SPX FLOW Waukesha Cherry-Burrell DA4 User manual

This manual suits for next models

2

Other SPX FLOW Control Unit manuals

SPX FLOW

SPX FLOW W61 User manual

SPX FLOW

SPX FLOW APV DELTA UF3 User manual

SPX FLOW

SPX FLOW APV DELTA SDMS4 User manual

SPX FLOW

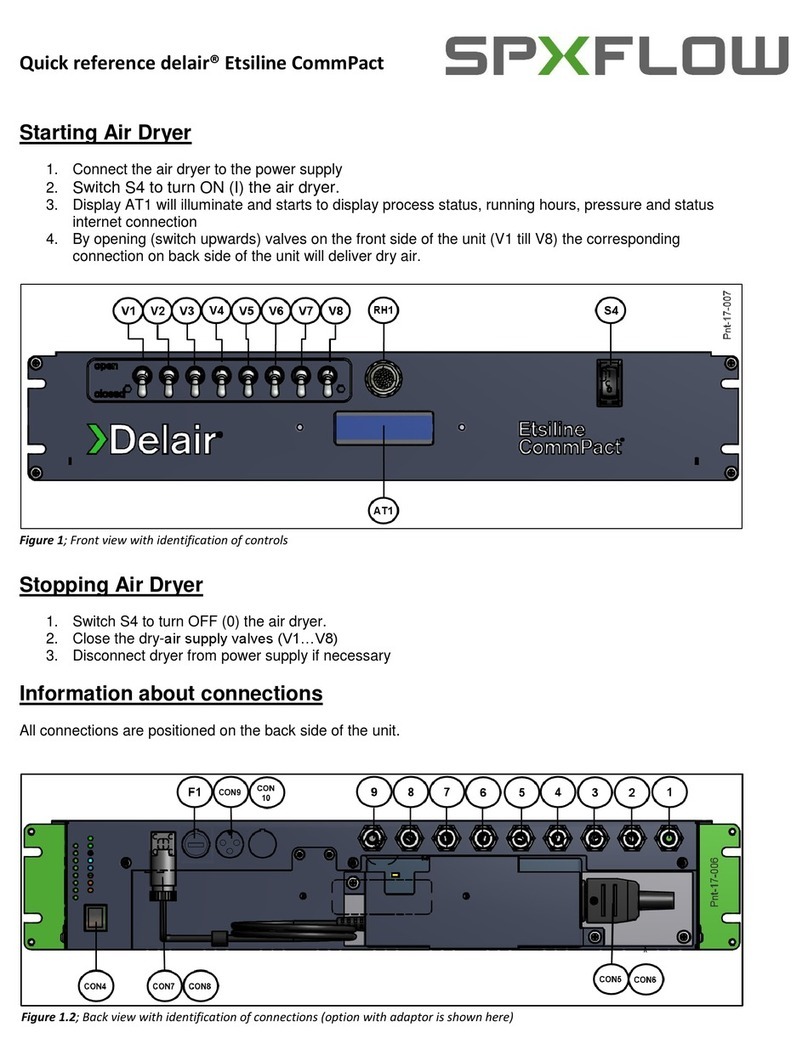

SPX FLOW Delair Etsiline CommPact User manual

SPX FLOW

SPX FLOW APV DELTA DE3 User manual

SPX FLOW

SPX FLOW APV DA4 User manual

SPX FLOW

SPX FLOW APV DELTA RGMS4 User manual

SPX FLOW

SPX FLOW WR60 Series User manual

SPX FLOW

SPX FLOW APV CU41-S User manual

SPX FLOW

SPX FLOW W70 Series User manual

SPX FLOW

SPX FLOW APV DELTA RGMS4 User manual

SPX FLOW

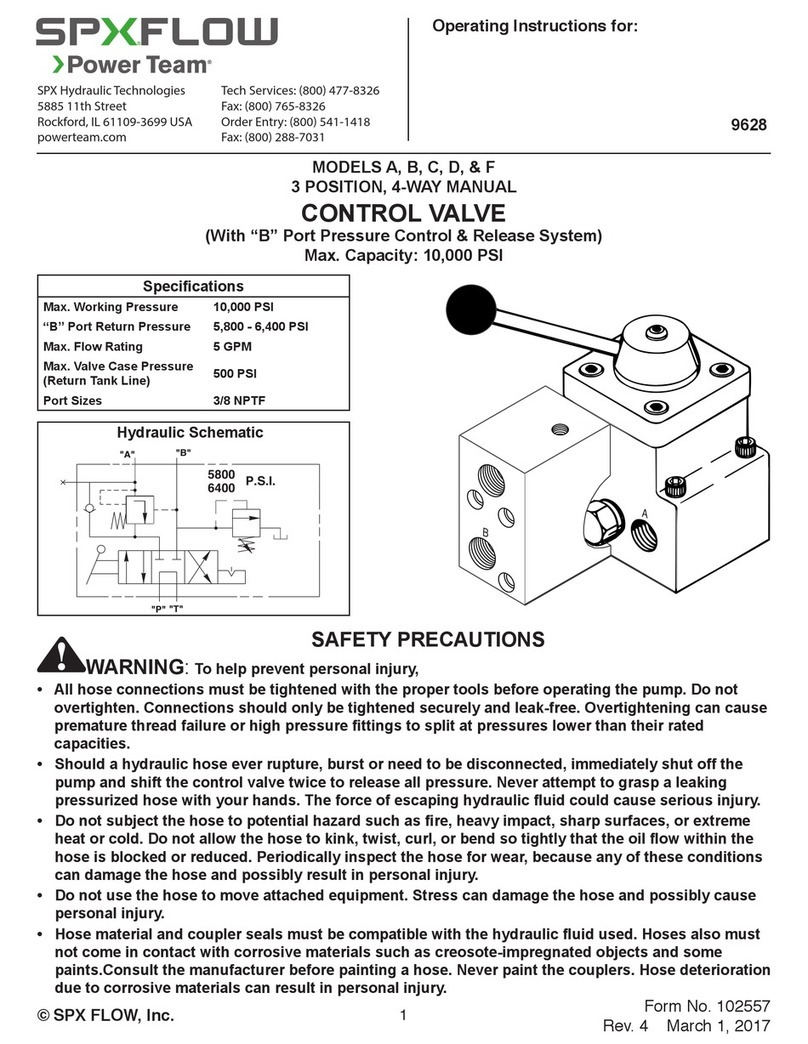

SPX FLOW Power Team A User manual

SPX FLOW

SPX FLOW APV DELTA DKR2 User manual

SPX FLOW

SPX FLOW APV DELTA RG4 User manual

SPX FLOW

SPX FLOW APV DELTA RG4 User manual

SPX FLOW

SPX FLOW APV DELTA SV1 User manual

SPX FLOW

SPX FLOW APV DELTA MS4 User manual

SPX FLOW

SPX FLOW APV DELTA UF3(A) User manual

SPX FLOW

SPX FLOW W71 User manual

SPX FLOW

SPX FLOW APV DELTA CPV User manual

Popular Control Unit manuals by other brands

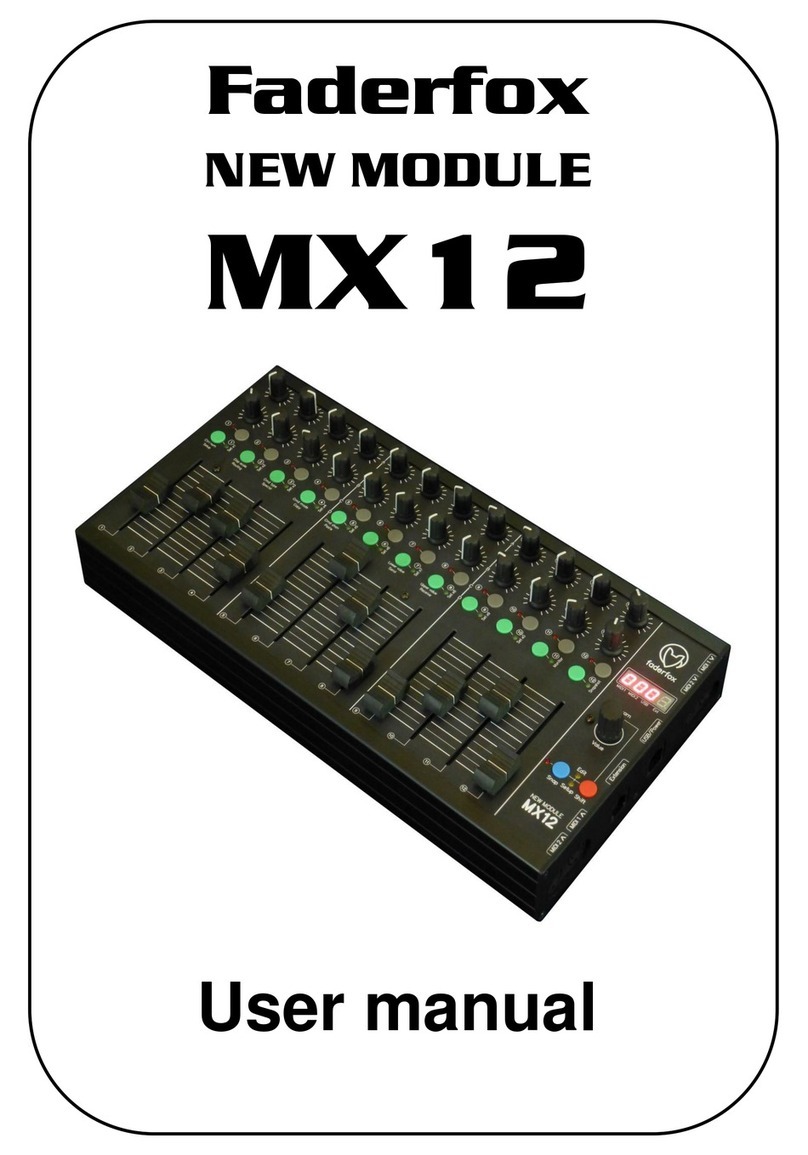

Faderfox

Faderfox MX 12 user manual

Pilz

Pilz PSSu E AI SHT2 operating manual

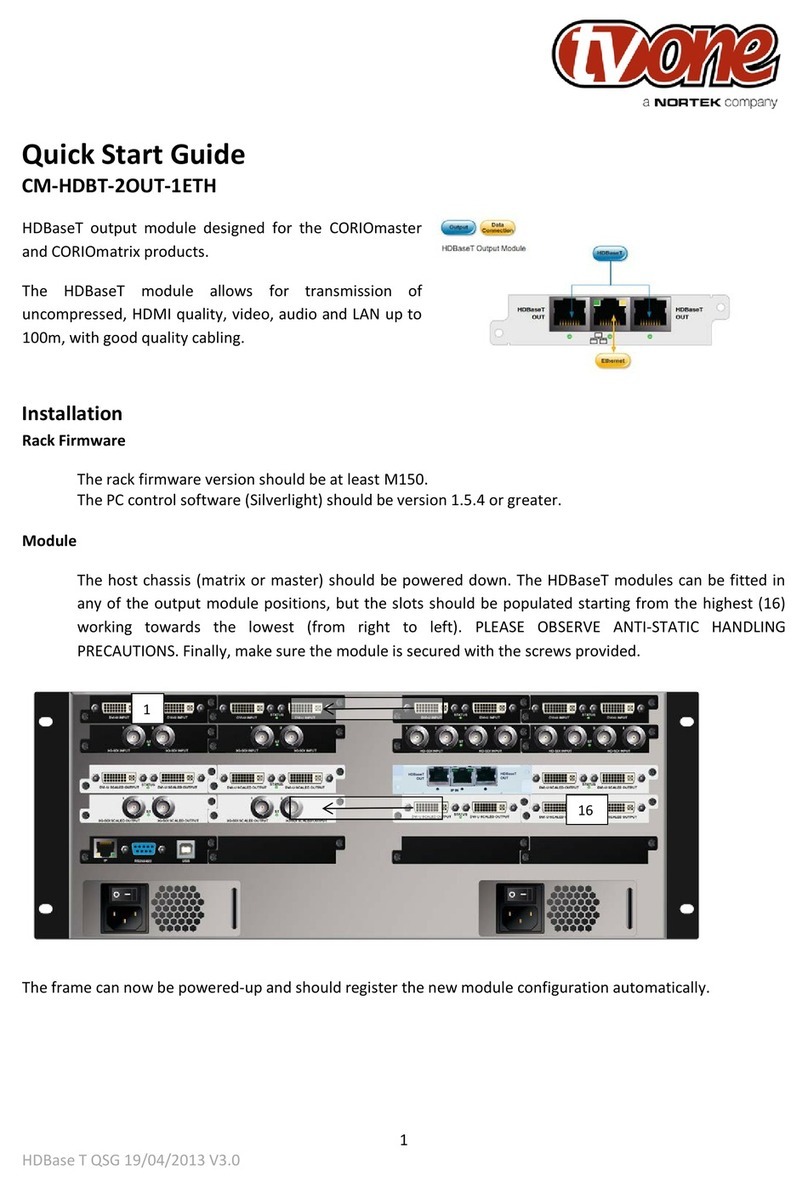

Nortek

Nortek tvone CM-HDBT-2OUT-1ETH quick start guide

UUGear

UUGear Witty Pi 3 user manual

Telit Wireless Solutions

Telit Wireless Solutions NE866B1 Hardware Design Guide

Glas-Col

Glas-Col PLSM Series Operating and safety instructions

Comelit

Comelit Simplebus1 Ultra UT1020 Technical manual

EMC

EMC VNXe3300 Replacing

GEM

GEM N086 Installation, Operating and Maintenance Instructions for the Installer and the User

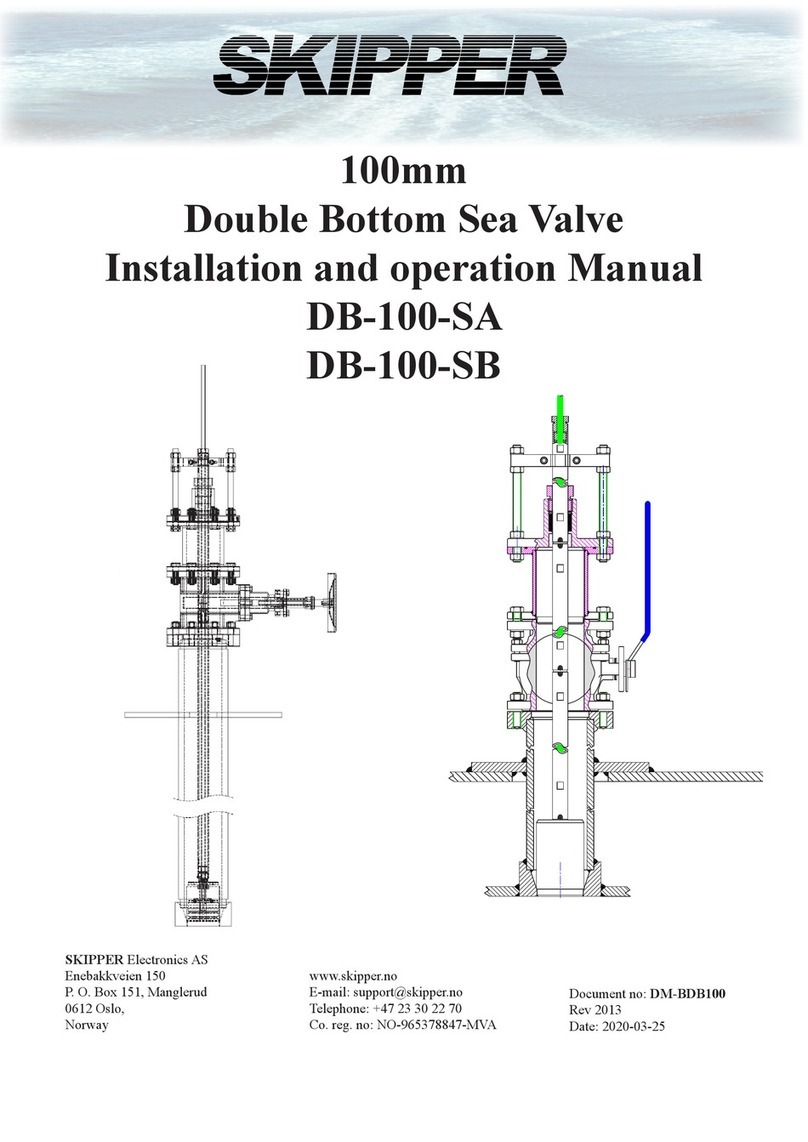

Skipper

Skipper DB-100-SA Installation and operation manual

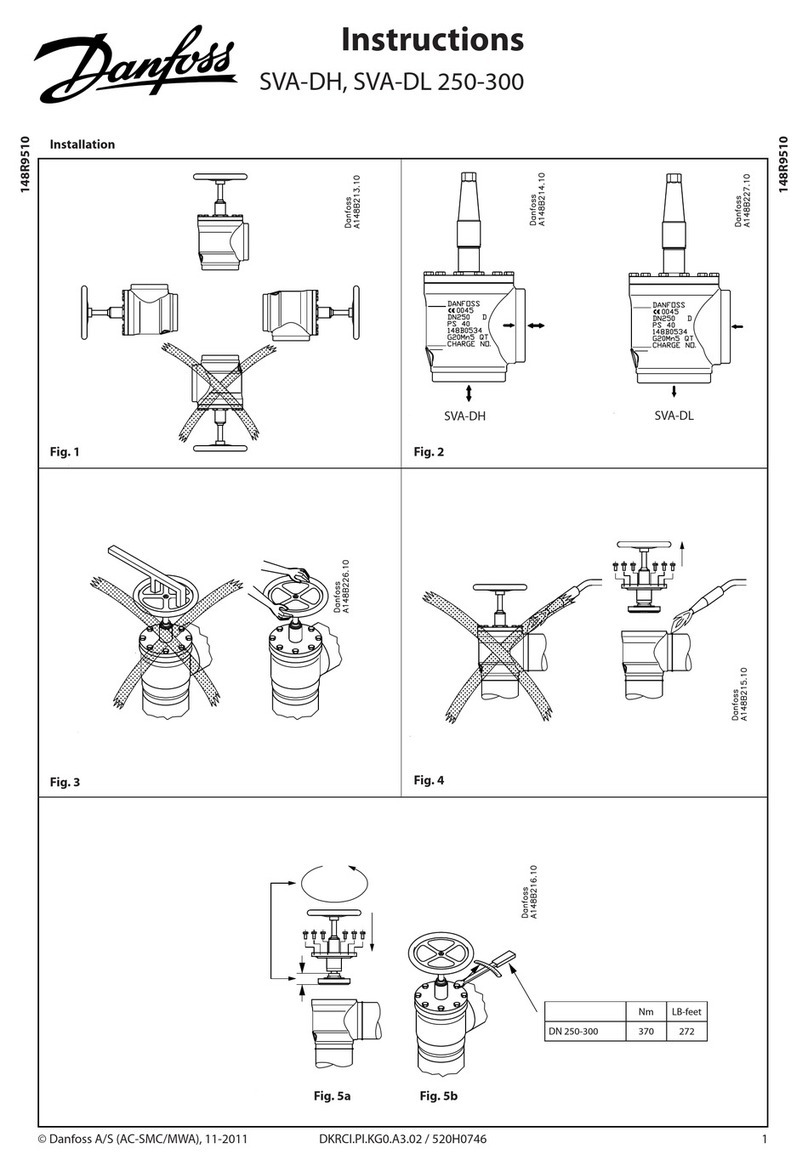

Danfoss

Danfoss SVA-DH Instructions for use

ALLEN & HEATH

ALLEN & HEATH Qu-24 reference guide