SprintRay ProWash S User manual

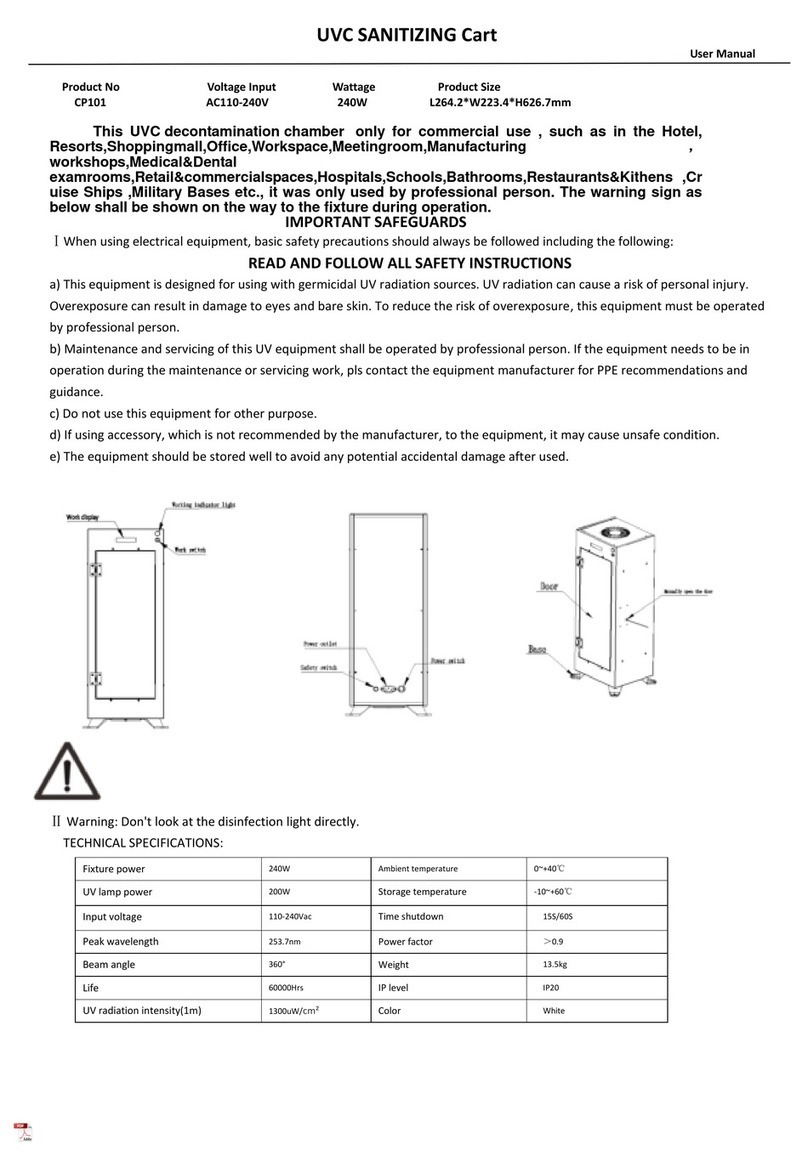

1In the Box

2Where to Set Up

Level surface away from light and heat.

A C

B

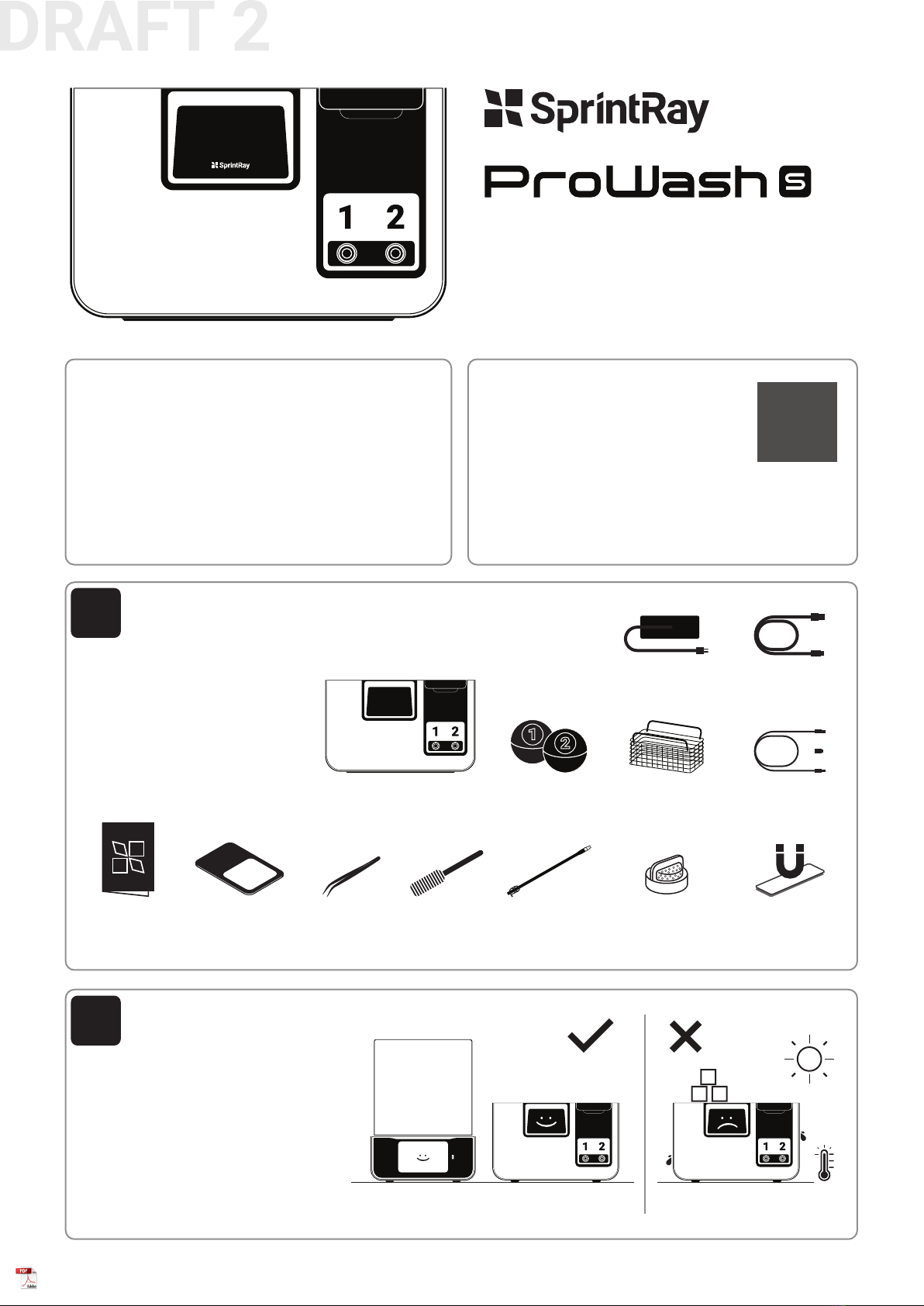

Congratulations!

Your new ProWash S is the world’s most advanced system

for cleaning 3D printed parts. Featuring improvements to

our patented Mechanical JettingTM technology and an

all-new, cloud-connected onboard computer, your digital

workflow just got a little simpler.

In this guide, you’ll find everything you need to get started

using ProWash S.

Training and Support

ProWash S comes with complimentary

phone and email support. If you have

questions, please get in touch:

Visit

Call

Email

support.sprintray.com

800-914-8004

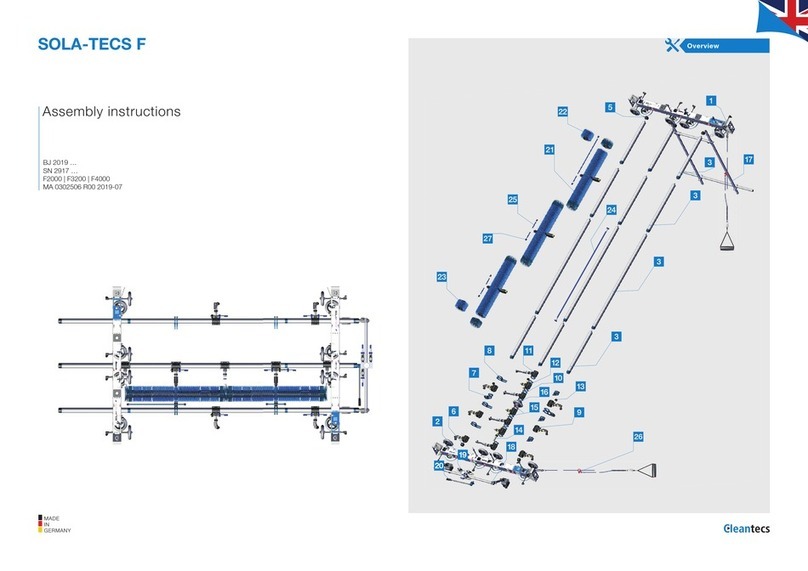

ProWash S Device

Drain Hose

Pre-installed

(Section 8)

Cleaning

Brush

(Section 9)

Basket

(Section 7)

Hydrometers

Pre-installed

(Section 4)

Power Cable

USB Cable

(Section 12)

Wash Filter

(Sections 2 & 9)

Metal

Tweezers

(Section 10)

Power Adaptor

Magnet Sticker

(Section 6)

Build Platform

Adaptor

(Section 6)

Onboarding

Card

Set up ProWash S in a well-ventilated area on

a level surface in a temperature-controlled

room. Keep it away from windows and bright

light sources.

Never place anything on ProWash S.

If possible, set ProWash S near your 3D

printer and curing device for optimal

workflow efficiency.

ProWash S comes out of the box

with most parts preinstalled.

The hydrometers are precalibrated

for each chamber and will float when

it’s time to replace IPA. Read more

about hydrometers in section 4.

Automated Multistage Cleaning System

Designed for Digital Dentistry

Quick Start Guide

Version 2 - Updated on 06/28/22

Model SRP2208A

QR Code

Hello Akash :)

3Plug in and Connect to Network

4The Basics

MAX

Use the provided power adaptor and cable to plug your

ProWash S into a surge protector or uninterrupted power

supply. Flip the switch on the back to the ‘On’ position.

On startup, ProWash S will prompt you to connect to a

network. You can join an existing Wi-Fi network using the

touchscreen or use an ethernet cable. Maintaining an

internet connection will allow ProWash S to receive updates.

If you need to reset your ProWash S, switch it off and then

unplug the power cable, wait 30 seconds, then plug it back in.

Wash Chamber

This chamber is where parts are

cleaned and dried. You can wash

parts directly on the SprintRay build

platform or remove and wash them

in the basket. IPA will automatically

pump in and out of the wash

chamber from the IPA tanks.

Never pour IPA directly into

this chamber; it should only

be poured into the tanks

Failure to replace IPA when a hydrometer

floats will void your warranty

IPA Tanks

Pour IPA directly into these tanks. Each tank

has a maximum capacity of 2 liters.

Tank 1

The IPA in this tank is used for the bulk wash,

so it will need to be changed more often.

Tank 2

The IPA in this tank is used for rinsing, so it

will not need to be replaced as often. It can be

recycled into tank 1 for extended life.

Drain Ports

Each tank has a drain port designed to mate with the drain

hose attached to the back of the machine. Refer to Section 8

for instructions on how to drain.

Hydrometers

Over time, the IPA in ProWash S will become saturated

with uncured resin and lose its cleaning effectiveness.

The hydrometers are precalibrated to measure resin

saturation and will float when it is time to replace IPA.

Submerged Hydrometer = IPA Okay

When a hydrometer is submerged, the IPA in the

tank is acceptable and ready for use.

Floating Hydrometer = Replace IPA

A floating hydrometer indicates that IPA has

become saturated with resin and will no longer

effectively wash your prints. Drain the tank, clean,

and fill with clean IPA.

Power Switch

Power Port

Drain Ports

Drain Hose

Touchscreen

5How to Add IPA

6Build Platform Information

MAX

MIN 500 mL

12

Minimum

500 mL

Required per tank

Maximum

2 Liters

Required per tank

Isopropyl

Alcohol 91%

Recommended

Always wear gloves and

proper eye protection.

Build Platform Adaptor

Compatible with Pro 55 and Pro 55s

Open the tank lid and add at least 500mL of IPA 91% or greater

to each tank. IPA 99% and ethanol may also be used depending

on preference, availability, and material requirements.

If the volume of IPA is insufficient to run a cleaning cycle, the

onboard computer will detect this and notify you.

Keep the tank lid closed to prevent the evaporation and

contamination of IPA.

When new IPA is added, hydrometers may float

for a few minutes before sinking

Depending on which SprintRay 3D printer you have, you may

need to attach a magnet and/or use a fitment adaptor when

using ProWash S.

How to Install the Magnet

If using Pro95 or Pro55, you’ll need to install the provided

magnet to enable the platform wash. Thoroughly clean the side

of the build platform before attaching the magnet sticker.

Using the Build Platform Adaptor

If using a Pro55 or Pro55 S, you’ll need to use the

included adaptor to enable the platform wash. Place the

adaptor atop the wash chamber so that the opening is

on the right and run a cleaning cycle as normal.

1/4 inch

1/2 inch

Center

Magnet

Pro55

Print Platform

Place magnet on the right side

Pro95

Print Platform

Place magnet on the right side

Label

Center

Magnet

Right Side

Right Side

Printer Model

Pro95

Pro55

Pro95 S

Pro55 S

Install Magnet

Yes

Yes

No, It is embedded

No, It is embedded

Use Adaptor

No

Yes

No

Yes

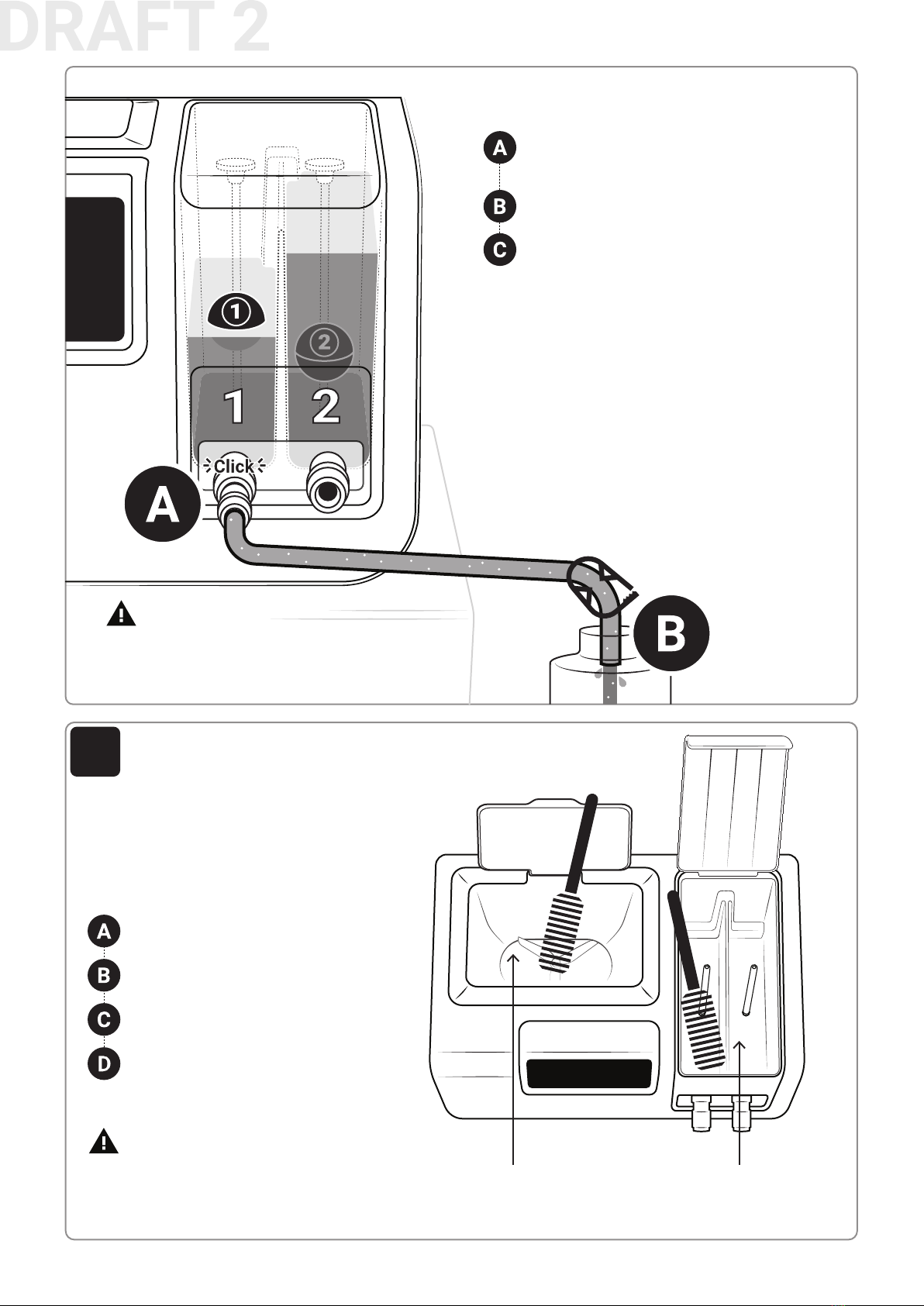

8How to Drain IPA from the Tanks

7How to Wash with ProWash S

Print Platform Wash

Remove the basket and place the Pro95/S build platform in the

wash chamber. If using Pro55/S, use the provided adaptor (see

Section 7). Use the touchscreen to select a cleaning cycle.

The system will not start until a platform is detected.

Combination Wash

To perform a combination wash, perform a full cleaning cycle

with the build platform. Remove the models and place them in

the basket. Select ‘Extra Rinse’ from the onboard computer, or

run a second cleaning cycle from the home screen.

Basket Wash

To use the basket, place models inside and close the lid.

Use the touchscreen to select a cleaning cycle.

The system will not start if the lid is open.

Recommended for:

- Models taller than 4”

- Hollow/shell models

Recommended for:

- Highly viscous resins

- Large print batches

- Dense supports

- Complex geometries

Recommended for:

- Models shorter than 4”

- Solid models

- Models for aligners

- Surgical guides

- Night guards

Do not stack models or crowd

them together, as this can

greatly reduce wash efficiency

When washing with the build

platform, remove the basket

from the wash chamber

Drain Hose

Clipped to the back

WARNING! WARNING!

Consult your materials IFU to

determine if a combination

wash is recommended

WARNING!

Unlocked

Solvent will flow

through the hose.

Locked

Solvent will not flow

through the hose.

ProWash S comes out of the box with the drain hose clipped

to the back.

To drain a tank, press the metal inlet tip into the drain port

until it firmly clicks into place. Once connected, IPA will run

through the hose. To disconnect, firmly slide the outer ring of

the drain port away from you.

Safety Clamp

When closed, this clamp stops the flow of

IPA to prevent accidental drainage.

Metal Inlet Tip

This metal tip is designed to quickly connect to

the drain ports on the front of ProWash S.

MAX 4”

9How to Clean ProWash S

MAX

MAX

Unlocked

Draining an IPA Tank

How to Dispose of IPA

ProWash S extracts the maximum life out of IPA so that you

generate less waste. But IPA and other solvents are hazardous

and should be treated with care.

Keep the original packaging on hand for storing drained IPA

after it has become saturated. Never flush IPA down the drain.

Used IPA should be properly disposed of through a hazardous

materials collection as required by local laws and regulations.

Consult your local environmental agency or the EPA office to

find the nearest hazardous materials collection facility.

Clean Wash Chamber

Scrub the inside and walls of the chamber and remove

debris. When prompted by the onboard software, follow

the procedure in Section 11 to clean the filter.

Clean an IPA Tank

Never flush IPA down the drain. Used IPA should be

properly disposed of through a hazardous materials

collection as required by local laws and regulations.

WARNING!

For best results, clean the tanks every time

you refresh IPA. The wash chamber should be

cleaned periodically as well.

WARNING!

Retrieve the drain hose from the back of the device,

then press the metal tip into the drainage port until it

clicks into place

Point the end of the hose into a disposal container,

then unlock the safety clamp to start the flow

Once the tank is empty, eject the drain hose by sliding

the outer ring of the drain port away from you

Remove the rubber stop, then slide the

hydrometer out of the tank

Use the provided brush to scrub the inside

of the tank, including the walls

Flush the tank by pouring in a small

volume of IPA or water, then draining

Replace the hydrometer into its

corresponding tank

Clean Wash Chamber

Clean all resin and residue

buildup from the surfaces.

Clean IPA Tank

Thoroughly scrub and clean the

walls and floor of the tanks.

10 How to Clean the Wash Filter

Care for Environment

SprintRay ProWash S uses patented technology to improve the efficiency of the

washing and drying processes. It’s better for your pocketbook and better for the

environment.

Here are three easy tips to help you go the extra environmental mile with your

used isopropyl alcohol (IPA):

For additional information, visit support.sprintray.com

Never flush IPA down the drain

Keep all IPA packaging for storing used IPA

Set up IPA recycling with a materials disposal company

The secondary mesh below the removable

filter should never be removed

WARNING!

ProWash S has a mesh filter that protects the plumbing from

resin and other debris. The filter should be cleaned when

prompted by the onboard software. If the filter is damaged or

cannot be cleaned, it should be replaced.

Remove

Clear the area around the filter to ensure

no debris falls into the plumbing when it

is removed. Turn counter-clockwise by

hand to unscrew.

Clean

Flush the filter with IPA to remove

resin debris. Use the provided

tweezers to remove any additional

debris from the mesh.

Reinstall

Replace the filter and turn it

clockwise to hand tighten.

Start by Locating the Filter

In the wash chamber near the propeller

FCC Warning:

This transmitter must not be co-located or operating in conjunction with any other antenna or transmitter.

Any Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

RF Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment.

This equipment should be installed and operated with minimum distance 20cm between the radiator & your body.

FCC ID:2A78L-SRP2210A