then set

this value.

5 to 652 psi (1.37 to 44.95 Bar) max. range

C_n Cut-inTemperature -59 to 125°F (-50.5 to 51.6°C)

Default is -59 (-50.5 C)

Cvt Cut-outTemperature -60 to 124°F (-51.1 to 51.0°C)

Default is -60 ( -51.1 C)

rnt Minimum Relay OnTime 0 to 10 Default is 0

rFt Minimum Relay OffTime 0 to 10 Default is 0

HCP Max Valve Capacity 0 to 100% Default is 100

Sup Supermarket Mode ON or OFF Default is ON

dnd Superheat Control Deadband 1 (+/-1°F) or 2 (+/-2°F) Default is 2

APPENDIX C - Setpoint Parameters

Counterclockwise

Clockwise

Default values are highlighted.

Page 18 – Bulletin 100-50-5.1

PARAMETERS

P Proportional Coefcient

Integral Coefcient

d Derivative Coefcient

SH Low Superheat Integral 1 to 100 Default is 25

StEp

Chosen at

Setup

Valve Type

156 1596 Step Bipolar Valve

1 3193 Step Bipolar Valve

500 2500 Step Bipolar Valve

66 6386 Step Bipolar Valve

500 500 Step Unipolar Valve

SPS Manual Valve Position 0 to 100% Open

Default is current valve position

nEt NetworkType nbUS (Modbus) or bACn (BACnet)

Addr Network Address 1 to 255 Default is 1

vD Baud Rate

6 9600

1 19200

4 38400

nPAr Network Parity

nne No Parity

EvEn Even Parity

dd Odd Parity

Un_P Pressure Units P Pounds Force Per

Square Inch

Ar Bars

Un_t Temperature Units FAHr Fahrenheit

CES Celsius

tt4p

Chosen at

Setup

Temperature SensorType

Readout Description

t4p 3K thermistor

t4p 2K thermistor

tP 98.6K thermistor

tP10 10K thermistor

Pt4p

Chosen at

Setup

Pressure SensorType

AS Absolute PressureType

AU Gauge (Sealed)

Pressure Type

Prn Pressure Sensor Range

Avt Based on Refrigerant

150 0-150 psi

00 0-300 psi

500 0-500 psi

65 0-652 psi

CAP Pressure Sensor Calibration Offset -5 to 5 psi (-.34 to .34 Bar)

Default is 0 psi (0.00 Bar)

C1 SuctionTemperature

Calibration Offset

-5 to 5°F (-2.7 to 2.7°C)

Default is 0

C T2 / RoomTemperature

Calibration Offset

-5 to 5°F (-2.7 to 2.7°C)

Default is 0

C T3Temperature Calibration Offset -5 to 5°F (-2.7 to 2.7°C)

Default is 0

C4 T4Temperature Calibration Offset -5 to 5°F (-2.7 to 2.7°C)

Default is 0

p High Pressure Alarm On or Off Default is On

SHF High Superheat Failsafe On or Off Default is Off

tt Manual StepperTimeout Override On or Off Default is Off

Sd Low Superheat Alarm Delay 30 to 3600 seconds Default is 30

Sd High Superheat Alarm Delay 1 to 240 minutes Default is 60

CAdr Controller Display Address 0 to 99

Default is 0 for display, 2 for w/o display

APPENDIX C - Setpoint Parameters (continued)

Clockwise

Counterclockwise

Default values are highlighted.

SUPS ON SUPS OFF

0 to 18 Default is 6 0 to 50 Default is 6

0 to 24 Default is 12 0 to 100 Default is 12

0 to 4 Default is 1 0 to 50 Default is 1

Bulletin 100-50-5.1 – Page 19

APPENDIX F - Controller Status

DISPLAY DESCRIPTION

C Compressor running

pdn Superheat Control Off (Pumpdown)

Compressor not running

APPENDIX G - Miscellaneous Displays

DISPLAY DESCRIPTION

End Press SELECT knob to exit menu

AD The wrong password has been entered

c Shows that readings refer to current controller

Ctr Shows which controller is displayed

ELECTRICAL

Supply Voltage

20-26VAC 50/60Hz or 22-26.6VDC; Class II input.

40VA is recommended for each controller

Digital Inputs

0-5VDC Maximum Range

Interface to dry contact or open collector

Analog Inputs

4 Temperature Sensors; 2K, 3K, 10K or 98.6K Ohm

1 Pressure Transducer .5 - 4.5VR

Relay Outputs

100-240VAC, 3A ind/250V

22-28VDC, 250mA digital output (For Alarm Relay)

Digital Display

LED - Red, 7 segment, 4 digit

Indicators

LED - Red, Power

User Interface

Optical Encoder (SELECT knob)

Data Interface

RS 485, Modbus, BACnet

MECHANICAL

Operating Temperature

-40°F to 158°F (-40°C to 70°C)

Humidity

0-95%RH (Non-Condensing)

Enclosure

PC - Light Gray

Wiring

Screw terminal

Mounting

DIN Rail - EN 50 022

COMPLIANCE

Environmental

RoHS

WEEE

Electrical

CE

UL/CUL (Recognized per 873)

FCC (Class A, part 15)

C-tick

APPENDIX E - Technical Specifications

APPENDIX D - Accessories

DESCRIPTION ITEM

NUMBER NOTES

Superheat Controls

Superheat Control with Display

Superheat Control without Display

Kelvin IId

952567

952569

952568

Standalone Controller with display

Standalone Controller, no display

Remote display unit

Power Supply 953444 Kelvin power supply 100-240 VAC/24VDC

Parker Sporlan Temperature Probes

2K Sensor

3K Surface Sensor (black)

3K Air Sensor (black)

10K Surface Sensor (orange)

10K Surface Sensor (blue)

10K Surface Sensor (red)

10K Air Sensor (green)

98.6K Surface Sensor (white)

952662

230545

230546

230072

230076

230078

230073

952565

Used with or without well

20 ft. Surface only

20 ft. Air only

20 ft. Surface only

20 ft. Surface only

20 ft. Surface only

20 ft. Air only

Surface only

Parker Sporlan Pressure Transducers*

PSPT0150SVSP-S

PSPT0300SVSP-S

PSPT0500SVSP-S

PSPT0652SVSP-S

952572

952574

952576

952579

0-150 psis transducer (all other refrigerants)

0-300 psis transducer (R410A)

0-500 psis transducer (R744)

0-652 psis transducer (R744)

Transducer Cables

PSPT000000CP50

PSPT000000CP20

953100

953192

5 meter (16 ft.) cable

2 meter (6.5 ft.) cable

Troubleshooting Accessories

SMA-12 953276 Handheld digital instrument for testing EEV performance.

*Select one per controller based on refrigerant.

Page 20 – Bulletin 100-50-5.1

APPENDIX H - Wiring Diagram

Note: Use caution when working

around high voltage components.

Dry Contacts (T3)

Evap. Outlet Temp. (T1)

Room Temp. (T2)

White

Green

Black

Black

24V

AC/DC

RS485

White

Green

Red

B-

Ground

A+

Suction Temperature

Sensor

Pressure

Transducer

Pumpdown

Relay

L1

L2

EEV

Load

Line

Liquid Line

Solenoid Valve

10”-14”

minimize

1”- 2” ideal

Evaporator

Aux. Temp. (T4)

Internal Relay

Rated 240v, 3A

*

*T3 can be used as an Auxillary Temperature Input or a Pumpdown Input signal.

Note: Piping and sensor insulation is not shown.

Refer to the evaporator manufacturer’s

installation/orientation instructions.

White: Signal

Green: Ground

Black: 5 VDC

Black

White

Green

Red

Return Air

+ 22-28 VDC 250mA

- Signal Output for Alarm Relay

For 500 Step Sporlan Unipolar Valve

4 -> Gray Wire

5 -> Orange Wire

6 -> Yellow Wire

7 -> Red Wire

8 -> Black Wire

Other manuals for Superheat

1

Table of contents

Other Sporlan Controllers manuals