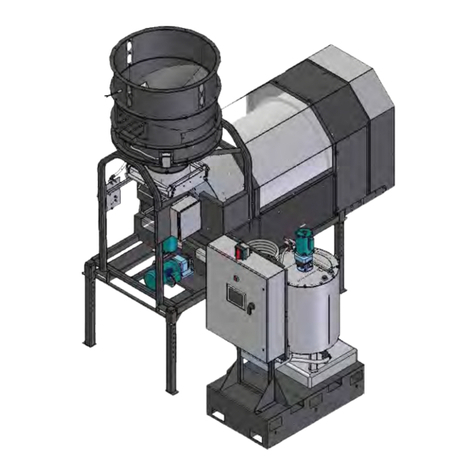

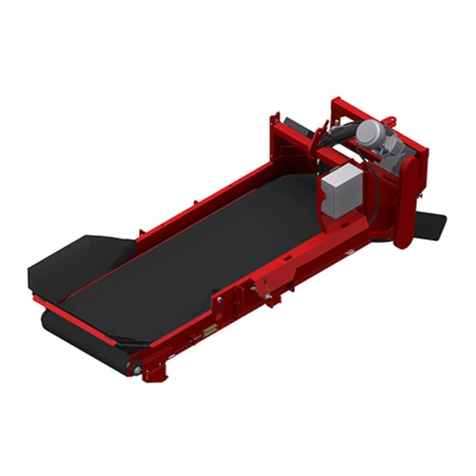

Spudnik 2350 User manual

OPERATORS/ PARTS MANUAL

MODEL 2350

PORTABLE SAMPLE TAKER

PUP CONVEYOR

Part # 290209

Operating Manual Overview

The purpose of this Spudnik Operating Manual is to make the

user familiar with this machine and to assure the machine is used

for what it has been designed to do.

This Operating Manual contains important information on how to

operate this machine properly and efficiently while maintaining all

safety regulations. Observing and practicing the information

within this Manual can effectively prevent danger, reduce repair

costs and downtimes, while increasing reliability and service life

of the machine.

The Operating Manual must always be available to users

wherever the machine is in use.

The Operating Manual must be read and applied by all persons

working on/with the machine, e.g.

Operation - including set-up, troubleshooting, care, etc.

Maintenance – servicing, inspection, repair.

Transport

Operators manual MODEL 2350 Sample Taker

Page 1

Table of Contents

Introduction ………………………………………………………………………………………………..3

Forward to Operating Manual …………………………………………………………………………...4

Warranty ……………………………………………………………………………………………………5

Product Characteristics ……………………………………………………………………………………6

Dangers, operating errors and exemption from liability .…………………………………….…………7

Safety ….…………………………………………………………………………………………….………8

General safety and accident prevention regulations …………………………….…………………….9

Special safety instructions .…………………………………………………………………………….…10-11

Electrical system, electronics …………………………………………………………………….10

Hydraulic system .…………………………………………………………..…………………..….11

Safety Check Instructions ………………………………………………………………………………..12

Warning symbols and other instruction notices on the machine ..……………………………………13

Configuration and functions of the machine ……………………………………………………….……14

Maintenance ………………………………………………………………………………………………..15-30

General Safety ………………………………………………………………………………………15-16

Special Safety Instructions …………………………………………………………………………17

Spare Parts Procurement …………………………………………………………………………..18

Disposing of Spare Parts …………………………………………………………………………..18

Cleaning After ……………………………………………………………………………………….19

Parts to Be Cleaned ………………………………………………………………………………...20

Storage ……………………………………………………………………………………………….21

Screwed Connections ………………………………………………………………………………22

Chassis ………………………………………………………………………………………………..23

Tires …………………………………………………………………………………………………..23

Mechanical Drives …………………………………………………………………………………..24

Chain Drives …………………………………………………………………………………………25

Belt Drives …………………………………………………………………………………………...26

Lubrication …………………………………………………………………………………………...27

Hydraulic System ……………………………………………………………………………………28-29

Electrical System ……………………………………………………………………………………29

Braking System ……………………………………………………………………………………..30

Machine Parts Breakdown ……………………………………………………………………………......33

DescriptionPage #

Operators manual MODEL 2350 Sample Taker

Page 3

Notes !!

Operators manual MODEL 2350 Sample Taker

Page 4

This operating manual is intended to familiarize the user with the 2350 Sample Taker Pup and its

designated use.

This operating manual contains important information on how to operate the machine safely, properly

and efficiently. Observing the instructions in this manual helpsto avoid dangers, reduce repair costs and

down-times, and to increase the reliability and service life of the machine. Please also take note of the

section “Dangers, operating errors and exemption form liability”.

This manual is to be supplemented by the respective national rules and regulations concerning accident

prevention and environmental protection.

The operating manual must always be available wherever the machine is in use.

This operating manual must be read and applied by all persons involved with the machine, such as:

•Operation, including setting up, troubleshooting during operations, care, disposal of fuels and

consumables

•Maintenance, (servicing, inspection, repair), and/or

•Transport

In addition to this operating manual and the relevant mandatory rules and regulations concerning

accident prevention and environmental protection of the country or region in which the machine is being

used, the generally recognized technical rules for safe and proper working must also be observed.

Foreword to the Operating Manual

Operators manual MODEL 2350 Sample Taker

Page 5

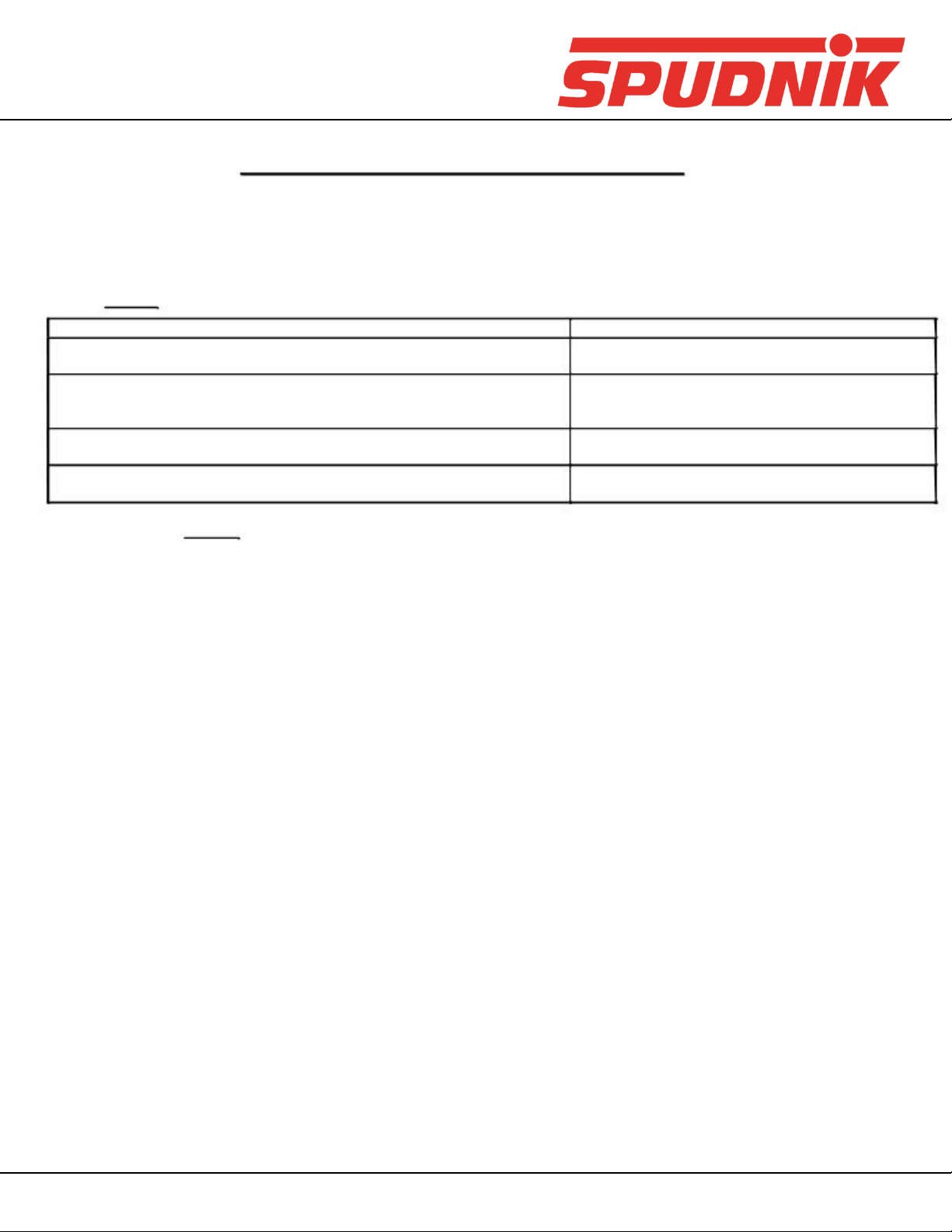

Limited Warranty Policy for New Spudnik Machinery

Spudnik Equipment Company LLC (“Spudnik”) warrants to the original purchaser each new Spudnik machine to be free from defects in

material and workmanship. Spudnik will repair or replace, at its option, any part covered by this warranty that is found to be defective

during the warranty period outlined below. Warranty service must be performed by an authorized dealer or representative of Spudnik. This

warranty is applicable only for the normal service life expectancy of the product or components, as noted in the following table. Once the

warranty period has begun, it cannot be stopped or interrupted.

What is included in the Spudnik Warranty:

Product Warranty Term

180 Days from 1st day of operation or 720 Hours of machine

Rollers, Sprockets, Roller Chain, Belt Lacing, and Bearings operation, whichever comes first

All paint to include: Insufficient coverage, failure of paint adherence, and excessive runs. 12 Months from date of delivery of new Spudnik product to

NOTE: Excessive runs not to exceed more than 15%of the painted surface on the the original retail customer

machine.

12 Months from date of delivery of new Spudnik product to

All other materials and workmanship (except as noted below)the original retail customer

30 days from date of purchase, or the remainder of the

Genuine Spudnik replacement parts and components original equipment warranty period, whichever is longer

Those items that are excluded from this warranty are as follows:

(1) any merchandise or components thereof, which, in the opinion of the company have been subject to: (a) Rock chip damage and other

abuse to painted surfaces, (b) damage caused by weather (to include UV damage), accident, or acts of God, (c) any product that has been

altered or modified in ways not approved by Spudnik Equipment Company LLC., (d) depreciation or damage caused by normal wear, lack

of reasonable and proper maintenance, misuse, failure to follow the product’s Operator Manual recommendations, (e) Using machine for

other than normal moving of agricultural products during planting, harvest, and processing seasons. Agricultural products to include:

Potatoes, beets, onions, carrots, grains, etc., (2) Used products, (3) Repairs made by unauthorized dealers.

To Obtain Warranty Service

To be eligible for the Spudnik warranty, purchaser must: (a) Have already remitted payment in full (b) have filled out and submitted the

Spudnik Delivery Declaration form to a Spudnik representative (c) report the product defect to an authorized dealer or Spudnik sales

representative and request repair within 30 days of noticing the defect and (d) make the product available to the dealer or service center

within a reasonable period of time, transportation charges prepaid.

The selling dealer has no authority to make any representation or promise on behalf of Spudnik, or to modify the terms or limitations of

this warranty in any way.

Limited Warranty Statement

To the extent permitted by law, Spudnik does not make any warranty, representation, or promises express or implied as to the quality,

performance, or freedom from defect of any Spudnik New Machinery. NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS IS

MADE. IN NO EVENT WILL SPUDNIK, AN AUTHORIZED SPUDNIK DEALER, OR ANY COMPANY AFFILIATED WITH SPUDNIK BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. This warranty is subject to any existing conditions of supply which may directly affect

our ability to obtain materials or manufacture replacement parts. Spudnik reserves the right to make improvements in design or changes in

specifications at any time, without incurring any obligation to owners of units previously sold. No one is authorized to alter, modify or

enlarge this warranty nor the exclusion, limitations and reservations.

To obtain more information, please contact your dealer or Spudnik at 1-208-785-0480.

Page 4

Operators manual MODEL 2350 Sample Taker

Page 6

Product Characteristics

Manufacturer's address

SPUDNIK EQUIPMENT COMPANY LLC

584 W 100 N

PO Box 1045

Blackfoot, ID 83221

Phone: (208) 785-0480

Fax: (208) 785-1497

www.spudnik.com

E-mail: spudnik@spudnik.com

Advice concerning inquiries and orders

Please quote the type designation and the machine number when ordering accessories and

spare parts.

The use of spare parts supplied by third parties shall only be permitted after consultation with

the manufacturer. Original spare parts and accessories approved by the manufacturer are a

contribution to safety. The use of other parts may invalidate the liability of the manufacturer for

any consequences arising out of such use.

Type plate on machine

Machine serial number

The machine serial no. is punched into

a plate on the frame.

The entire designation has the status of a legal document and may not be

removed, changed or rendered illegible!

Operators manual MODEL 2350 Sample Taker

Page 7

Dangers, operating errors and exemption from liability

1.No responsibility will be accepted for possible dangers arising from operating the machine in

a way which does not comply with its designated use.

2.Damage to agricultural produce particularly vulnerable to damageduring processing cannot

be entirely ruled out. Weather conditions, the quality of the produce and many other

circumstances beyond our or the operator’s control have an influence on the vulnerability to

damage the produce being processed. For example, when processingthe submerged

weight, the manuring (nitrogen content), the degree of maturity (firmness of the skin), the

temperatures during processing and many other circumstances can have an influence on

the vulnerability to damage. These examples do not claim to be exhaustive.

3.To avoid damage to agricultural produce the user must adapt the machine to the respective

operating conditions. The results produced by the machine must be constantly monitored

and checked.

4.SPUDNIK shall not be liable for any damage to agricultural produce and other items which

occurs as a result of operating and adjustment errors or other incorrect usage.

5.SPUDNIK accepts no liability for any damage caused as a result of operators not complying

with the designated use of the machine. This also applies to damage to agricultural produce

which, because of certain external influences, cannot be avoidedwith the current state of

the art.

Operators manual MODEL 2350 Sample Taker

Page 8

Safety

This operating manual contains basic directions which should be observed during setting-up, operation and

maintenance. Therefore, this operating manual absolutely must beread by the personnel concerned prior to

starting up and using the machine, and must be available for them at all times. Any instructions which are not

understood must be clarified before initial operation of the machine, for clarification, please consult your

SPUDNIK agent or contact us directly.

All safety instructions must be observed, both the general safety instructions given here and the specific

safety instructions given elsewhere in this manual.

Observe the advice contained in the operating manual as well as the generally applicable safety and accident

prevention regulations!

If safety instructions are not complied with, you risk injury toyourself and others as well as damage to the

environment or the machine. Non-compliance with safety instructions can also void claims for damages.

Identification of important instructions in the operating manual

Text marked with this symbol alerts you to possible accident andinjury hazards; hazards to

machinery; practical applications, settings or functions; or environmental protection measures.

Qualification and training of personnel

•Any work on or with the machine may only be performed by reliable personnel. Statutory minimum age limits

must be observed.

•Employ only trained or instructed staff; the individual responsibilities of the personnel for operation, setting-

up, maintenance and repair must be clearly established.

•Make sure that only authorized personnel work on or with the machine.

•Define the machine operator’s responsibilities –also with regard to observing traffic regulations. The operator

must have the authority to refuse any instructions issued by third parties which contravene safety!

•Persons requiring training or instruction and those in a generaltraining course, should not be allowed to work

on or with the machine unless they are under the constant supervision of an experienced person.

•Work on the machine’s electrical system may only be carried out by an electrician orby persons working

under the supervision and guidance of an electrician; all such work must be carried out in accordance with

electrical engineering regulations.

•Work on the wheels, braking and steering systems may only be performed by specially trained personnel.

•Work on the hydraulic system may only be carried out by personnel with special knowledge and experience

of hydraulics.

•The use of spare parts, accessories and auxiliary equipment not supplied and/or not approved by SPUDNIK

can have detrimental effect on the construction of the SPUDNIK machine or on its functions and hence impair

the active and./or passive driven an/or operational safety (accident prevention).

•SPUDNIK shall not be liable for any damage caused by the use of parts, accessories and auxiliary equipment

not supplied and/or approved by SPUDNIK.

•Conversions of or modifications to the machine may only be carried out after consultation with SPUDNIK.

Operators manual MODEL 2350 Sample Taker

Page 9

General safety and accident prevention regulations

The safety advice and information given in this operating manual, the valid national regulations

concerning accident prevention and any applicable internal employment, operational and safety

regulations of the operator are to be observed.

1.Warning signs and other notices on the machine provide importantinformation for safe

operation. Observing them will serve your safety.

2.Before starting work, make yourself familiar with all the equipment and controls as well

as their functions. To do so when you have already started work is too late!

3.The user should wear close-fitting clothing. Avoid loose-fitting clothing!

4.Keep the machine clean to avoid the risk of fire!

5.Check around the machine before moving off or starting up (watchout for children)!

Make sure you have adequate all-around visibility.

6.Observe the respective regulations when using public roads!

7.Only start up the machine when all guards are attached and in their correct (protective)

position!

8.Stay clear of the turning and pivoting areas of the machine!

Non-observance of the safety and accident prevention regulations entails the

following risks:

-Endangering the operator or other nearby persons as a result of safety devices not being

fitted or being in their correct (protective) position!

-Damaging important machine functions!

-Errors when carrying out maintenance or repair work!

-Endangering the operator or other nearby persons through certainmechanical or

chemical peculiarities!

-Risk of pollution due to leaks in the hydraulic system, fuel tank, pipes, as well as in the

engine and gearbox!

Operators manual MODEL 2350 Sample Taker

Page 10

Electrical system, electronics

Use only original fuses with the specified current rating! Switch off the machine immediately if a fault

occurs in the electrical power supply.

Work on the electrical system or equipment may only be carried out by an electrician, or by specially

instructed personnel under the control and supervision of an electrician, and in accordance with the

applicable electrical engineering regulations.

The machine’s electrical equipment is to be inspected and tested at regular intervals. Defects such as

loose connection or scorched cables must be rectified immediately.

The machine is fitted with electronic components and modules, the function of which may be influenced by

the electromagnetic fields of other equipment. Such interferencecan lead to potentially dangerous

situations if the following safety advice is not observed.

If electrical or electronic devices and/or components are retrofitted to the machine then it is the

responsibility of the user to check whether such installations interfere with the vehicle’s electronics or

other components.

This particularly applies to:

-Mobile telephones,

-Radio equipment.

In particular, the following conditions must also be satisfied if mobile communications systems (e.g. radio,

telephone are to be installed subsequently:

-Only approved devices complying with the relevant national regulations may be installed.

-The device(s) must form a permanents installation.

-the operation of portable or mobile devices in the tractor or onthe machine is only permitted via a

connection a a permanent external aerial.

-The transmitter part must be installed separately from the vehicle electronics.

-A properly installed aerial is to be fitted with a good earth connection between aerial and vehicle chassis.

The installation instructions of the machine manufacturer are also to be observed for the wiring and fitting

as well as the maximum current consumption.

Special safety instructions

Operators manual MODEL 2350 Sample Taker

Page 11

Hydraulic system

1.The hydraulic system is under high pressure!

2.Make sure that the hydraulic system is depressurized (tractor and machine) when connecting the

hydraulic hoses to the tractor’s hydraulic system.

3.Hydraulic hose lines should be inspected at regular intervals and replaced if damaged or worn! New

hose lines must comply with the technical specification of the machine manufacturer! Hoses and

hose couplings undergo a natural ageing process, even if stored and used correctly; therefore, their

period of storage and use is limited. The service life of a hosemay deviate from these figures if

experience has shown this to be the case, in particular taking into account the potential danger.

4.Fluids escaping under high pressure (hydraulic oil) can penetrate the skin and cause serious

injuries! If such injuries occur, call a doctor immediately! Risk of infection!

5.Lower the machine, depressurize the system and switch off the engine before working on the

hydraulic system!

6.Take care when working on the hydraulic system. Hot hydraulic oil can cause serious burns! Let the

hydraulic system cool down beforehand and wear gloves! Collect and dispose of old oil in

accordance with the regulations!

Special safety instructions

Operators manual MODEL 2350 Sample Taker

Page 12

Safety check instructions

1. Make sure main disconnect and All switches are “OFF”

2. Look at the voltage label on the control panel. Make sure thevoltage from the machine it is attached to, is

the same as the Sample Taker voltage. (Any questions please callyour nearest service center.)

3. Look and make sure that everything is out of the way of the sliding door, where the sample is taken.

4. Plug Sample Taker in and Turn main disconnect “ON”.

5. For phasing, it is important to push the Sample Taker belt switch momentarily, to insure correct direction of

the belt.

Operators manual MODEL 2350 Sample Taker

Page 13

SIGNAL WORDS:

DANGER, WARNING, and CAUTION are signal words with messages:

DANGER: An immediate and specific hazard, which WILL result in

severe injury or death if proper precautions are not taken.

WARNING: A specific hazard or unsafe practice, which COULD result in

severe injury or death.

CAUTION: Unsafe practices, which COULD result in personal injury if

proper precautions are not taken.

Warning symbols and other instruction notices on the machine

Power driven machinery.

Can cause severe injury.

Disconnect power before servicing.

Keep hands, feet, clothing away from power

driven parts.

Do not run machine until all shields are in place.

Read operator’s manual before servicing.

UNGROUNDED MACHINE Can

cause severe injury or death.

Connect to external ground per

national electrical code.

MACHINE STARTS WITHOUT

NOTICE Can cause severe

injury.

Disconnect main power before

mounting.

HIGH VOLTAGE Will cause

severe injury or death.

Disconnect main power before

servicing.

Operators manual MODEL 2350 Sample Taker

Page 14

Configuration and Function of the Machine

1. Make sure that “Emergency Stop”button is pulled out.

2. Push the green push button switch, labeled “Belt”, to initiate belt drive.

3. Turning the switch labeled “Truck”to the “Hand” position and it will run regardless of the Sample Taker.

Turning the switch to “Auto” and it will run with the Sample Taker.

4. Carefully slide the sample taker basket, (or if using the mini conveyor, a box or another container), is in

place.

5. To take a sample, push the green illuminated door switch “ON”. It is now waiting for a command.

6. The command is given by pushing the green push button on the external mounted white box on the side of

the machine. When this is pushed, it will signal that a sample is in process with a green light on the front of the

electrical panel.

7. After the light goes off, it is finished with the sample process and is ready for another command to begin the

process over, at anytime.

8. Carefully remove the sample taker basket. Keeping your hands and body from under or around the Sample

Taker functions. If you are using the mini conveyor, turn it “ON” only for the time it takes to remove the product

and then turn it “OFF”.

Operators manual MODEL 2350 Sample Taker

Page 15

Maintenance

General safety instructions

Regular maintenance is a prerequisite for operational reliability. The following safety

advice is to be observed during any maintenance, cleaning or repair work.

To prevent accidents, all relevant rules and regulations concerning safe and

competent working must be observed!

•Observe the adjustment, maintenance and inspection activities and intervals specified in this operating

manual, including details concerning the replacement of parts, subassemblies and equipment. These activities

may only be executed by trained personnel.

•Instruct operating personnel before beginning special operationsand maintenance work! Delegate a

supervisor!

•Always observe the relevant safety measures and instructions specified in the operating manual when

carrying out work related to the operation, adaptation, conversion or adjustment of the machine as well as

maintenance, inspection and repair activities.

•Ensure the working area is adequately secured during the maintenance work!

•Use suitable, tested tools when working on the machine. Wear gloves!

•Switch off the machine completely before maintenance and repair work and ensure that it is secured against

inadvertent starting. The machine must not be switched on again while the work is being carried out!

-Switch off operating facilities.

-In the case of tractors, self-propelled harvesting machines and engine-driven machines, switch off the

engine, remove the ignition key and, if necessary, lock the cabin. Nobody is allowed to be within reach of the

controls so that functions cannot be switched on again by accident.

-Switch off the main switch and attach a warning sign, if necessary.

-Disconnect the machine from the power supply. Depressurize the hydraulic system and compressed air lines

and disconnect them from the supply.

•Carry out maintenance and repair work only when the machine is positioned on firm and level ground and

has been secured against inadvertent movement and toppling.

•When replacing individual parts and larger subassemblies, they should be carefully attached to lifting gear

and secured against falling down. To avoid the risk of accidents, sharp edges, corners and dangerous

projections must be covered and a warning sign attached. Use only suitable hoisting and lifting gear with

adequate load capacity which is in a proper working condition. Never work or stand under suspended loads!

•The securing of loads and the instruction of crane operators should only be entrusted to experienced

persons. A signaler giving instructions must be within sight of the crane operator and must be provided with a

radio link.

•Only carry out overhead assembly work using suitable ladders andplatforms. Never climb on the machine

itself! Wear a safety harness when carrying out maintenance workat greater heights.

•Keep all handles, steps, handrails, platforms, landings and ladders free from dirt, snow and ice.

Operators manual MODEL 2350 Sample Taker

Page 16

Maintenance

•Clean the machine, especially connections and threaded unions ofany traces of oil, fuel or

preservatives before carrying out maintenance/repairs. Never useaggressive detergents. Use lint-free

cleaning cloths.

•Before cleaning the machine with water or steam jets (high-pressure cleaners) or other cleaning

agents, cover or tape all openings which –for safety and operational reasons -must be protected

against ingress of water, steam or leaning agents. Special care must be taken with electric motors and

switching cabinets, as well as all additional electrical or electronic components. After cleaning, remove

all covers and tape completely.

•After cleaning, examine all fuel, lubricant and hydraulic oil lines for leaks, loose connections, scuffing

marks and damage. Any defects found must be rectified without delay.

•Immediately retighten any screwed connections that have been unscrewed during maintenance and

repairs.

•Any safety devices removed for setting-up, maintenance or repair purposes must be refitted and

checked immediately upon completion of the maintenance and repair work.

•Ensure that all fuels, consumables and replaced parts are disposed of safely and with minimum

environmental impact.

Operators manual MODEL 2350 Sample Taker

Page 17

Maintenance

Special safety instructions

Safety devices

Never stand beneath suspended loads!

Never stand or work beneath suspended loads!

Engage safety catches!

Never stand or work beneath suspended loads.

Adjustment and maintenance work on these parts of the machine may only be carried

out with the safety devices engaged.

Operators manual MODEL 2350 Sample Taker

Page 18

Maintenance

Spare parts procurement

Please quote the details on the type plate(s) as well as the machine’s serial no. on every order

for spare parts or accessories, or inquires of a technical nature.

The use of spare parts supplied by third parties Is prohibited. Original spare parts and

accessories approved by the manufacturer are a contribution to safety and guarantee proper

functioning. No liability can be taken for consequences resulting from the use of other parts.

When replacing electrical or hydraulic parts, ensure that only original SPUDNIK spare

parts are used. The use of non-SPUDNIK parts can cause malfunctioning of the machine.

Type plate on machine

Machine serial number

The machine serial no. is punched into

a plate on the frame.

The entire designation has the status of a legal document and may not be removed,

changed or rendered illegible!

Disposing of replaced parts

The following points should be observed before replacing or disposing of parts.

-Replaced parts which still function should be cleaned and storedin an orderly manner.

-Machine parts which cannot be repaired should only be disposed of at appropriate

collecting points or be collected by a scrap metal dealer.

So called “valuable”materials should be deposed of in a proper way, i.e. plastics,

rubber, scrap metal, etc. should be recycled.

Collect and dispose of old oil in accordance with the regulations.

Operators manual MODEL 2350 Sample Taker

Page 19

Table of contents

Other Spudnik Farm Equipment manuals

Spudnik

Spudnik 2400 Programming manual

Spudnik

Spudnik 6200 User manual

Spudnik

Spudnik AIRSEP 992 User manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 990 User manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik AIRSEP 992 Owner's manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 990 User manual

Spudnik

Spudnik 8060 User manual

Spudnik

Spudnik 1255 Owner's manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 2230 Owner's manual

Spudnik

Spudnik 990 Owner's manual

Spudnik

Spudnik 1860 User manual

Spudnik

Spudnik 4300 BULK BED User manual

Spudnik

Spudnik 80 Series User manual

Spudnik

Spudnik 560 Owner's manual

Spudnik

Spudnik BBL 1000 User manual