Full manuals available online or use QR code

14300 De La Tour Drive

South Beloit, IL 61080

Phone: (815) 624-6915

Fax: (815) 624-6965

www.americancontrolelectronics.com

1Q PWM Chassis Adjustable Speed Drive

for PMDC or Field Wound Brushed Motors

PWL400

......................................................115/230 VAC ± 10%, 50/60 Hz, single phase

..........................................................................................................................1.05

..............................................................50 or 100 VDC

............................................................100 or 200 VDC

...................................................................................................1 Amp

.....................................................................................1 - 12 seconds

..................................................................coast to stop - 12 seconds

..................................................................0 - 2.5 VDC

.....................................................................0 - 5 VDC

.......................................................................................100K ohms

...................................................................................1% base speed or beer

......................................................................................................................100:1

............................................................................................0.5G maximum

...............................................................................................0.1G maximum

...................................................................................10°C - 40°C

..............................................................................................................................1.5 lbs

UL/cUL Recognized Equipment, file # E132235

CSA Cerfied Component, file # LR41380

AC Line Voltage

Form Factor

Field Voltage with 115 VAC line voltage

with 230 VAC line voltage

Maximum Field Current

Acceleraon Time Range

Deceleraon Time Range

Analog Input Voltage Range (Signal must be isolated; S1 to S2)

with 115 VAC line voltage

with 230 VAC line voltage

Input Impedance (S1 to S2)

Load Regulaon

Speed Range

Vibraon (0 - 50 Hz)

(>50 Hz)

Ambient Temperature Range

Weight

Safety Cerficaons..........................................

Safety Cerficaons..................................................

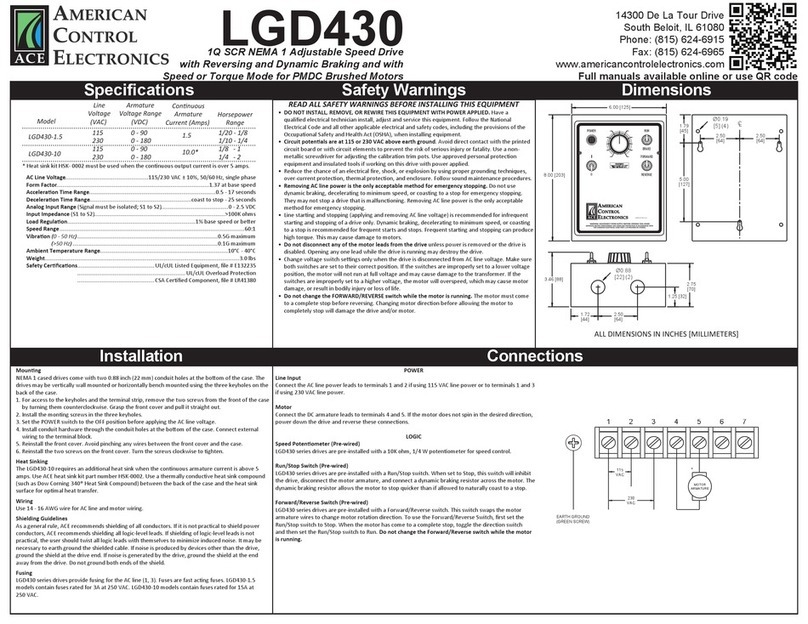

* Heat sink kit HSK- 0003 must be used when the connuous output current is over 5 amps.

1/20 - 1/4

1/10 - 1/2

1/8 - 1/2

1/4 - 1

1/4 - 1

1/2 - 2

Horsepower

Range

3.0

5.0

10.0*

Connuous

Armature

Current (Amps)

0 - 130

0 - 240

0 - 130

0 - 240

0 - 130

0 - 240

Armature

Voltage Range

(VDC)

115

230

115

230

115

230

Line

Voltage

(VAC)

PWL400-3

PWL400-5

PWL400-10

Model

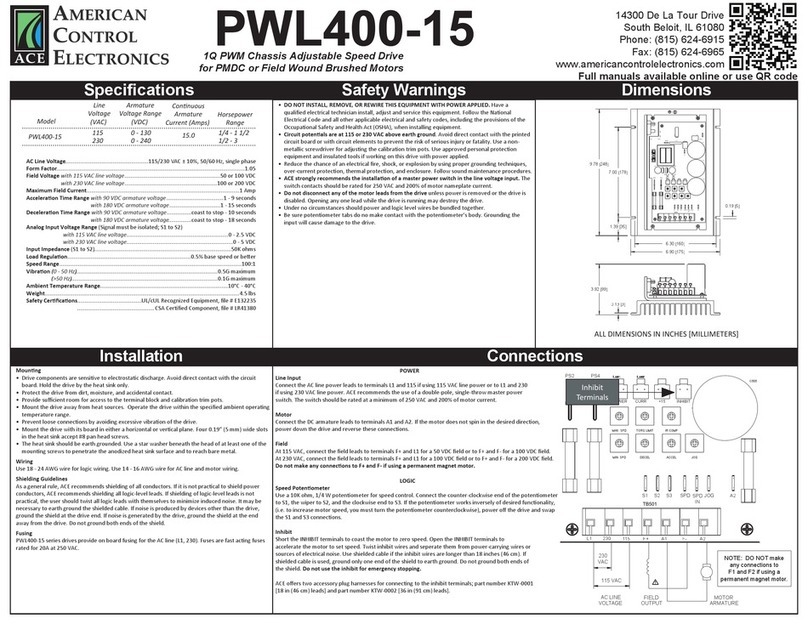

Specifications Safety Warnings

• DO NOT INSTALL, REMOVE, OR REWIRE THIS EQUIPMENT WITH POWER APPLIED. Have a

• qualified electrical technician install, adjust and service this equipment. Follow the Naonal

• Electrical Code and all other applicable electrical and safety codes, including the provisions of the

• Occupaonal Safety and Health Act (OSHA), when installing equipment.

• Circuit potenals are at 115 or 230 VAC above earth ground. Avoid direct contact with the printed

• circuit board or with circuit elements to prevent the risk of serious injury or fatality. Use a non-

• metallic screwdriver for adjusng the calibraon trim pots. Use approved personal protecon

• equipment and insulated tools if working on this drive with power applied.

• Reduce the chance of an electrical fire, shock, or explosion by using proper grounding techniques,

• over-current protecon, thermal protecon, and enclosure. Follow sound maintenance procedures.

• ACE strongly recommends the installaon of a master power switch in the line voltage input. The

•switch contacts should be rated for 250 VAC and 200% of motor nameplate current.

• Do not disconnect any of the motor leads from the drive unless power is removed or the drive is

• disabled. Opening any one lead while the drive is running may destroy the drive.

• Under no circumstances should power and logic level wires be bundled together.

• Be sure potenometer tabs do no make contact with the potenometer’s body. Grounding the

• input will cause damage to the drive.

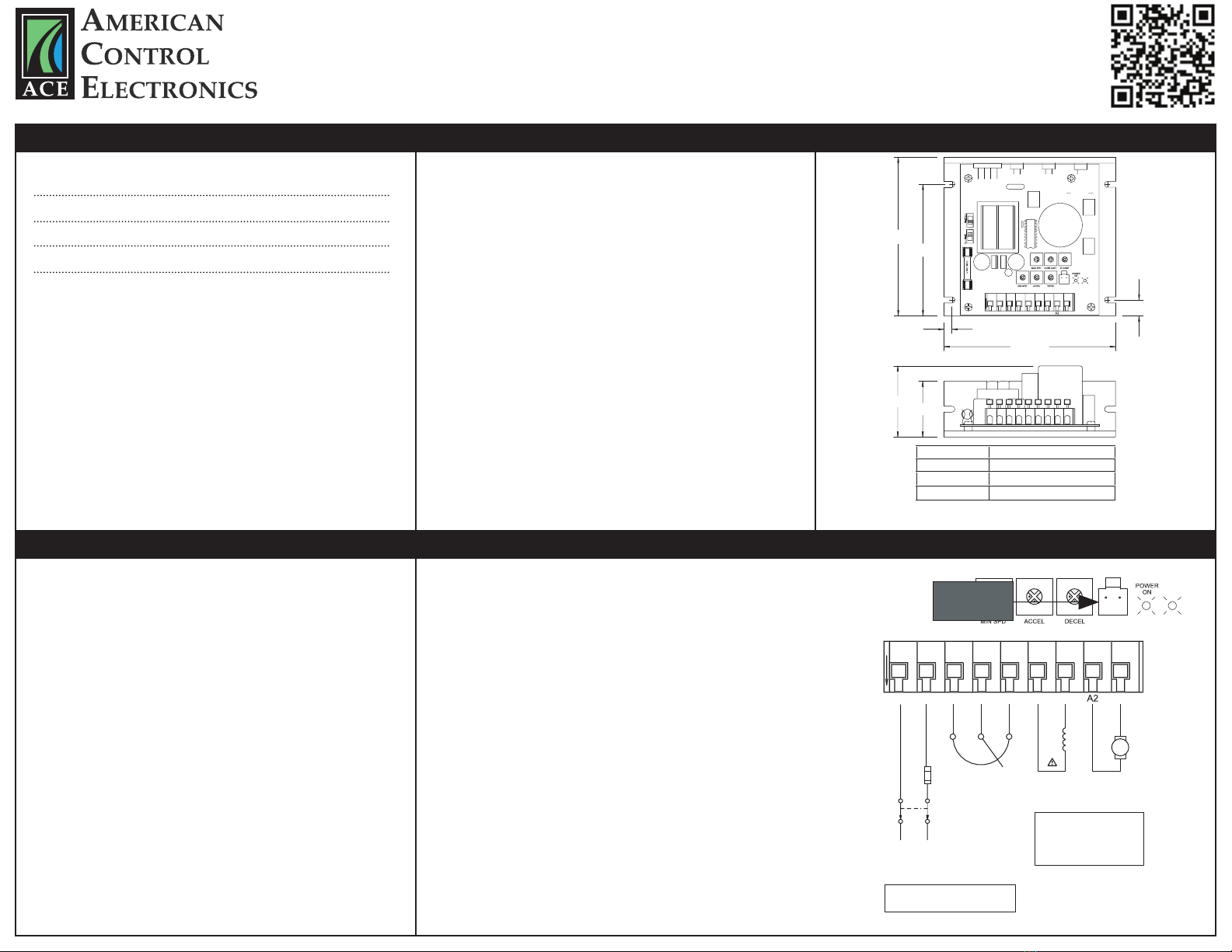

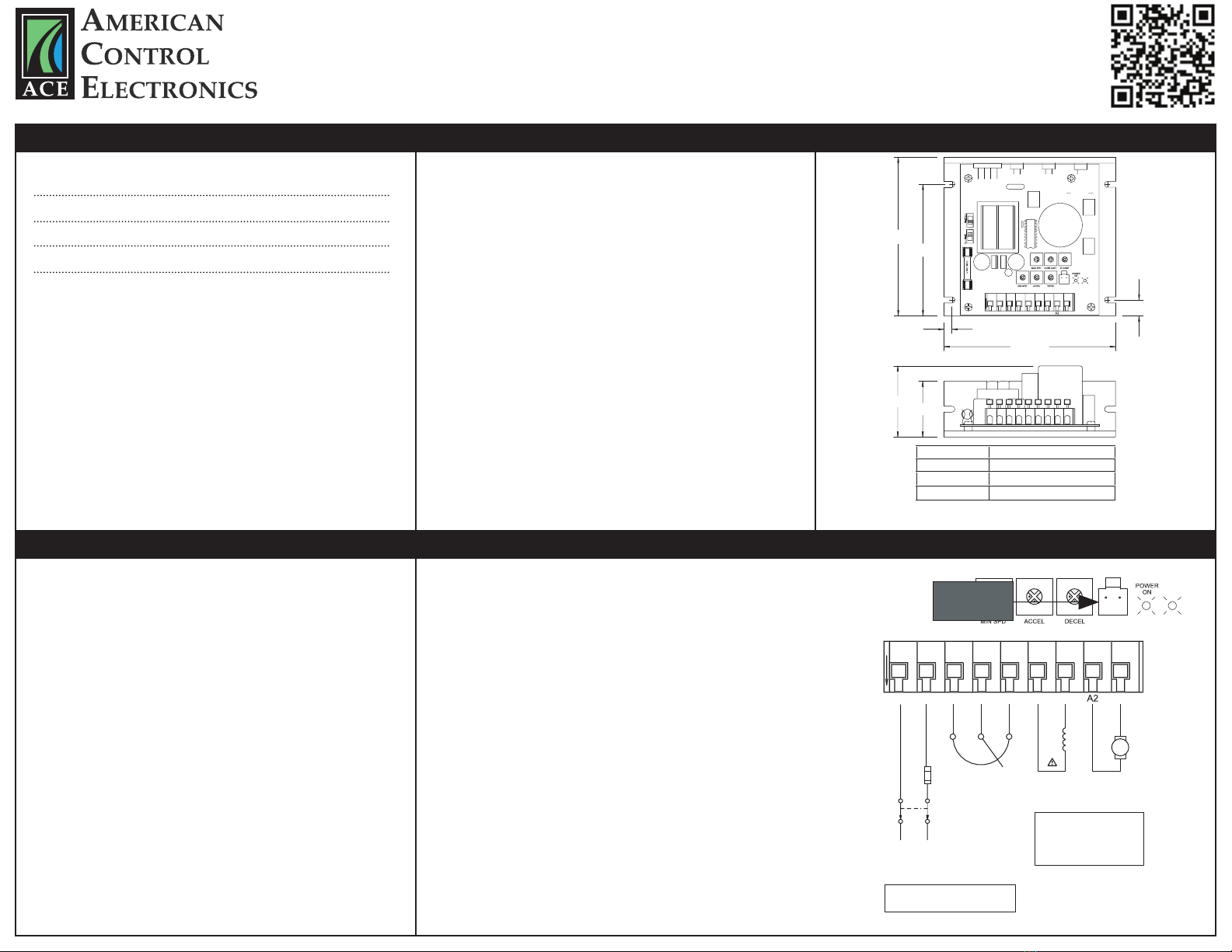

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Dimensions

MODEL DIMENSION “A” HEIGHT

PWL400-3 2.25 [57]

PWL400-5 3.00 [76]

PWL400-10 3.75 [95]

05WS 2

05C

BT

0

5

L

AF

-T A

IT N

I 2

I 1

2L

S 2

S

S 1

2F

A

I

S 05

W

T 1

A

A

R

HT 1

Q 05 1

LI

IBIHNI

LI

U

R

2

R

R 1

B

D

05

B2

Q 05

R

B

0

5

621[79.4

31.4

501

0 52.

6

83.5 [ 731

.

5

57.1 [ 54 ]

A

32 20 03

Installation

Mounng

• Drive components are sensive to electrostac discharge. Avoid direct contact with the circuit

• board. Hold the drive by the chassis or heat sink only.

• Protect the drive from dirt, moisture, and accidental contact.

• Provide sufficient room for access to the terminal block and calibraon trim pots.

• Mount the drive away from heat sources. Operate the drive within the specified ambient operang

• temperature range.

• Prevent loose connecons by avoiding excessive vibraon of the drive.

• Mount the drive with its board in either a horizontal or vercal plane. Six 0.19” (5 mm) wide slots

• in the chassis accept #8 pan head screws. Fasten either the large base or the narrow flange of the

• chassis to the subplate.

• The chassis should be earth grounded. Use a star washer beneath the head of at least one of the

• mounng screws to penetrate the anodized chassis surface and to reach bare metal.

Heat Sinking

The PWL400-10 requires an addional heat sink when the connuous armature current is above 5

amps. Use ACE heat sink kit part number HSK-0003. Use a thermally conducve heat sink compound

(such as Dow Corning 340® Heat Sink Compound) between the chassis and the heat sink surface for

opmal heat transfer.

Wiring

Use 18 - 24 AWG wire for logic wiring. Use 14 - 16 AWG wire for AC line and motor wiring.

Shielding Guidelines

As a general rule, ACE recommends shielding of all conductors. If it is not praccal to shield power

conductors, ACE recommends shielding all logic-level leads. If shielding of logic-level leads is not

praccal, the user should twist all logic leads with themselves to minimize induced noise. It may be

necessary to earth ground the shielded cable. If noise is produced by devices other than the drive,

ground the shield at the drive end. If noise is generated by the drive, ground the shield at the end

away from the drive. Do not ground both ends of the shield.

Fusing

PWL400 series drives provide an on board fuse for the AC line (L1) HOT. Fuse is a fast acng fuse.

PWL400-3 models contain a fuse rated for 8A at 250 VAC. PWL400-5 models contain a fuse rated for

10A at 250 VAC, and PWL400-10 models contain a fuse rated for 20A at 250 VAC. If using 230 VAC line

power, fuse the L2 connecon. Use fast acng fuses rated for 250 VAC or higher and 150% of the

maximum armature current.

Line Input

Connect the AC line power leads to terminals L1 and L2. ACE recommends the use of a double-pole,

single-throw master power switch. The switch should be rated at a minimum of 250 VAC and 200% of motor

current.

Motor

Connect the DC armature leads to terminals A1 and A2. If the motor does not spin in the desired direcon,

power down the drive and reverse these connecons.

Field

At 115 VAC, connect the field leads to terminals F1 and L1 for a 50 VDC field or to F1 and F2 for a 100 VDC field.

At 230 VAC, connect the field leads to terminals F1 and L1 for a 100 VDC field or to F1 and F2 for a 200 VDC field.

Do not make any connecons to F1 and F2 if using a permanent magnet motor.

Speed Potenometer

Use a 10K ohm, 1/4 W potenometer for speed control. Connect the counter-clockwise end of the potenometer

to S1, the wiper to S2, and the clockwise end to S3. If the potenometer works inversely of desired funconality,

(i.e. to increase motor speed, you must turn the potenometer counterclockwise), power off the drive and swap

the S1 and S3 connecons.

Inhibit

Short the INHIBIT terminals to coast the motor to zero speed. Open the INHIBIT terminals to

accelerate the motor to set speed. Twist inhibit wires and seperate them from power-carrying wires or

sources of electrical noise. Use shielded cable if the inhibit wires are longer than 18 inches (46 cm). If

shielded cable is used, ground only one end of the shield to earth ground. Do not ground both ends of

the shield. Do not use the inhibit for emergency stopping.

ACE offers two accessory plug harnesses for connecng to the inhibit terminals; part number KTW-0001

[18 in (46 cm) leads] and part number KTW-0002 [36 in (91 cm) leads].

Connections

POWER

LOGIC

BT

S

MOTOR

ARMATURE

+

FIELD

OUTPUT

NOTE: DO NOT make

any connections to

F1 and F2 if using a

permanent magnet motor.

*FUSE

STOP

SWITCH

AC LINE

VOLTAGE

120/240 VAC

10K OHM

SPEED ADJUST

POTENTIOMETER

CW

* NOTE: Do not add fuse to L2

unless input voltage is 230 VAC.

LI

IBIHNI T LI

R

Inhibit

Terminals