5Installation

66

InstallationInstallation

WARNING!

ELECTRIC SHOCK HAZARD

Disconnect the mains supply

before working on the unit. DO

NOT TOUCH PRESETS, SWITCHES

AND JUMPERS! Always use the

correct insulated adjustment

tools.

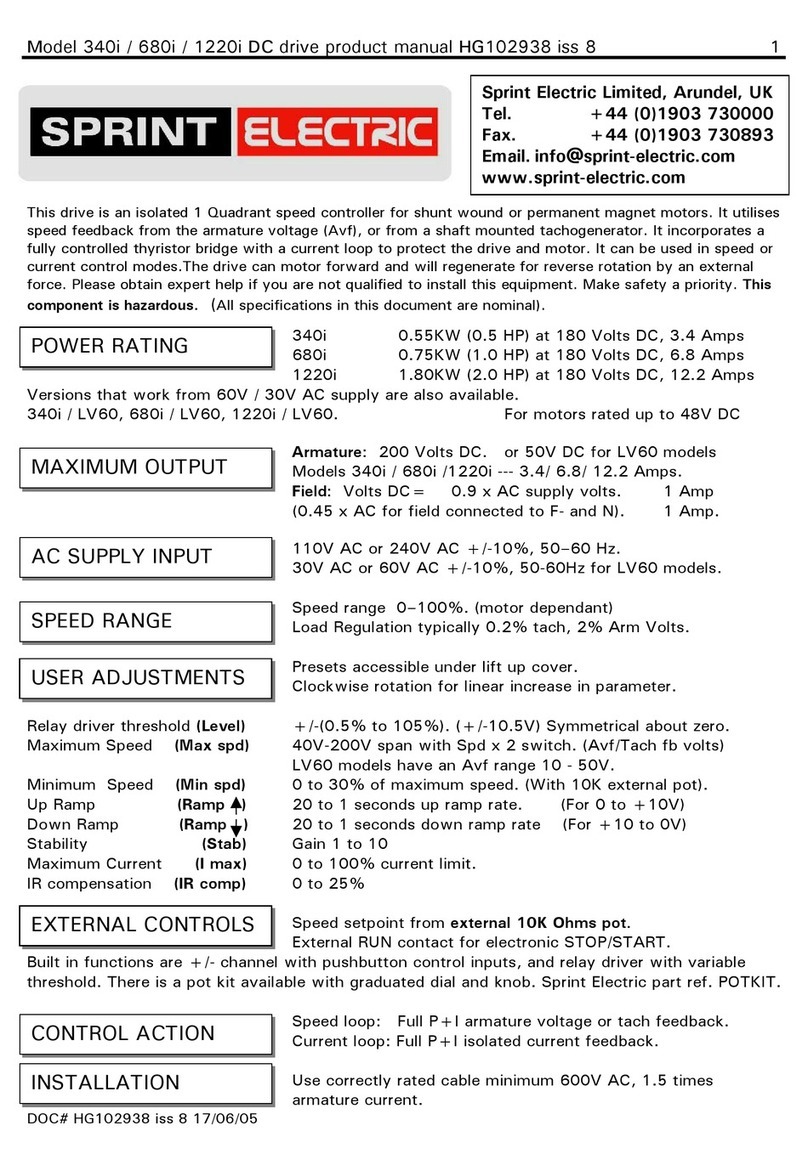

6.1

Motor installation

• Foot-mounted motors must be level and

secure.

• Ensure accurate alignment of the motor

shaft and couplings.

• Do not hammer pulleys or couplings

onto the motor shaft.

• Protect the motor from ingress of

foreign matter during installation.

Earthing: Connect the motor to the system

enclosure earth.

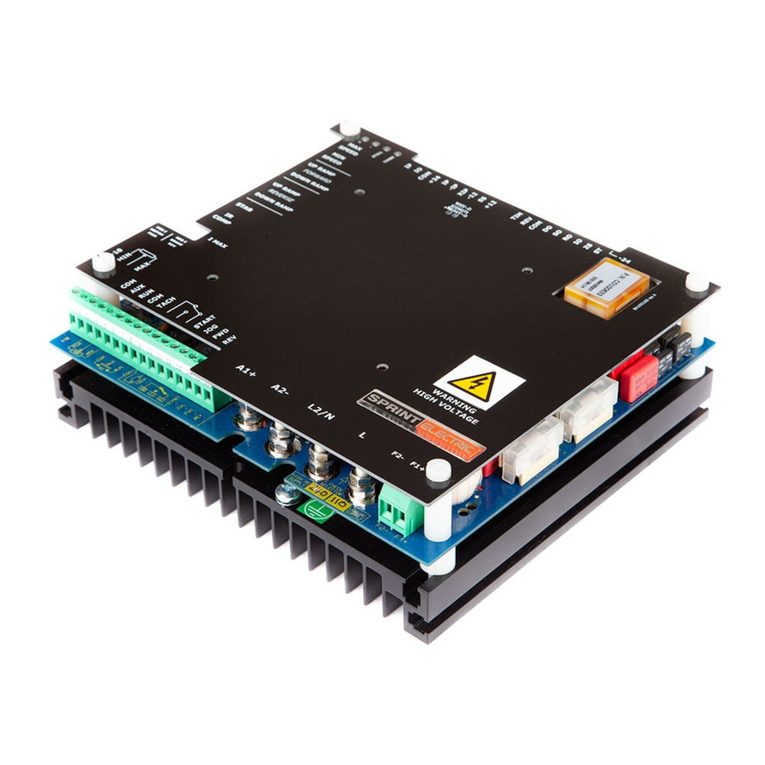

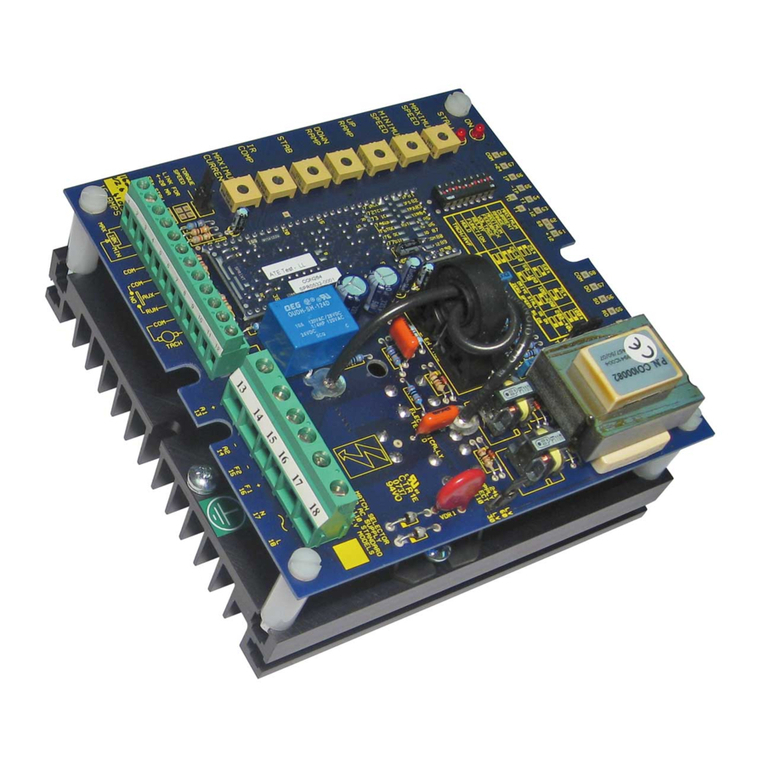

6.2

Drive Installation

Requirements during installation and

operation:

HEATSINK AIRFLOW: Optimise the heatsink

airow.

• Avoid vibration.

• Protect the drive from pollutants.

• The ambient operating temperature

must be within -10ºC and +40ºC.

POWER CABLING: Use correctly rated

cable: minimum 600 Vac, 2 x armature

current

FUSING: Refer to "6.4 Fusing" on page

9.

CONTROL SIGNALS: All control inputs to

these drives are NON-ISOLATED. Do not

connect any of the terminals to earth or

other low voltage. A common HAZARD is

accidental earthing of the external pot and

contact wiring. Avoid running signal cables

close to power cables.

SUPPRESSION: The drives have excellent

noise immunity. However, installations

involving electrical welding or RF induction

heating may require additional lters on the

line and armature terminals. Contactor coils

and sparking contacts may also require

suppression. A 100 Ω resistor in series with

a 0.1 µF capacitor is usually adequate in

these situations. Refer to page 4 for

EMC guidelines.

CAUTION!

EQUIPMENT DAMAGE HAZARD

Reversing systems: do not

transpose the armature

connections until the motor has

stopped, otherwise damage will

occur.

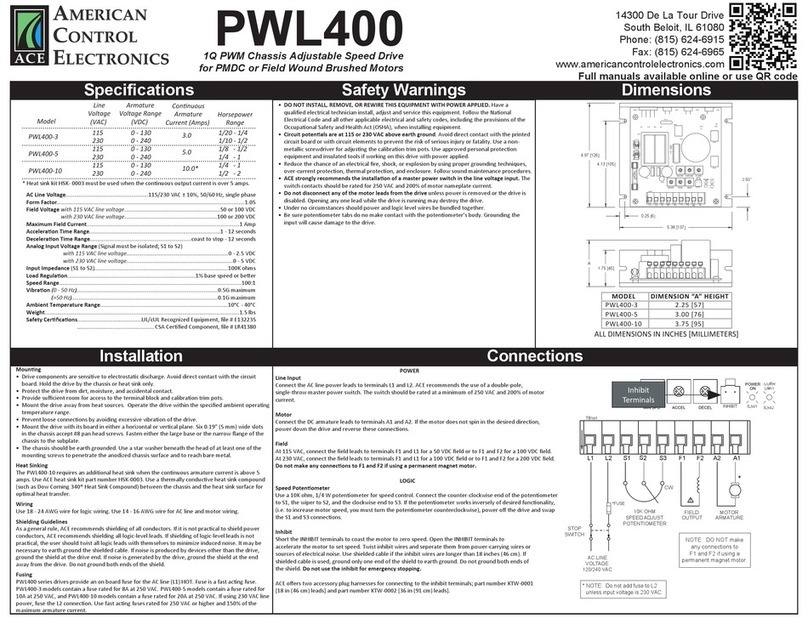

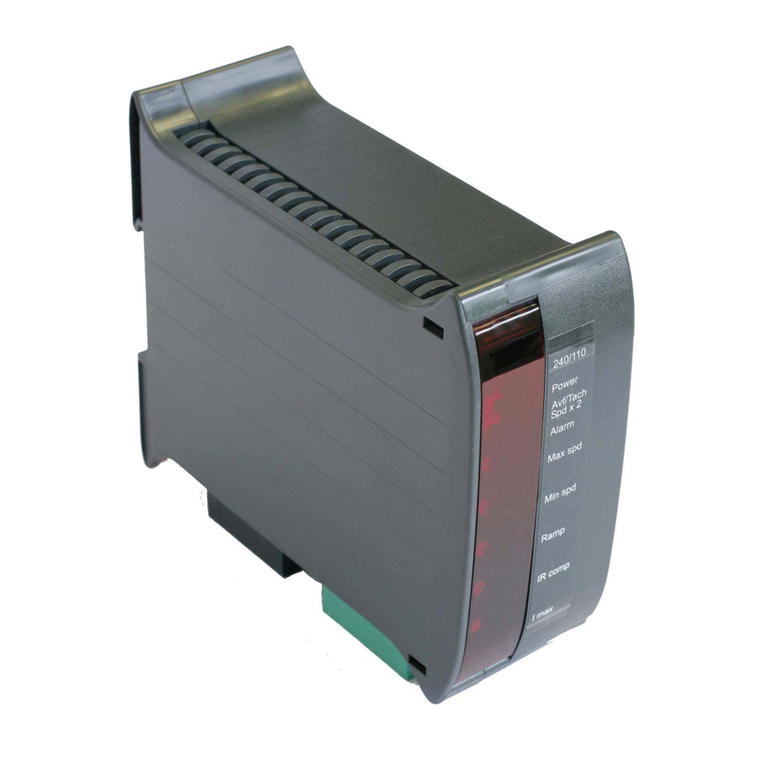

SUPPLY: Connect the incoming AC supply

to the rocker switch on the enclosure front

panel.

NOTE: units are Factory preset for 240 Vac

(or 60 Vac for LV units). To use with 110

Vac (or 30 Vac for LV units), change the

mains selector jumper on the drive unit

and move the AC input from Terminal 21

to Terminal 22 on the reversing unit.

Please ensure that the supply selection

jumper on the drive matches the incoming

supply. Failure to do this may result in

permanent damage to the drive unit and

will invalidate any warranty.

CAUTION!

EQUIPMENT DAMAGE HAZARD

For frequent stopping, it is

not good practice to rely on

switching the supply off and

on again to stop and start the

drive with the run contact

permanently closed.

This practice may result in an

uncontrolled current pulse for

one half mains cycle under

certain conditions, e.g. main

contact bounce, and might lead

to undesired motor movement

or device damage.