SPRSUN CGK/C-9 User manual

Installation manual

CGK/C-9 220V/50Hz/1ph

(Product No: A11244)

Air source heat pump (heating + hot water)

PCB No: CG248027

Operating panel No: CG248028

Safety precaution

a. To avoid electrical shock, make sure to disconnect power supply

1minute or more before operating the electrical part. Even after

1minute, always measure the voltage at the terminals of main

circuit capacitors or electrical parts and, before touching, make

sure that those voltages are lower than the safety voltage.

b. Power supply wire line size must be selected according to this

manual. And must be grounded.

c. Don’t put in hands or stick to air outlet grill when fan motor are

working.

d. Don’t use wet hand touch wire lines, and don’t pull any wire lines of

the unit.

e. Water or any other kind liquid is forbidden to poured into the unit.

f. Select correct air breaker and leakage protection switch.

g. Don’t touch the fin of source side heat exchanger, it may hurt your

finger.

h. If any wire line is loose or damaged, suggest let qualified person to

fix it.

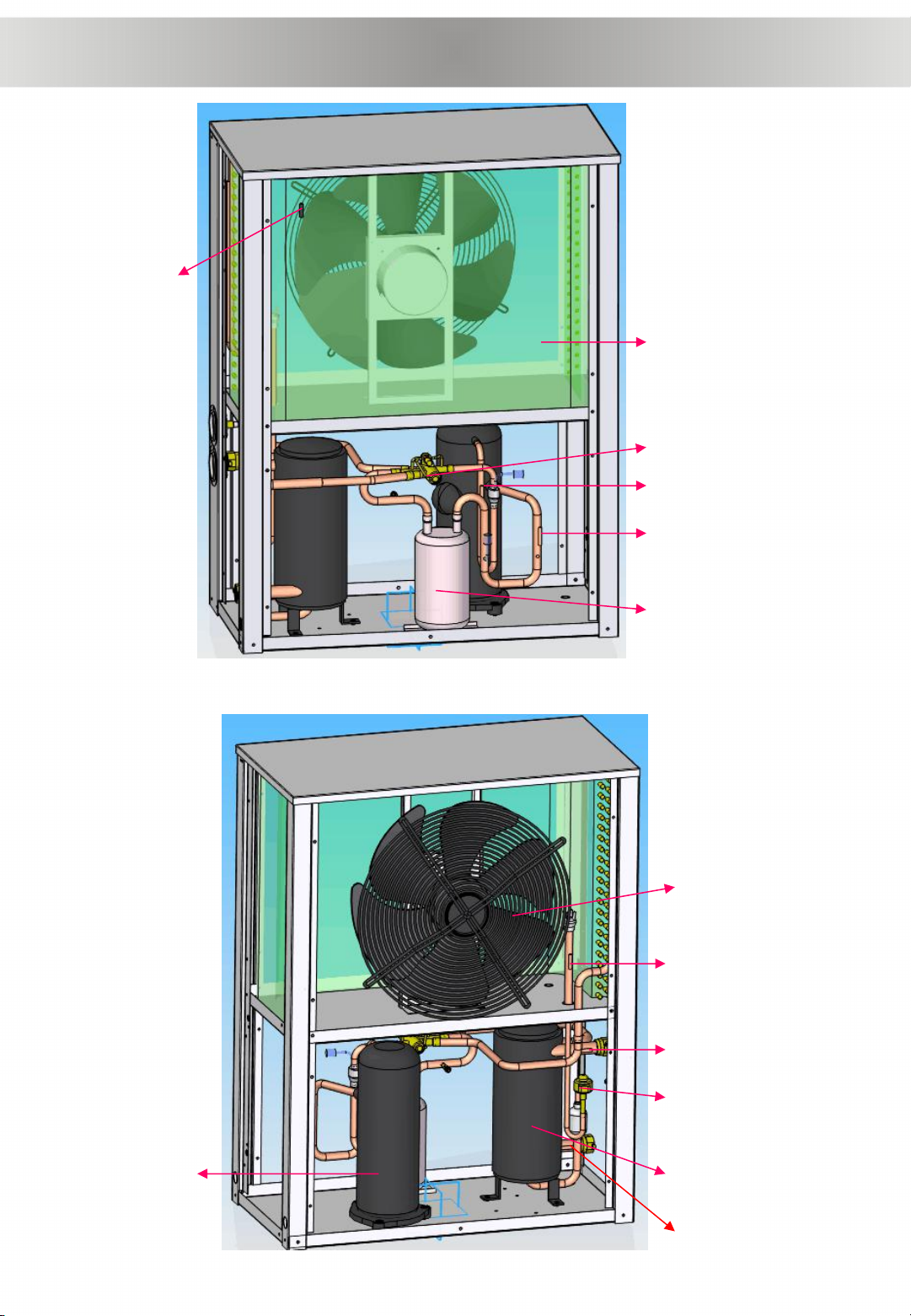

To know the product from exterior

High pressure gauge

Low pressure gauge

Water outlet

Water inlet

Air inlet

Air outlet

Electric

box plate

Cable

holes

Important parts in heat pump

T1

EVA

4WV

T3

G-L

Fan

T4

T5

EEV

CONCOM

T2

T6

Important parts in heat pump

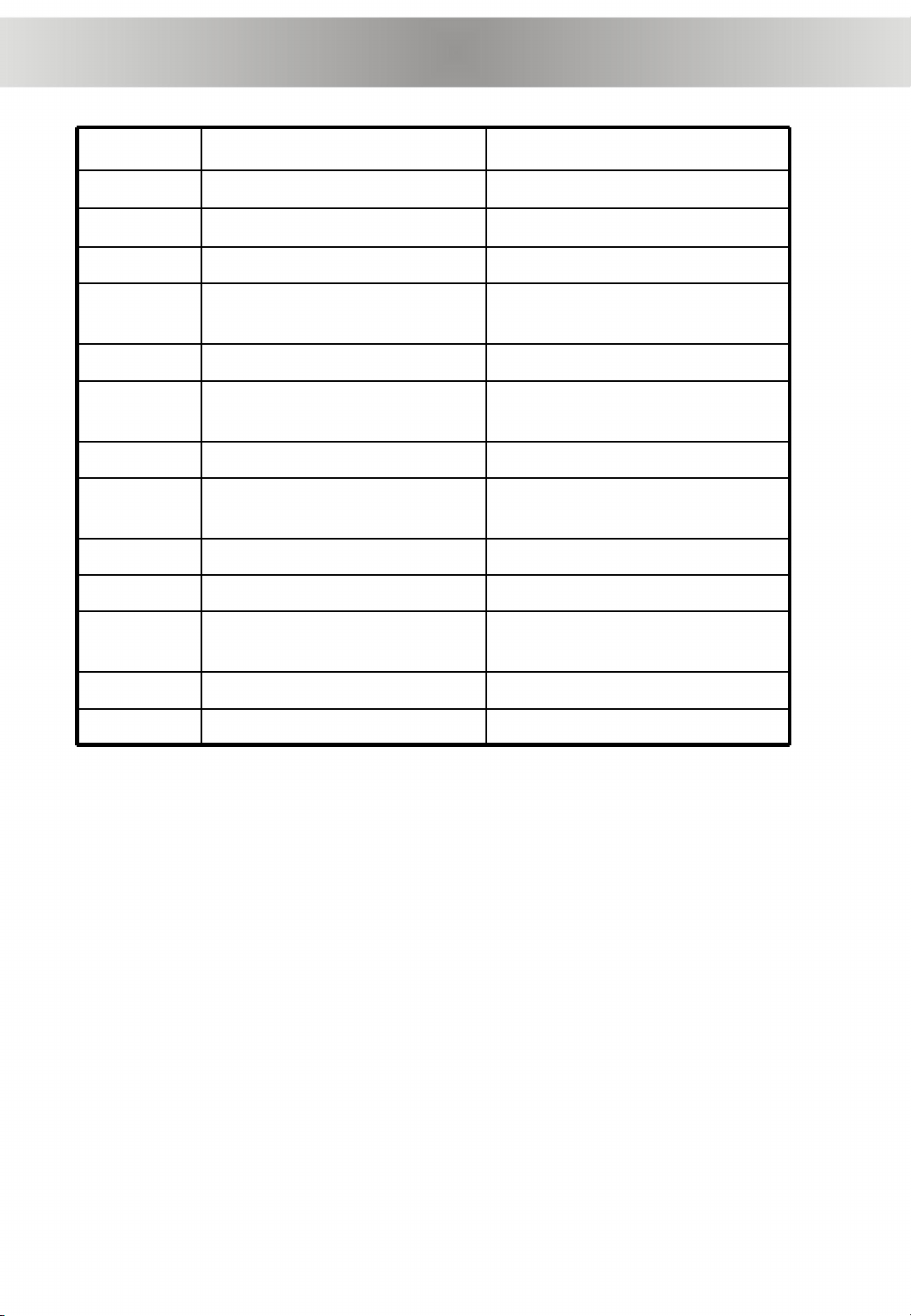

Code

Name

Remarks

T1

Ambient temp sensor

Connect to port CN11 on PCB

T2

Outlet gas temp sensor

Connect to port CN12 on PCB

T3

Inlet gas temp sensor

Connect to port CN8 on PCB

T4

Air heat exchanger coil temp

sensor

Connect to port CN9 on PCB

T5

Outlet water temp sensor

Connect to port CN3 on PCB

T6

Floor heating water temp

sensor

Connect to port CN6 on PCB

Fan

Fan motor

EVA

Evaporator

Source side air-gas heat

exchanger

G-L

Gas-liquid separator

COM

Compressor

CON

Condenser

Load side water-gas heat

exchanger

EEV

Electronic expansion valve

4WV

Four way valve

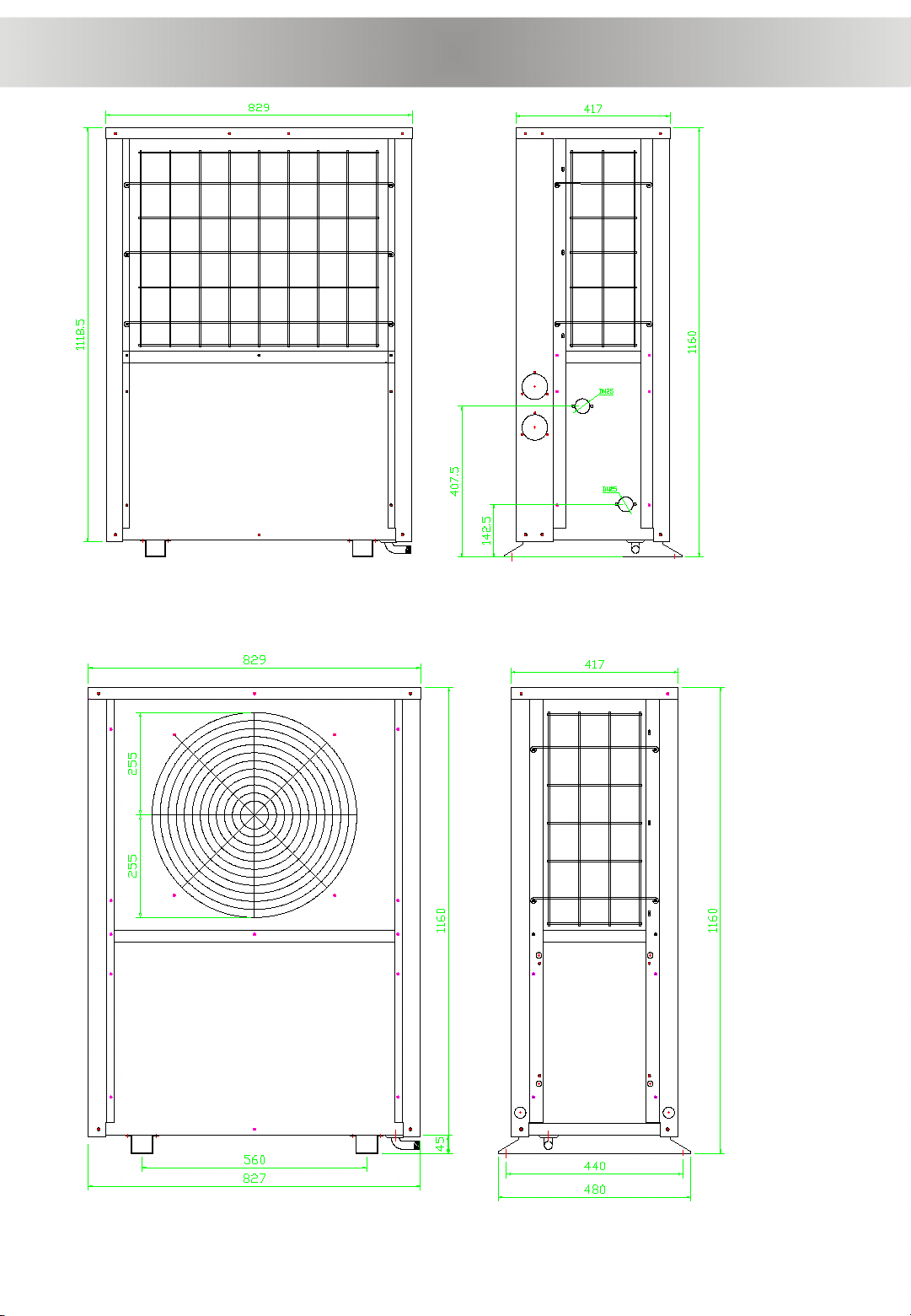

Heat pump size

Back view Right view

Front view Left view

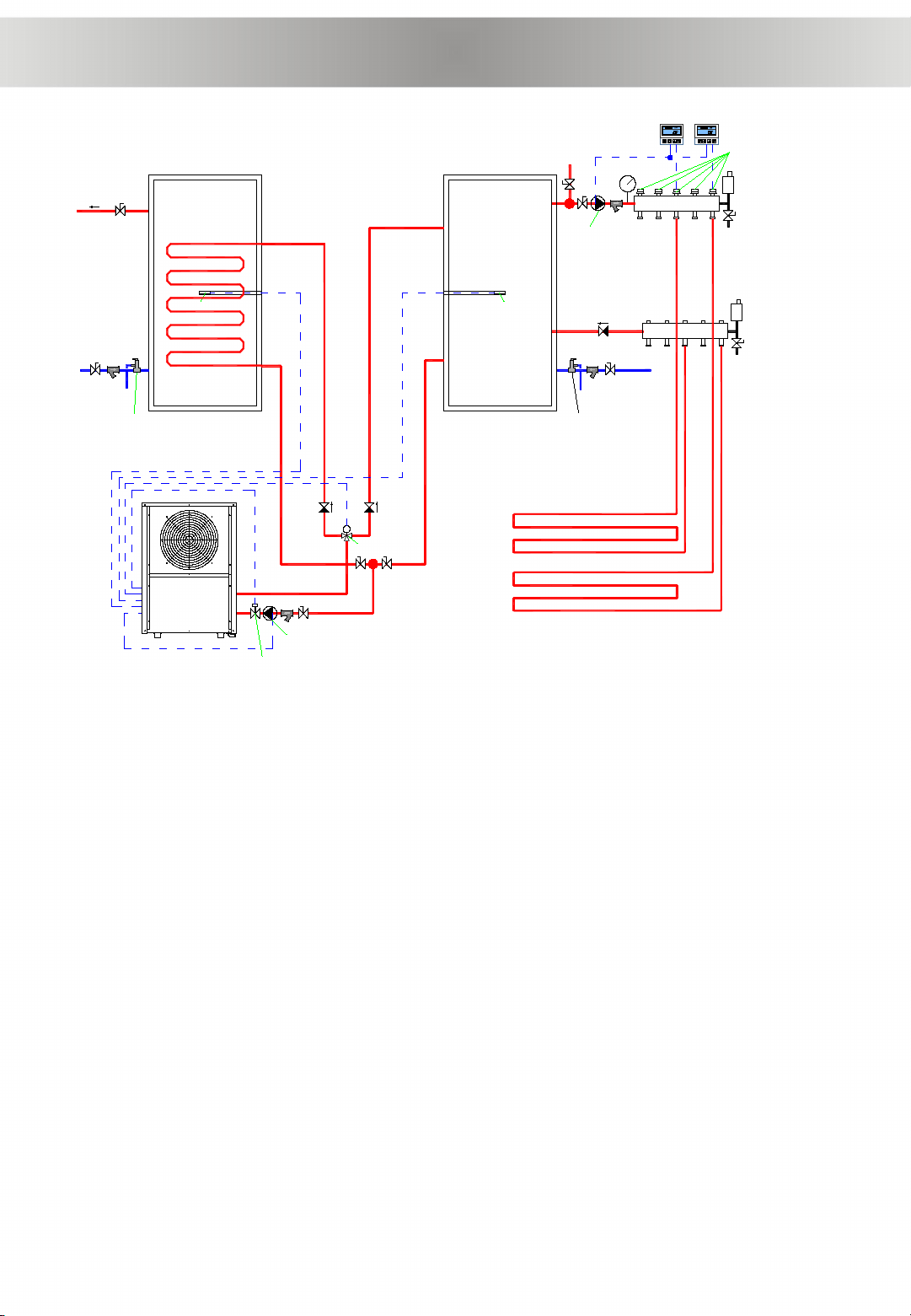

M

Hot water

outlet

Connect to

city water

Hot

water

tank

AC water

tank

Connect to

city water

T1 T2

Heat pump

3WV

P1

P2

Floor heating

Room thermostat

Special valve for floor

heating loop

Water separator

Water collector

WFS

F1

F2 F3

F4

NRV2NRV1

NRV3

SV2SV1

Installation diagram

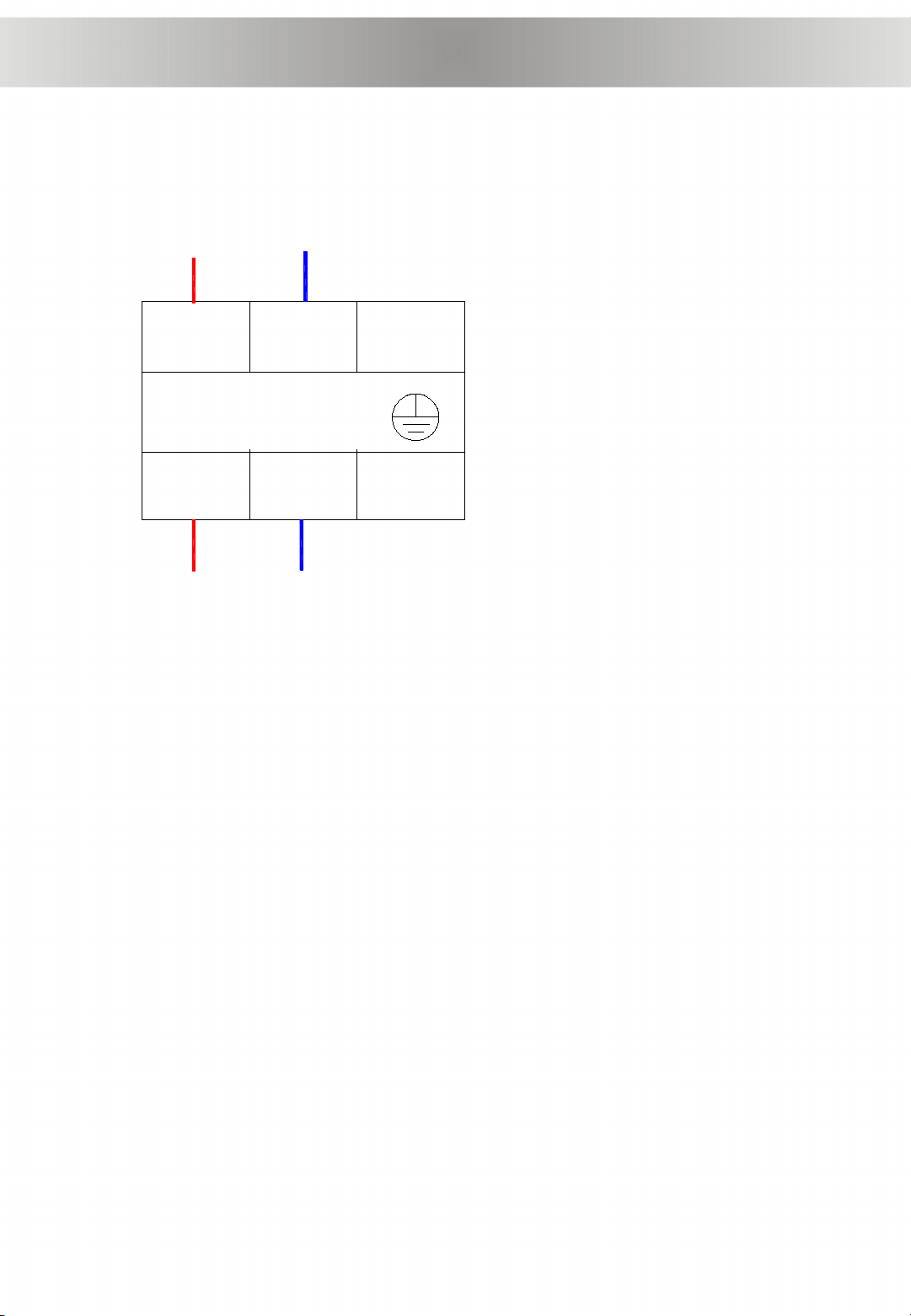

1. Hot water tank temp sensor (T1)

The sensor should be put in the sensor tube which is

installed in hot water tank.

2. Floor heating water temp sensor (T2)

2.1 Floor heating temp sensor has been installed on the

inlet water pipe inside heat pump before leave factory.

2.2 If floor heating system doesn’t install water tank,

installer needn’t deal with the temp sensor (we don’t

suggest the system without floor heating water tank)

2.3 If floor heating system has water tank, installer should

remove the sensor from inlet pipe and install it in water

tank (we suggest install a floor heating water tank).

Note: Water temp sensors probe can’t touch water directly,

should be put in sensor tube which is installed in water

tank, like the drawing.

Introduction of the system

3. Heat pump circulating water pump (P1)

3.1 This water pump is controlled by heat pump controller.

3.2 Hot water side and floor heating side share the circulating water pump.

3.3 By setting parameter F5 through password 0814, installer can set P1 stop or

non-stop when both hot water and floor heating side have reached preset temp.

3.4 P1 rated water flow is: 1820L/H, head should be ≥5m + water pressure drop

of other parts outside heat pump.

4. Floor heating terminal water pump (P2)

4.1 This water pump is not controlled by heat pump controller, but by floor heating

room thermostat. When any floor heating start, P2 will start, when all floor heating

stop, P2 will stop.

4.2 The wiring diagram of P2 connect to room thermostat can refer to following

parts.

5. Three way valve (3WV):

5.1 Three way valve is controlled by heat pump controller.

5.2 When room linkage switch is connected: hot water is priority, means if both hot water

side and floor heating side need be heated, the three way valve will change to hot

water side, until hot water tank reach preset temp, then the valve will change to floor

heating side. If hot water needn’t be heated, the three way valve will stat at floor

heating side.

5.3 When room linkage switch is disconnected: the three way valve will only stay at hot

water side.

6. Water flow switch (WFS)

6.1 Water flow switch must be installed.

6.2 Because factory hasn’t install the water flow switch in heat pump, so installed should

install it outside heat pump

6.3 Water flow switch is controlled by heat pump controller, input ON/OFF signal to

controller, the port is dry contact.

7. Water pipes:

7.1 Circulating water pipe size should be DN25 (PPR pipe is Φ32), water pipe connector

on heat pump is DN25, copper material, internal thread.

7.2 Water pipes must be insulated.

8. About water filled in floor heating pipe

8.1 The water must be purified.

8.2 The water is suggested mixed anti-freeze (same as anti-freeze in car). Because some

place is very cold, and if user leave home for long time, and need turn off the heat

pump, floor heating system may ice up.

Introduction of the system

8. About hot water tank

8.1 Because the three way valve, a coil heat exchanger must be installed in hot

water tank. Otherwise, the sanitary hot water will be mixed with floor heating water.

8.2 The coil heat exchanger capacity should be about 18KW. And the inner

diameter of coil should be ≥DN25. If <DN25, can install two coil in parallel.

8.3 Hot water tank is suggested to be pressured type. Because heat pump

controller doesn’t have cool water compensating controlling function.

8.4 Hot water tank compensating water pipe must be connected to city water

system. And make sure the pressure of city water is stable and ≥0.15Mpa

9. Floor heating water tank

9.1 The water tank is suggested to be pressured type

9.2 Water compensating pipe should be connected to city water. And the valves

must be opened. In case there is leakage or after cleaned Y filter water reduced, can

compensate water automatically.

10. Y type filter (F1-F4)

10.1 Y type filter must be installed on water compensating pipe of water tank.

10.2 Y type filter must be installed in front of P1.

10.3 Y type filter must be installed on water separator of floor heating.

Y type filter should be checked and cleaned if there is abnormal condition.

11. Safe valve (SV1, SV2)

11.1 On the water compensating pipe of water tank, always install a safe valve.

11.2 The safe valve will release water if water tank pressure is over 0.7Mpa to

protect.

11.3 The safe valve have the function of non-return valve when water tank pressure

is less than 0.7Mpa.

Introduction of the system

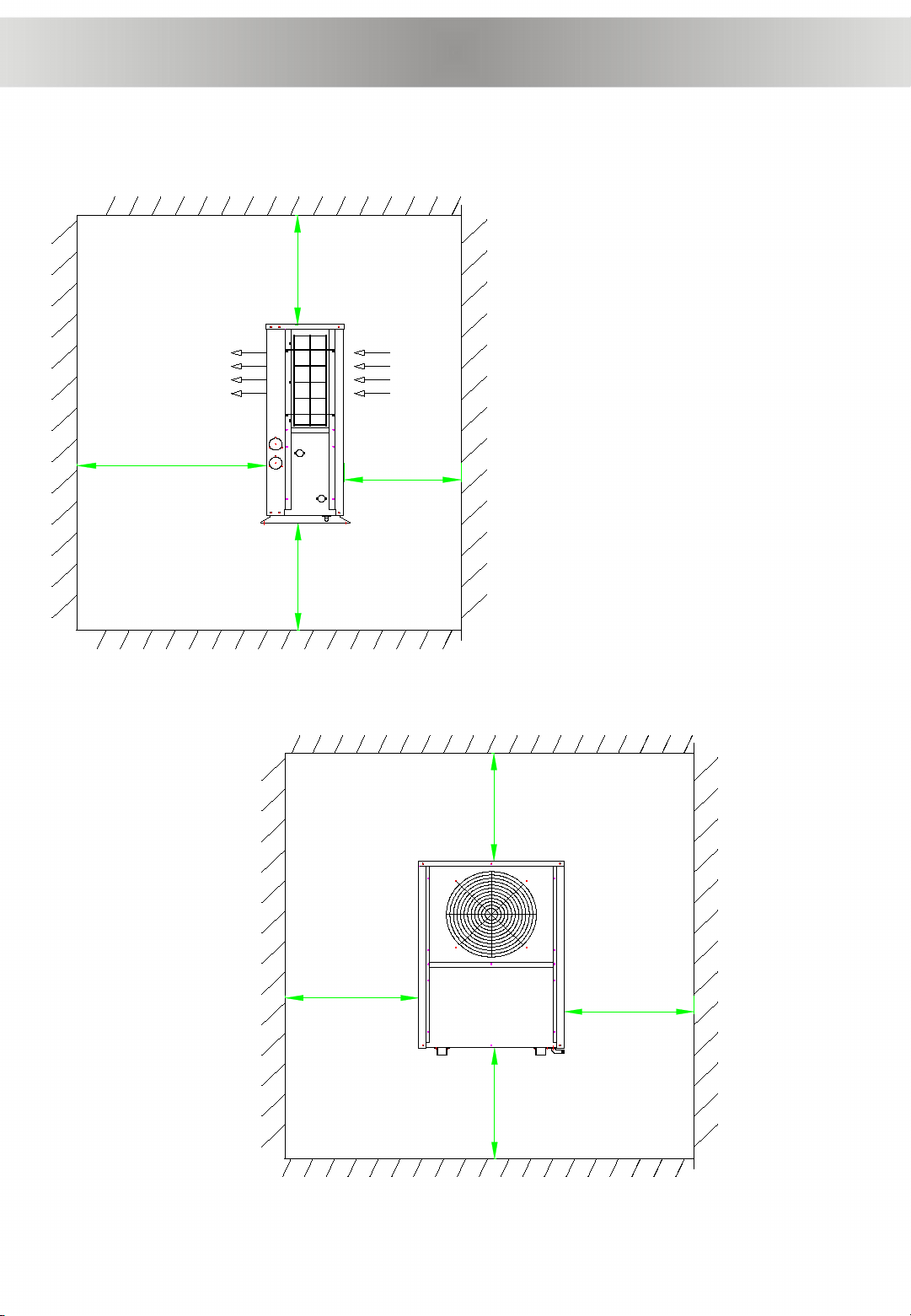

Heat pump installation notes

1) The heat pump must be installed in open space. Normally is installed on the

roof of house.

2) The unit should be placed in dry and well-ventilated environment. If the

environment is humid, electronic components may get corroded or short circuit.

3) Heat pump mustn’t be installed in the environment where corrosive, volatile, or

flammable liquid or gas exists.

4) Because of the noise is a little loud, please don’t install the heat pump near

bedroom or living room or meeting room.

5) The bottom of the heat pump should be at least 50cm higher than ground,

because rain water, snow may enter inside if the installation is on ground.

Heat pump can be installed on concrete basic or steel support.

6) Please install a shed for the heat pump, otherwise, rain water can reduce the

lifetime of the shell, and snow may cover the air outlet.

7) Water drainage ditch should be set around the heat pump, when heat pump is

working, there is condensing water flow down, or when defrosting, there are

plenty of water flow down too.

8) Heat pump should far away from kitchen exhaust, because the finned tube is

not easy to clean if there is oil on it.

≥0.5m

≥0.5m

≥2m

≥0.5m

Top side

Ground

Front

side

Back

side

2. Installation

2.4 Distances to barrier and ground

≥0.5m

≥1m

≥0.5m

≥0.5m

Top side

Ground

Front

side

Back

side

Other notes of installation

1) Heat pump must be installed on flat concrete blocks or a raised concrete

platform, or steel bracket.

2) Between heat pump and basic or bracket, at leas 4pcs anti-shock pads

should be placed

Concrete basic Steel bracket

Anti-shock pad

Expansion bolt

3) Before make basic or bracket, please check heat pump dimension

4) Before fix heat pump on basic, please confirm heat pump direction according to

project design.

5) Normally use expansion bolt to fix heat pump on concrete basic.

6) Make sure circulating water pipe must be ≥DN25 (or PPR32), and pipes must be

insulated.

7) When install water temp sensor on pipe or in water tank, make sure temp

sensor will not touch water directly, best through a sensor tube. Like below

picture.

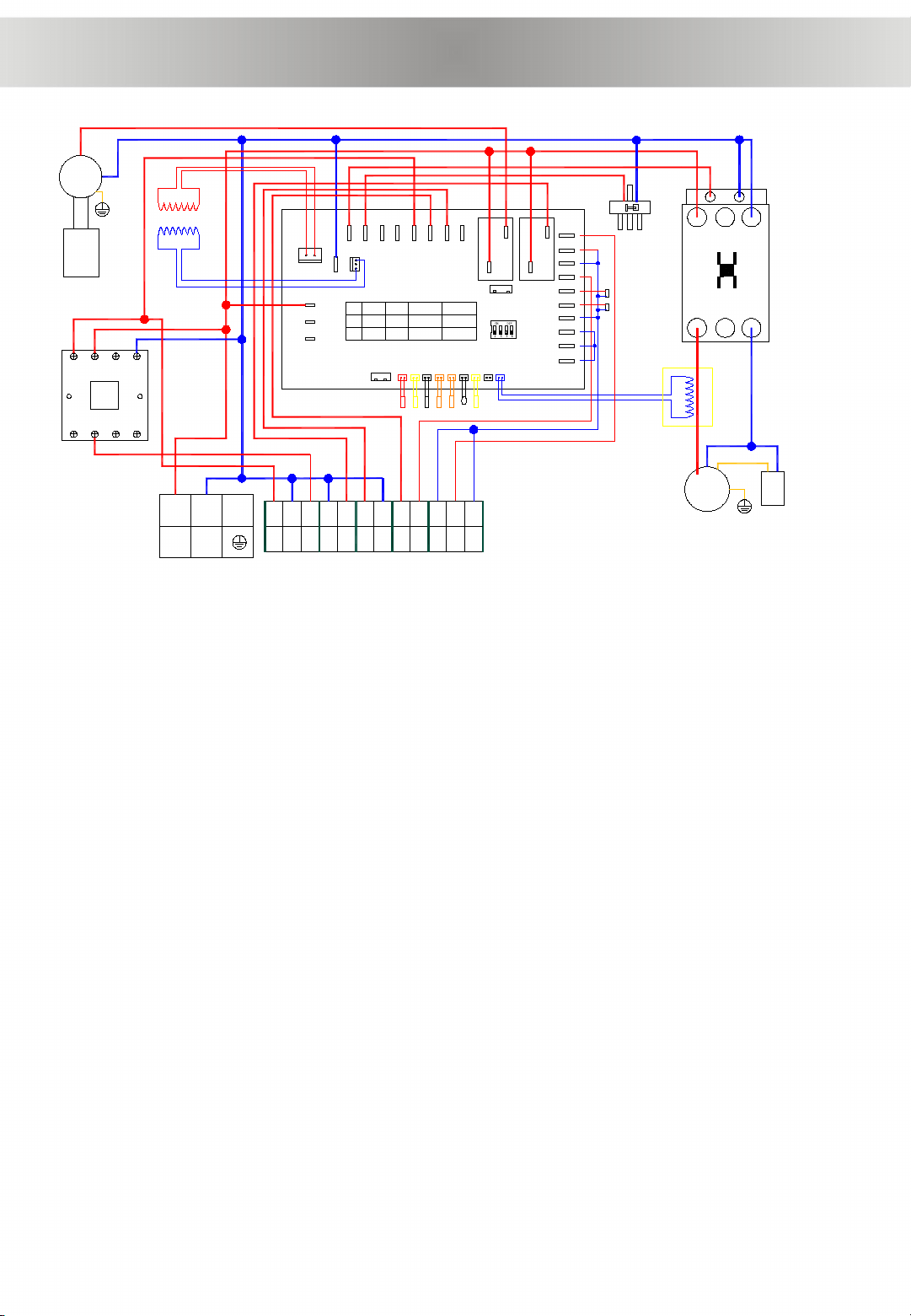

Wiring diagram

Secondary

AC-N

OUT1

CN1

CN2

Electric expansion valve

COM

Primary

N input

S3

Figure

ON

S2

S1

COM2 IN1 IN2 IN3 IN4 IN5 IN6 IN7 IN8

Compressor

OUT2 OUT3 OUT4 OUT5 OUT6 OUT7 OUT8

Communication

CN1 CN2 CN3 CN6 CN8 CN9 CN11 CN12 CN13 CN14

AR

B

C

GND 12V

GND

Cycle

heating

Instant + cycle

heating

1 phase

3 phase

S4

Hot water

Swimming pool

Tank

L N

Fan

motor

A1 A2

1L1 3L2 5L3

2T1 4T2 6T3

220V/50Hz/1ph single compressor system

wiring diagram

Fan motor

capacitance

Transformer

Current

transformer

Compressor

CS

R

Compressor

capacitance

4-way valve

Solenoid valve A

3-way valve

A/C electric heater

Hot water electricheater

Solenoid valve B

L input

Fan motor

L input

Cycle water pump

Linkage

Water pressure switch

Water flow switch

High pressure switch

Low pressure switch

High water level

Low water level

S

T

Standby

Standby

floor heating

Air HE coil

Outlet gas

Inlet gas

Air

Standby

Current

4-way valve

high pressure switch

low pressure switch

6 5 4 3

7 8 1 2

Cycle water pump

Water flow

Room Linkage

floor heating valve

hot water valve

N

Crankcase heater

N

Outlet water

room linkage

Hot water electric heater

Floor heating electric heater

REMARKS:

The max current of the hot water cycle water pump is 10A

The max current of the Hot water electric heater is 6A

The max current of the floor heating electric heater is 6A

N

COM

COM

Cycle water pump

Water flow

Room Linkage

Floor heating valve

hot water valve

Hot water electric heater

Floor heating electric heater

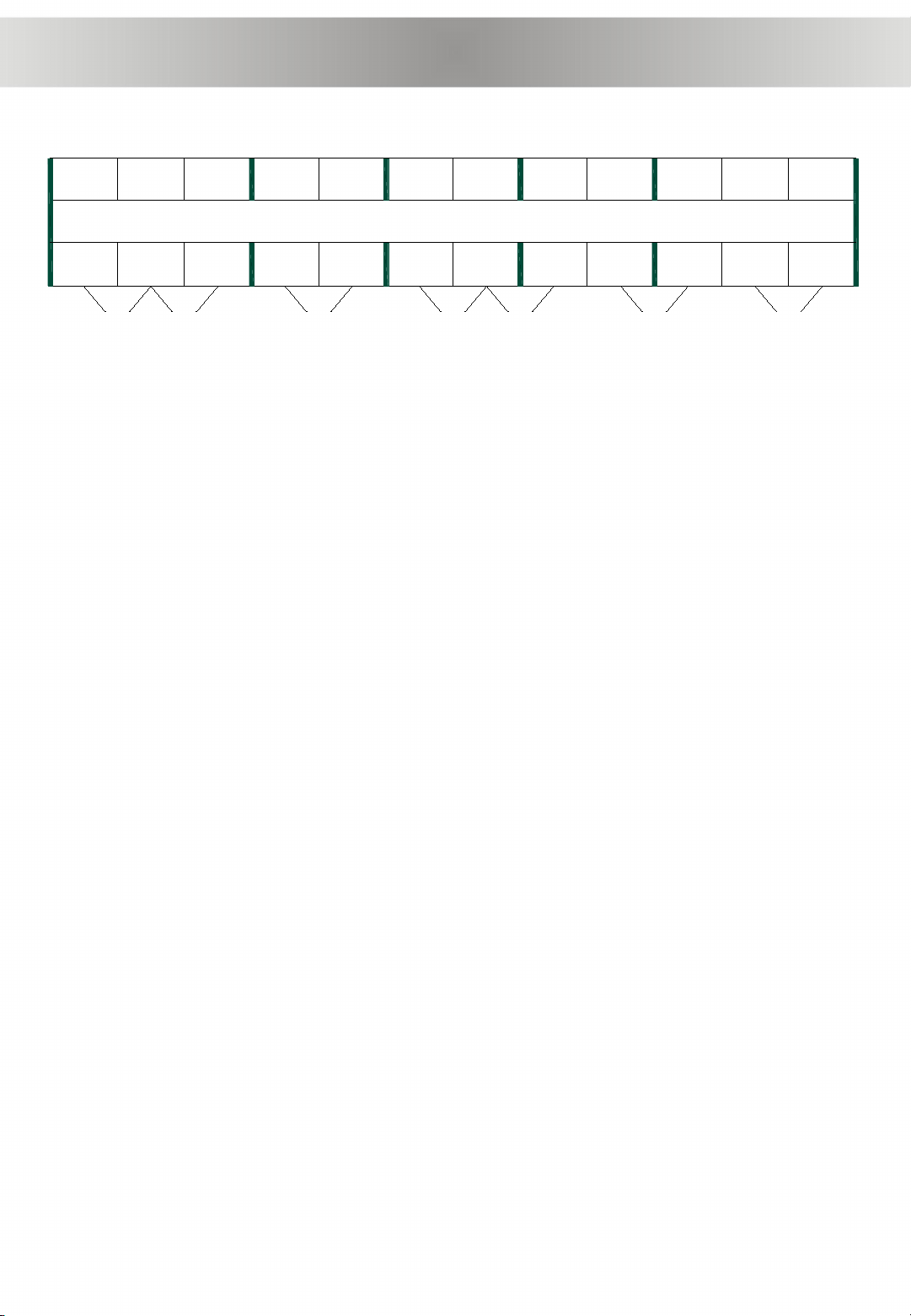

1 N 2 N N3 4 5 6 F 7 F

F a c t o r y s i d e

I n s t a l l e r s i d e

Terminal details of wiring

1. Floor heating valve:

When floor heating side work, 3-way valve coil get electricity. The terminal supply

220V/1ph voltage.

2. Hot water valve:

When hot water side work, 3-way valve coil loss electricity. The terminal supply

220V/1ph voltage.

3. Cycle water pump:

Rated current should be less than 12A, and power supply is 220V/1ph, if the

current is larger than 12A, should through AC contactor, like below drawing.

4. Hot water electric heater:

Max carrying current is 6A. 220V/50Hz/1ph. If electric heater input power is >1KW,

should though a AC contact to connect to the terminal.

5. Floor heating electric heater:

Max carrying current is 6A. 220V/50Hz/1ph.

(This terminal is optional, it can be chassis electric heater of heat pump too. When place

your order from factory, If select there is chassis electric heater, then floor heating electric

heater will not be included, but will change to chassis electric heater)

6. Water flow switch:

It is ON/OFF input signal, dry contact.

We didn’t install water flow switch inside, please install the water flow switch on water

pipe and connect the wire line to water flow terminals. If don’t install water flow switch,

please bridge connecting it.

7. Room linkage:

It is ON/OFF input signal, dry contact.

At hot water + heating mode:

If room linkage connects, heat pump will performs heating + hot water mode.

If room linkage disconnects, heat pump will performs hot water mode only.

Factory have connects the room linkage switch manually.

If installer want that when any floor heating start, heat pump performs heating + hot

water mode, when no floor heating work, heat pump only performs hot water mode, can

connect all room thermostat to the linkage. Drawing details can refer to below drawing.

Communication

CN1 CN2 CN3 CN6 CN8 CN9 CN11 CN12 CN13 CN14

Tank

floor heating

Air HE coil

Outlet gas

Inlet gas

Air

Standby

Current

Outlet water

Communication: connect operating panel

Tank: Hot water tank temp sensor (installer should install the probe in tank)

Outlet water: Outlet water temp sensor (has been installed in heat pump)

Air HE coil: Source side (air) heat exchanger coil temp sensor (has been installed in

heat pump)

Outlet gas: outlet gas temp sensor of compressor (has been installed in heat pump)

Inlet gas: Inlet gas temp sensor of compressor (has been installed in heat pump)

Air: ambient air temp sensor (has been installed in heat pump)

Floor heating: floor heating water temp sensor (has been installed in heat pump,

installer can move the probe into floor heating water tank)

Current: detect compressor current (has connected by factory)

Analog signal input

Power supply terminal block

L N Power Supply

Input

Output

Size of power supply line:

L line: 1.5mm2

N line: 1.5mm2

Voltage: 220V~240V/50Hz/1Ph

Max working current: 17A

Circuit breaker: 32A

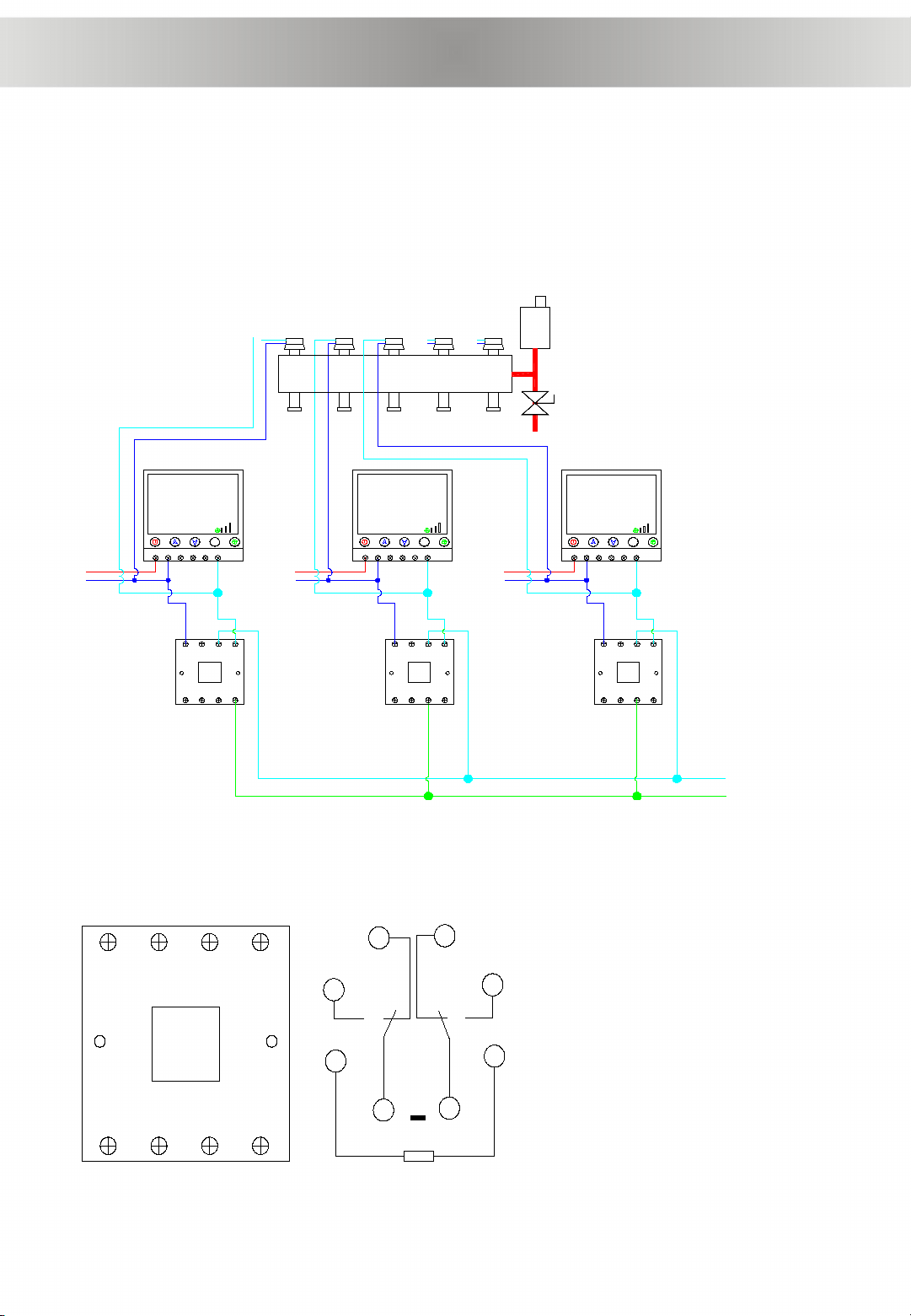

For floor heating system, if want P2 (heating system water pump)

stops when all floor heating loops needn’t work, can connect all the

room thermostat to P2h, the wiring diagram as below.

Wiring diagram of all room thermostat control water pump (P2)

AC 220V

L

N

P2

L1 L3 L5

T2 T4 T6

L1 L3 L5

T2 T4 T6

L1 L3 L5

T2 T4 T6

AC 220V

L

N

AC 220V

L

N

Water separator

AC

contactor

M

L N H M L V

20C°

M

23:25

L N H M L V

20C°

M

23:25

L N H M L V

20C°

M

23:25

Room

thermostat

Floor heating

water separator

Wiring diagram of all room thermostat connect to room linkage terminal

AC 220V

L

N

Room

linkage

AC 220V

L

N

AC 220V

L

N

Water separator

L N H M L V

20C°

M

23:25

L N H M L V

20C°

M

23:25

L N H M L V

20C°

M

23:25

65

4

3

7 8 1 2

65

4

3

7 8 1 2

65

4

3

7 8 1 2

Change-over

switch

Room

thermostat

Floor heating

water separator

If want heat pump only performs at hot water side when floor heating side no need,

can connect all room thermostats to “Room linkage” terminal.

6

5

4

3

7 8 1 2

2

1

8

7

6

54

3

coil

2 and 7 input side connect 220V

power supply,output side connect

coil

1,3,4 are a group,1 and 3 normal

open,1 and 4 normal close。when

coil loss electricity, 1 and 4

connects,when coil get electricity,1

and 3 connects。

8,6,5 are a group. 8 and 5 normal

close,8 and 6 normal open. when

coil loss electricity, 5 and 8

connects,when coil get

electricity,6 and 8 connects.

This manual suits for next models

1

Table of contents

Other SPRSUN Heat Pump manuals