AA190DAGSeriesAirMotor‐DrivenTankWasher|11/11/2010|REV.1

2

TABLE OF CONTENTS

FORWARD ...................................................................................................................................3

INTRODUCTION ..........................................................................................................................3

SPECIFICATIONS AND OPERATING CONDITIONS ..........................................................................4

DATA SHEETS

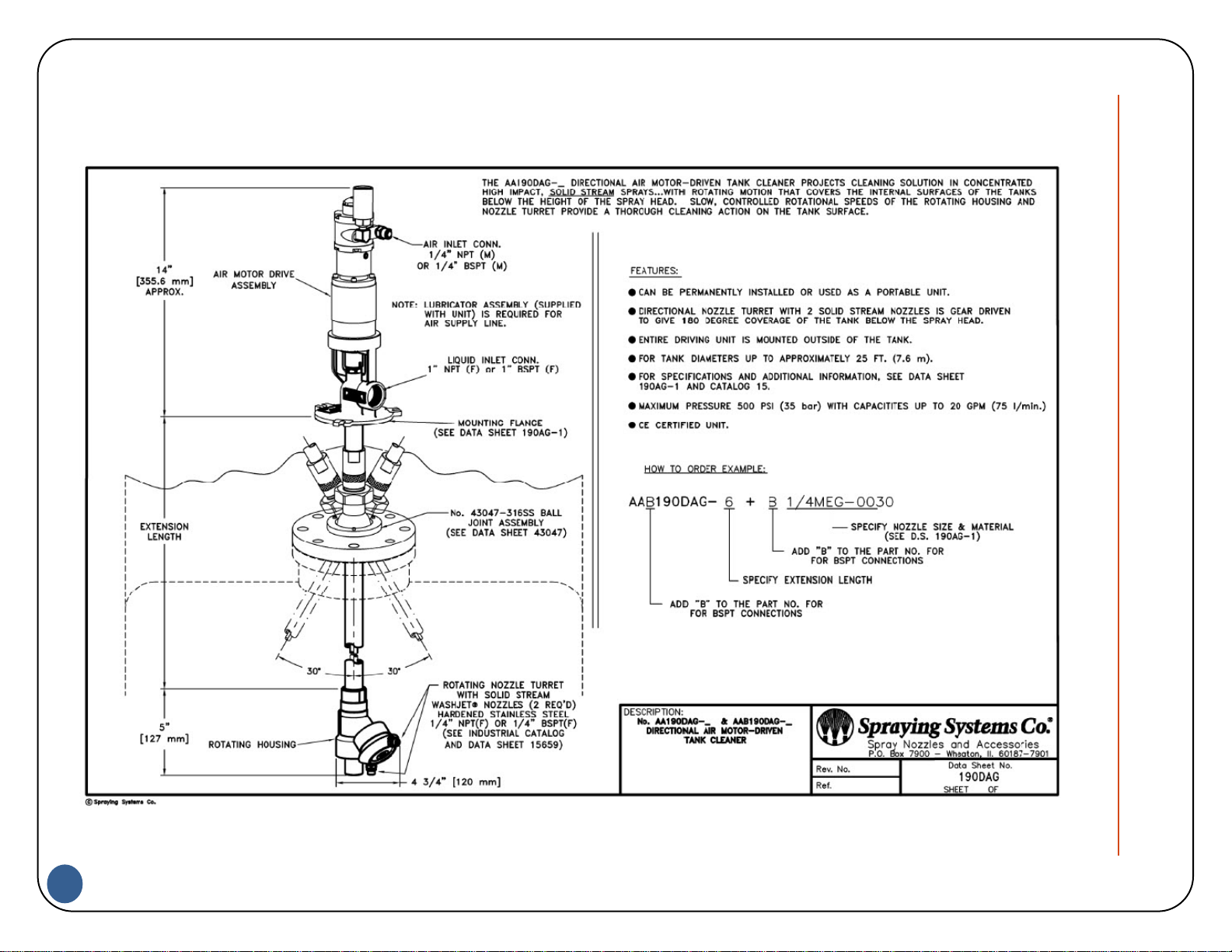

AIR MOTOR DRIVEN TANK CLEANER FEATURES AND ORDERING – DS 190DAG................................5

TANK CLEANER DIMENSIONAL DATA AND FLOW RATE DATA – DS 190DAG-1..................................6

AIR MOTOR DRIVEN TANK CLEANER FEATURES AND ORDERING – DS 190DAGH .............................7

HIGH PRESSURE TANK CLEANER DIMENSIONAL DATA AND FLOW RATE DATA – DS 190DAGH-1........8

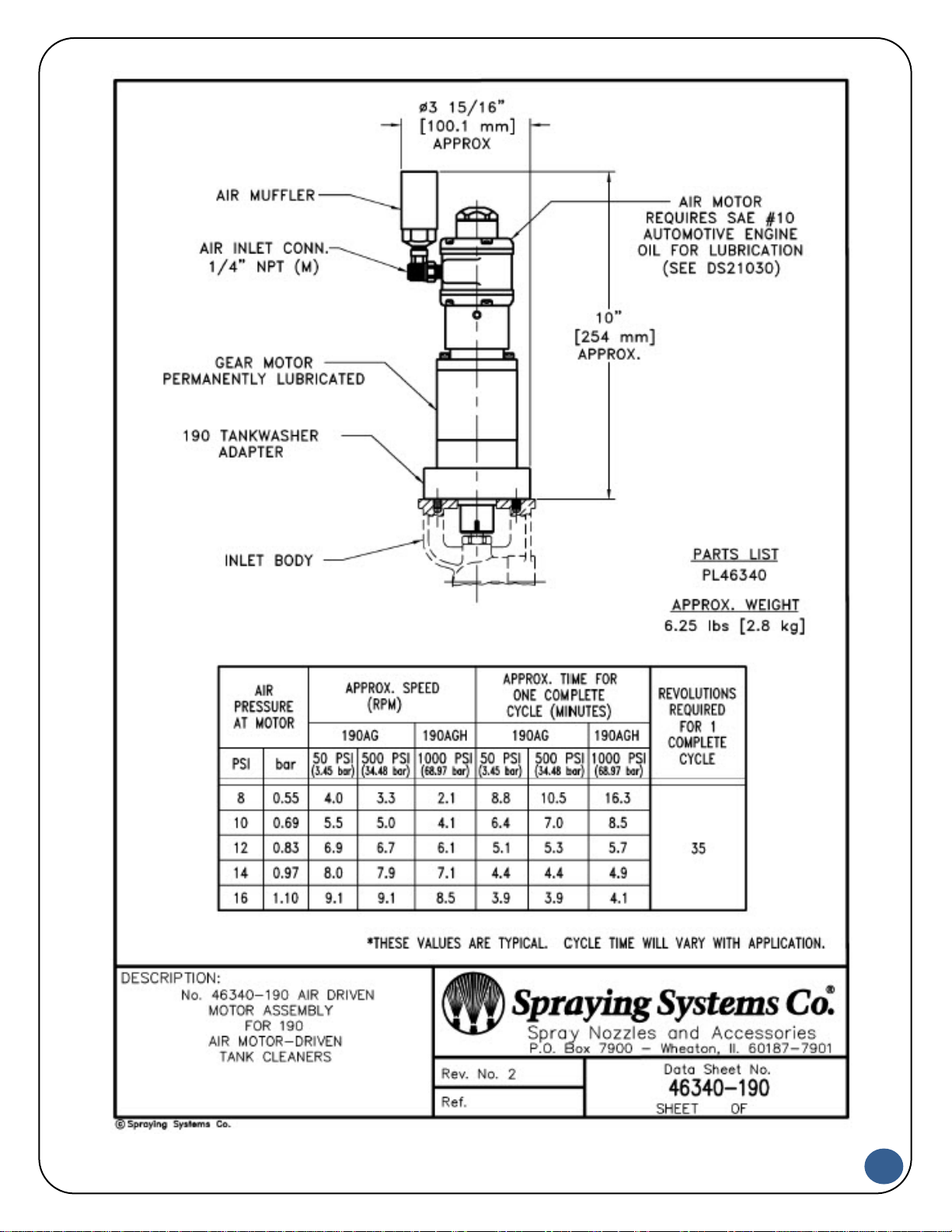

DRIVE ASSEMBLY PERFORMANCE AND DIMENSIONAL DATA – DS 46340-190.....................................9

SAFETY PRECAUTIONS ............................................................................................................... 10

INSTALLATION

CONNECTIONS ....................................................................................................................10-11

MOUNTING ............................................................................................................................. 11

LIQUID INLET CONNECTION..................................................................................................... 11

MECHANICAL CLEARANCES ..................................................................................................11-12

GROUNDING ........................................................................................................................... 12

HIGH IMPACT SPRAYS ............................................................................................................... 12

AIR MOTOR LUBRICATION........................................................................................................ 13

AUTOMATIC LURICATION ........................................................................................................ 13

OPERATION ............................................................................................................................... 13

MAINTENANCE

REMOVAL / REPLACEMENT OF SPRAY NOZZLES ......................................................................... 14

REMOVAL / REPLACEMENT OF NOZZLE HUB BUSHINGS .............................................................. 14

REMOVAL OF AIR MOTOR DRIVE............................................................................................... 14

REMOVAL / REPLACEMENT OF AIR MOTOR DRIVE COUPLING..................................................... 14

REMOVAL OF UPPER SHAFT SEAL AND LOWER BUSHING RETAINER .........................................14-15

REASSEMBLY OF UNIT .............................................................................................................. 15

REPLACEMENT OF AIR MOTOR DRIVE........................................................................................ 15

PARTS LISTS

AIR MOTOR DRIVEN TANK CLEANER – PL 190DAG ...................................................................... 16

HIGH PRESSURE AIR MOTOR DRIVEN TANK CLEANER FEATURES AND ORDERING – PL 190DAGH.... 17

AIR MOTOR DRIVE ASSEMBLY – PL 46340 .................................................................................... 18

LUBRICATOR ASSEMBLY – PL21030............................................................................................. 19

WARRANTY ............................................................................................................................... 20

MAINTENANCE RECORD ............................................................................................................ 21

DECLARATION OF CONFORMITY ............................................................................................... 22

•