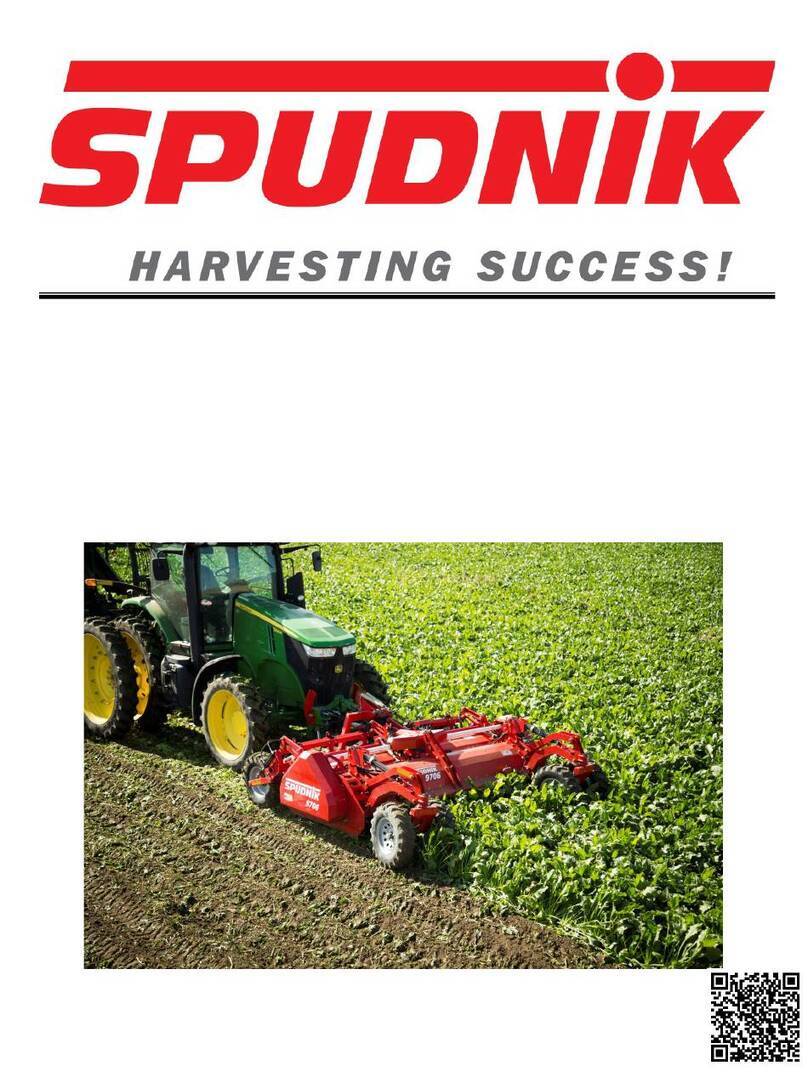

Spudnik 991 Owner's manual

Owner/Operator Manual

Ser # 991-55-5

MODEL 991

Custom Eliminator

Operating Manual Overview

The purpose of this Spudnik Operating Manual is to make the

user familiar with this machine and to assure the machine is used

for what it has been designed to do.

This Operating Manual contains important information on how to

operate this machine properly and efficiently while maintaining all

safety regulations. Observing and practicing the information

within this Manual can effectively prevent danger, reduce repair

costs and downtimes, while increasing reliability and service life

of the machine.

The Operating Manual must always be available to users

wherever the machine is in use.

The Operating Manual must be read and applied by all persons

working on/with the machine, e.g.

Operation - including set-up, troubleshooting, care, etc.

Maintenance – servicing, inspection, repair.

Transport

Operator's Manual Model 991

Page 1

Operator's Manual Model 991

Page 2

Operator's Manual Model 991

Page 2

Warranty Policy .........................................................................................4

Safety ...........................................................................................................5

General Safety Practices ............................................................................6

Hydraulics Safety Practices .......................................................................7

Transporting Safety Practices ...................................................................8

Operation Safety Practices ........................................................................9

Safety Labels .............................................................................................10

Maintenance ..............................................................................................12

Machine Parts Breakdown ……….……………....……………………..14

Schematics ………......................................................................................52

Table of Contents

Operator's Manual Model 991

Page 3

Limited Warranty Policy for New Spudnik Machinery

Spudnik Equipment Company LLC (“Spudnik”) warrants to the original purchaser eachnew Spudnik machine to be free from defects in

material and workmanship. Spudnik will repair or replace, at its option, any part coveredby this warrantythat is found to be defective

during the warranty period outlined below. Warranty service must be performed by an authorized dealer or representative of Spudnik. This

warranty is applicableonly for the normal service life expectancyof the product or components, as noted in the following table. Once the

warranty period has begun, it cannot be stopped or interrupted.

What is included in the Spudnik Warranty:

Product Warranty Term

180 Days from 1st day of operationor 720 Hours of machine

Rollers, Sprockets,Roller Chain, Belt Lacing, and Bearings operation, whichever comes first

All paint to include: Insufficient coverage, failure of paint adherence, and excessive runs. 12 Months from date of delivery of new Spudnik product to

NOTE: Excessive runs not to exceedmore than 15% of the painted surfaceon the the original retail customer

machine. 12 Months from date of delivery of new Spudnik product to

All other materials and workmanship (except asnoted below)the original retail customer

30 days from date of purchase, or the remainder of the

Genuine Spudnik replacement partsand components original equipment warranty period, whichever is longer

Those items that are excluded from this warranty are as follows:

(1) any merchandise or components thereof, which, in the opinion of the company have been subject to: (a) Rock chip damage and other

abuse to painted surfaces, (b) damage caused by weather (to include UV damage), accident, or acts of God, (c) any product that has been

altered or modified in ways not approved by Spudnik Equipment Company LLC., (d) depreciation or damage caused by normal wear, lack

of reasonable and proper maintenance, misuse, failureto follow the product’s Operator Manual recommendations, (e) Using machine for

other than normal moving of agricultural products during planting, harvest, and processing seasons. Agricultural products to include:

Potatoes, beets, onions, carrots, grains, etc., (2) Used products, (3) Repairs made by unauthorized dealers.

To Obtain Warranty Service

To be eligible for the Spudnik warranty, purchaser must: (a) Havealready remitted payment in full (b) have filled out and submitted the

Spudnik Delivery Declaration form to a Spudnik representative (c) report the product defect to an authorized dealer or Spudnik sales

representative and request repair within 30 days of noticing the defect and (d) make the product available to the dealer or service center

within a reasonable period of time, transportation charges prepaid.

The selling dealer has no authority to make any representation or promise on behalf of Spudnik, or to modify the terms or limitations of

this warranty in any way.

Limited Warranty Statement

To the extent permitted by law, Spudnik does not make any warranty, representation, or promisesexpressor implied asto the quality,

performance, or freedom from defect of any Spudnik New Machinery. NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS IS

MADE. IN NO EVENT WILL SPUDNIK, AN AUTHORIZED SPUDNIK DEALER, OR ANY COMPANY AFFILIATED WITH SPUDNIK BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. This warranty is subject to any existing conditions of supply which may directly affect

our ability to obtain materials or manufacture replacement parts. Spudnik reserves the right to make improvements in design or changes in

specifications at any time, without incurring any obligation to owners of units previously sold. No one is authorized to alter, modify or

enlarge this warrantynor the exclusion,limitations and reservations.

To obtain more information, please contact your dealer or Spudnik at 1-208-785-0480.

Operator's Manual Model 991

Page 4

Operator's Manual Model 991

Page 4

SAFETY

This Safety Alert Symbol Means:

Attention!

Become Alert!

Your Safety is Involved!

This Symbol identifies important safety

information on the safety decals and in this

manual. When you see this symbol, be alert to

the possibility of injury or death.

You are responsible for the safe operation and maintenance of your Spudnik Eliminator. All operators

and anyone doing work or maintenance on the Eliminator must be trained in the operation, maintenance

procedures, and related SAFETY information contained in this manual. All operator’s and

maintenance personnel must receive this training at least annually to be in compliance with OSHA

regulation 1928.57. This manual is a guide to good safety practices that should be followed during

operation.

This Operator’s Manual is the most important safety device on the Eliminator. It is the operator’s

responsibility to read and understand ALL operating and safety instructions in this manual.

ANY UNAUTHORIZED MODIFICATIONS TO MACHINE IS CONSIDERED A BREACH OF

CONTRACT AND REMOVES ALL LIABLITY FROM THE MANUFACTURER. Unauthorized

modifications may impair the function of the machine and/or safety and could affect the life and

warranty of the Eliminator.

Think Safety! Work Safely!

The life you save could be your own!

Danger, Warning, and Caution are signal words with messages:

Danger: An immediate and specific hazard, which will result in severe injury or death if

proper precautions are not taken.

Warning: A specific hazard or unsafe practice, which could result in severe injury or death.

Caution: Unsafe practices, which could result in personal injury if proper precautions are

not taken.

Operator's Manual Model 991

Page 5

SAFETY

General Safety and Accident Prevention Regulations

The primary responsibility for safe operation of the Spudnik Eliminator is with the

owner/operator.

OSHA (Occupational Safety and Health Administration) requires that all operator’s be

trained at the time of initial assignment, and annually thereafter by the employer, in the

safe operation of the machine.

Read and understand the operator manual before operating, maintaining, or adjusting

the Eliminator.

Untrained individuals and/or children should not be allowed on or around the

Eliminator at any time.

Keep hands, feet, long hair, and clothing away from moving/rotating parts while it is

running.

Do not attempt to service, lubricate, clean, or adjust Eliminator while it is running.

Inspect all mechanisms before starting the Eliminator and replace all worn or

damaged parts.

Make sure all guards and shields are properly installed and secured before operating

the Eliminator.

Replace all worn or missing bolts with SAE Grade 5 or better unless specifically

stated otherwise.

Do not ride or mount the Eliminator while it is moving.

Do not perform maintenance on machine unless:

- Tractor is switched OFF and key is removed from ignition

- A warning sign is attached to the main switch of the machine

- Maintenance sight is secured

- Work is being done by trained individuals and someone had been appointed to

supervise

- Machine is on dry, level, and stable ground

- Proper lifting devices are used for lifting heavy loads (including hoists with adequate

load capacity and in proper working condition)

Operator's Manual Model 991

Page 6

Operator's Manual Model 991

Page 6

SAFETY

Specific Safety Instructions

Risk of injury when hitching up or unhitching machines to and from the tractor.

Never allow persons to stand between the tractor and the machine unless the towing vehicle is

secured against rolling away by means of the parking brake and/or chocks.

Secure all moving parts before transport.

Warning symbols indicate dangerous areas of the machine. Observation of the warning symbols

serves to ensure the safety of all persons working with the machine.

Hydraulic Safety Practices

When working on machine parts that are supported by hydraulic cylinders,ALWAYS support the

structure by some other means than the cylinders.

Before applying pressure to the system, make sure that all components, fittings, steel lines, and

hoses are tight and undamaged.

Wear proper eye and hand protection, and use wood or cardboard as a backstop when looking

for leaks.

A high-pressure hydraulic leak can ignite if exposed to an open flame or spark.

Seek immediate medical attention if hydraulic fluid pierces the skin. Serious toxic reactions

and/or infections may result.

Operator's Manual Model 991

Page 7

SAFETY

Transporting Safety Practices

Check to see if all bolts on tow tongue are in good condition, in place, and

secure.

Remove the pin from the towable gearbox wheel drive.

Release hydraulic pressure to the elevator lift cylinder.

It is recommended that all pups be removed from the Eliminator before

transport.

If leveling jacks are on the Eliminator, be sure that they are lifted all the way

up and are secured with 1” Bolts.

Towing speed should not exceed 20 mph due to farm rated tires and

wheels.

The slow moving vehicle sign required by the local highway and transport

authorities must be in place.

Sign must be clean and visible by overtaking and oncoming traffic.

Do not allow riders on Eliminator during transport.

Operator's Manual Model 991

Page 8

Operator's Manual Model 991

Page 8

SAFETY

Operating Safety Practices

Eliminator should be operated on a flat secure surface.

When using leveling jacks, make sure that the jacks are on secure

ground. Do not lift the wheels off of the ground.

Do not allow anyone to climb on or under the Eliminator while in

operation.

Do not put feet or hands between the picking table and dirt return

conveyor while machine is in operation.

Disconnect electrical power supply to machine when cleaning clogged

rollers or chain, removing obstructions, or removing dirt build up from

components.

Keep personnel from getting between the machine and other

machinery when placing equipment that delivers or removes product

from the Eliminator.

Do not allow anyone to pick dirt or potatoes off of the transition table

or roller table during operation. This action could result in physical

injury or death.

Properly ground all electrically operated equipment.

This machine is designated to have on operator standing on the same

side as the control panel and hydraulic drives.

Operator's Manual Model 991

Page 9

SAFETY

Safety Labels

Keep Safety labels and signs clean and legible at all times,

Replace Safety labels and signs that are missing or have become illegible.

When replacing parts that display a safety label, make sure that the new parts also

displays the safety label.

Safety labels and signs are available from your dealer’s parts department.

How to install Safety Labels

1. Be sure the installation area is clean and dry

2. Decide on the exact position before you remove the backing paper.

3. Remove the smallest portion of the split backing paper.

4. Align the label over the specified area and carefully position the small portion with the

exposed sticky backing in place.

5. Slowly peel back the remaining paper and carefully smooth the remaining portion of the

label in place.

6. Small air pockets can be pierced with a pin and smoothed using a piece of the label

backing paper.

Operator's Manual Model 991

Page 10

Operator's Manual Model 991

Page 10

MAINTENANCE

The hydraulic system used to power auxiliary functions uses AW 32 Hydraulic oil for

prime mover. Hydraulic reservoir fill level should be checked at start of each season,

and filled as needed. Hydraulic oil reservoir has a 5-gallon capacity.

Oil in hydraulic system should be drained and changed when it becomes dirty and/or

contaminated.

All wheel bearings and wheel hubs should be greased and packed at least once a

year.

Grease Steering Spindles once every week.

All bearings are of a sealed type and are lubricated by the manufacturer. Bearings will

not have grease zerks installed. One pump of grease is sufficient. Over greasing

sealed bearings will result in seal being broken and rapid failure of bearing. If seal is

broken, bearing should be greased daily until replaced.

To avoid contamination of product, hydraulic fittings must be checked daily for leaks

and replaced or tightened as necessary.

Oil in gearboxes must be checked every hundred hours of operation.

(#991214 - Oil,Lube,80/90W#4096 -15#Pail - 1 Qt=1.75lbs)

Oil should be changed when it becomes dirty and/or contaminated.

Disconnect electrical power to machine whenever maintaining, repairing, or servicing

Replace damaged or missing drive shields and safety labels at start of every season.

Proper belt alignment and tension are key to a long belt life.

Belts should be kept in alignment between conveyor sides. Alignment should be an

even distance on both sides from the belt to the conveyor sides.

BELT ALIGNMENT PROCEDURES

Belt runs to loose side (narrowest space between belt and side).

1. Tighten loose side as necessary or loosen other side as necessary.

2. Belt tension must be great enough to prevent slippage between drive pulley

and belt.

Check lug nut daily, and keep tires inflated at correct PSI.

Be sure the electrical system is setup with proper phase and adequate voltage.

Drive chains should be kept clean and tensioned correctly to prolong chain life. Ideal chain

tension should allow ½” maximum flex when deflected. Over tightening will cause damage to

bearings and sprockets. New roller chain drives should be inspected after 50 hours of

operation, and every 500 hours thereafter. During inspection, look for drive interference,

damaged chain or sprockets, loose set screws, proper sprocket alignment, chain tension, proper

lubrication, foreign material buildup, and percent elongation. To check for elongation, measure

from pin to pin and compare with new chain. When replacing chain or sprockets, it is best to

replace both at the same time.

Check V-belts for cracking and wear and replace as needed. A sign of belt wear would be a belt

that has stretched and is running in the bottom of the groove on the pulleys.

Check the hinge points and pivot bolts every 100 hours of machines operation for fatigue and

excessive wear. Replace as needed to avoid personal injury.

Operator's Manual Model 991

Page 11

OPERATING INSTRUCTIONS

1. Center any machine that feeds the Eliminator squarely to the elevator.

This allows the potatoes to spread out evenly and provides better sizing

and dirt elimination.

2.Adjust the elevator to the required height to eliminate drop.

3.Any equipment that receives product from the Eliminator needs to be

adjusted up close to the discharge chute. This will help eliminate

bruising of the potatoes.

4.The transition table will move with the rollers when they are adjusted.

Be sure that the letdown chute stays within the machine that receives the

product when adjusting the rollers.

5.Make sure that everyone is clear of the rollers and transition table

before adjusting the rollers.

6.Check to see that all shields are in place and secured. Make sure that

everyone is clear of the machine.

7. Make sure that all of the connectors and plugs on the machine are

attached, and are clear of water and other materials.

8. Make sure that the electrical panel door is closed and that there is no

maintenance being done on the machine.

9.Check the voltage label on the electrical panel door, to make sure that

you have the proper voltage.

10.All switches are turned to the “OFF” position.

11.The 16/4 cord coming off of the hopper end of the Eliminator is the

Evenflow stop circuit, used to turn the bottom belt on the Evenflow on and

off with the elevator of the Eliminator.

12.When using the Eliminator with a system, make sure the 16/5 wire

coming out of the main electrical panel is plugged in and the Conveyor

System switch is turned “ON.” When not using the Eliminator in a

system, leave the 16/5 unplugged and turn the conveyor System switch is

turned “OFF.”

13.Plug the machine in and test the direction on three phase system by

bumping a motor that does not have an Inverter, “briefly.” Making sure the

belt is going in the right direction. (Even though the power is hooked up

wrong, the inverter keeps the motor running in the right direction).

14.In “HAND” position, the machine will run each belt individually on

command. In “AUTO” position, the machine will run with the rest of

the system.

15.With all of the switches turned to “AUTO” and the Conveyor System

switch turned to “ON”, push and hold the green push button switch

until the buzzer stops. The conveyor system will start first. After it is

running, the Eliminator will start. When the Conveyor System switch is

turned “OFF”, there will be a brief delay and then the machine will

start.

Operator's Manual Model 991

Page 12

Operator's Manual Model 991

Page 12

991,AIRSEPCHAMBER-2014FB0470

44

Item# QTY DESCRIPTION PART#:

1 2 991AIR CHAMBER,INSIDE FRAME LIFT 176518

2 1 991FINGERHOLDERBAR 176520

3 2 991SHAKER,BEARING HUB 176521

4 1 991AIR CHAMBERDEBRISACCESCOVER 176534

5 1 991,72",BAFFLE2 198906

6 1 991,72",BAFFLE3 198907

7 1 991,72",BAFFLE4 198908

8 1 991,72",BAFFLE5 198909

9 1 991,72",BAFFLE6 198910

10 4 991SHAKERADJUSTMENTBOLT 198918

11 1 991BELTREARBAFFLE 262432

12 1 991BELTFINGERED 262433

13 2 991SIDE ADJUSTMENTPLATE GASKET 982552

14 1 991REARBAFFLE 982556

15 1 BAFFLE,FLOOR,AIRSEPCHAIMBER 176574

16 2 BRNG,INSERT1 1/4",2.83O.D. SET. SLS-120 231107

17 2 BRNG,2BOLT,FLNG.SCJT1-7/16"BORE 231050

18 2 BRNG,BALL,W/OHOUSING,SHAKER 231417

19 3 CARR-LANELATCH 982566

20 3 CARR-LANELATCHRECIEVER 982567

21 2 CLEVIS,FORK,THREADEDENDS,M8 981646

22 6 COLLAR,SHAFT,SET,SCREW,3/4" 501901

23 1 COUPLING,HYD,DRV,1-7/16"x1-1/4"3/8"x5/16 181504

24 1 CYL,2.00"x4",TIEROD,14.25",1.125",3/4 602610

25 1 DOOR,ACCESS,LOWERAIR CHAMBER 198948

26 1 FRAME,INSIDE,AIRCHAMBER 198944

Item# QTY DESCRIPTION PART#:

27 2 GIBHEADKEY3/8"x1-1/2" 982503

28 1 HANDLE,SHIELD,6140 NA4ZN 981664

29 9 NUT,BLIND THREAD,3/8INSIDE,5/8 OUTSIDE 182048

30 4 NUT,HEX,M12 502617

31 4 NUT,HEX,M12X1.75LEFTHAND 502855

32 4 OSCILLATING MOUNTAU18LHTHREAD 982469

33 4 RETAININGRINGEXTERNAL70MM 502866

34 2 RLR,BC,PU,5/8X3.5X2.625X5FL,SCGROVD 351267

35 1 ROD,1/2"x70-1/8" 040276

36 1 SHAFT,1-7/16"x86" 051233

37 2 SHAKERCAP,SMALL 176558

38 2 SHAKER,COVERPLATE 176174

39 2 SHAKER,ECCENTRIC,AIRSEP.500"OFFSET 176172

40 1 SPRING,GAS,7.87STROKE,200#FORCE,M8THRED 981950

41 1 STEELROLL,72"AIRSEP 198951

42 36 STIFFENER,ROCKDOOR,AIRSEP 176711

43 1 SUPPORT,INSIDE FRM,LH,AIR CHAMBER 198942

44 1 SUPPORT,INSIDE FRM,RH,AIRCHAMBER 198943

45 1 UHMW,1/4"x5"x72" 982551

46 4 WASHER,10GAx1-1/2"DIA,13/32"ID 176519

47 2 WASHER,3/16"x2"DIA,17/32"ID 176524

22 45

146

17

14

13

3

39

38

16

18

33

27 37 NA

47

Operator's Manual Model 991

Page 13

991,AIRSEPCHAMBER-2014FB0470

36

1

46

40

43

9

8

7

6

5

A A

SECTION A-A

41

20

25

15

21

21

35

19

25

10

B

DETAILB

2

12

29

23

34

41

17

46

122

11

32

42

30

31

26

24

36

14

6

C

DETAIL C

Operator's Manual Model 991

Page 14

991,AIRSEPCHAMBER-2014FB0470

428 19 20 25

40

42 2

12 41

34

Operator's Manual Model 991

Page 15

991,SHAKER ASSEMBLYFB0471

4

2

5

1

Item# QTY DESCRIPTION PART#:

1 1 991 SHAKERPLATE,72" 198923

2 1 FRAME,991 SHAKER,72" 198904

3 12 NUT,BLINDTHREAD,3/8 INSIDE,5/8OUTSIDE 182048

4 4 OSCILLATINGMOUNTAU18RHTHREAD 982378

5 2 PIN,991 SHAKER 198903

5

1

23

2

Operator's Manual Model 991

Page 16

991,HOOD,AIRSEPACCESSFB0473

34

1

2

Item# QTY DESCRIPTION PART#:

1 1 AIRHOOD,ACCESS WELDMENT 198946

2 1 AIRHOOD,ACCESS DOOR 198947

3 4 CLEVIS,FORK,THREADEDENDS,M8 981646

4 2 SPRING,GAS,7.87STROKE,200#FORCE,M8THRED 981950

Operator's Manual Model 991

Page 17

991,ASSY,REAR,CONVEYORSFB0474

A

A

SECTION A-A

Item# QTY DESCRIPTION PART#:

1 2 991 VINECONVEOR ACCESS COVERPLATE 176522

2 1 991 REARTOPCOVERPLATE 176536

3 1 991 REARBOTTOMCOVERPLATE 176537

4 1 991 BRACKET,VINECONVEYOR SHEAR 176538

5 2 991,VINECONVEYOR ACCESPANEL 176738

6 1 991 SHEAR,VINE CONVEYOR 982555

7 1 ARM,TORQUE,HYD,DRV,2HOLE,991SHAKER 176576

8 2 ARM,TORQUE,HYD,DRV,4HOLE 1/2"x12" 901495

9 1 ASSY,BC,72"x11MMx36MM STRCUSH3B8'4" 352836

10 1 ASSY,BC,72"x11MMx40MM TURF,3B,15'6" 353440

11 2 BRACKET,VINECHAINRLR MNT 198905

12 4 BRNG,PB,1-7/16"BORE,TTB,1/7/16,FAFNIR 231241

13* 2 CORDHOOK,BOLTABLE 176907

14 2 COUPLING,HYD,DRV,1-7/16"x1-1/4"3/8"x5/16 181504

15 1 FRAME,991 REAR,AIRVENT 198949

16 1 FRAME,991 REAR,BACKLH 198913

17 1 FRAME,991 REAR,BACKRH 198912

18 1 FRAME,991 REAR,FRONTLH 198917

19 1 FRAME,991 REAR,FRONTRH 198916

20 1 FRAME,991 REAR,MIDDLELH 198915

21 1 FRAME,991 REAR,MIDDLERH 198914

22 4 GROMMET,EPDM,2"ID,1/4"WOG,3"OD 982304

23 1 MTR,HY,18.3CUIN,1-1/4"KEY,SAE-A,RS-SERIE 601591

24 1 MTR,HY,6.1CUIN,1-1/4"KEY,2-HOLE,TF-SERIE 603321

25 1 MTR,HY,9.9CUIN,1-1/4"KEY,SAE-A,RE-SERIES 602096

26 2 RLR,BC,PU,5/8X3.5X2.375X5FL,PC 351311

27 2 RLR,BC,PU,5/8X3.5X2.625X5FL,SCGROVD 351267

823

7

11

19 21

17 315

2

8

25 1

9

28

31

2018

27

29

33

26

4

6

31

2

15

3

10

16

12

14

32

22

Item# QTY DESCRIPTION PART#:

28 14 RLR,BC,PU,5/8X4X1,PC 351314

29 4 SHFTDT3/4"x73",DT3/8" 051232

30 2 SHFT,TK,1-7/16"x80-1/2"(10-10-12) 051230

31 6 SPRCKT,CAST,10T36MM1-7/16"B 321555

32 14 STANDOFF,RLR,BLTD,CHN,5/8"x1-1/4" 351309

33 2 SUPPORT,991 REAR,BOLTABLE 198950

24 14 30

30 30

5

Operator's Manual Model 991

Page 18

AIR-SEP100HPBLOWER CARTFB0478

Item# Quantity Description Part#

1 1 991FANVFD PANELMNT24x36x10 176523

2 1 991FANVFD PANELBRACKET 176525

3 1 991,BRACKET,FAN RPM SENSOR 176526

4 1 991FAN,SHIELDBACK 176545

5 1 991FAN,SHIELDMOUNTUPPERLH 176546

6 1 991FAN,SHIELDMOUNTUPPERRH 176547

7 2 991FAN,SHIELDMOUNTLOWER 176548

8 1 991FANDISCONNECTPANEL 198961

9 4 BELT,POWERBAND,1/5V125RED3 262439

10 1 BLOWER,30",BEARINGMOUNT,66X0-2013 198262

11 1 BLOWER,30"HOUSING,66X0-2013 198263

12 2 BRNG,4BOLTFLANGE,2-7/16",SPHRCLRLR,ECC 231406

13 1 BUSHING,QD,Ex2-7/16"BORE 781602

14 1 BUSHING,QD,Ex2-7/8"BORE 781603

15 1 CONE,CHICAGOBLOWER,SIZE 30 982440

16 1 FABRICATEDBLOWER,OUTSIDE BEARING MOUNT 198541

17 1 FAN MOUNT,BASE 198953

18 1 FAN,TOPMOUNT 198952

19 1 FRABRICATEDBLOWEREXPDSCREEN 198488

20 1 FRAME,991FANCART 198954

21 1 HANDLE,REVOLVING,3.82"LG,.05"x0.79" 982220

21

24

37

Item# Quantity Description Part#

22 2 HOSE,ASSEM,3/4"x30"12FJS-12FJS,12M4K 602599

23 1 IMPLELLER,CHICAGOBLOWER,SIZE30 982438

24 1 JACK,CRANK 196930

25 1 KEY,SQUARE,5/8x3.5"C4140 502864

26 4 KNOB,CONTROL,DIECASTDT5/8"-11UNC 981255

27 1 LABEL,CAUTION,MOVING,DRIVES,CANCAUSE 300086

28 1 LABEL,WARNING,EXPOSED,DRIVE,CAN CAUSE 300087

29 1 MTR,MNT,100HORSEPOWERMOTOR 198955

30 2 PLATE,1/4"x1"x8-13/32" 012523

31 4 ROD,THREADED 040101

32 4 SCREW,FLAT,SCKT,HD,5/8"-11 x3-1/2" 502669

33 1 SHAFT,2-7/16"x38.910" 051235

34 1 SHEAVE,4GROOVE,E,5V,10.3" 781600

35 1 SHEAVE,4GROOVE,E,5V,14.0" 781601

36 1 SHIELD,991FAN 198956

37 2 TIRE&RIM,750x16/10NANKANGN101,6HOLE 951485

38 2 WASHER,3/16"x3"DIA,17/32"ID 176528

39 2 WASHER,3/16"x2"DIA,17/32"ID 176524

40 1 WASHER,SHAFTEND,AIRKNIFEBLOWER 176169

30

1

8

218

17

36

27

29

D

D

6

26

31

33

28

4

5

7

20

39

7

22

13

34

9

35

14

11

F

F

Operator's Manual Model 991

Page 19

Table of contents

Other Spudnik Farm Equipment manuals

Spudnik

Spudnik 780 User manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 5140 Owner's manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 9706 User manual

Spudnik

Spudnik 990 User manual

Spudnik

Spudnik AIRSEP 992 Owner's manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 1255 Owner's manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 2400 Programming manual

Spudnik

Spudnik 930 User manual

Spudnik

Spudnik 930 User manual

Spudnik

Spudnik 80 Series User manual

Spudnik

Spudnik 925 Owner's manual

Spudnik

Spudnik 990 User manual

Spudnik

Spudnik BBL 1000 User manual

Spudnik

Spudnik 6160 WINDROWERS User manual

Spudnik

Spudnik 1115 Owner's manual

Spudnik

Spudnik 1110 User manual