SPX Cooling Technologies Marley Geareducer 2200 User manual

Geareducer®models 2200 - 2250 - 2250S - 2400

OPERATION - MAINTENANCE – REPAIR

Z0490769_C ISSUED 06/2022 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT

user manual

3

operation and service

Protection Against Corrosion

All Marley Geareducer units ship from the factory with a protective

coating of epoxy enamel paint on all unmachined parts and with

rust-proofing oil and grease on machined surfaces. Machined sur-

face coatings normally protectthe Geareducer against atmospheric

corrosion during storage periods for up to six months. However, if

oil is added to the Geareducer, the new oil will dissolve the rust-

proofing grease and require that the Geareducer be run once a

week to keep a protective coating of oil on all interior machined

surfaces.

Check Geareducer exterior yearly and touch up with epoxy paint if

required. If your Geareducer is equipped with an oil gauge and drain

line, coat any exposed threads at pipe joints to prevent corrosion.

Alignment

In order to assure long service life, the Geareducer and motor must

be level, and the drive shaft or coupling must be properly aligned.

Refer to the alignment instructions in the Driveshaft or Coupling

Manual shipped with the cooling tower. Copies are also available

from your local Marley sales representative.

Initial Operation

Check to be sure that the Geareducer is filled with oil and that

there are no visible oil leaks. If equipped with an external dipstick/

oil level gauge, be sure the oil full mark corresponds with the full

level at the Geareducer.

Note—If this tower is equipped with a two-speed motor, allow a

time delay of at least 20 seconds when switching from high speed

to low speed. Allow a time delay of at least two minutes when

changing direction of fan rotation. Failure to provide these delays

may significantly reduce equipment service life.

Lubricants

To insure maximum performance and servicelife, itis recommended

Marley factory lubricants be used in all Marley Geareducers.

Marley lubricants can be purchased through your local Marley

sales representative.

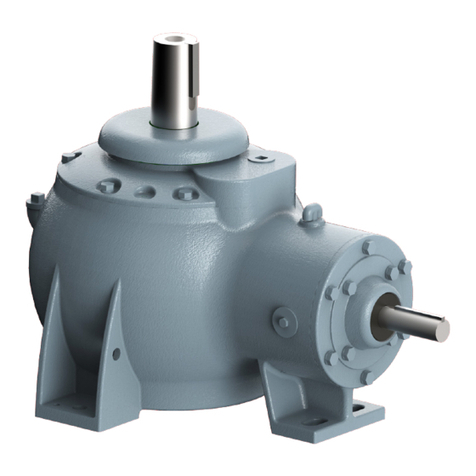

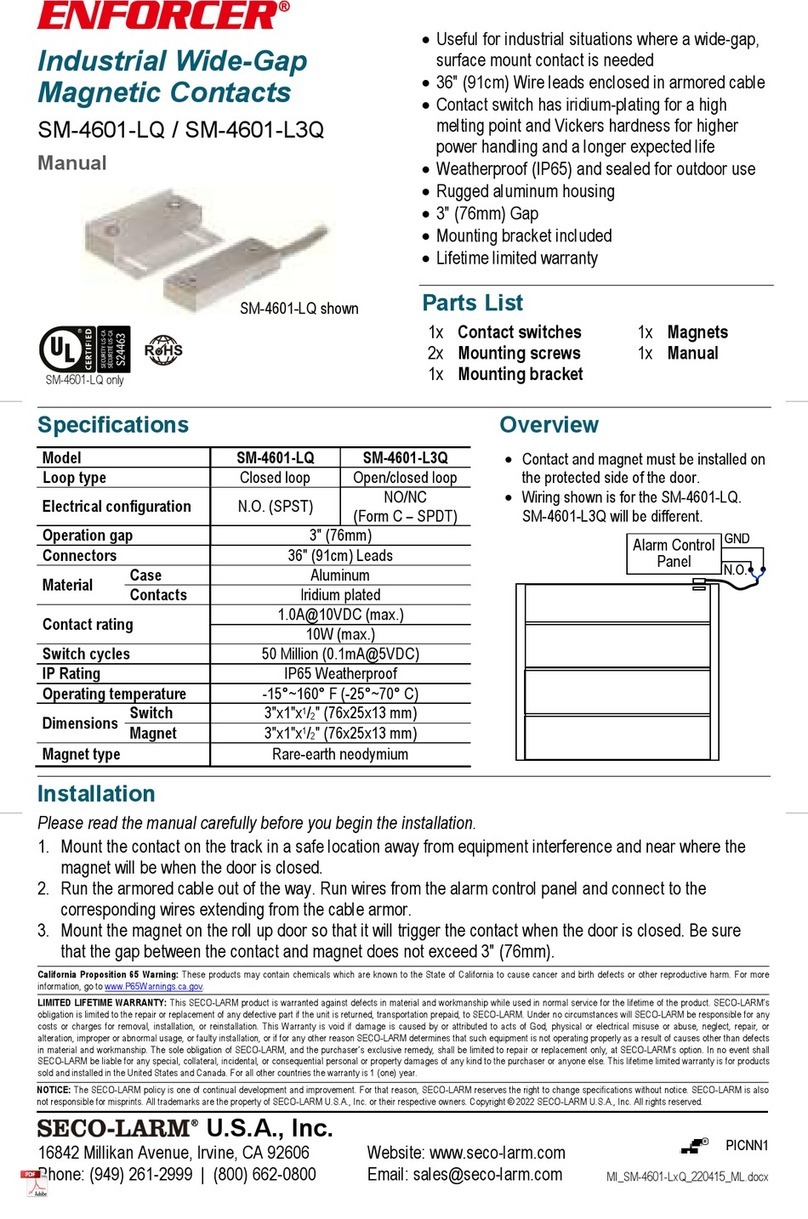

Figure 1 Service Fittings

Drain Plug

Vent Inspection

Oil Level

Check and Fill

Vibration Mounting

Location 1/4 - 28 UNF

4

operation and service

If lubricants other than Marley factory lubricants are used, they must

not contain any additives (such as detergents orEP additives)which

are adversely affected by moisture and could reduce the service

life of the Geareducer. The responsibility for use of lubricants other

than Marley factory lubricants rests with the customer/owner and

the lubricant supplier.

Note—Geareducer is designed for 5-year oil change intervals.

To maintain five-year change intervals, use only Marley Gearlube.

Marley Gearlube must be inspected every six months to ensure

the oil has not been contaminated. If turbine-type mineral oil is

used the oil must be changed every six months.

Seasonal temperature changes may require one viscosity of oil for

summer operation and another for winter operation. Refer to the

tables below for the seasonal selection information.

Table 1 Synthetic oil—5-year oil change interval

Winter or Summer Severe Duty/High Temperature

Air Temperature at Geareducer

Below 110°F (43°C) Above 110°F (43°C)

ISO 150 ISO 220

R– Refer to instructions within this manual

Note: It is recommended at least weekly, that the general operation and condition be observed. Pay particular attention to any changes

in sound or vibration that may signify a need for closer inspection.

Maintenance Service Monthly Semi-annually Seasonal Startup or Annually

Geareducer Drive

Inspect and tighten all fasteners including oil plug x x

Check for and repair oil leaks x x x

Check oil level x R x

Change oil R R

Make sure vent is open x x

Check driveshaft or coupling alignment x

Inspect and tighten driveshaft or coupling fasteners x

Check driveshaft or coupling bushing / flex elements for unusual wear x

Lube Lines (if equipped)

Check for oil leaks in hoses and fittings x R x

5

Scheduled Maintenance

Warning—Make certain that mechanical equipment is inoper-

able during periods of maintenance—or during any situation of

possible endangerment to personnel. If your electrical system

contains a disconnect switch, lock it out until the period of expo-

sure to injury is over.

Monthly—Check Geareducer oil level. Shut down the unit and

allow 5 minutes for the oil level to stabilize. Add oil if required,

noting the addition in your maintenance log. If equipped with an

external dipstick/oil level gauge, small quantities of oil can be

added at that location.

Semi-annually— If using turbine-type mineral oil, change oil—see

Changing Geareducer Oil for instructions. Check that all the

assembly bolts and cap screws are tight, that oil plugs and pipe

connections are in place and free from leaks, and that the vent on

the Geareducer (and external dipstick/oil level gauge, if present) is

clear—a clogged vent can lead to oil leaks. Intermittent operation

and extended periods of downtime can cause condensation of

water in the oil. If using synthetic Marley Gearlube, the oil condition

must be inspected every six months—see Changing Geareducer

Oil for maximizing service life.

Annually—Check mechanical equipment anchor bolts, drive shaft

coupling bolts, and coupling set screws. Tighten as required. Check

Geareducer exterior yearly and touch up with epoxy paint, if re-

quired. Coat all exposed threads at pipe joints to prevent corrosion.

Every 5 Years—If using synthetic Marley Gearlube, change oil.

To maintain five-year change intervals, use only synthetic Marley

Gearlube. It is recommended to monitor the oil condition every

six months throughout the five-year period per the instructions in

Changing Geareducer Oil.

operation and service

Changing Geareducer Oil

Drain the Geareducer oil by removing the drain plug. See

Figure 1 for location. If equipped with an external dipstick/oil

level gauge, remove the drain plug at that location, and drain the

entire system.

When using synthetic oil with extended service intervals remove a

sample for lab analysis and look for evidence of foreign material,

such as water, metal shavings or sludge. If you find unacceptable

condensation or sludge, flush the Geareducer with mineral oil

before refilling.

After inspection is complete, fill the Geareducer with 10 quarts

(9.5 liters) of oil. See Figure 1 for location. If the Geareducer is

equipped with an external dipstick/oil level gauge an additional 2

to 3 quarts (1.9 to 2.8 liters) of oil will be required. Be certain that

the vent on the Geareducer (and external dipstick/oil level gauge,

if present) is not plugged. Verify that the gauge/drain line is full

and that there aren't any leaks at the connections.

Repair and Overhaul

If your Geareducerever needsreplacement orrepair, werecommend

returning the unit to a Marley factory service center. Contact your

Marley sales representative to discuss course of action. The Order

Number on your cooling tower will be required if the Geareducer

is shipped back to the factory for repair. Obtain a “Customer

Return Material” tag from the Marley sales representative in you

area. To find your Marley sales representative call 913 664 7400

or visit spxcooling.com.

Major repairs require the use of a fully equipped machine shop.

If you decide to repair or overhaul your Geareducer, refer to the

Field Repair Section and Geareducer Parts List.

6

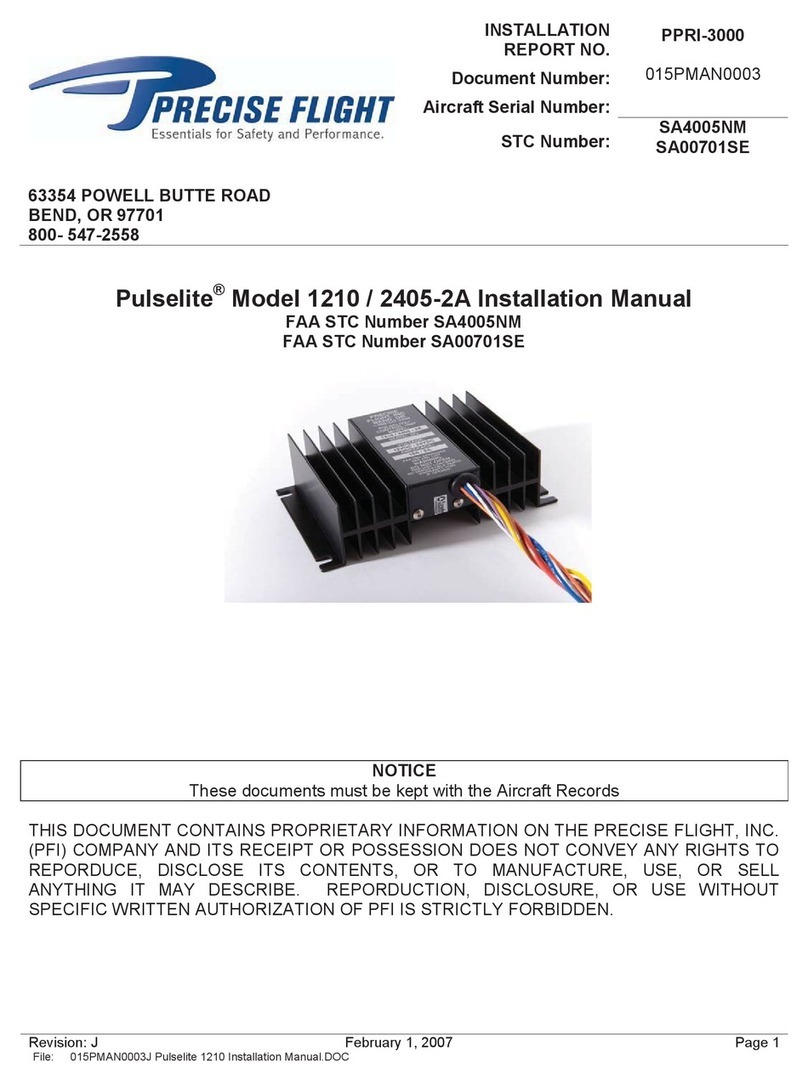

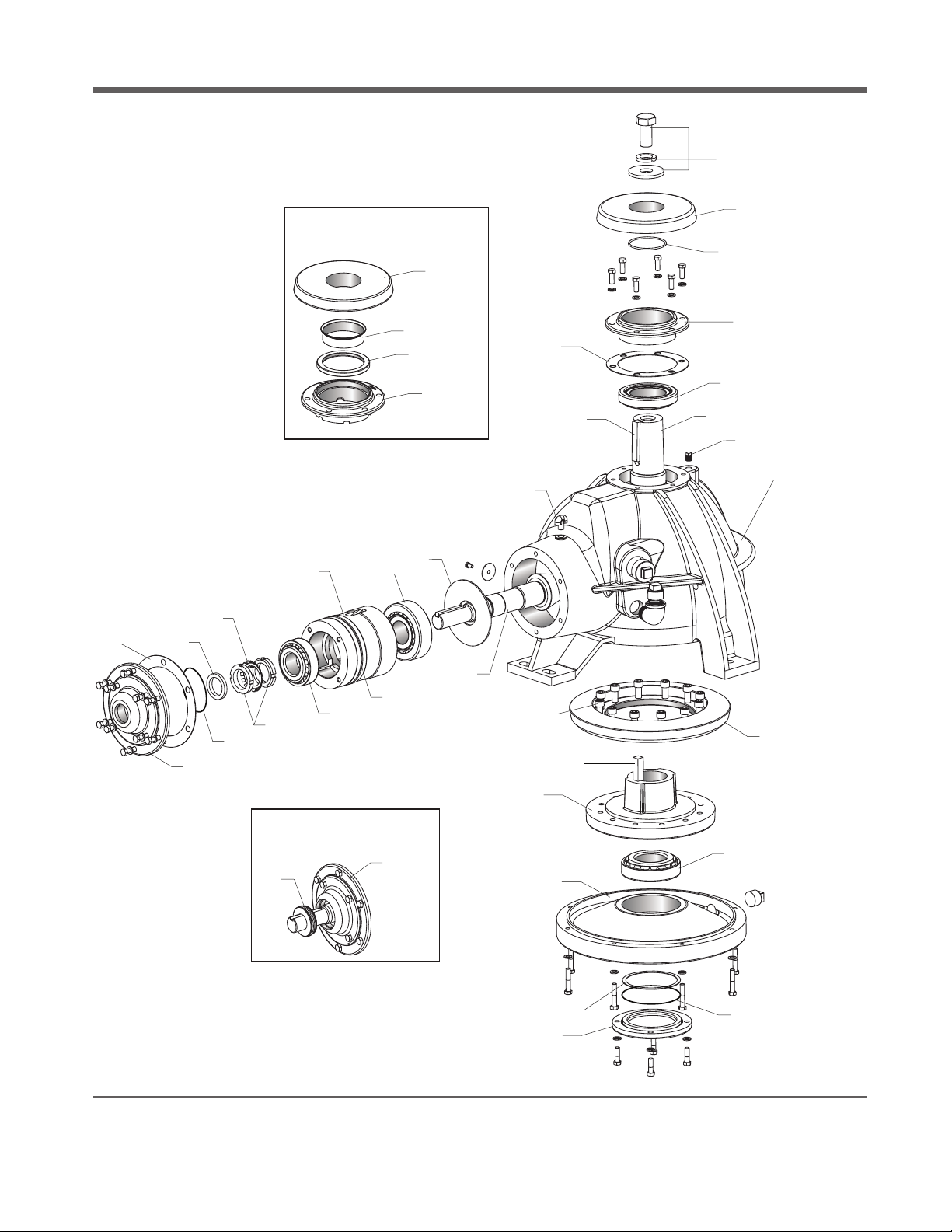

Figure 2 Exploded Cross Section

GEAREDUCER

CASE

AIR VENT

PINION CAGE

BEARING RETAINER

CAP

503

420

BOTTOM CAP

8

411

202

101

102

WATER SLINGER

BEARING RETAINER

210

420

502

203

PINION CAGE

CAP

320 501

103

104

312

311

301

101

NPT PLUG

201

PINION

CAGE

CAP

501

WATER

SLINGER

BEARING

RETAINER

521

520

505

412

504

“O”-RING

2250S

ASSEMBLY

2250S

ASSEMBLY

field repair

7

1Complete Geareducer Assembly.

8Ring Gear Hub.

100 Spiral Bevel Gear Set.

101 Set of matched spiral bevel gears including integral

pinion shaft with key.

Gear ratios as follows:

3.45 to 1 3.79 to 1 4.10 to 1

4.56 to 1 5.11 to 1 5.50 to 1

6.12 to 1 6.50 to 1 7.33 to 1

102 Ring gear attaching hardware.

103 Locknuts.

104 Lockwasher.

200 Fan Shaft Set.

201 Fan shaft.

202 Ring gear hub key. This is a special high strength

key. It must be obtained from Marley.

203 Fan key.

210 Fan attaching hardware.

Cap screws and washers.

301 Oil Slinger.

310 Set of Two Pinion Shaft Bearings.

311 Head, tapered roller bearing.

312 Tail, tapered roller bearing.

320 Pinion Cage Shims.

410 Fan Shaft Bearing Set.

411 Lower tapered roller bearing.

412 Upper tapered roller bearing.

420 Fan Shaft Shims.

500 O-Rings Set.

502 Water slinger O-ring, 3" ID × 31⁄4" OD × 1⁄8".

503 Bearing retainer O-ring, 5" ID × 51⁄4" OD ×1⁄8".

504 Pinion cage O-ring, 53⁄4" ID × 6" OD × 1⁄8".

505 Pinion cage cap O-ring, 4" ID × 43⁄8" OD × 3⁄16".

506 Oil slinger O-ring, 115⁄16" ID × 21⁄8" OD × 5⁄32".

501 Pinion Shaft Oil Seal.

**520 Fan Shaft Oil Seal

**521 Fan Shaft Oil Seal Sleeve

**Fan shaft Oil Seal and Sleeve used in "S" Models only.

Parts List

8

field repair

General

Geareducers can be repaired in the field—however, major repairs

require the use of a fully equipped machine shop. When field repair

or replacement of parts is necessary, the following procedure is

recommended for the disassembly and assembly of the unit. If any

O-ring, oil seal or gasket is to be reused, care should be taken

not to damage it during disassembly. Parts which contain O-rings

or seals should not be jerked or twisted past a shoulder or edge.

These parts are marked with an asterisk (*) in the description

below. O-rings, oil seal and gaskets should be carefully inspected

for damage before being reinstalled. Always use new O-rings and

oil seal during a major overhaul.

Disassembly

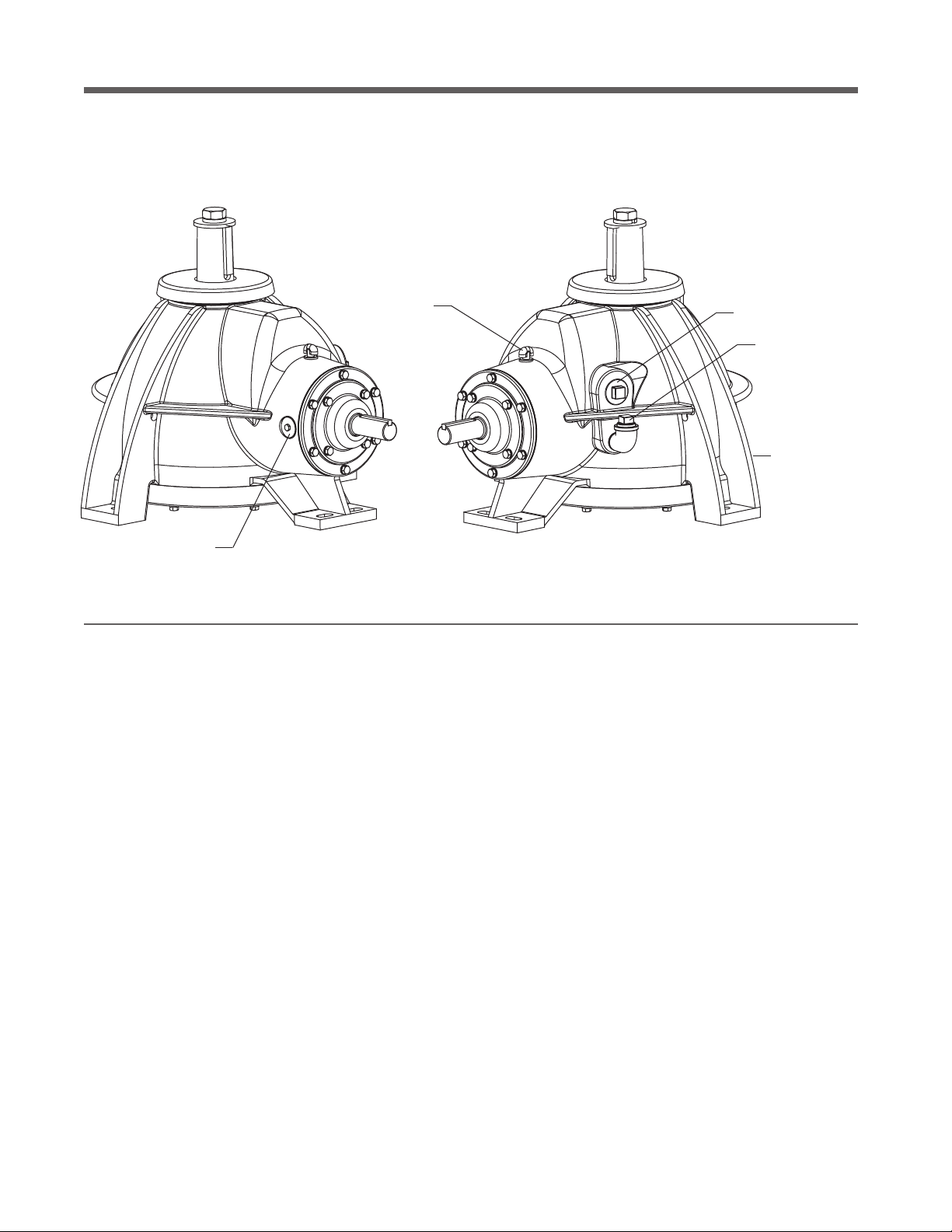

Part numbers and references—refer to Figure 2 and 3.

1. Remove drain plug and drain oil.

2. Remove outer ring of bolts in pinion cage cap and remove

pinion subassembly*.

Note—The thickness of the shim pack (320) is important in reset-

ting the gears. The shim pack should either be saved or carefully

measured with a micrometer. If the gears are to be replaced, record

the pinion setting distance that is etched on the pinion gear.

3. Remove water slinger*.

4. Turn case upside down and remove bearing retainer cap* and

shim pack (420).

Note—The thickness of this shim pack is important in the back-

lash setting of the gears. The shim pack should either be saved

or carefully measured with a micrometer.

5. Remove bottom cap and fan shaft assembly.

6. Turn Geareducer case right side up andremove bearing retainer

and shim pack (420).

Note—The thickness of this shim pack is important in setting the

fan shaft bearing endplay. This pack should be saved or carefully

measured with a micrometer.

7. Remove bearing cups (411 and 412) from the bottom cap and

Geareducer case using a soft metal punch or mallet.

8. For "S" Models Only: Remove fan shaft lip seal (520) from

upper bearing retainer, and sleeve (521) from water slinger.

Pinion Cage Disassembly

1. Remove pinion cage cap* from pinion cage.

2. Remove O-rings* (504 and 505).

3. Remove locknuts and lockwasher (103 and 104) then press

pinion shaft (101) out of pinion cage. This will free tail bear-

ing cone (312). A hydraulic press or jack is recommended for

removing or assembling press fit parts.

4. Press oil slinger*, O-rings* (301 and 506), and head bearing

cone(311) from the pinion shaft. Bearings must not be exposed

to dirt, dust or moisture.

5. Press bearing cups (311 and 312) out of pinion cage.

Fan Shaft Disassembly

1. Remove ring gear (101) from the ring gear hub (8).

2. Press ring gear hub and lower bearing cone (411) off of the

fan shaft (201).

3. Remove lower fan shaft key (202).

4. Press the top bearing cone (412) off of the shaft.

Assembly

Before assembling a new pinion gear in the pinion cage, check

match numbers on pinion gear and spiral bevel ring gear to be

certain that they are a matched set. Gears are lapped in matched

sets at the factory and should not be separated. Numbers are

etched on both the pinion and ring gear as illustrated in Figure 4.

All parts that are to be reused should be thoroughly cleaned before

being reinstalled. Do not remove new bearings from packaging

until ready to use. Clean all bearings (new or used). Do not spin

dry bearings. Take each bearing set and roll the cup on the cone

to note any roughness. Replace bearing if necessary. If bearings

cannot be installed immediately after cleaning, lubricate and cover

to protect against dust, moisture, etc.

If a press is not available to install bearing cones, they can be

heated as long as the temperature does not exceed 275°-300°F

(135°-149°C). If the bearings get hotter than this, they will begin

to draw and soften. Bearings can be heated with infrared lamps

or with oil baths. If an oil bath is used, the bearing should be sup-

ported an inch or so above the pan to prevent local overheating.

9

MATCHED NUMBER TO BE COMPARED WITH THE SAME

NUMBER ON THE RING GEAR. (EXAMPLE CO-43)

PINION SETTING DISTANCE. (EXAMPLE 4.860)

BACKLASH (NORMAL) AT WHICH THE GEARS WERE

LAPPED. (EXAMPLE .010)

MATCHED NUMBER TO BE COMPARED WITH THE SAME

NUMBER ON THE PINION GEAR. (EXAMPLE C0-43)

THE PINION SETTING DISTANCE IS THE DISTANCE

THE END OF THE PINION SHOULD BE FROM THE

CENTERLINE OF THE RING GEAR SHAFT.

Figure 4 Gear Match Numbers and Setting Data

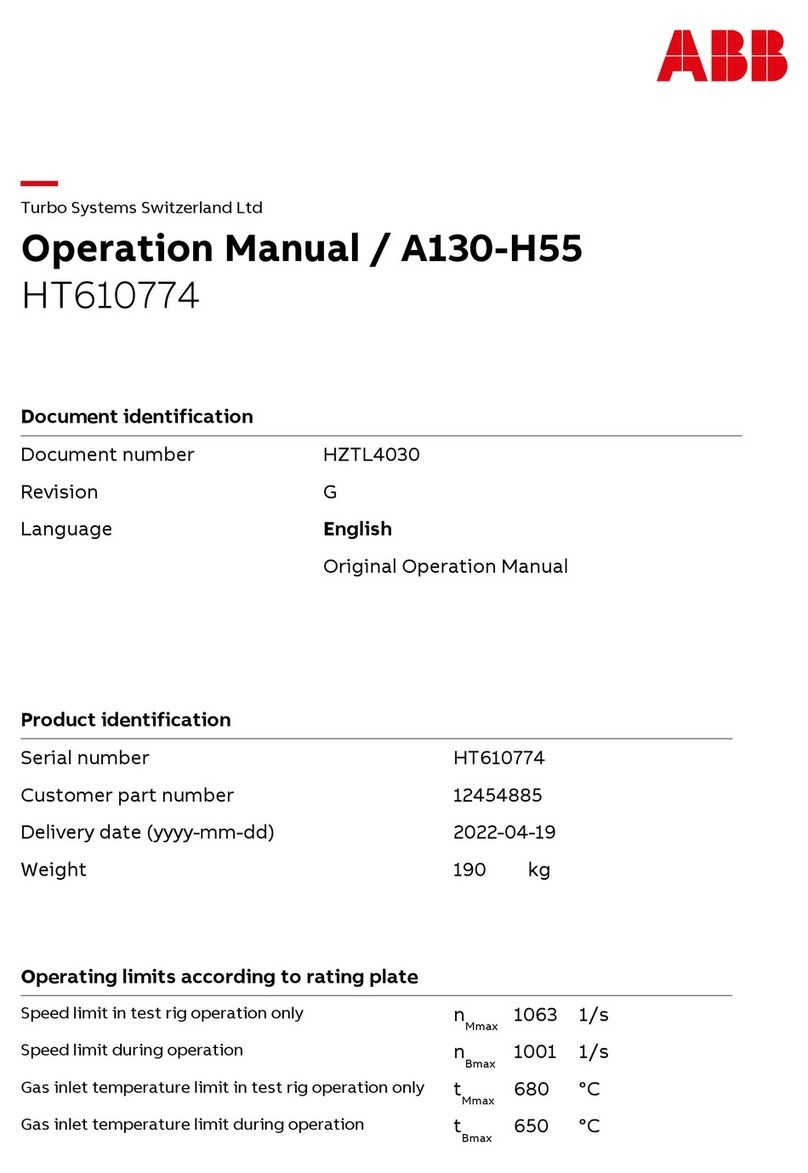

Figure 3 Cross Section

FAN HUB

RETEN T I ON H A RD W A RE

FAN SHA FT

W A TER SL I N GER

BEA RI N G RETA I N ER

PIPE PLUG

GEA RED U C ER CA SE

O I L SEA L

PINION SHAFT

PINION CAGE

CAP

PINION CAGE

O - RI N G

O RI N G

OIL SLINGER

PINION GEAR

BOTTOM COVER CAP

RI N G GEA R

O - RI N G

BOTTOM BEARING

RETA I N ER CA P

RI N G GEA R

HUB

O - RI N G

D RA I N P L U G

AIR VENT

10

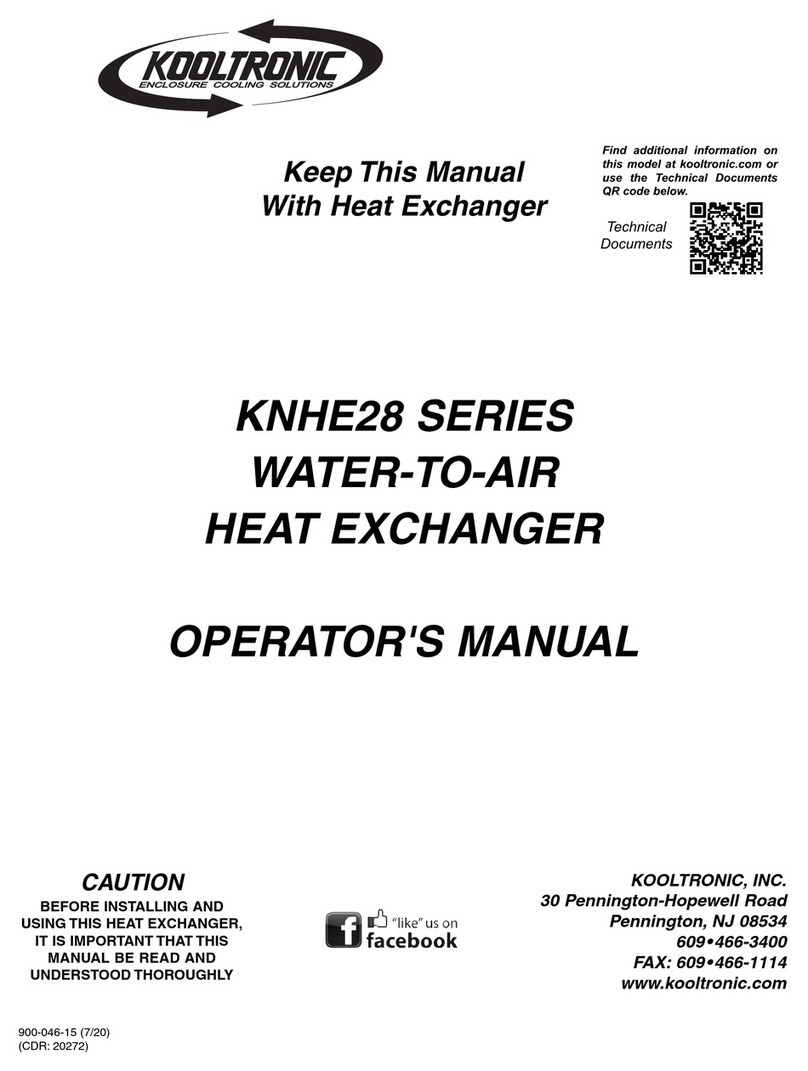

Figure 5 Flange Seal of Bottom Bearing Cap

Pinion Cage Subassembly

1. Place O-ring (506) on pinion shaft (101).

2. Place oil slinger (301) on pinion shaft.

3. Press head bearing cone (311) on pinion shaft making sure

oil slinger and bearing are against gear.

4. Press bearing cups (311 and 312) into pinion cage.

5. Lower pinion cage on pinion shaft, until head bearing cone

and cup mate.

6. Press tail bearing cone (312) on pinion shaft until it mates with

its bearing cup.

7. Install locknuts and lockwasher (103 and 104). Tighten nuts on

bearing cone until 5 to 15 in·lbƒ(565-1695 mN·m) of bearing

preload is obtained. Bearing preload is the resistance in the

bearings to shaft rotation measured in in·lbƒ required to rotate

the shaft at uniform velocity. Preload is necessary to insure the

stability of the gear engagement. Crimp the lockwasher to hold

the two nuts in place.

8. Install O-ring (504) in groove.

9. Press oil seal (501) into pinion shaft.

10.Position O-ring (505) and push cap - with seal - in place on

shaft. Attach cap to pinion cage with cap screws.

11.Record the pinion setting distance that is etched on the pinion

gear.

Installation of Fan Shaft

1. Press ring gear hub (8) and the upper and lower bearing cones

(411 and 412) on the fan shaft (201). Install ring gear (101) on

ring gear hub and tighten cap screws to 90 ft·lbƒ(123 N·m) .

2. Install upper fan shaft bearing cup (412) and bearing retainer

without shims.

3. Turn the Geareducer case upside down and install the fan

shaft assembly seating the upper fan shaft bearing cone into

its cup. Install the lower bearing cup (411).

4. Install the bottom cover cap using sealer as indicated in Figure

5and tighten cap screws to 25 ft·lbƒ(34 N·m). Use old shim

pack or make up equivalent thickness shim pack (420) and

install the bottom bearing retainer cap. Do not install the O-ring

for the bottom bearing retainer at this time. Tighten the cap

screws to 25 ft·lbƒ(34 N·m).

5. Turn the Geareducer right side up and rotate the fan shaft

several turns in each direction to seat the bearing rollers. With

a dial indicator and using the Geareducer case as a reference,

measure and adjust the fan shaft bearings to .003-.005" (.076-

.127mm) endplay. The endplay is adjusted by adding shims

(part 420) under the upper bearing retainer.

6. For "S" Models Only: Once proper end play is obtained install

fan shaft oil seal in the upper bearing reatainer.

1/8" DIA. BEAD

OF RTV SILICON

GASKET SEALER

Installation of Pinion Cage

1. The "X" marked pinion and gear teeth should be clearly identi-

fied with chalk or other markings which can be seen from the

inspection opening or the bottom of the case.

2. Find the difference between the pinion setting distance of

the old gear and the new pinion gear and adjust the old shim

pack (320) or make a new shim pack to compensate for the

different setting distances.

Example:

Pinion setting distance of old gear 4.883

Pinion setting distance of new gear 4.878

Difference .005

Remove .005 from shim gap.

3. Install shims (320) and pinion cage subassembly.

Note—Care must be taken not to damage the pinion gear teeth

by forcing them into the ring gear teeth.

field repair

11

Gear Setting Procedure

The proper mounting of the gear set is essential to obtain long

life and smooth operation of the gears. The pinion and ring gears

were positioned approximately in the preceding steps. The correct

gear position is determined by the gear tooth contact pattern and

by the backlash.

With the "X" marked tooth on the pinion gear engaged between

the two "X" marked teeth on the ring gear, check the backlash

with a dial indicator as shown in Figure 6. Lock the pinion shaft

against rotation. The amount of movement of the fan shaft, mea-

sured at a distance equal to the outside radius of the ring gear

is the backlash. The backlash on the 6.50/1 gear set should be

between .013 and .018" (.33 and .46mm). The backlash on all

other ratios should be between .010 and .015" (.25 and .38mm).

With the "X" teeth engaged, the backlash should be approximately

in the middle of the allowable range. Check the backlash at three

other points around the ring gear to be sure the backlash is within

the specified limits. Adjust ring gear axially by removing or adding

shims (420) at bottom bearing retainer.

Note—To maintain bearing adjustment corresponding shim (420)

adjustment must be made at the bearing retainer.

Example: Removing .003" shims at the bottom bearing retainer

requires the addition of .003" shims at the top bearing retainer to

maintain correct bearing adjustment.

Recheck the backlash to make sure it is within the proper limits.

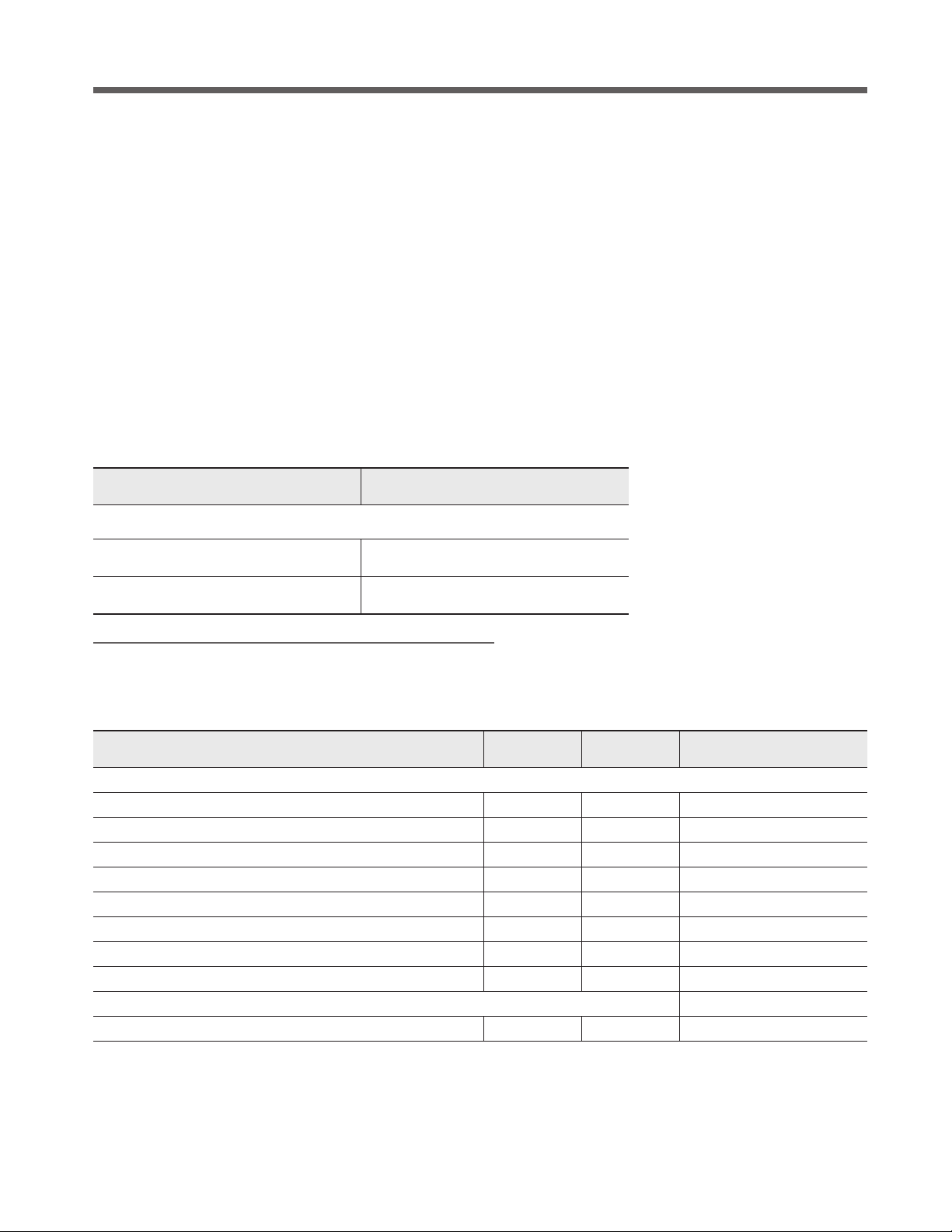

With gears adjusted to the proper backlash, blue (Prussian blue in

oil) the pinion teeth. By using a long handled brush or swab, the

pinion teeth can be reached through the inspection opening. Drive

the pinion by turning the fan shaft in both directions for several

revolutions. Observe the markings on both gears on both sides of

the teeth. Compare the markings with the contact pattern shown

in Figure 7.

If contact pattern is incorrect, adjust the pinion position with shims

between the pinion cage cap and Geareducer case.

When tooth contact is correct, recheck backlash. If necessary,

adjust ring gear to obtain proper backlash and recheck contact

pattern. Proper contact is more important of the two. On a used set

of gears, it may be necessary to set the gears with slightly greater

backlash in order to obtain proper tooth contact. Should a condi-

tion be encountered where correct contact cannot be obtained,

contact your local Marley sales representative for information on

factory repair service.

Final Assembly

1. Remove bottom bearing retainer cap and install the O-ring

(503). Reinstall the bottom bearing retainer cap and tighten

the cap screws to 25 ft·lbƒ(34 N·m).

2. For "S" Models Only:Installwear sleeve (521)on waterslinger.

3. Install O-ring (502) in water slinger.

4. Install water slinger on fan shaft (8).

5. Replace air vent and all pipe plugs.

6. Fill with lubricant selected from Table I.

COLLAR

SET SCREW

TOP VIEW

OF INDICATOR

POINT OF MEASUREMENT

OUTSIDE RADIUS OF GEAR

DIAL INDICATOR

Figure 6 Gear Backlash Measurement

field repair

Figure 7 Tooth Contact Pattern—Correct and Incorrect

DIRECTION OF ROTATION

RING GEAR

ORIGINAL

PATTERN

AFTER

BREAK IN

**

*

*

CONVEX SIDE

ENTERING

CONCAVE SIDE

LEAVING

CONCAVE SIDE

CONVEX SIDE

OUT-OF POSITION CONTACT

Cause: Pinion too close to

gear center.

Remedy: Move pinion out.

OUT-OF POSITION CONTACT

Cause: Pinion too far from

gear center.

Remedy: Move pinion in.

Correct Pinion and Ring Gear Tooth Contact Patterns Incorrect Ring Gear Tooth Contact Patterns

Z0490769_C (M99-1260E) | ISSUED 06/2022

COPYRIGHT © 2022 SPX TECHNOLOGIES

In the interest of technological progress, all products are subject to design

and/or material change without notice.

Geareducer

USER MANUAL

SPX COOLING TECH, LLC

7401 WEST 129 STREET

OVERLAND PARK, KS 66213 USA

spxcooling.com

This manual suits for next models

3

Table of contents

Other SPX Cooling Technologies Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

CHIEF

CHIEF MI300i Complete manual

INOXPA

INOXPA ASPIR EX Installation, service and maintenance instructions

Bosch

Bosch rexroth COIL D36 Technical user's manual

Oxford Instruments

Oxford Instruments NanoScience Optistat CF Operation manual

Xylem

Xylem McDonnell & Miller PSE-800-M Application, Installation, Operation, and Maintenance Manual

Casadei

Casadei K 320 Instruction and maintenance manual