SPX FLOW Colloid Mill User manual

Colloid Mill

FORM NO.: 95-03028 REVISION: 09/2019 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

SPX FLOW, Inc.

611 Sugar Creek Road

Delavan, WI 53115

Phone: (262)728-1900 or (800)252-5200

Fax: (262)728-4904 or (800)252-5012

E-mail: wcb@spxow.com

Website: www.spxow.com

Information contained in this manual is subject to

change without notice and does not represent a

commitment on the part of SPX FLOW, Inc. No part

of this manual may be reproduced or transmitted in

any form or by any means, electronic or mechani-

cal, including photocopying and recording, for any

purpose, without the express written permission of

SPX FLOW, Inc.

Copyright © 2019 SPX FLOW, Inc.

All Rights Reserved.

Revision Date: 09/2019

Publication: 95-03028

3

95-03028

09/2019

Warranty ................................................................................................................................ 4

Shipping Damage or Loss............................................................................................................................ 4

Warranty Claim ............................................................................................................................................ 4

Safety .................................................................................................................................... 5

Warnings and Replacement Labels ............................................................................................................. 6

Introduction/Specications..................................................................................................... 6

Specications............................................................................................................................................... 6

Colloid Mill Unit Dimensions ........................................................................................................................ 7

Installation and Start-Up........................................................................................................ 8

Variation of inlet port .................................................................................................................................... 8

Overhead equipment ................................................................................................................................... 8

Wiring........................................................................................................................................................... 8

Rotation........................................................................................................................................................ 8

Seal ush............................................................................................................................................... 8

Lubrication ................................................................................................................................................... 9

Method of feeding and capacity ................................................................................................................... 9

Colloid Mill Troubleshooting................................................................................................... 9

Maintenance........................................................................................................................ 10

Cleaning..................................................................................................................................................... 10

Flushing .............................................................................................................................................. 10

Disassembly............................................................................................................................................... 10

Assembly ................................................................................................................................................... 12

Adjustment and Calibration........................................................................................................................ 12

Flush Water Seal Replacement ................................................................................................................. 13

Gear Case Service..................................................................................................................................... 14

Service Preparation ............................................................................................................................. 14

Front Seal Replacement...................................................................................................................... 14

Rear Seal Replacement ...................................................................................................................... 14

Bearing Replacement .......................................................................................................................... 14

Sanitary Seal Replacement ................................................................................................................ 15

Parts List.............................................................................................................................. 16

Colloid Mill Gear Case ............................................................................................................................... 16

Colloid Mill Fluid Head ............................................................................................................................... 18

Sanitary Seal.............................................................................................................................................. 20

Waukesha Cherry-Burrell®Brand Colloid Mill

Table of Contents

Table of Contents

95-03028 09/20194

Waukesha Cherry-Burrell®Brand Colloid MillWarranty

Warranty

LIMITED WARRANTY: Unless otherwise mutually agreed to in writing, (a) SPX FLOW US, LLC (SPX FLOW)

goods, auxiliaries and parts thereof are warranted to the Buyer against defective workmanship and material for

a period of twelve (12) months from date of installation or eighteen (18) months from date of delivery, whichever

expires rst, and (b) SPX FLOW services are warranted to Buyer to have been performed in a workmanlike

manner for a period of ninety (90) days from the date of performance. If the goods or services do not conform

to the warranty stated above, then as Buyer’s sole remedy, SPX FLOW shall, at SPX FLOW’s option, either

repair or replace the defective goods or re-perform defective services. If Buyer makes a warranty claim to SPX

FLOW and no actual defect is subsequently found, Buyer shall reimburse SPX FLOW for all reasonable costs

which SPX FLOW incurs in connection with the alleged defect. Third party goods furnished by SPX FLOW will

be repaired or replaced as Buyer’s sole remedy, but only to the extent provided in and honored by the original

manufacturer’s warranty. Unless otherwise agreed to in writing, SPX FLOW shall not be liable for breach

of warranty or otherwise in any manner whatsoever for: (i) normal wear and tear; (ii) corrosion, abrasion or

erosion; (iii) any good or services which, following delivery or performance by SPX FLOW, has been subjected

to accident, abuse, misapplication, improper repair, alteration (including modications or repairs by Buyer, the

end customer or third parties other than SPX FLOW), improper installation or maintenance, neglect, or excessive

operating conditions; (iv) defects resulting from Buyer’s specications or designs or those of Buyer’s contractors

or subcontractors other than SPX FLOW; or (v) defects resulting from the manufacture, distribution, promotion

or sale of Buyer’s products; (vi) damage resulting from the combination, operation or use with equipment,

products, hardware, software, rmware, systems or data not provided by SPX FLOW, if such damage or harm

would have been avoided in the absence of such combination, operation or use; or (vii) Buyer’s use of the goods

in any manner inconsistent with SPX FLOW’s written materials regarding the use of such product. In addition,

the foregoing warranty shall not include any labor, dismantling, re-installation, transportation or access costs, or

other expense associated with the repair or replacement of SPX FLOW goods. THE WARRANTIES CONTAINED

HEREIN ARE THE SOLE AND EXCLUSIVE WARRANTIES AVAILABLE TO BUYER AND SPX FLOW HEREBY

DISCLAIMS ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ANY

PERFORMANCE OR PROCESS OUTCOME DESIRED BY THE BUYER AND NOT SPECIFICALLY AGREED

TO BY SPX FLOW. THE FOREGOING REPAIR, REPLACEMENT AND REPERFORMANCE OBLIGATIONS

STATE SPX FLOW’S ENTIRE AND EXCLUSIVE LIABILITY AND BUYER’S EXCLUSIVE REMEDY FOR ANY

CLAIM IN CONNECTION WITH THE SALE AND FURNISHING OF SERVICES, GOODS OR PARTS, THEIR

DESIGN, SUITABILITY FOR USE, INSTALLATION OR OPERATIONS.

Shipping Damage or Loss

If equipment is damaged or lost in transit, le a claim at once with the delivering carrier. The carrier has a signed

Bill of Lading acknowledging that the shipment has been received from SPX FLOW in good condition. SPX FLOW

is not responsible for the collection of claims or replacement of materials due to transit shortage or damages.

Warranty Claim

Warranty claims must have a Returned Material Authorization (RMA) from the Seller or returns will not be

accepted. Contact 800-252-5200 or 262-728-1900.

Claims for shortages or other errors must be made in writing to Seller within ten (10) days after delivery. This

does not include transit shortage or damages. Failure to give such notice shall constitute acceptance and waiver

of all such claims by Buyer.

5

95-03028

09/2019

Waukesha Cherry-Burrell®Brand Colloid Mill Safety

Safety

Warnings and cautions are provided in this manual to help avoid serious injury and/or possible damage to

equipment:

DANGER

WARNING

CAUTION

Immediate hazards which WILL result in severe personal injury or death.

Hazards or unsafe practices which COULD result in severe personal injury or death.

Hazards or unsafe practices which COULD result in minor personal injury or product or

property damage.

READ AND UNDERSTAND THIS MANUAL PRIOR TO INSTALLING, OPERATING, OR SERVICING THIS

EQUIPMENT

SPX FLOW recommends users of our equipment and designs follow the latest Industrial Safety Standards. At

a minimum, these should include the industrial safety requirements established by:

1. Occupational Safety and Health Administration (OSHA)

2. National Fire Protection Association (NFPA)

3. National Electrical Code (NEC)

4. American National Standards Institute (ANSI)

WARNING

Severe injury or death can result from electrical shock, burn, or unintended actuation of

equipment. Recommended practice is to disconnect and lockout industrial equipment from

power sources, and release stored energy, if present. Refer to the National Fire Protection

Association Standard No. NFPA70E, Part II and (as applicable) OSHA rules for Control of

Hazardous Energy Sources (Lockout-Tagout) and OSHA Electrical Safety Related Work

Practices, including procedural requirements for:

• Lockout-tagout

• Personnel qualications and training requirements

• When it is not feasible to de-energize and lockout-tagout electrical circuits and equipment

before working on or near exposed circuit parts

Before putting SPX FLOW equipment into operation, the operator shall analyze the application for all foresee-

able risks, their likelihood to occur and the potential consequences of the identied risks as per ISO 31000

and ISO/IEC 31010 in their actual current version.

Locking and Interlocking Devices: These devices should be checked for proper working condition and

capability of performing their intended functions. Make replacements only with the original equipment manu-

facturer’s OEM renewal parts or kits. Adjust or repair in accordance with the manufacturer’s instructions.

Periodic Inspection: Equipment should be inspected periodically. Inspection intervals should be based on

environmental and operating conditions and adjusted as indicated by experience. At a minimum, an initial

inspection within 3 to 4 months after installation is recommended. Inspection of the electrical control systems

should meet the recommendations as specied in the National Electrical Manufacturers Association (NEMA)

Standard No. ICS 1.3, Preventative Maintenance of Industrial Control and Systems Equipment, for the gen-

eral guidelines for setting-up a periodic maintenance program.

Replacement Equipment: Use only replacement parts and devices recommended by the manufacturer to

maintain the integrity of the equipment. Make sure the parts are properly matched to the equipment series,

model, serial number, and revision level of the equipment.

95-03028 09/20196

Waukesha Cherry-Burrell®Brand Colloid MillIntroduction/Specications

Replacement Label 33-62

Replacement label 33-61

Warnings and Replacement Labels

The Waukesha Cherry-Burrell brand Colloid Mill produces controlled, highly sheared, uniform dispersions and

stable emulsions made up of uniform globules of moderate neness.

A serrated conical stator and a serrated rotating cone make up the emulsifying head.

Operating clearance can be adjusted in .001-inch increments between .010 and .240 inches.

Capacities range from 6.7 to 33.3 gpm (25 to 126 l/m).

Viscosity range is limited only by the maximum 150 psi feed pressure.

Specications

Model

Nominal

Speed Pressure

Nominal

Capacity To

Inlet

Outlet

Nominal

Temp. Range

CM 3600 RPM to 150 psi

(10 bar)

6.7 to 33.3 GPM

(25 to 126 l/m)

2” San. IMDA to 200° (93° C)

WARNING

Stop Machinery to Clean, Service or Repair. To avoid serious injury, do not install or service the

mill unless all power is o and locked out.

WARNING

To avoid electrocution, ALL electrical should be done by a registered Electrician, following

Industry Safety Standards. All power must be OFF and LOCKED OUT.

WARNING

To avoid possible serious injury, shut o and drain product from mill prior to disconnecting the

piping.

CAUTION

Mill parts have sharp edges. To avoid a cutting injury, wear gloves and handle parts carefully.

Replacement Label 121694+

Introduction/Specications

7

95-03028

09/2019

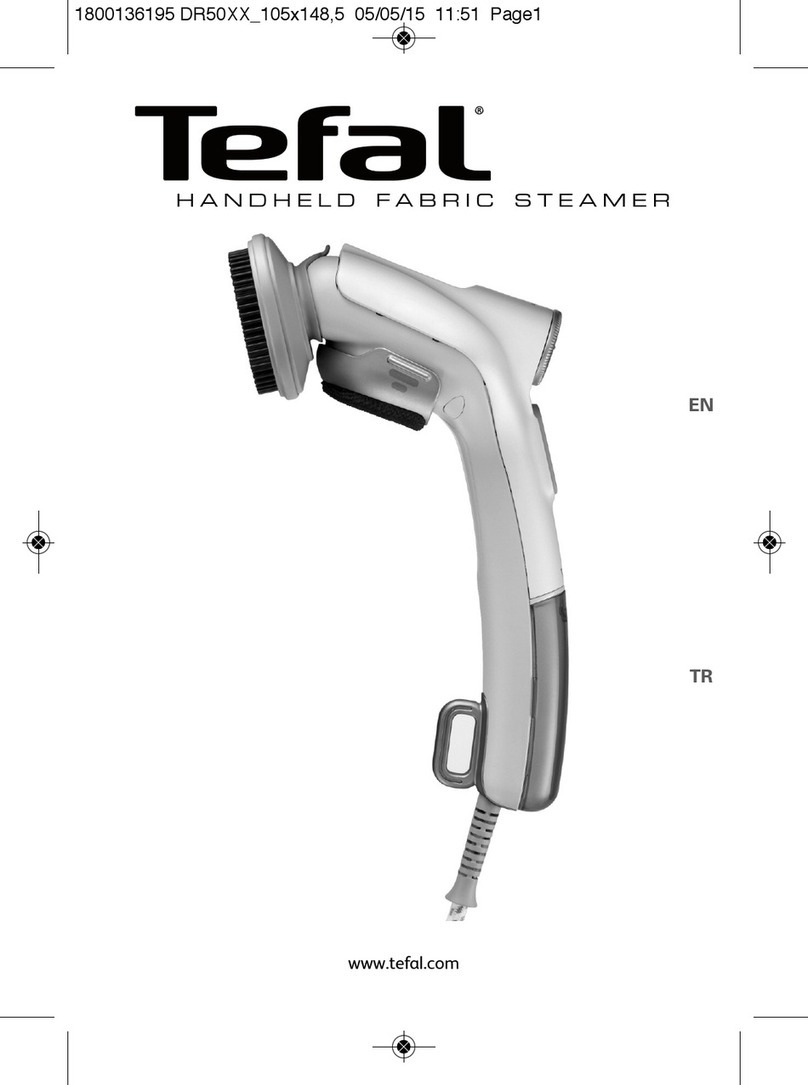

Waukesha Cherry-Burrell®Brand Colloid Mill Introduction/Specications

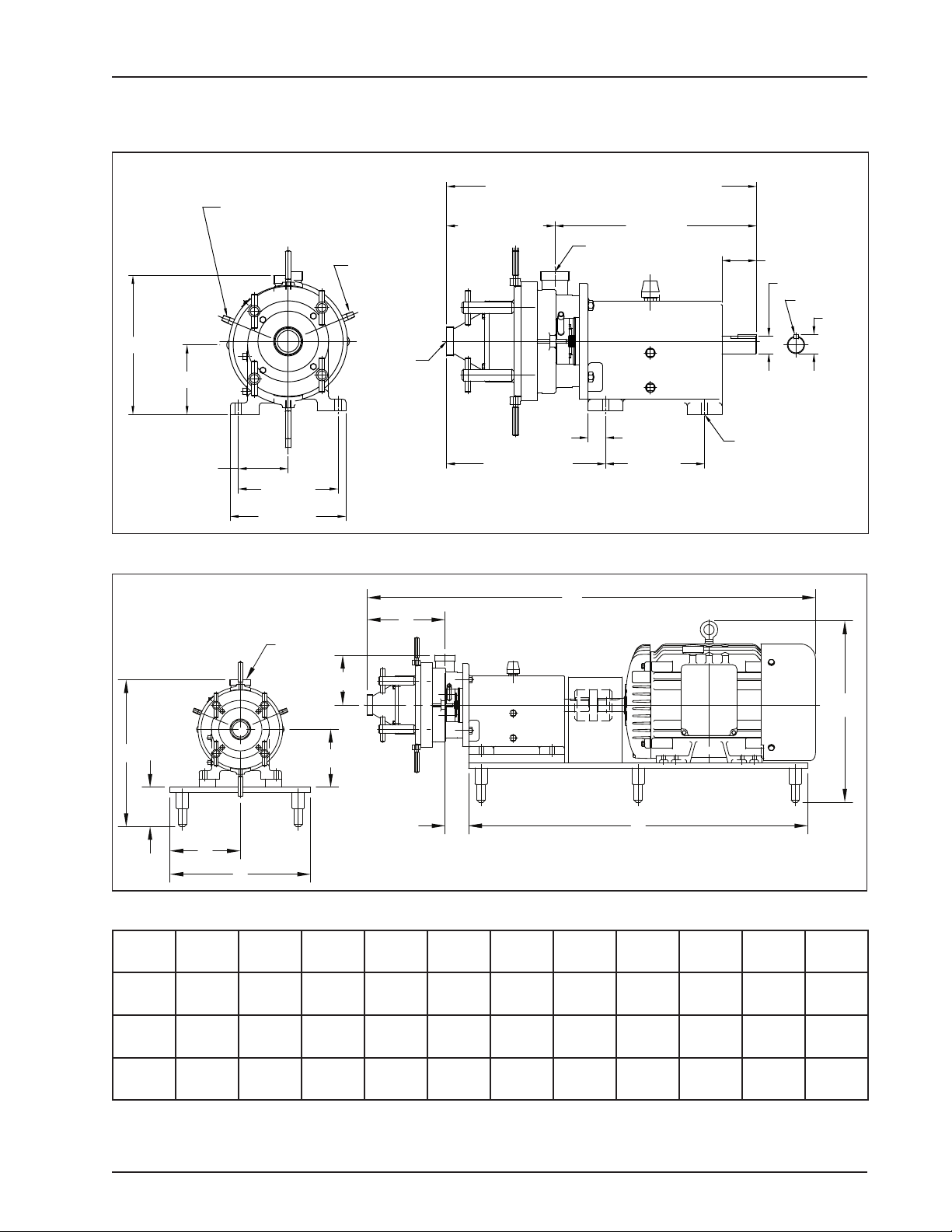

4.31 [110]

8.63 [219]

10.00 [254]

6.00 [152]

12.00 [305]

1.50 [38] TYP.

8.56 [217]

13.75 [349] MIN.

14.88 [378] MAX.

9.38 [238] MIN.

10.51 [267] MAX. 17.44 [443]

26.81 [681] AS SHOWN, WITH STATOR ALL THE WAY IN

27.94 [710] WITH STATOR ALL THE WAY OUT

3.00 [76]

Ø1.50 [38]

1.65

[42]

Ø.56 [14]

.38 KEY [10]

2"-8 IMDA INLET

2"-8 IMDA

OUTLET

1/4-18 NPT PIPE

NIPPLE SEAL

FLUSH OUTLET

1/4-18 NPT PIPE

NIPPLE SEAL

FLUSH INLET

DP100-011

Figure 1

Colloid Mill Unit Dimensions

F

C B

J

X

A

G

2"-8 IMDA

Y

D

T

E

DP100-012

NOTE: The pump is shimmed to “D” height.

Figure 2

Unit

Size A B C D E F G J T X Y

15 HP 51.57

(1310)

41.00

(1041)

2.88

(73)

6.25

(159)

4.75

(121)

8.50

(216)

17.00

(432)

17.69

(449)

17.00

(432)

9.40

(239)

6.00

(152)

20 HP 53.32

(1354)

41.00

(1041)

2.88

(73)

6.25

(159)

4.75

(121)

8.50

(216)

17.00

(432)

17.69

(449)

17.00

(432)

9.40

(239)

6.00

(152)

25 HP 54.20

(1377)

41.00

(1041)

2.88

(73)

7.00

(178)

4.75

(121)

8.50

(216)

17.00

(432)

21.90

(556)

17.00

(432)

9.40

(239)

6.00

(152)

Dimensions shown in IN (mm)

95-03028 09/20198

Waukesha Cherry-Burrell®Brand Colloid MillInstallation and Start-Up

Installation and Start-Up

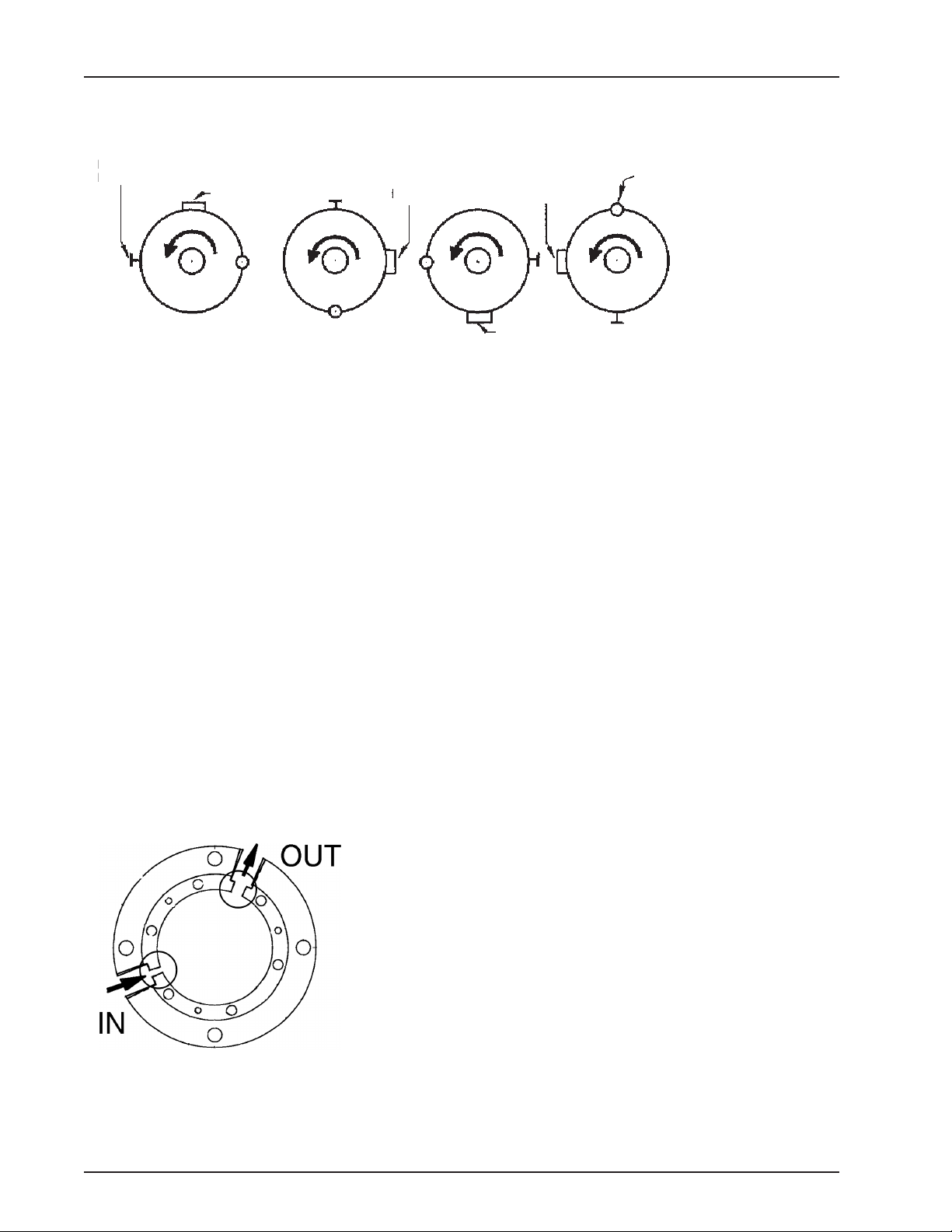

ROTATION

Counter-clockwise

when facing the

outlet port.

See Figure 3. The mill is shipped from the factory with the inlet port as

shown in Position 1. For convenience, the inlet port can be relocated

to any of the other three positions (see Disassembly Procedure). If

Position 4 is used the calibrations at the pointer will be upside down.

We suggest the use of a mirror.

The mill is equipped with a face type seal which must be water

cooled. The IN and OUT ports for introducing the water to the seal

are located in the gland.

NOTE: These are 1/4-inch pipe nipples, but the IN hole is smaller

than the OUT hole to prevent over-pressurizing (Figure 4).

The IN port must be used and the ow of water must be throttled to

produce a ush of 0.125 to 0.25 gpm (0.47 to 0.95 l/m). Flows in

this range provide safe cooling without damage to the lip seal.

Recommendation: use a solenoid valve in the water line to turn on

the water simultaneously with the mill. If the solenoid valve is not

used, turn on the water ush line before starting the mill.

Figure 4

Gland

Figure 3

Indicator

Pointer Knurled Lock Screw

Inlet

Position 1

Outlet Outlet Outlet Outlet

Position 2 Position 3 Position 4

Inlet Inlet

Inlet

Variation of inlet port

Overhead equipment

Wiring

Rotation

Follow accepted engineering practice when connecting the inlet and

outlet with the overhead equipment, piping, or tubing. Use hangers

to eliminate any weight, stress or strain on the mill. Remember, if a

direct connection is made with any overhead tank, install expansion

joints in the line. This will prevent mechanical loads on the mill which

would damage it or aect its operation.

3 Phase, 60 Cycle, 230-460 Volts. Follow the wiring directions on

the motor. Check the direction of rotation.

The rotation direction is counter-clockwise when facing the outlet

port. If run clockwise, the rotor retaining nut may back o, resulting

in damage to the mill.

Seal Flush

9

95-03028

09/2019

Waukesha Cherry-Burrell®Brand Colloid Mill Colloid Mill Troubleshooting

Inlet

Outlet

Figure 6

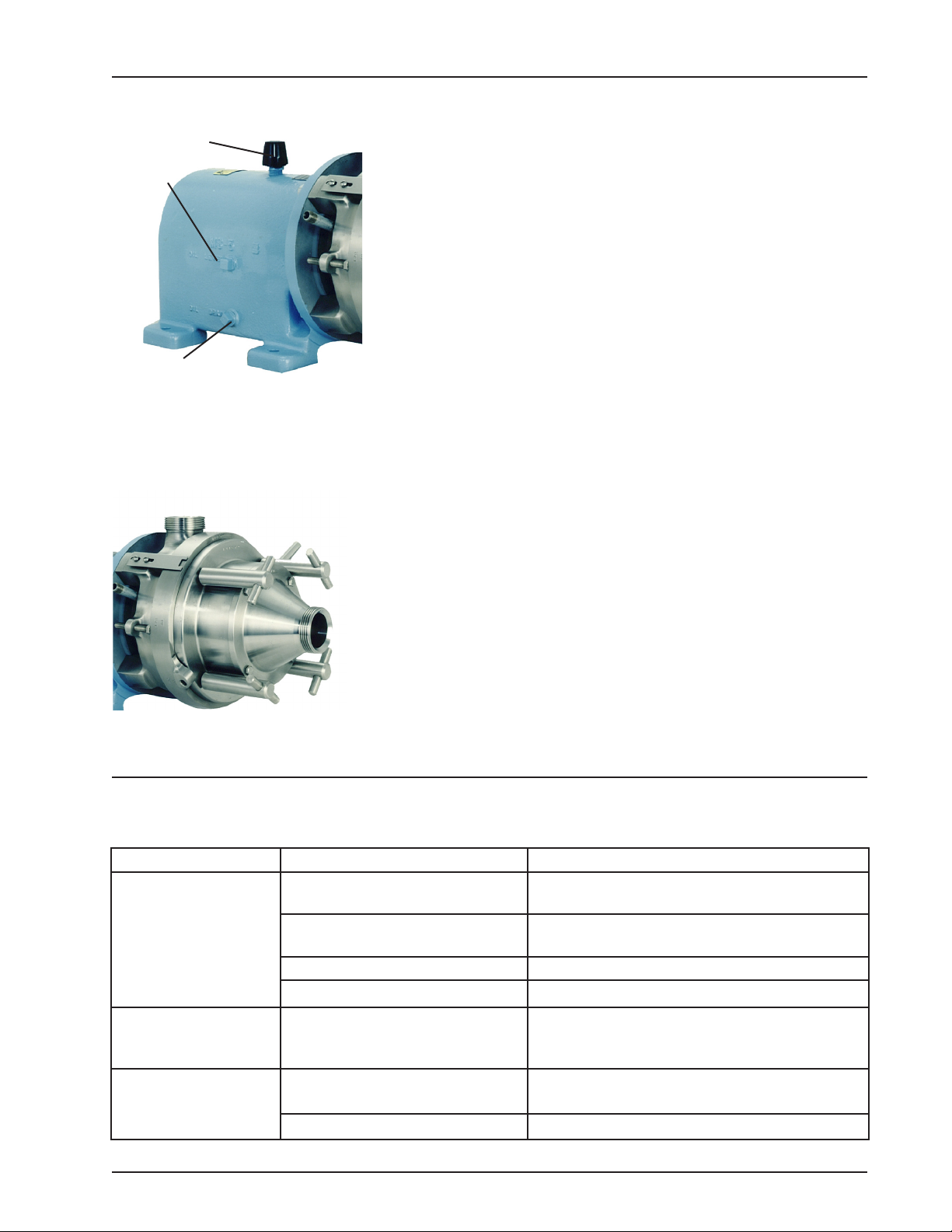

The mill is shipped with oil in the bearing case. The level should be

checked at the oil level hole and if necessary, oil should be added

through the oil ll hole.

Use Mobil oil DTE BB ISO Grade 220 R & O (Rust inhibited) gear

oil. If DTE BB is not available, use S.A.E. 40 non-detergent mineral

oil. The mill is shipped with a solid cap screw in the oil ll hole. This

should be removed and replaced with the breather cap which is

wired to the mill.

Frequency of lubrication is dependent upon temperature and moisture

conditions. If the room temperature is normal, 70° to 80° F (21° C

to 27° C), and water does not contact the bearing case, change

the oil every 240 operating hours. When the temperature varies

from hot to cold or the mill is ushed out with water, condensation

will occur in the bearing case, requiring more frequent oil changes.

Normal operating temperature of the bearing case is 170° to 190°

F (77° C to 88° C).

Colloid Mill Troubleshooting

Problem Likely Cause Solution(s)

Seals leaking Exceeding 150 PSI pressure

limitation of pump

Open up gap reduce pressure

Seal ush water improperly

plumbed

Connect ush water to IN/OUT ports as

stamped on gland

Water pressure too high Adjust to 0.125 to 0.25 gpm (0.47 to 0.95 l/m)

Seals misaligned on pin Re-align seals to proper t.

Noisy operation /

Excessive power draw

Loose rotor nut causing rotor to

stator contact

Tighten nut to 75 ft-lb.

Check mill rotation (counterclockwise facing

outlet port)

Inconsistent milling

results

Loose adjusting ring Set gap and tighten knurled screw in hole.

Tighten bolt and nut on opposite side.

Worn rotor or stator Replace worn parts

Oil level

Oil drain

Breather cap

Figure 5

Lubrication

The inlet and outlet ports are 2 inch sanitary male threads. The

inlet port is located in the body—its position can be changed. (See

Figure 3 on page 8.) The outlet port is located in the cover of the

mill. The mill must be fed with a pump; a Waukesha Cherry-Burrell

brand positive displacement pump is recommended. The capacity

of the mill is 6.7 to 33.3 gpm (25 to 126 l/m).

Method of feeding and

capacity

95-03028 09/201910

Waukesha Cherry-Burrell®Brand Colloid MillMaintenance

Maintenance

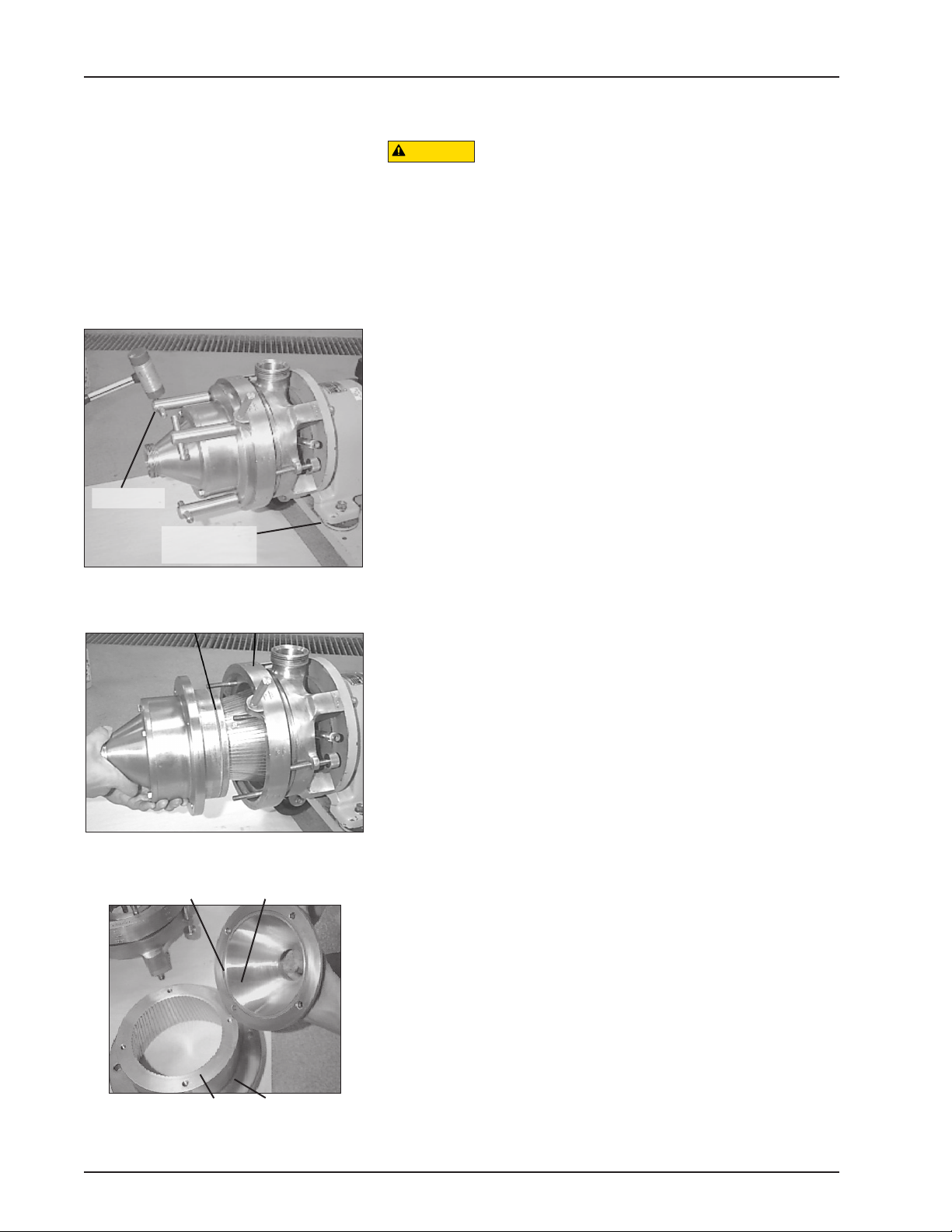

4. Remove the cover capscrews and pull o the cover, then

remove the O-ring.

5. Pull the stator o the studs and remove the O-ring.

In some instances the unit can be cleaned by ushing water through it

while the mill is in operation. However, some of the water will remain

in the bottom of the cone-shaped stator. If this is not acceptable,

dismantle the unit for cleaning.

1. Remove the “T” handles.

2. Back out the knurled lock screw.

CAUTION

Handle all parts carefully to avoid nicks and

scratches which will be detrimental to the operation

of the mill.

Cleaning

O-ring Adjusting ring

Figure 8

Cover

Stator O-ring

O-ring

Figure 9

Figure 7

T-handle

Knurled lock

screw

Flushing

Disassembly

3. Pull the cover/stator assembly outward.

NOTE: You will experience some resistance to the stator

movement due to friction from the O-ring.

As soon as the O-ring is free, the cover and stator assembly can

be easily removed. It is not necessary to remove the adjusting

ring. Disassembly to this point allows complete drainage.

NOTE: To prevent wearing of the faces between the adjusting

ring and stator, lubricate these surfaces occasionally with an

approved silicone-type lubricant.

11

95-03028

09/2019

Waukesha Cherry-Burrell®Brand Colloid Mill Maintenance

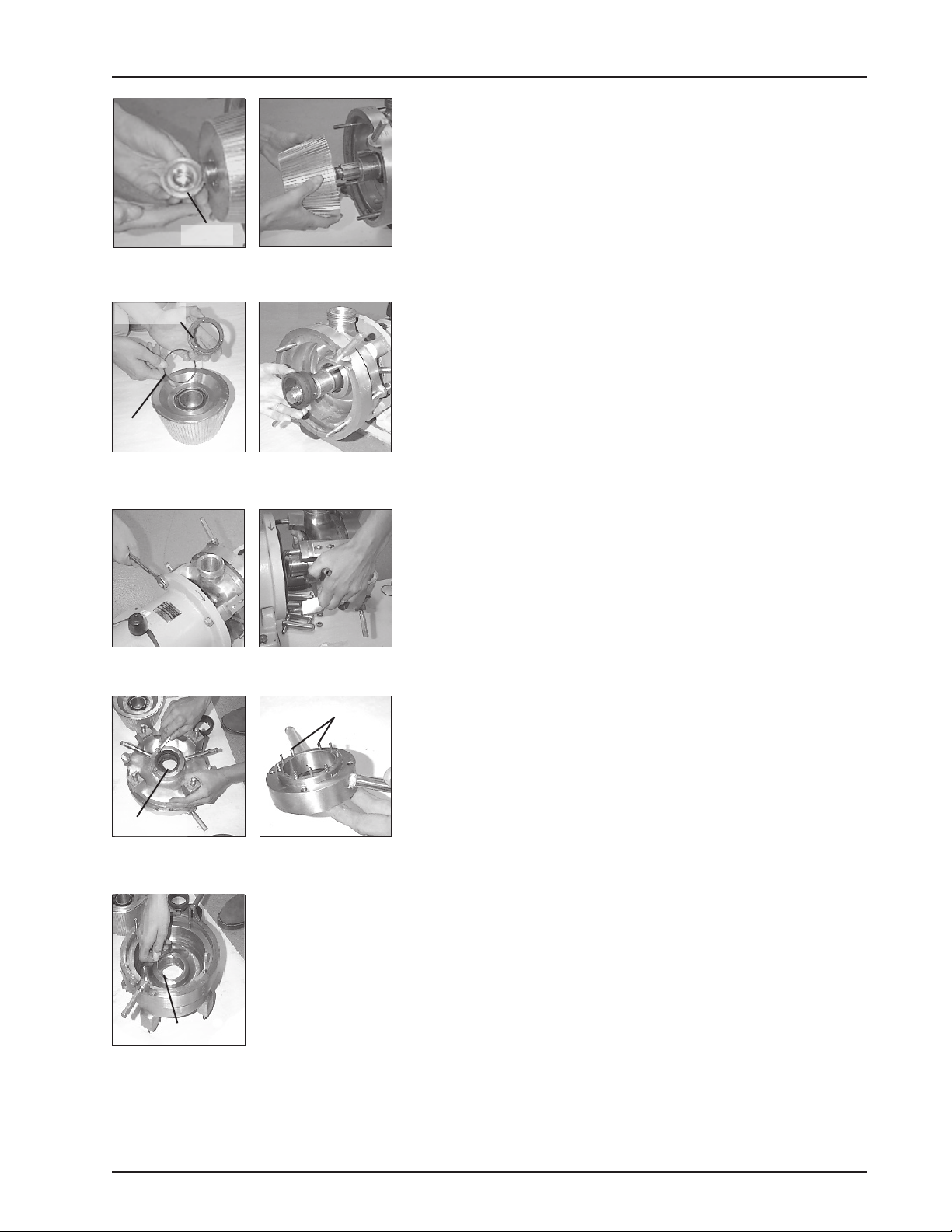

6. Remove the rotor retaining nut, then remove the O-ring from

the nut. (See Figure 10.)

7. Slide the rotor o the shaft, making sure to handle it with care

to avoid damage to the rotor or to the seal seat, which is con-

tained in the rotor. (See Figure 11.)

Figure 13

Figure 10

Springs

Figure 14

Figure 12

Figure 11

Figure 15

Figure 16 Figure 17

Figure 18

O-ring

Lip seal

O-ring

8. Gently pull the seal seat from the back of the rotor and re-

move the O-ring. (See Figure 12.)

9. Remove the seal assembly from the shaft. (See Figure 13.)

10. Remove the four 1/2-13 hex nuts which secure the body to

the bearing case and slide the body forward o the shaft. (See

Figure 14 and Figure 15.)

O-ring

Seal seat

11. Remove the four capscrews from the gland on the back side

of the body and disassemble the gland.

NOTE: There are six loose springs in the gland.

The gland lip seal can be pressed out if replacement is re-

quired. (See Figure 16 and Figure 17.)

12. Remove the O-ring from inside the body. Use the O-ring

removal tool (part no. AD0096001) if necessary. (See Figure

18.)

NOTE: Clean and inspect all parts thoroughly. DO NOT reuse

the seal or seal seat if it is scratched, chipped or worn.

95-03028 09/201912

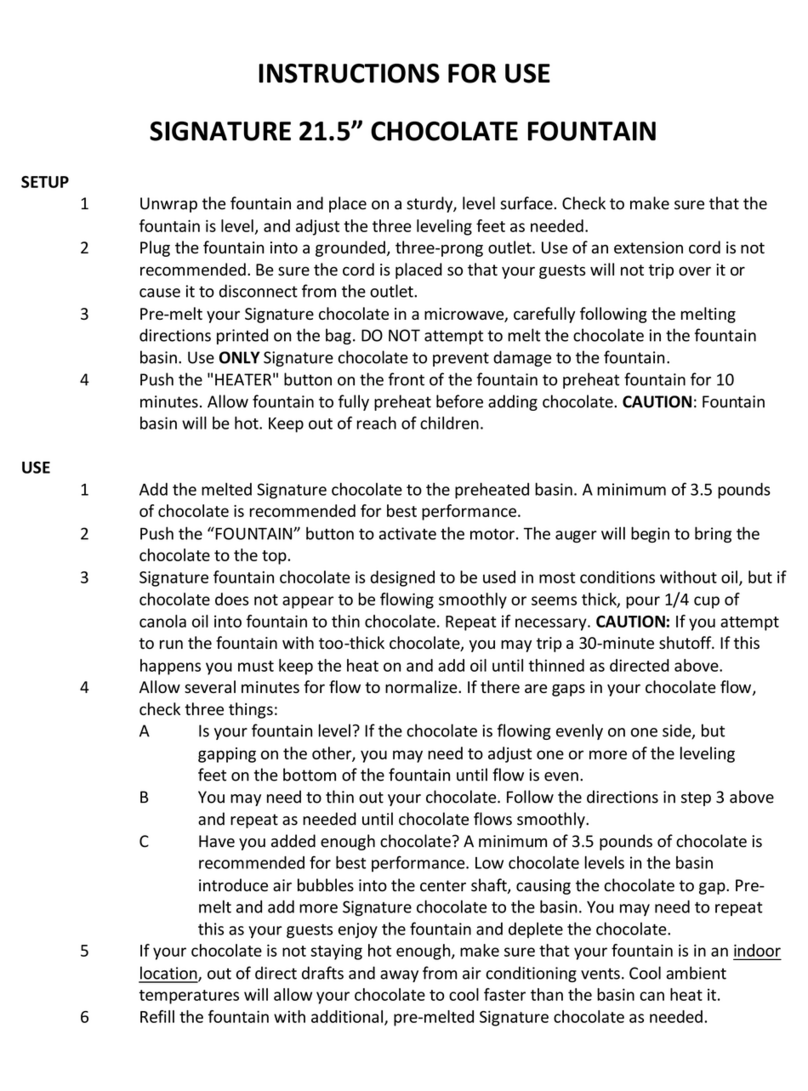

Waukesha Cherry-Burrell®Brand Colloid MillMaintenance

Small (1/8”) hole

(IN)

Figure 19 - Water ush system

Locking holes

Knurled

locking screw

Figure 20

Stator

Adjusting ring

T-handles

Indicator

Lock bolt

Figure 21

Large (1/4”) hole

(OUT)

Flushing backwards can cause seal leakage and

ush media will enter the product zone.

CAUTION

1. Apply a suitable lubricant to all O-rings and insert them in their

respective grooves.

NOTE: Place the seal seat O-ring over the seal seat and then

insert the seat into the rotor.

2. Follow the disassembly procedure in reverse order to com-

plete assembly. Torque the rotor nut to approximately 75 ft-lb

(102 N·m).

3. The seal water to the mill must be connected to the gland

connection marked IN (the ports are stamped “IN” and

“OUT”). The inlet of the gland contains the smaller (1/8”) hole.

The outlet contains the larger (1/4” hole). (See Figure 19).

The mill can be adjusted to have a clearance between the rotor and

the stator from a minimum of 0.010” (0.254 mm) to a maximum of

0.240” (6.1 mm), in increments of 0.001” (0.025 mm).

The body and the adjusting ring are calibrated as a unit and serialized;

they must not be interchanged with other Waukesha Cherry-Burrell

brand Colloid Mills.

The stator is held rmly against the adjusting ring by “T” handles

(Figure 21).

Adjust the clearance between the rotor and stator by turning the

adjusting ring counter-clockwise (when facing the outlet port) to

increase the clearance, and clockwise to decrease the clearance.

The adjusting ring is engraved with numerals indicating the clearance

in increments of 0.010” (0.254 mm). The indicator pointer indicates

the desired clearance. For setting in between the increments of

0.010” (0.254 mm), the drill point spacing is equal to 0.001” (0.025

mm) clearance. The drill point spacing coincides with the locking

hole spacing. There are 18 locking holes in the ring, spaced 20°

apart (Figure 20).

Rotating the ring by 20° (hole to hole distance) changes the milling

clearance by 0.001” (0.025 mm).

Example: to obtain 0.014” radial clearance, locate the 0.010 punch

mark under the pointer. Turn the ring counterclockwise four additional

drill points (or locking holes), and lock it in place with the knurled lock

screw (Figure 20). Tighten the “T” handles to rmly hold the stator

against the adjusting ring. The clearance will be 0.014” (0.36 mm).

Adjust the lock bolt and tighten the nut (Figure 21).

Assembly

Adjustment and

Calibration

13

95-03028

09/2019

Waukesha Cherry-Burrell®Brand Colloid Mill Maintenance

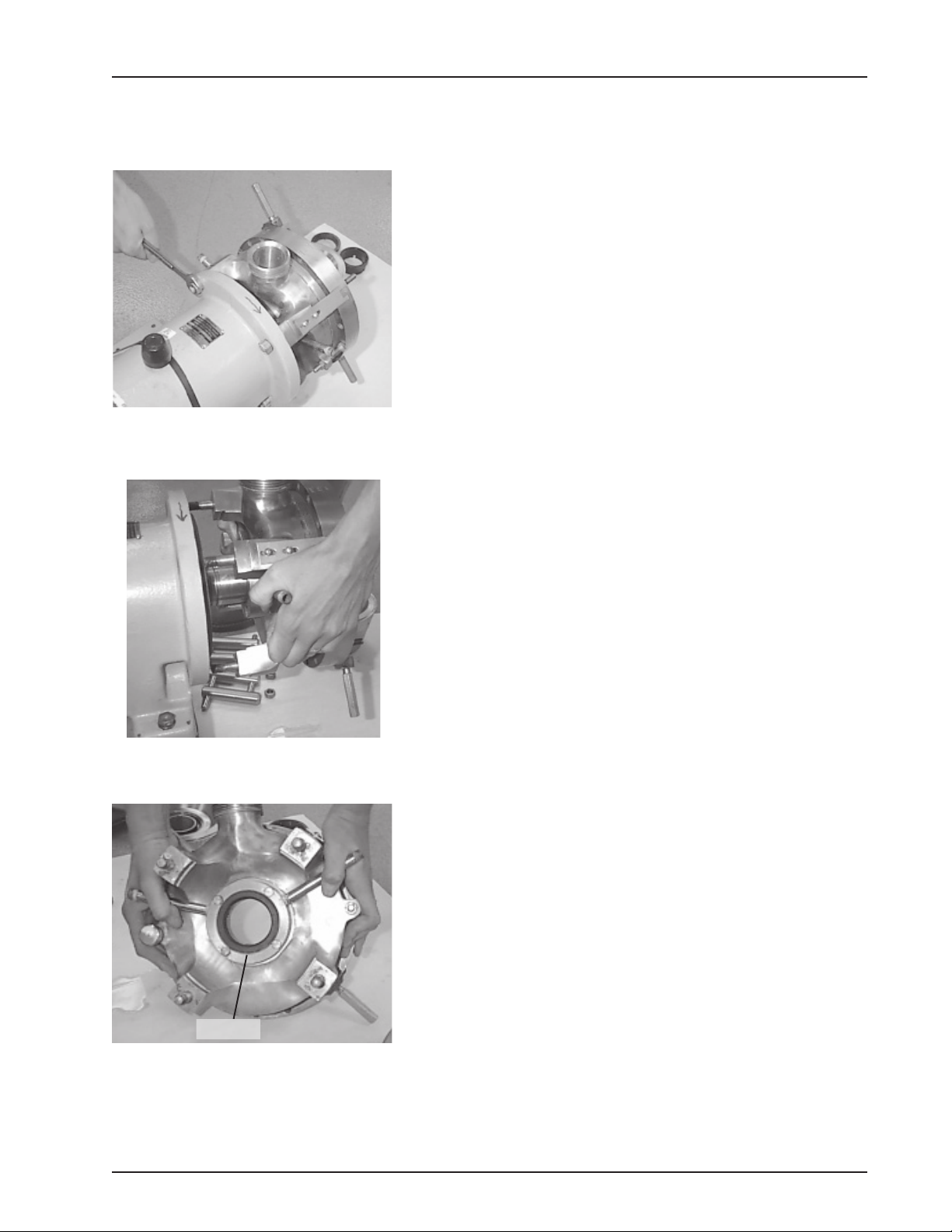

1. Disassemble as described in “Disassembly” on page 10.

2. Remove the four body nuts (Figure 22).

3. Slide the body forward o the shaft (Figure 23).

4. Pull the seal out with a hook tool. Insert a new water lip seal

with the lip facing in. (See item 18 in Figure 29 on page 15.)

5. Re-assemble in reverse order.

Flush Water Seal

Replacement

Figure 22 - Remove body nuts (4)

Figure 23 - Remove body

Figure 24 - Replace lip seal

Lip seal

95-03028 09/201914

Waukesha Cherry-Burrell®Brand Colloid MillMaintenance

Tools required for seal and/or bearing replacement:

• Assorted hand tools including soft hammer.

• Bearing puller or press.

• Hook tool for seal removal.

• Spanner wrench for bearing retainer nut removal

• Rotor Nut Wrench part no. GD0019000

• Anti-seize compound and seal lubricating grease.

• 2 quarts DTE BB Mobil oil or equivalent.

Service Preparation

1. Shut OFF and lock out all power.

2. Remove all product and ushing from the mill.

3. Disconnect all piping to the mill.

4. Remove the pump anchor screws and slide the gearcase o

the motor coupling.

5. Place the mill on a sturdy work surface.

6. Disassemble the wet end of the mill completely. (See “Disas-

sembly” on page 10.)

7. Drain the oil from the gear case (Figure 25).

Front Seal Replacement

1. See Figure 26. Pull o the slinger.

2. Remove the four capscrews, then remove the bearing retainer

assembly (front seal inside).

3. Note the seal lip position and knock out the old seal

4. Place lubrication around the new seal and press it into the

bearing retainer. Replace the gasket, if necessary. Lubricate

the seal lip and install the bearing retainer and slinger.

Rear Seal Replacement

1. See Figure 27. Pull the rear oil seal o the drive shaft with a

hooked tool.

2. Place tape over the shaft keyway and install a new seal. (Lu-

bricate the seal lip before sliding it onto the shaft.)

Bearing Replacement

1. Remove the rear seal. Remove the rear bearing retaining ring.

Press the drive shaft out through the front of the gear case

(through the rear bearing) (Figure 27).

2. Remove the bearing locknut from the shaft (counter-clock-

wise) and press o the front bearing (Figure 26).

3. Press the rear bearing out of the front of the gear case (Figure

27).

Gear Case Service

CAUTION

To avoid a cutting injury, wear gloves and handle

parts carefully.

Figure 25

Oil level

Breather cap

Oil drain

Figure 26

Bearing retainer

assembly

Gasket

Front seal

Slinger

Figure 27

Rear seal

Retaining

ring Rear

bearing

15

95-03028

09/2019

Waukesha Cherry-Burrell®Brand Colloid Mill Maintenance

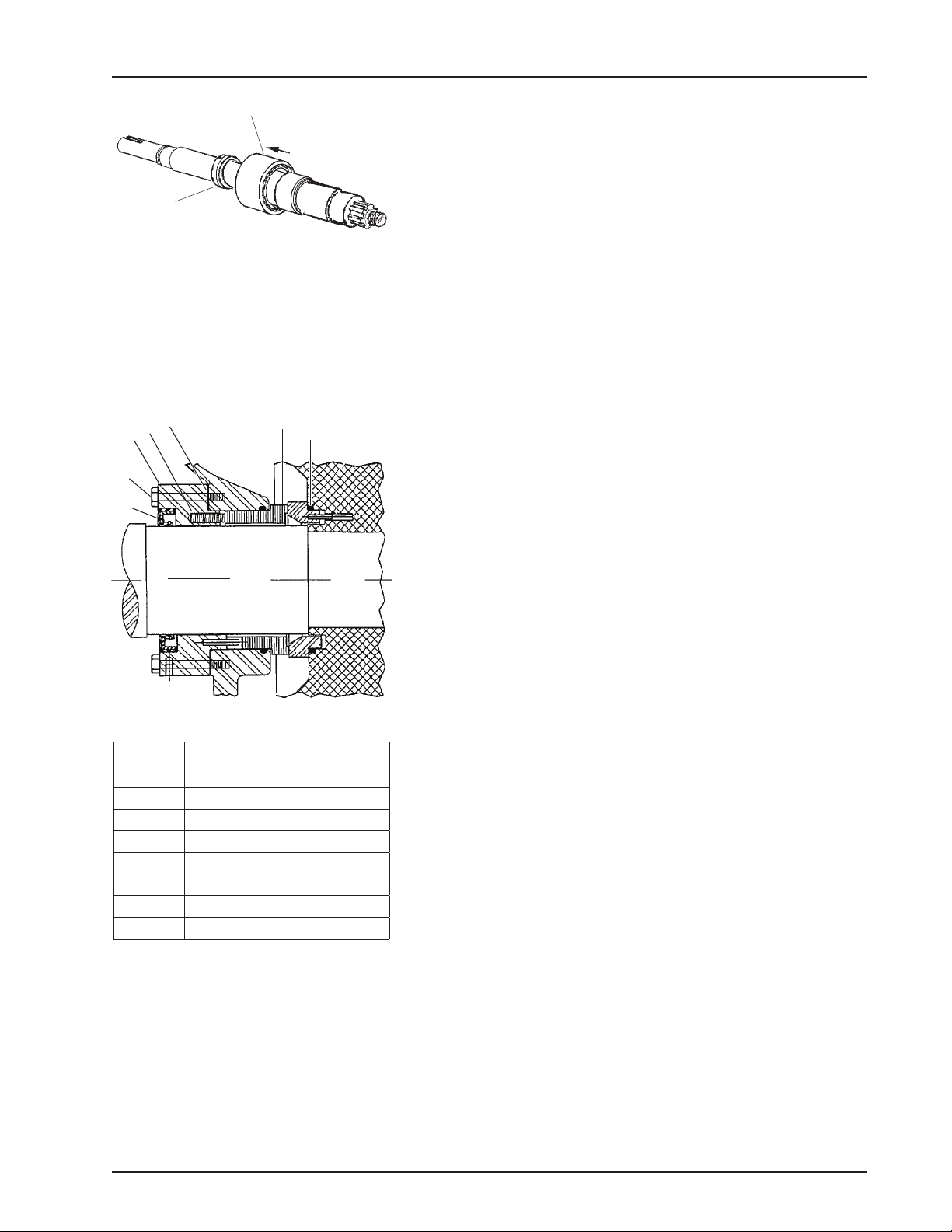

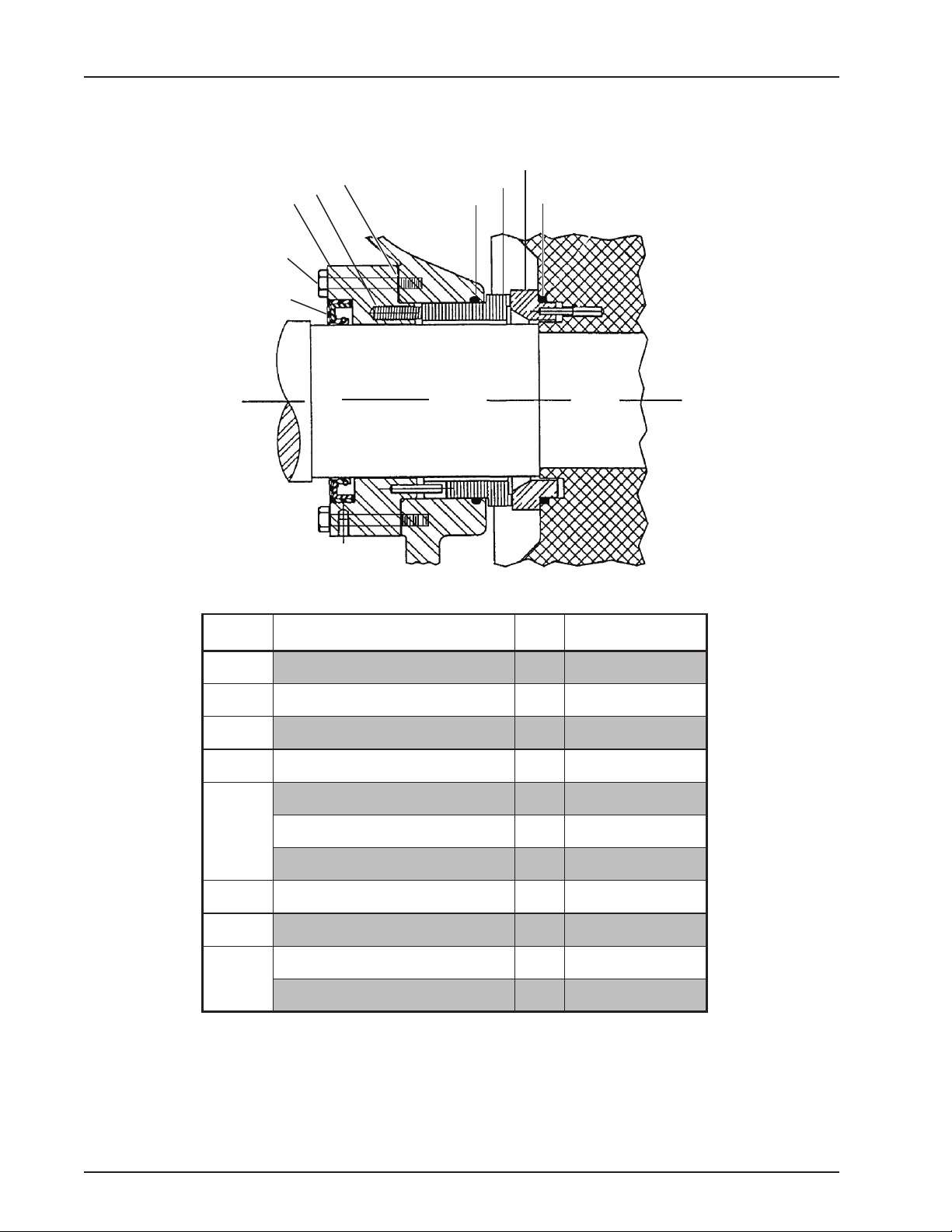

NOTE: Use care at all times to avoid chipping or scratching the seal

or seat. Keep the seal face areas clean and dry.

1. See Figure 29. Install the gland plate lip seal (18) into the rear

of the gland plate (17).

2. Apply a small amount of sealant to one end of each of the six

springs (19) and place them in the gland spring holes (17).

3. Install the gasket (16) to the sealing face of the gland plate

(17).

4. Attach the gland plate (17) to the mill body using the existing

capscrews.

5. Install one O-ring (24) into the groove in the mill body.

6. Attach the body to the bearing case (using 4 nuts).

7. Lubricate the O-ring (24) and small O.D. of the seal (20) with

a compatible lubricant. Install the seal into the mill, aligning

the notches on the seal with the pins in the gland plate.

NOTE: Avoid grease-type lubricants which can harden and bind

the seal; use food-grade lubricant when processing food products.

8. Lubricate the remaining O-ring (24) with a compatible lubri-

cant and install it on the small O.D. of the seat (21).

9. Install the seat (21) (with pins and O-ring) into the rear of the

rotor, aligning the pins with the holes in the rotor.

10. Install the rotor onto the shaft, being careful to avoid damage

to the seat (21) or seal (20). Tighten the rotor nut to 75 ft-lb

(102 N·m).

11. Complete the mill assembly. (Reverse steps 2 and 3 on page

13.)

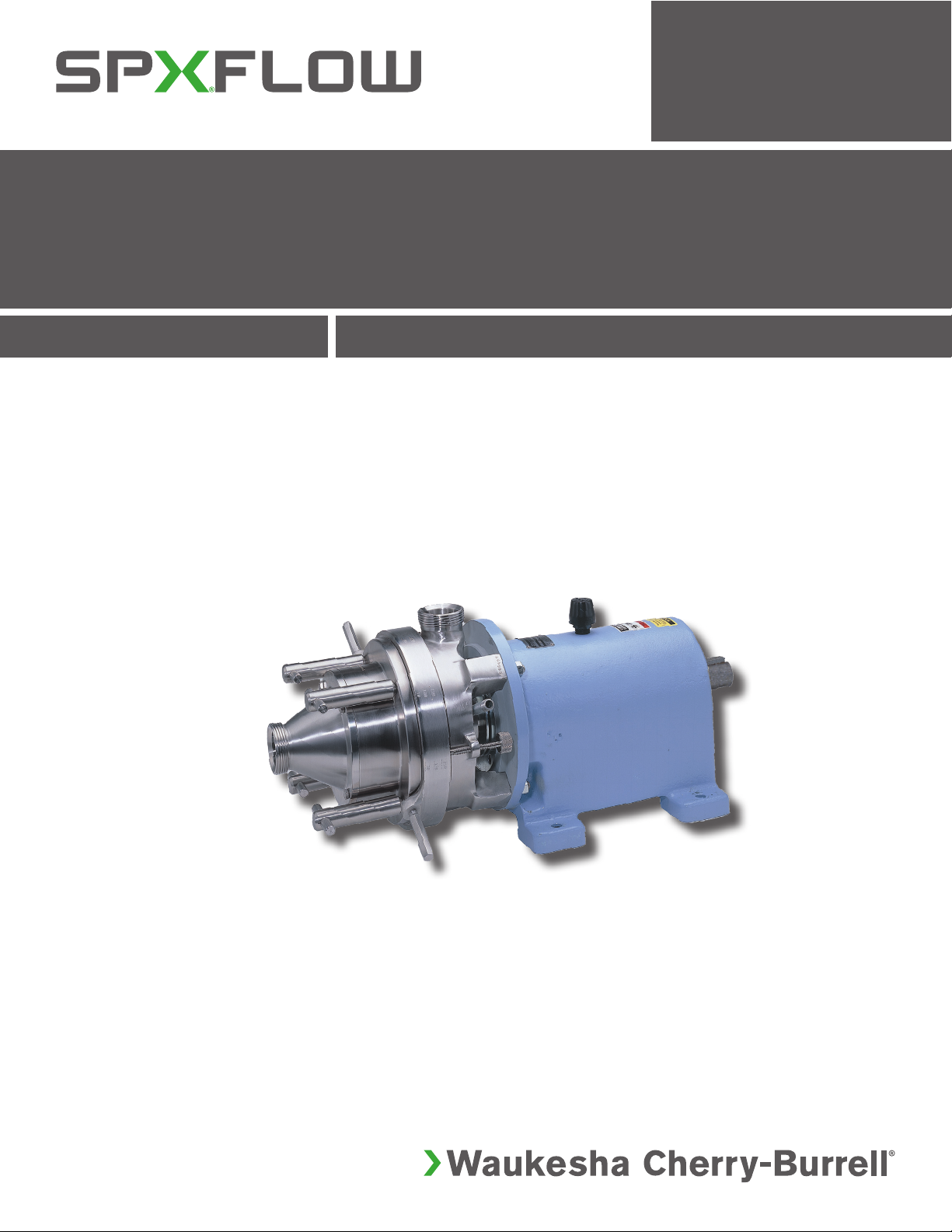

Sanitary Seal Replacement

DP100-004

18

22

17

19 16

24

20

21

24

Figure 29

Item No. Description

16 Gland Gasket

17 Gland Plate

18 Gland Plate Lip Seal

19 Spring

20 Stationary Seal

21 Rotating Seat

22 Capscrew

24 Seal Seat & Body O-ring

NOTE: See page 20 for part numbers.

4. Clean and lubricate all parts thoroughly before reassembling.

NOTE: Do not unwrap the new bearings until ready to install.

5. Lubricate the inner races and press the new bearings onto the

shaft. Tighten the locknut on the front bearing to 40 ft-lb (54

N·m) (Figure 28).

6. Lubricate the outer races and press the shaft assembly into

the case. Replace the retaining ring and rear seal (Figure 24).

7. Replace the mill assemblies.Torque the rotor nut to 75 ft-lb

(102 N·m). Rell the crankcase with 2 quarts of Mobil DTE BB

oil.

Figure 28

Front bearing

Locknut

95-03028 09/201916

Waukesha Cherry-Burrell®Brand Colloid MillMaintenance

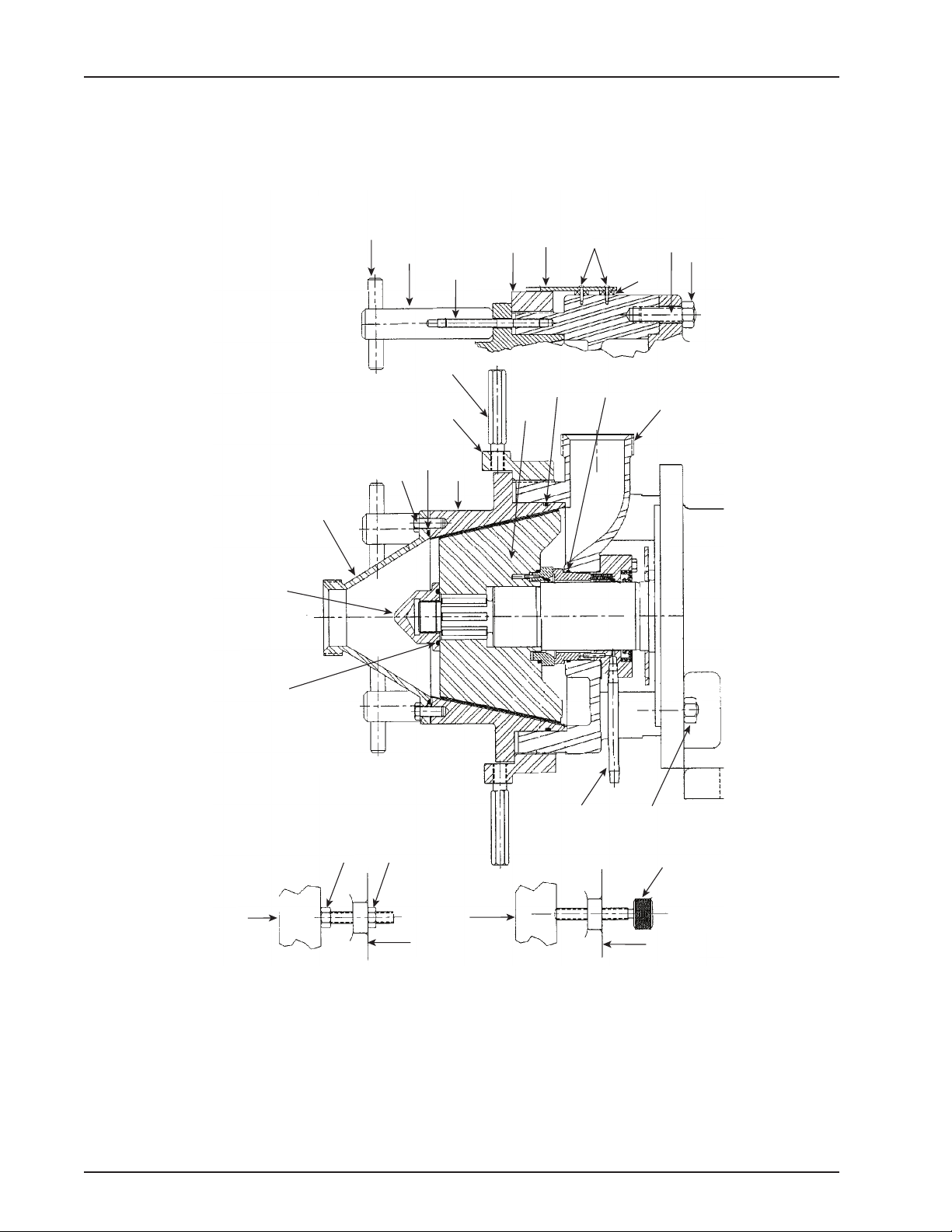

DP100-003

14

15 1

65432

11

13

7

8912

10

Colloid Mill Gear Case

52

51

48,

49

50,

49

DP100-005a

Parts List

52

17

95-03028

09/2019

Waukesha Cherry-Burrell®Brand Colloid Mill Maintenance

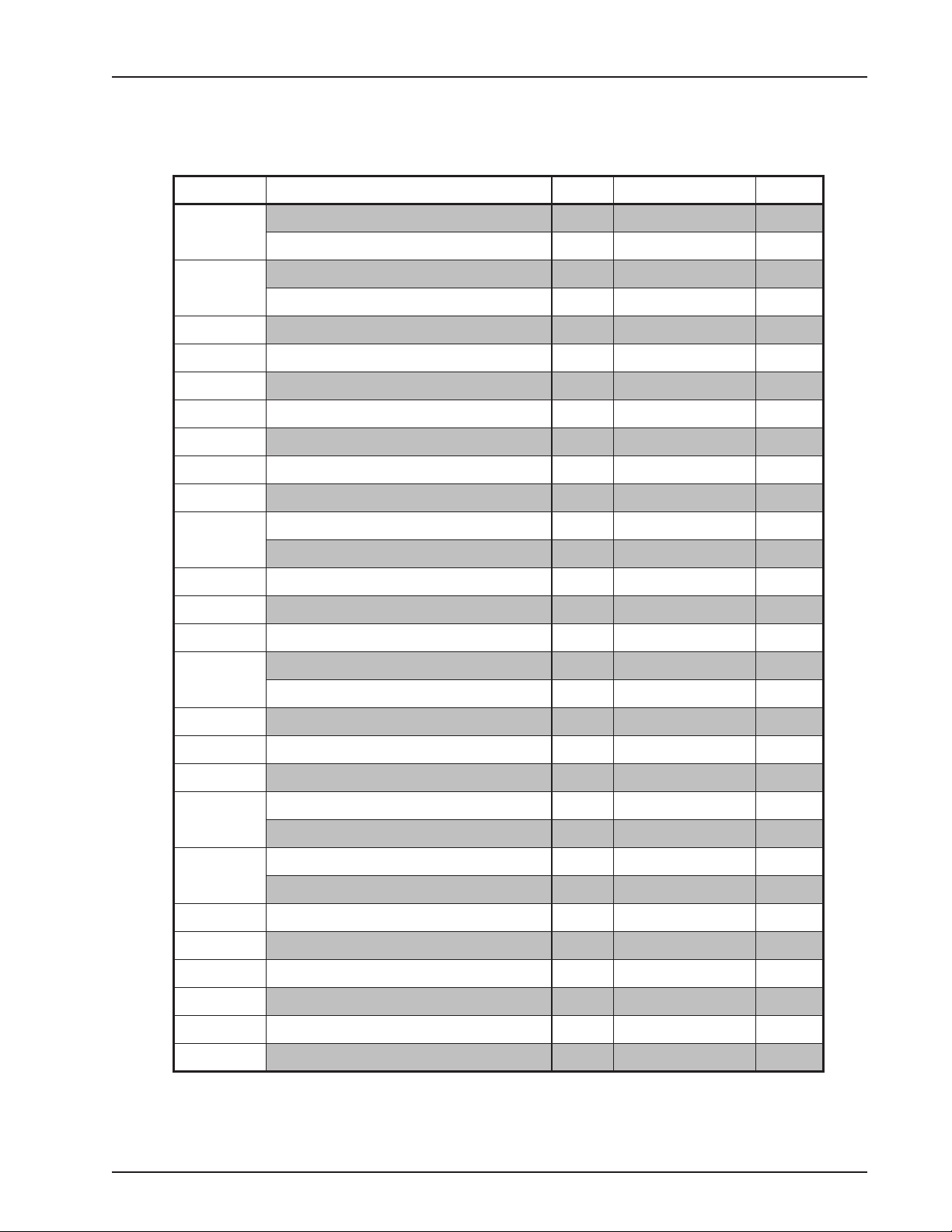

ITEM NO. DESCRIPTION QTY PART NO. NOTES

1Gear Case 1 0MS005000

2Drive Shaft 1 0MS008000

3Front Bearing 1 0MS036300

4Bearing Locknut 1 0MS036N00

5Rear Bearing 1 0MS036000

6Retaining Ring 1 BD0087R00

7Front Bearing Retainer Gasket 1 0MS042B00

8Front Bearing Retainer 1 0MS080000

9Pump End Shaft Seal 1 0MS030100

10 Capscrew 4 30-274

11 Drive End Shaft Seal 1 0MS030000

12 Slinger 1 0MS045000

13 Breather 1 139779+

14 Level Indicator 1 115799+

15 Drain Plug 1 115798+

48 Nameplate, Sanitary 1 001061002

49 RHDS 6 30-355

50 Caution Label, Yellow 1 33-62

51 Key 1 000037003

52 Rotor Nut Wrench 1 CD0019001

PL5081-CH12

Colloid Mill Gear Case

95-03028 09/201918

Waukesha Cherry-Burrell®Brand Colloid MillMaintenance

DP100-005

39

38 37

30 44

46,

47

45

28 29

30

23

26 25

30

27

23

2943

32

34

40

42 41 35

30

31

33

36 24 23

Colloid Mill Fluid Head

NOTE:

Torque rotor nuts

to 75 ft-lb

Used to set adjusting

ring at minimum

setting of 0.010”

Used to hold

adjusting ring

setting

NOTE:

Body rotor

clearance starts

at 0.101” and

ends at 0.220”

in increments of

0.010”

19

95-03028

09/2019

Waukesha Cherry-Burrell®Brand Colloid Mill Maintenance

ITEM NO. DESCRIPTION QTY PART NO. NOTES

23 Body, 2” Bevel Seat 1 0MS001000

Body, 2” TCF 1 35886+

24 Seal Seat & Body O-ring, FKM 2 V70150

Seal Seat & Body O-ring, Silicone 2 S75150

25 Hex Nut 1 36-55

26 Capscrew 1 30-86

27 Knurled Lock Screw 1 0MS129000

28 Stud - Body 4 0MS011000

29 Hex Nut 4 36-70

30 Adjusting Ring 1 0MS003000

31 Adjusting Ring Handle 2 0MS054000

32 O-ring, Rotor Nut, FKM 1 V70222

O-ring, Rotor Nut, Silicone 1 S75222

33 Rotor 1 0MS010000

34 Rotor Retaining Nut 1 0MS052000

35 Stator 1 0MS004000

36 O-ring, Stator, FKM 1 V70263

O-ring, Stator, Silicone 1 S75263

37 Stud, Handle Shaft 4 0MS011100

38 Handle Shaft 4 0MS099000

39 Handle Pin 4 0MS100000

40 Cover, 2” Bevel Seat 1 0MS002000

Cover, 2” TCF 1 35887+

41 O-ring, Cover, FKM 1 V70253

O-ring, Cover, Silicone 1 S75253

42 Capscrew 4 30-151

43 Pipe Nipple 2 0MS018000

44 Indicator 1 0MS056100

45 Spacer 2 0MS454000

46 Machine Screw 2 30-299

47 Lockwasher, #10 2 43-21

PL5081-CH13

Colloid Mill Fluid Head

95-03028 09/201920

Waukesha Cherry-Burrell®Brand Colloid MillMaintenance

DP100-004

18

22

17

19 16

24

20

21

24

KIT # 35379+ Convert single spring seal to multiple spring seal

Sanitary Seal

Item No. Description Qty Part No.

16 Gland Gasket 1 0MS042G00

17 Gland Plate 1 0MS058200

18 Gland Plate Lip Seal 1 0MS030200

19 Spring 6 0MS304200

20

Stationary Seal, Carbon 1 0MS306003

Stationary Seal, Silicon Graphite 1 0MS306004

Stationary Seal, Silicon Carbide 1 0MS306009

21 Rotating Seat, Silicon Graphite 1 0MS014002

22 Capscrew 4 30-98

24

Seal Seat & Body O-ring, FKM 2 V70150

Seal Seat & Body O-ring, Silicone 2 S75150

PL5081-CH11

This manual suits for next models

1

Table of contents