Spudnik 560 Owner's manual

OWNER’S / OPERATOR’S MANUAL

Part # 290163

MODEL 560

TELESCOPING PILER

11

MISSION STATEMENT

Our mission is to consistently provide

high quality, reliable, safe, and well-designed

products and services to meet or exceed the needs

of our customers.

Operating Manual Overview

The purpose of this Spudnik Operating Manual is to make the user familiar with this

machine and to assure the machine is used for what it has been designed to do.

This Operating Manual contains important information on how to operate this machine

properly and efficiently while maintaining all safetyregulations. Observing and

practicing the information within this Manual can effectively prevent danger, reduce

repair costs and downtimes, while increasing reliability and service life ofthe machine.

The Operating Manual must always be available to users wherever the machine is in use.

The Operating Manual must be read and applied by all persons working on/with the

machine, e.g.

•Operation -including set-up, troubleshooting, care, etc.

•Maintenance –servicing, inspection, repair.

•Transport

22

33

Service Centers

Phone:(208)785-0480-Fax: (208)785-1497

E-Mail: [email protected]

Web Site:www.spudnik.com

BLACKFOOT PASCO GRAFTON

584 West 100 North 5802 North Industrial Way 1410 12th St. West

P.O. Box 1045 Pasco, Wa. 99301 Grafton, Nd. 58237

Blackfoot, ID 83221 Phone (509) 543-7166 Phone (701) 352-9603

Phone (208)785-0480 Fax (509) 543-7169 Fax (701) 352-9610

Fax (208)785-1497

HEYBURN PRESQUE ISLE

300 Centennial Dr. 110 Airport Dr.

Heyburn, ID 83336 Presque Isle, Me. 04769

Phone (208)436-8052 Phone (207) 764-4686

Fax (208) 436-9170 Fax (207) 764-4674

44

TABLE OF CONTENTS

PAGE

Introduction 4

Warranty 5

Safety 6,7

Safety Practices 8 -10

Safety Labels 11

Piler Operation 12

Piler Operation With Remote 13

Lubrication 14

Maintenance 15

Elevator & Boom Belt Options

19

Machine Parts Breakdown

Table Of Contents

20

Hydraulic Schematic 92

Electrical Schematic 96

55

INTRODUCTION

Welcome to the SPUDNIK line of potato handling equipment. We appreciate your

decision to make our equipment a part of your operation, and look forward to a long-term

partnership. We strive to put the best quality and workmanship into each of our machines,

and hope as you use your MODEL 560 TELESCOPING PILER, that you will find this to be

true. This owner’s / operator’s manual has been prepared to aid you in safe operation and

service of your Telescoping Piler.

Read manual carefully to learn how to operate your machine safely and within

design limits of machine. Failure to do so could result in personal injury and/or damage to

machine.

This manual is an important part of this machine, and should accompany it when

moved from location to location.

Warranty is provided as part of the SPUDNIK EQUIPMENT COMPANY LLC service

program for customers who operate, and maintain their equipment as outlined in this

manual.

OWNER REGISTRATION

Name _____________________________________________

Address ___________________________________________

City ______________________________________________

State / Province _____________________________________

Country ___________________________________________

Model Number ____________ Serial Number _____________

Purchase Date _____________________________________

66

Limited Warranty Policy for New Spudnik Machinery

Spudnik Equipment Company LLC (“Spudnik”) warrants to the original purchaser each new Spudnik machine to be free from defects in material and

workmanship. Spudnik will repair or replace, at its option, any part covered by this warranty that is found to be defective during the warranty period

outlined below. Warranty service must be performed by an authorized dealer or representative of Spudnik. This warranty is applicable only for the

normal service life expectancy of the product or components, as noted in the following table. Once the warranty period has begun, it cannot be

stopped or interrupted.

What is included in the Spudnik Warranty:

Those items that are excluded from this warranty are as follows:

(1) any merchandise or components thereof, which, in the opinion of the company have been subject to: (a) Rock chip damage and other abuse to

painted surfaces, (b) damage caused by weather (to include UV damage), accident, or acts of God, (c) any product that has been altered or modified in

ways not approved by Spudnik Equipment Company LLC., (d) depreciation or damage caused by normal wear, lack of reasonable and proper

maintenance, misuse, failure to follow the product’s Operator Manual recommendations,(e) Using machine for other than normal moving of agricultural

products during planting, harvest, and processing seasons. Agricultural products to include: Potatoes, beets, onions, carrots, grains, etc.,(2) Used

products, (3) Repairs made by unauthorized dealers.

To Obtain Warranty Service

To be eligible for the Spudnik warranty, purchaser must: (a) Have already remitted payment in full (b) have filled out and submitted the Spudnik

Delivery Declaration form to a Spudnik representative (c) report the product defect to an authorized dealer or Spudnik sales representative and

request repair within 30 days of noticing the defect and (d) make the product available to the dealer or service center within a reasonable period of

time, transportation charges prepaid.

The selling dealer has no authority to make any representation or promise on behalf of Spudnik, or to modify the terms or limitations of this warranty

in any way.

Limited Warranty Statement

To the extent permitted by law, Spudnik does not make any warranty, representation, or promises express or implied as to the quality, performance,

or freedom from defect of any Spudnik New Machinery. NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS IS MADE. IN NO

EVENT WILL SPUDNIK, AN AUTHORIZED SPUDNIK DEALER, OR ANY COMPANY AFFILIATED WITH SPUDNIK BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. This warranty is subject to any existing conditions of supply which may directly affect our ability to

obtain materials or manufacture replacement parts. Spudnik reserves the right to make improvements in design or changes in specifications at any

time, without incurring any obligation to owners of units previously sold. No one is authorized to alter, modify or enlarge this warranty nor the

exclusion, limitations and reservations.

To obtain more information, please contact your dealer or Spudnik at 1-208-785-0480.

Product

Warranty Term

Rollers, Sprockets, Roller Chain, Belt Lacing, and Bearings

180 Days from 1

st

day of operation or 720 Hours of machine

operation, whichever comes first

All paint to include: Insufficient coverage, failure of paint adherence, and excessiveruns.

NOTE: Excessive runs not to exceed more than 15% of the painted surface on the

machine.

12 Months from date of delivery of new Spudnik product to

the original retail customer

All other materials and workmanship (except as noted below)

12 Months from date of delivery of new Spudnik product to

the original retail customer

Genuine Spudnik replacement parts and components

30 days from date of purchase, or the remainder of the

original equipment warranty period, whichever is longer

7

SAFETY

You are responsible for the safe operation and maintenance of your SPUDNIK

TELESCOPING PILER. All operators and anyone doing work or maintenance on the

Telescoping Piler must be trained in the operation, maintenance procedures, and related

SAFETY information contained in this manual. All operators and maintenance personnel

must receive this training at least annually to be in compliance with OSHA regulation

1928.57. This manual is a guide to good safety practices that should be followed while

operating the Telescoping Piler.

The operator is the most important safety device on the machine. It is the operator’s

responsibly to read, and understand ALL operating, and safety instructions in manual.

ANY UNAUTHORIZED MODIFICATIONS TO MACHINE IS CONSIDERED A

BREACH OF CONTRACT, AND REMOVES ALL LIABILITY FROM THE

MANUFACTURER. Unauthorized modification may impair function of machine, and/or

safety, and could affect the life, and warranty of the Telescoping Piler.

THINK SAFETY! WORK SAFELY!

THE LIFE YOU SAVE MAY BE YOUR OWN!

88

SAFETY

SAFETY ALERT SYMBOL

THE SAFETY ALERT SYMBOL MEANS:

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The SAFETY ALERT SYMBOL identifies important safety information on the safety labels

and in this manual. When you see this symbol be alert to the possibility of personal injury

or death.

SIGNAL WORDS:

DANGER, WARNING, and CAUTION are signal words with messages:

DANGER: An immediate and specific hazard, which WILL result in

severe injury or death if proper precautions are not taken.

WARNING: A specific hazard or unsafe practice, which COULD result in

severe injury or death.

CAUTION: Unsafe practices, which COULD result in personal injury if

proper precautions are not taken.

99

SAFETY PRACTICES

GENERAL SAFETY PRACTICES

• The primary responsibility for safe operation of the Spudnik Telescoping Piler lies with

the owner/operator.

• OSHA (Occupational Safety and Health Administration) requires that all operators be

trained at the time of initial assignment, and annually thereafter by the employer in the

safe operation of the Telescoping Piler.

• Read, and understand the operator’s manual before operating, maintaining, or

adjusting the Telescoping Piler.

• Untrained individuals, and children should not be allowed on, or around the

Telescoping Piler at anytime.

• Keep hands, feet, long hair, and clothing away from moving, and/or rotating parts.

• Never wear ill-fitting, baggy, or frayed clothing when working around, or on any drive

system component.

• Do not attempt to service, lubricate, clean, or adjust the Telescoping Piler while it is

running.

• Inspect all mechanisms before starting the Telescoping Piler, and replace all worn, or

damaged parts.

• Make sure all guards, and shields are properly installed, and are secured before

operating the Telescoping Piler.

• Replace all worn or missing bolts with SAE Grade 5, or better unless specifically stated

otherwise.

1010

SAFETY PRACTICES

HYDRAULIC SAFETY PRACTICES

• Before applying pressure to the system make sure all components, fittings, steel lines,

and hoses are tight, and undamaged.

• Remove, or safely block all loads that are supported by hydraulic cylinders before

loosening any hydraulic line, fitting, or hose.

• Wear proper eye, and hand protection, and use wood, or cardboard as a backstop

when looking for hydraulic leaks.

• A high-pressure hydraulic leak can ignite if exposed to an open flame, or spark.

• Seek immediate medical attention if hydraulic fluid pierces the skin, serious toxic

reactions, and/or infections will result.

TRANSPORTING SAFETY PRACTICES

• Towing speed should not exceed 20 MPH due to farm rated tires, and wheels.

• It is recommended that all pups be removed from Telescoping Piler before transporting.

• Replace and secure trailing braces on boom, and elevator, and bottom boom chain,

and release hydraulic pressure on elevator, and boom cylinders.

• The outriggers must be lifted, and secured with the 1” lock pin.

• The boom must be retracted, and kept straight with piler while loading, unloading, or

towing the Telescoping Piler.

• Whenever possible, it is recommend that the Telescoping Piler be placed on a trailer

when moving long distances.

• Make sure the pin in the tow tongue is secure, and the pins are removed from towable

gearbox wheel drive.

• When towing the Telescoping Piler, the local highway, and transport authorities require

a slow moving vehicle sign.

• The slow moving vehicle sign must be clean and visible by overtaking and oncoming

traffic.

• Keep the towing vehicle and the Telescoping Piler under control when going down

long, and/or steep grades.

• Do not allow riders on the Telescoping Piler during transportation.

1111

SAFETY PRACTICES

OPERATING SAFETY PRACTICES

• Always keep children, and unqualified personnel away from the machinery to avoid

serious injury, or death.

• Properly ground all electrically operated equipment.

• Piler should be operated on a flat secure surface.

• Be sure that there is no one around the Telescoping Piler when moving it back, and

forth, except the operator.

• Do not lift, rotate, or extended the boom until the outriggers are lowered, and are

secured with the 1” lock pins.

• Outriggers must be down, and locked tightly in position while piler is in operation.

• Disconnect electrical power to the machine when cleaning clogged belts, or chain,

removing obstructions, or removing dirt buildup from components.

• Never ride, or walk on the boom while the piler is in operation.

• Never stand under the boom while the piler is operating.

• Never stand, or work on the boom unless the boom is being securely supported from

underneath by something other than the cylinders.

• All trailing braces should be in position, and hydraulic pressure released from cylinders,

or boom and elevator should be securely supported from underneath, while machine is

in storage.

• Piler should be stored on a flat secure surface.

1212

SAFETY LABELS

• Keep safety labels and signs clean and legible at all times.

• Replace safety labels and signs that are missing or have become illegible.

• When replacing parts that display a safety sign, make sure that the new parts also

displays the safety sign.

• Safety labels and signs are available from your dealer’s parts department.

HOW TO INSTALL SAFETY LABELS

1. Be sure the installation area is clean and dry.

2. Decide on the exact position before you remove the backing paper.

3. Remove the smallest portion of the split backing paper.

4. Align the label over the specified area and carefully position the small portion with the

exposed sticky backing in place.

5. Slowly peel back the remaining paper and carefully smooth the remaining portion of the

label in place.

6. Small air pockets can be pierced with a pin and smoothed using the piece of label

backing paper.

1313

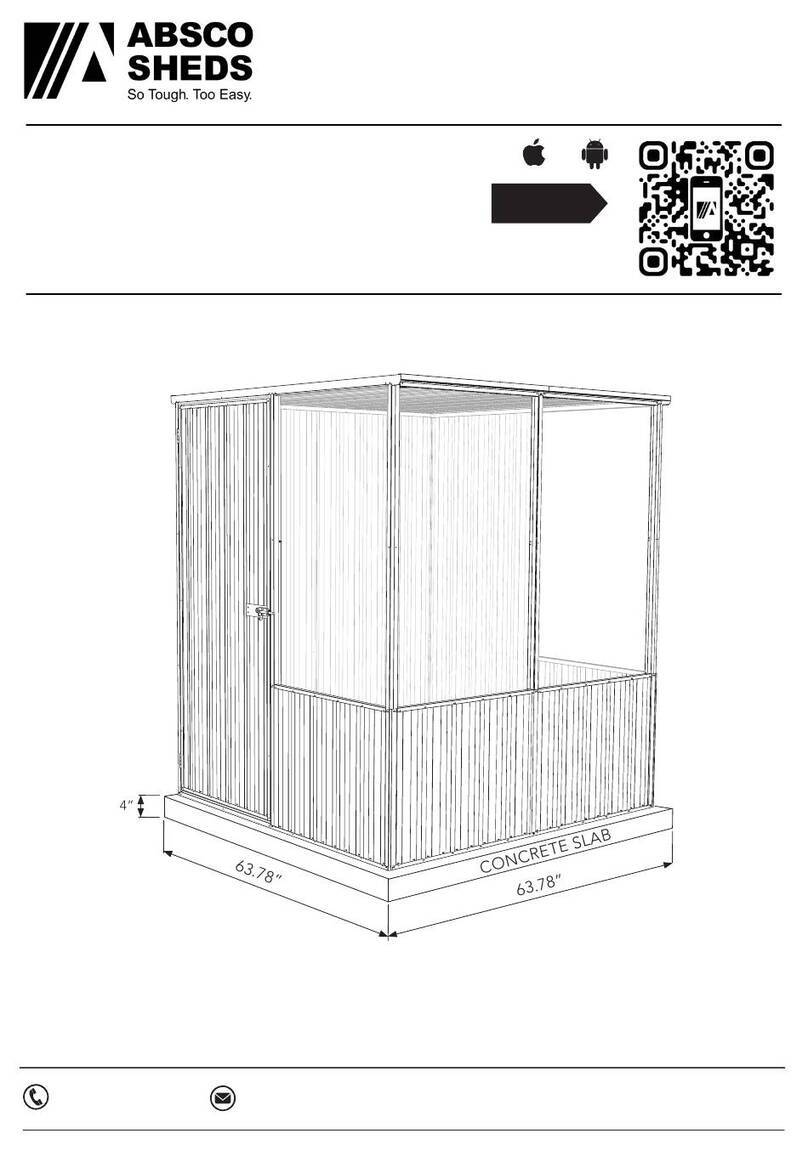

PILER OPERATION

The model 560 piler has been designed to pile potatoes for storage and to load them on

trucks and trailers for transport, in the most efficient manner to maintain integrity and

structure of product.

Controls can be located on right or left side of piler and should be operated by

single operator, standing by side of piler. If the machine is equipped with

remote control, the operator has the option of moving freely around the

machine.

OPERATION INSTRUCTIONS

To shift from high speed to low speed on the ground drive you must shut the

ball-valve, located on left wheel drive motor.

Be sure that the Outriggers are down and lock pins are in place before the boom is

rotated.

MANUAL RUN OPTION

(HAND)

1. Make sure main disconnect and all switches are off.

2. Look at piler voltage sticker. Make sure power source voltage is same as piler voltage.

Also, make sure power source and cord sizes are adequate to handle amp load of piler.

(Any questions please call your nearest service center.)

3. Plug piler in and turn main disconnect ON.

4. For phasing it is important to select only the elevator switch. Turning switch to HAND,

only for a second, to make sure elevator motor is running in the right direction. Then

continue to run desired motors.

5. When finished running piler, turn switches to OFF, then turn main disconnect OFF.

6. Do not forget to unplug machine before any maintenance or repair is initiated on piler.

1414

PILER OPERATION WITH REMOTE

(AUTO)

1. Follow step 1-4 from page #12, (MANUAL RUN OPTION).

2. Make sure all persons are clear of machine, and no maintenance is being performed,

turn all switches to AUTO position.

3. Turn radio control switch to ON.

4. Push the ON button on the transmitter (hand held unit). The hydraulics will start when

the function buttons are pushed.

5. Now you are ready to run the belts. Push and hold the START button on the transmitter

until buzzer stops, then release the START button. Belts will start in sequence; bottom

belt , top belt, and elevator.

6. The hydraulic functions for the boom are listed on the push button pad, on the

transmitter.

7. There is an EMERGENCY STOP button on the transmitter. When pressed, hydraulics

and belt will shut down. To start piler again, push the transmitter button OFF, then the

ON button again.

VARIABLE SPEED

1. The potentiometer inverter on the main electrical panel door, (refer to section M-56,

page #85, item #3) will run the variable speed of the belts. With the remote control

option use the FAST & SLOW buttons on the transmitter.

1515

LUBRICATION

• The hydraulic system used to power auxiliary functions uses Dexron III E ATF

(automatic transmission fluid) for prime mover. Hydraulic reservoir fill level should be

checked at start of each season, and filled as needed. Hydraulic oil reservoir has a 15-

gallon capacity. The all-hydraulic piler has a 30-gallon oil reservoir capacity.

(# 991362 - FLUID,AUTOMATIC,TRANS DEXRON III E PENNZ)

• ATF in hydraulic system should be changed every 1000 hours of machine operation.

• Top and lower post bearings need to be greased at least once a day.

• Boom hinge pins, inside and out, need to be greased once a week.

• Steering bushing need to be greased once a week.

• All wheel bearings and wheel hubs should be greased and packed at least once a year.

• Change hydraulic oil filter every 300 hours of machine operation.

• Oil should be changed when it becomes dirty, and/or contaminated.

• Oil in gearboxes must be checked every 100 hours of operation.

(# 991214 - OIL,LUBE,80/90W#4096 35#PAIL 1QT=1.75LB)

• All bearings are of sealed type and are lubricated by manufacturer. Bearings will only

need to be greased at start of season. Over greasing sealed bearings will result in seal

being broken and rapid failure of bearing. If seal is broken, bearing should be greased

daily until replaced. One pump of grease at start of season is sufficient.

1616

MAINTENANCE

• Disconnect electrical power to machine whenever maintaining, repairing, or servicing

piler.

• Replace damaged or missing drive shields and safety labels at start of every season.

• Proper belt alignment and tension are key to long belt life.

• Belts should be kept in alignment between conveyor shell; alignment should be an

even distance between belt and conveyor shell on each side.

BELT ALIGNMENT PROCEDURE

Belt runs to loose side (narrowest space between belt and side)

Tighten loose side as necessary or loosen other side as necessary.

Belt tension must be great enough to prevent slippage between drive pulley and

belt.

• Keep tires inflated correctly.

Drive wheels 12-16.5 LT = 75 PSI. Cold, Steering wheels 7.50-16 LT = 60 PSI. Cold,

Outrigger wheels 6.70-15 = 35 PSI. Cold.

• Check boom hinge points and post hinge pins every 100 hours of machine operation

for fatigue and excessive wear. Replace as needed to avoid personal injury.

• To avoid contamination of product all hydraulic fittings should be checked daily for

leaks and replaced or tightened as necessary.

1717

ART#

DESCRITION

61660

BELT,ASSY,560,30"x41'4",1"CLT BELT ELEV

61661

BELT,ASSY,560,30"x41'4",1"CHEV BELT ELEV

351 85

ASSY,BC,30"x11MMx36MM 3D1S1U1SCUSH 4 '0"

35 030

ASSY,BC,30"x11MMx4 MM 3D1S1U1SCUSH 4 '0"

6166

BELT,ASSY,560,36"x41'4",1"CLT BELT ELEV

61663

BELT,ASSY,560,36"x41'4",1"CHEV BELT ELEV

351 86

ASSY,BC,36"x11MMx36MM 3D1S1U1SCUSH 4 '0"

35 031

ASSY,BC,36"x11MMx4 MM 3D1S1U1SCUSH 4 '0"

61561

BELT,ASSY,560,30"x55'0",FLAT TOP BOOM

6163

BELT,ASSY,560,30"x55',1/"CLT TOP BOOM

61635

BELT,ASSY,560,30"x55',1/"CHEV TOP BM

61561

BELT,ASSY,560,30"x55'0",FLAT TOP BOOM

6163

BELT,ASSY,560,30"x55',1/"CLT TOP BOOM

61635

BELT,ASSY,560,30"x55',1/"CHEV TOP BM

61559

BELT,ASSY,560,30"x44'0",FLAT 48'BTM BOOM

61630

BELT,ASSY,560,30"x44',1/"CLT 48'BTMBOOM

61633

BELT,ASSY,560,30"x44',1/"CHEV 48'BTM B

61560

BELT,ASSY,560,30"x48'0",FLAT 50'BTM BOOM

61631

BELT,ASSY,560,30"x48',1/"CLT 50'BTMBOOM

61634

BELT,ASSY,560,30"x48',1/"CHEV 50'BTM BM

61564

BELT,ASSY,560,36"x55'0",FLAT TOP BOOM

61647

BELT,ASSY,560,36"x55',1/"CLT TOP BM

61650

BELT,ASSY,560,36"x55',1/"CHEV TOP BM

61564

BELT,ASSY,560,36"x55'0",FLAT TOP BOOM

61647

BELT,ASSY,560,36"x55',1/"CLT TOP BM

61650

BELT,ASSY,560,36"x55',1/"CHEV TOP BM

6156

BELT,ASSY,560,36"x44'0",FLAT 48'BTM BOOM

61645

BELT,ASSY,560,36"x44',1/"CLT 48'BTM BM

61648

BELT,ASSY,560,36"x44',1/"CHEV 48'BTM BM

61563

BELT,ASSY,560,36"x48'0",FLAT 50'BTM BOOM

61646

BELT,ASSY,560,36"x48',1/"CLT 50'BTM BM

61649

BELT,ASSY,560,36"x48',1/"CHEV 50'BTM BM

560 TO 30" BOOM BELT

560 BOTTOM 30" BOOM BELT

560 TO 36" BOOM BELT

560 BOTTOM 36" BOOM BELT

BELTS FOR THE 560 ILER

560 30" BELT ELEVATOR

560 30" CHAIN ELEVATOR

560 36" BELT ELEVATOR

560 36" CHAIN ELEVATOR

18

Model 560 Piler

18

SHIELDS&SAFETYLABELSPLACEMENT

5 2

34 7

5 3

1

5

465 2

19

Model 560 Piler

19

Table of contents

Other Spudnik Farm Equipment manuals

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 990 User manual

Spudnik

Spudnik 1860 Programming manual

Spudnik

Spudnik 990 User manual

Spudnik

Spudnik 1110 User manual

Spudnik

Spudnik 9706 User manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 930 User manual

Spudnik

Spudnik 995 Owner's manual

Spudnik

Spudnik 990 User manual

Spudnik

Spudnik 990 User manual

Spudnik

Spudnik 780 User manual

Spudnik

Spudnik 80 Series User manual

Spudnik

Spudnik AIRSEP 992 Owner's manual

Spudnik

Spudnik 930 User manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 6200 User manual

Spudnik

Spudnik 2350 User manual

Spudnik

Spudnik 991 Owner's manual

Spudnik

Spudnik 990 Owner's manual