670 Series

Installation Guide

D200109X014

English – February 2015

Introduction

This installation guide provides instructions for

installation, startup and adjustment. To receive a copy of

the instruction manual, contact your local Sales Office or

view a copy at www.fisher.com. For further information

refer to: 670 Series Instruction Manual, D200109X012.

PED Categories

This product may be used as a safety accessory

with pressure equipment in the following Pressure

Equipment Directive categories. It may also be

used outside of the Pressure Equipment Directive

using sound engineering practice (SEP) per table

below. For information on the current PED revision

see Bulletin: D103053X012.

PRODUCT SIZE CATEGORIES FLUID TYPE

1/4 NPT SEP 1

Specifications

Description (Regulator Type Number)

See Table 1

Pressure Ratings(1)

See Table 1

Proof Test Pressure

All Pressure Retaining Components have been

proof tested per Directive.

Installation

!

WARNING

Only qualified personnel should install

or service a regulator. Regulators

should be installed, operated and

maintained in accordance with

international and applicable codes

and regulations and Emerson Process

Management Regulator Technologies,

Inc. instructions.

If the regulator vents fluid or a leak

develops in the system, it indicates that

service is required. Failure to take the

regulator out of service immediately

may create a hazardous condition.

Personal injury, equipment damage

or leakage due to escaping fluid

or bursting of pressure-containing

parts may result if this regulator is

overpressured or is installed where

service conditions could exceed the

limits given in the Specifications

section, or where conditions exceed

any ratings of the adjacent piping or

piping connections.

To avoid such injury or damage,

provide pressure-relieving or pressure-

limiting devices (as required by

the appropriate code, regulation or

standard) to prevent service conditions

from exceeding limits.

Additionally, physical damage to the

regulator could result in personal injury

and property damage due to escaping

fluid. To avoid such injury and damage,

install the regulator in a safe location.

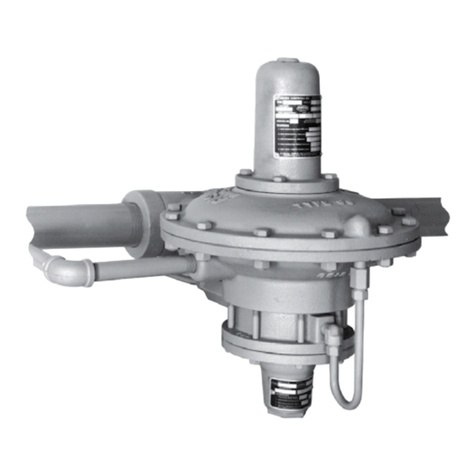

Clean out all pipelines before installation of the

regulator and check to be sure the regulator has

not been damaged or has collected foreign material

during shipping. For NPT bodies, apply pipe

compound to the external pipe threads. For flanged

bodies, use suitable line gaskets and approved piping

and bolting practices. Install the regulator in any

position desired, unless otherwise specified, but be

sure flow through the body is in the direction indicated

by the arrow on the body.

Note

It is important that the regulator be

installed so that the vent hole in the

spring case is unobstructed at all times.

For outdoor installations, the regulator

should be located away from vehicular

traffic and positioned so that water, ice

and other foreign materials cannot enter

the spring case through the vent. Avoid

placing the regulator beneath eaves or

downspouts and be sure it is above the

probable snow level.

1. The pressure/temperature limits in this installation guide and any applicable standard or code limitation should not be exceeded.