SPX Power Xpress User manual

Power Xpress™

Bollard Charge Station

Installation Guide

2

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

Technical Support

1-877-805-EVSE (3873)

Copyright © 2012 Service Solutions U.S. LLC

All rights reserved.

The information, specications, and illustrations in this guide are based on the latest

information available at the time of printing. Service Solutions U.S. LLC reserves the right to

make changes at any time, without notice.

3

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

TABLE OF CONTENTS

INSTALLATION SAFETY..................................................................................................4

INSTALLATION CONTENTS: BOLLARD AND EVSE (EL-50650) ...........................................5

Power Xpress EVSE (EL-50600-300) for Bollard Charge Station ....................................5

Bollard and Hardware (EL-50600-500) .......................................................................5

TOOLS SUGGESTED FOR INSTALLATION (NOT PROVIDED)..............................................6

APPLICABLE ELECTRICAL SYSTEMS................................................................................7

220/240V Single Phase (North America).....................................................................7

208V 3-Phase Wye Connection (North America)..........................................................7

240V 3-Phase Delta Connection (North America) with Center Tap on One Leg ..............8

230V Above Ground (Europe)

230V Single Phase....................................................................................................9

ELECTRICAL REQUIREMENTS FOR BATTERY CHARGING................................................10

AMPERAGE AND BREAKER PARAMETERS ......................................................................11

STANDARD INSTALLATION ..........................................................................................13

EVSE POWER AND STATUS LED INDICATIONS ..............................................................22

TROUBLESHOOTING ...................................................................................................23

Ground Fault Circuit Interrupt (GFCI) Tripped ...........................................................24

Missing Ground ......................................................................................................24

LIMITED WARRANTY ...................................................................................................25

4

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

INSTALLATION SAFETY

SAVE THESE IMPORTANT SAFETY INSTRUCTIONS.

This guide contains important instructions that must be followed during the installation of the electric ve-

hicle supply equipment (EVSE). All instructions should be carefully read before installation of the EVSE.

WARNING: Turn OFF the circuit breaker

at the service or distribution panel before

performing any electrical work or repairs.

WARNING: The EVSE should be installed by

a licensed electrician in accordance with all

local electrical codes, ordinances, and all

authorities having jurisdiction.

WARNING: Do not install the EVSE near

ammable, explosive, or combustible

materials. Do not locate or store ammable,

explosive, or combustible materials near the

EVSE.

WARNING: Improper installation of the

EVSE can result in personal injury or

product damage.

WARNING: This EVSE installation guide

is not a substitute for electrical safety

precautions.

WARNING: Use this EVSE within the

specied operating parameters. Failure to

do so may result in injury or death.

WARNING: Locate and install this EVSE in

a location where the charge cable will not

be stepped on, tripped over, or subject to

damage or stress.

WARNING: The EVSE must be connected to a

grounded, metal, permanent wiring system,

or an equipment-grounding conductor

must be run with the circuit conductors

and connected to the equipment grounding

terminal on the EVSE.

CAUTION: Incorrect installation of the EVSE

can result in damage to the vehicle’s battery

and to the EVSE itself. These damages will void

the warranty for the vehicle and the EVSE.

CAUTION: Do not operate the EVSE in

temperatures beyond its operating range of

-40°F to +122°F (-40°C to +50°C).

5

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

INSTALLATION CONTENTS: BOLLARD AND EVSE (EL-50650)

Power Xpress EVSE (EL-50600-300) for Bollard Charge Station

1

EVSE (including attached cable with strain

relief and grommet, input/output decals, ag

tag, and vehicle coupler)

POWER

STATUS

RESET

1 Decal and cover kit

1-877-805-EVSE (3873)

http://evse.spx.com

1 Cable-management hook

1 Power Xpress Bollard Charge Station Installation Guide

1 Power Xpress EVSE User Manual

Bollard and Hardware (EL-50600-500)

1Bollard (including upper and lower plastic

covers)

2Cable-management retaining screws (pre-

installed)

1Locating set screw (plastic bag attached to bol-

lard)

6

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

TOOLS SUGGESTED FOR INSTALLATION (NOT PROVIDED)

Tape measure Wire cutters

2-ft Level Wire stripper

Pencil Nonmetallic wire stripper

Power hammer drill Masonry drill bit set

Small at-blade screwdriver Needle-nose pliers

7/16in

7/16-in. Open-end wrench Expandable pliers

1/2-in. Ratchet and sockets Torque wrench

7

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

APPLICABLE ELECTRICAL SYSTEMS

IMPORTANT: The on-site service connection must

be properly identied before installation of the

EVSE. If you are unsure of the available service

connection, consult the local utility company or

contact Service Solutions US at 1-877-805-EVSE

(3873).

NOTE: The L1, L2, and ground outputs (H, N for

Europe) in the following illustrations corre-

spond to the inputs on the EVSE.

NOTE: For the (earth) ground connection, always

connect the neutral at the service panel to

earth ground. Ground fault protection is not

possible unless the neutral (center tap on

the service transformer) is connected to an

earth ground.

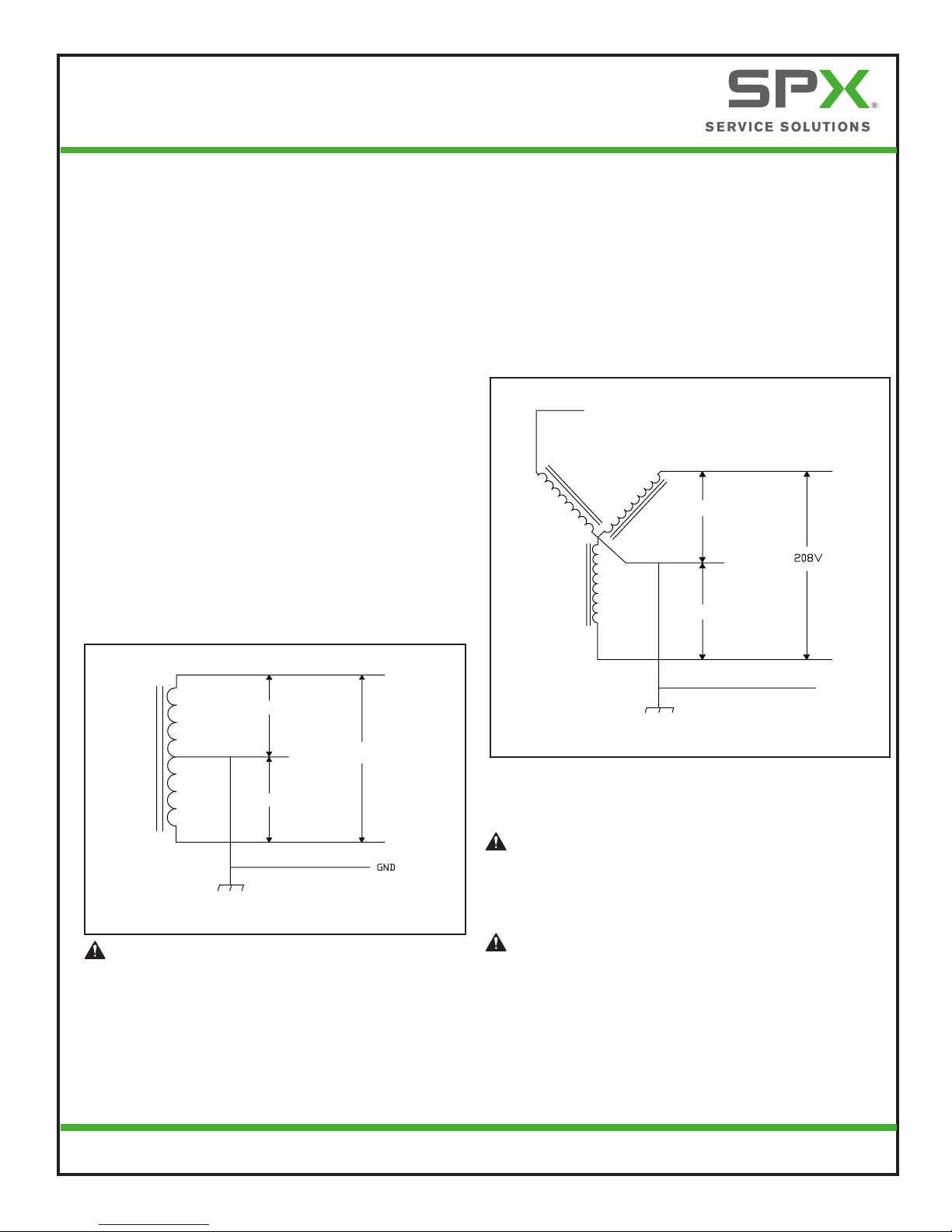

220/240V Single Phase (North America)

NEUTRAL

(NOT USED)

120V

120V

L2

L1

240V

Figure 1. 220/240V Single Phase

WARNING: The EVSE is a single-phase

device. Do not connect all three phases

of a 3-phase feed. Only three wires are

connected, take care that the service

transformer secondary connection is

known, and the three wires from the

main-panel circuit breaker are correctly

connected and labeled.

208V 3-Phase Wye Connection (North

America)

Any two of the legs can be used to provide 208V to the

EVSE with a Wye-connected secondary. For example,

L1 and L2, or L1 and L3, or L2 and L3. Reference the

wiring diagram below.

L3 (NOT USED)

120V

NEUTRAL

(NOT USED)

120V

L1

L2

GND

Figure 2. 208V 3-Phase Wye Connection

NOTE: A current-carrying neutral is not required for the

EVSE for 208V connections.

WARNING: The EVSE must be installed by a

licensed electrician and in accordance with

all local electrical codes, ordinances, and all

authorities having jurisdiction.

WARNING: Do not install the EVSE near

ammable, explosive, or combustible

materials. Do not locate or store ammable,

explosive, or combustible materials near the

EVSE.

8

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

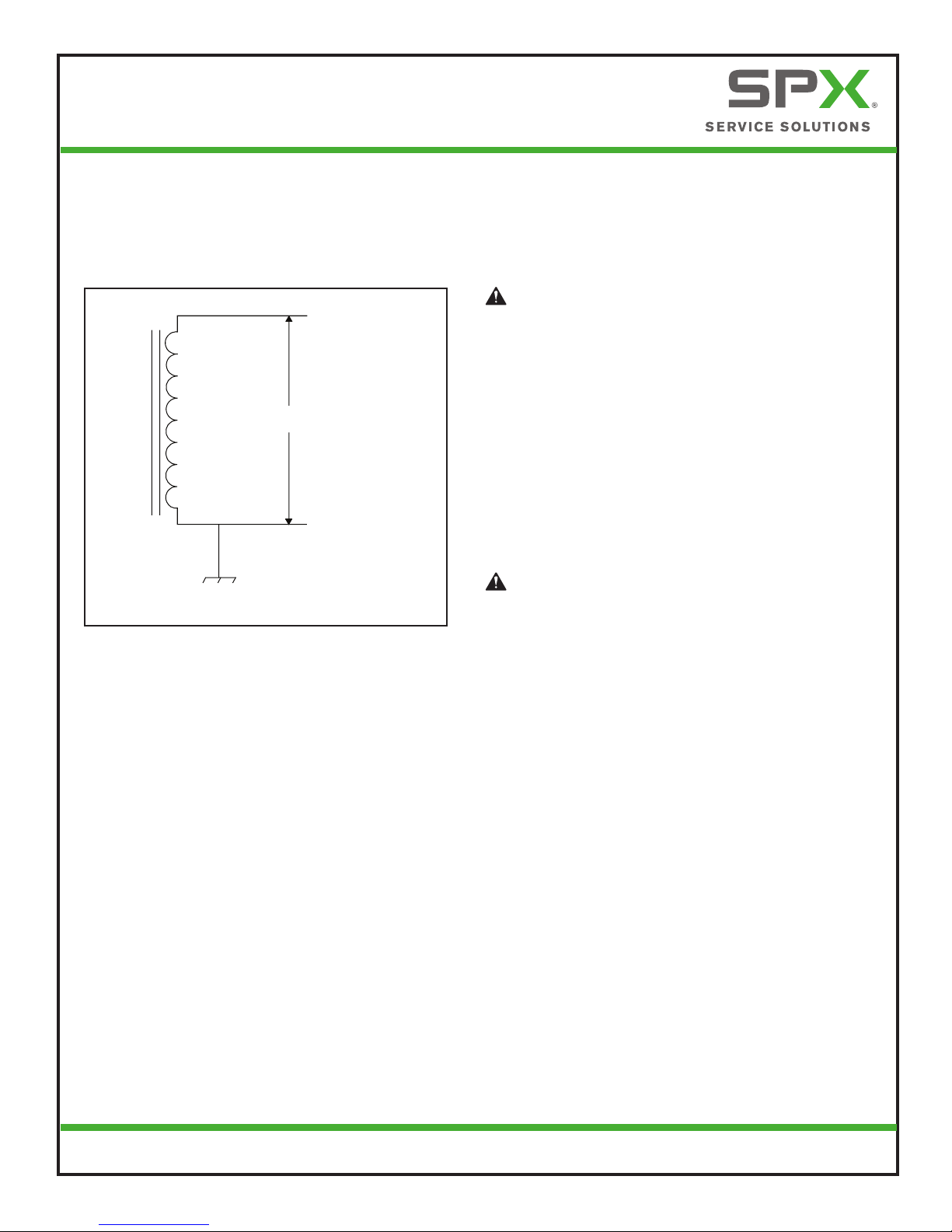

NOTE: The third line (L3 on the illustration of the

delta) is 208V, with respect to the neutral,

and is sometimes referred to as a “stinger.”

WARNING: Do not use this third line.

NOTE: The two used phases must each measure

120V to neutral or ground.

NOTE: Consult the utility company or the trans-

former manufacturer’s literature to verify

that the single leg can supply the required

power.

NOTE: The EVSE will only operate properly if it de-

tects the presence of a ground wire con-

nected to a neutral point on the transformer

secondary.

WARNING: Do not use a 3-phase delta-

connected transformer secondary

without a center tap on one leg and/or

without a neutral point available for the

required ground connection.

240V 3-Phase Delta Connection (North

America) with Center Tap on One Leg

One leg must be center-tapped, and only the two

phases on either side of the center tap can be used

with the delta connection.

L3 (NOT USED)

L1

CENTER TAP

L2

120V

120V

NEUTRAL

(NOT USED)

L1

240V

L2

GND

Figure 3. 240V 3-Phase Delta Connection

9

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

230V Above Ground (Europe)

230V Single Phase

LINE (H)

230VAC

NEUTRAL (N)

EARTH

Figure 4. 230V Single Phase

WARNING: The EVSE is a single-phase

device. When connecting the line and

neutral wires, take care that the service

transformer secondary connection is

known, and the wires from the main

circuit breaker panel are correctly

connected and labeled. The following

service connections are primarily used in

Europe and Australia (sometimes known

as “TT Power Grid”). Please reference

the following diagram. The line, neutral,

and earth outputs on the illustration

correspond to the inputs on the EVSE.

WARNING: The line connection must

measure 230V RMS to neutral. Earth must

also be connected to the EVSE.

10

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

CAUTION: The AC electrical connection must

have a grounded, dedicated service-main. No

other loads shall be connected to the same

circuit. Use of a non-dedicated circuit could

exceed the current rating of the circuit breaker

and cause it to trip or open.

6 in.

18 in.

24 in.

G

F

B

AH

C

D

E

A. Conduit extending up to 24 in. (61 cm) from

ground level or per local code

B. Conduit sweep

C. THWN rigid-metal, Schedule 40 or 80 conduit

D. THWN nonmetallic, Schedule 40 or 80 conduit

E. UF burial wire (ground solid)

F. Ground level

G. Service panel

H. Minimum wire length of 66 in. (168 cm)

Figure 5. Wire Run Variations

WARNING: The EVSE must be installed

by a licensed electrician in accordance

with all national and local electrical codes,

ordinances, requirements and all authorities

having jurisdiction.

The conduit may extend up to 24 in. (61 cm) from

ground level. The wiring should extend 66 in. from

the base mounting of the bollard. A sweep is used to

direct the circuit from the conduit to the electric circuit

from the service panel. The three types of acceptable

wire runs are:

• THWN rigid metal Schedule 40 or 80 conduit,

buried 6 in. (15 cm) below ground level, or per

local electrical code.

• THWN nonmetallic Schedule 40 or 80 conduit,

buried 18 in. (46 cm) below ground level, or

per local electrical code.

• UF burial wire (ground solid), buried 24 in. (61

cm) below ground level, or per local electrical

code.

• THHN, THWN, or THWN-2 wires are recom-

mended to allow for proper space requirements

inside the 1/2 in. exible conduit required in-

side the bollard.

ELECTRICAL REQUIREMENTS FOR BATTERY CHARGING

11

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

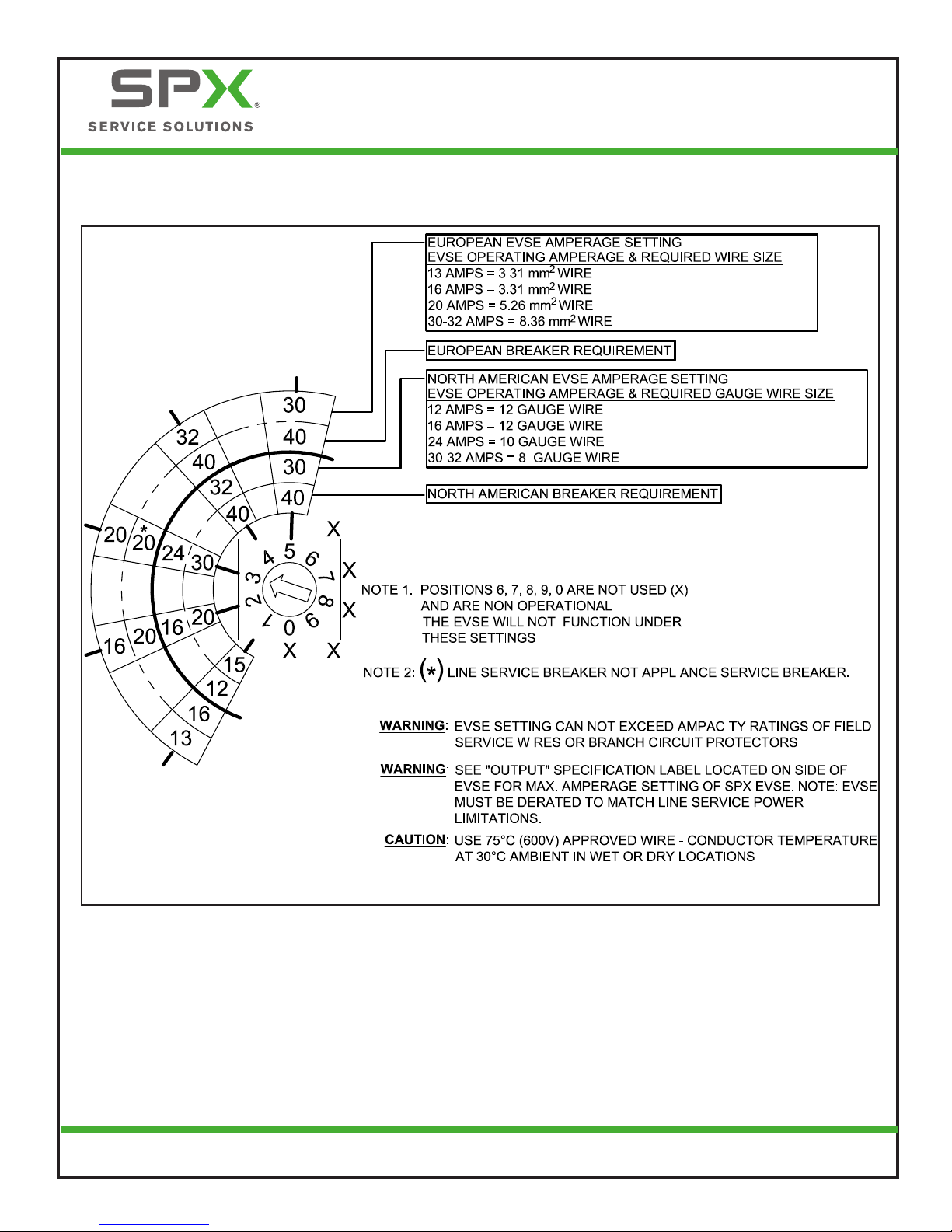

AMPERAGE AND BREAKER PARAMETERS: FIELD REQUIREMENTS AND

ADJUSTMENTS FOR EVSE INSTALLATION (NOT REQUIRED FOR 40 AMP

CIRCUIT INSTALLATION)

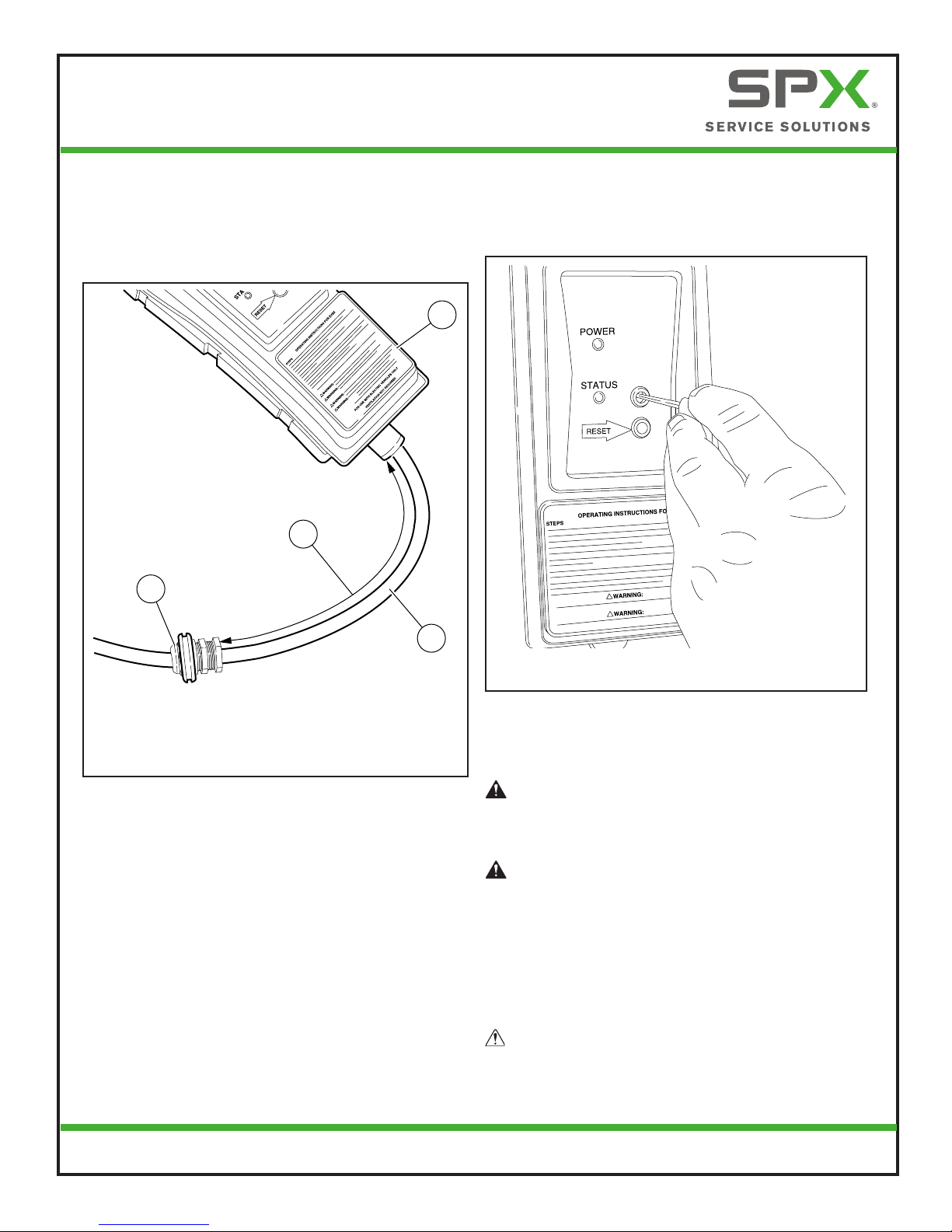

1. Unpack the EVSE.

A

B

D

C

A. EVSE body

B. EVSE cable

C. Strain relief with grommet

D. 18 in. (46 cm)

Figure 6. EVSE

NOTE: The EVSE has been factory set at 30 amp

output for a 40 amp circuit. Proceed to

“Standard Installation” if installing on a 40

amp circuit. For all other amperages, com-

plete Steps 2 and 3 for EVSE adjustment.

2. Remove the domed cap from the current-

adjustment selector (positioned just above the

reset button on the front of the EVSE).

3. Using a small, at-blade screwdriver, set the

current-adjustment selector to the applicable

output current-limiting setting as specied in

“Figure 8. Current-Adjustment Settings”.

Figure 7. Setting the

Current-Adjustment Selector

NOTE: Positions 6, 7, 8, 9, 0 are not used (X) and

are non-operational. The EVSE will not

function under these settings.

WARNING: The EVSE setting cannot

exceed ampacity ratings of eld service

wires or branch circuit protectors.

WARNING: See “output” specication

label located on the side of the EVSE

for maximum amperage setting, per

limitations of vehicle cable and coupler.

NOTE: The EVSE must be de-rated to match line

service power limitations.

CAUTION: Use 75°C (600V) approved wire,

conductor temperature at 30°C ambient in wet

or dry locations.

12

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

Figure 8. Current-Adjustment Settings

13

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

STANDARD INSTALLATION

1. Lay down the bollard box and remove the

banding.

2. Lift the top off the box and remove the bollard

from the packaging material.

3. Remove the upper cover from the bollard

assembly by removing the cable-management

retaining screws (E) on the rear of the bollard.

4. Remove plastic bag containing locating set

screw (not shown) from inside bollard.

A

B

C

D

E

A. Upper plastic cover

B. Metal Bollard

C. Lower plastic cover (Do not remove)

D. Seal

E. Cable-management retaining screws

Figure 9. Bollard Disassembly

NOTE: The upper and lower plastic bollard covers

are a matched set and cannot be used inter-

changeably with those from other bollards.

The standard installation design for the Power

Xpress Bollard is a bolt-down external plate.

The standard diameter of the bollard is approxi-

mately 7 in. The bollard height will vary with the

application.

Figure 10. Typical Installation

10 in.

7½ in.

15/16 in.

10 in.

7½ in.

Figure 11. Base Plate Dimensions

14

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

CAUTION: Read all instructions before installing

the EVSE.

WARNING: Main service power must be

off and disconnected before attempting

to install the EVSE.

WARNING: The bollard weighs 20 lb per

foot, and the bottom end is signicantly

heavier than the top end. Take proper

precautions and use safe lifting practices

when lifting the bollard.

CAUTION: All adapter and connection ttings

must be classied as liquid-tight. The following

types of exible conduit are recommended:

LFMC (liquid-tight exible metal conduit),

LFNC-B (liquid-tight exible nonmetal conduit),

or LFNC-A (liquid-tight fexible nonmetal

conduit).

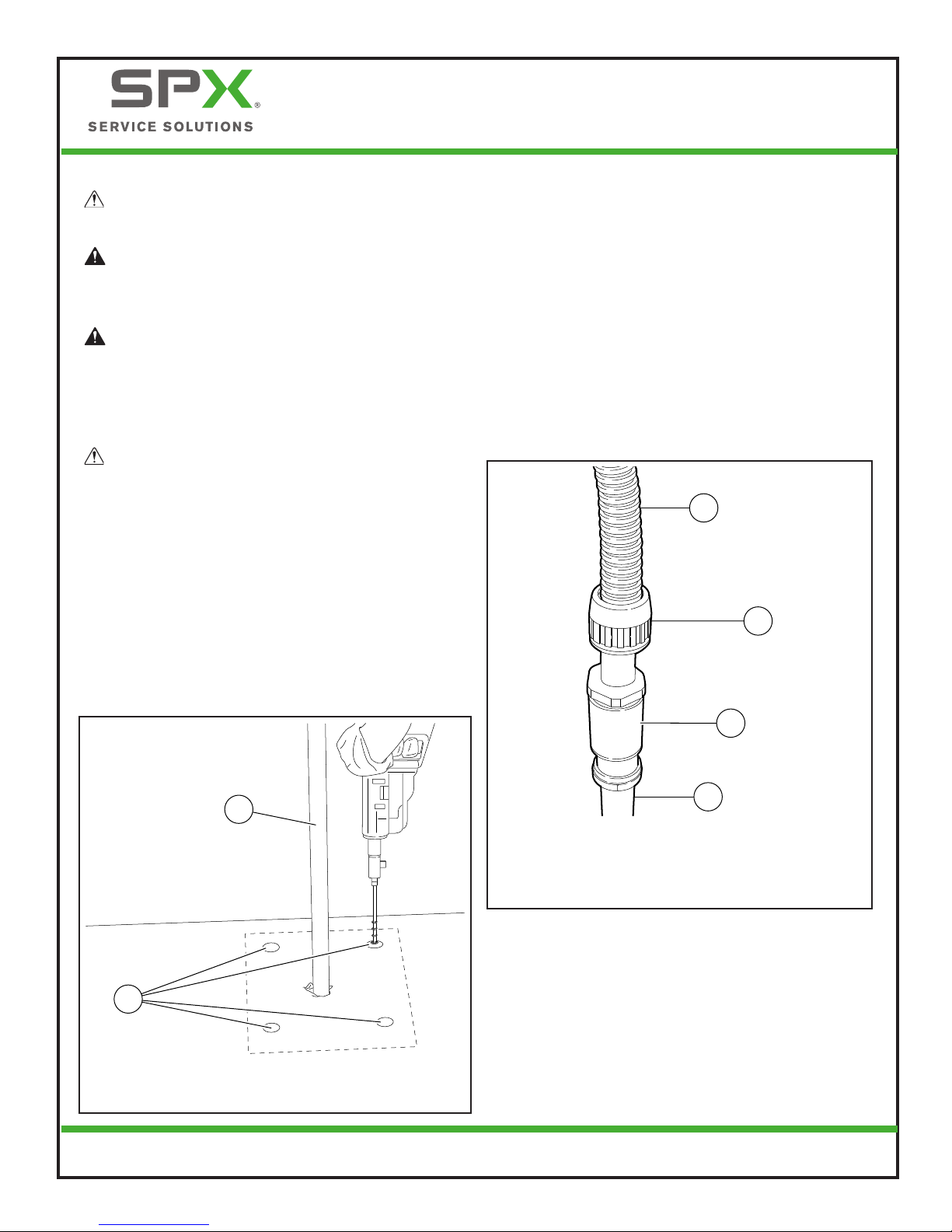

1. Place the bollard where it is to be installed and

drill holes.

2. Install the 3/4 in. anchor bolts in accordance

with industry standards for the type of

mounting being performed.

A

B

A. Conduit stand pipe

B. Marked locations for anchor bolts

Figure 12. Drill Holes

NOTE: Depending on the type and size of the con-

duit stand pipe, a variety of adapters may

be used to convert the stand pipe to 1/2-in.

liquid-tight exible conduit.

3. Slide the wires through the required adapters

and the 1/2-in. liquid-tight exible conduit.

4. Install 1/2-in. liquid-tight exible conduit to the

conduit stand pipe.

NOTE: Consult national and local codes for ap-

proved, liquid-tight exible conduit.

B

C

D

A

A. 1/2-in. liquid-tight exible conduit

B. Liquid-tight tting

C. Threaded adapter

D. Conduit stand pipe

Figure 13. Stand Pipe Conduit Connection

15

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

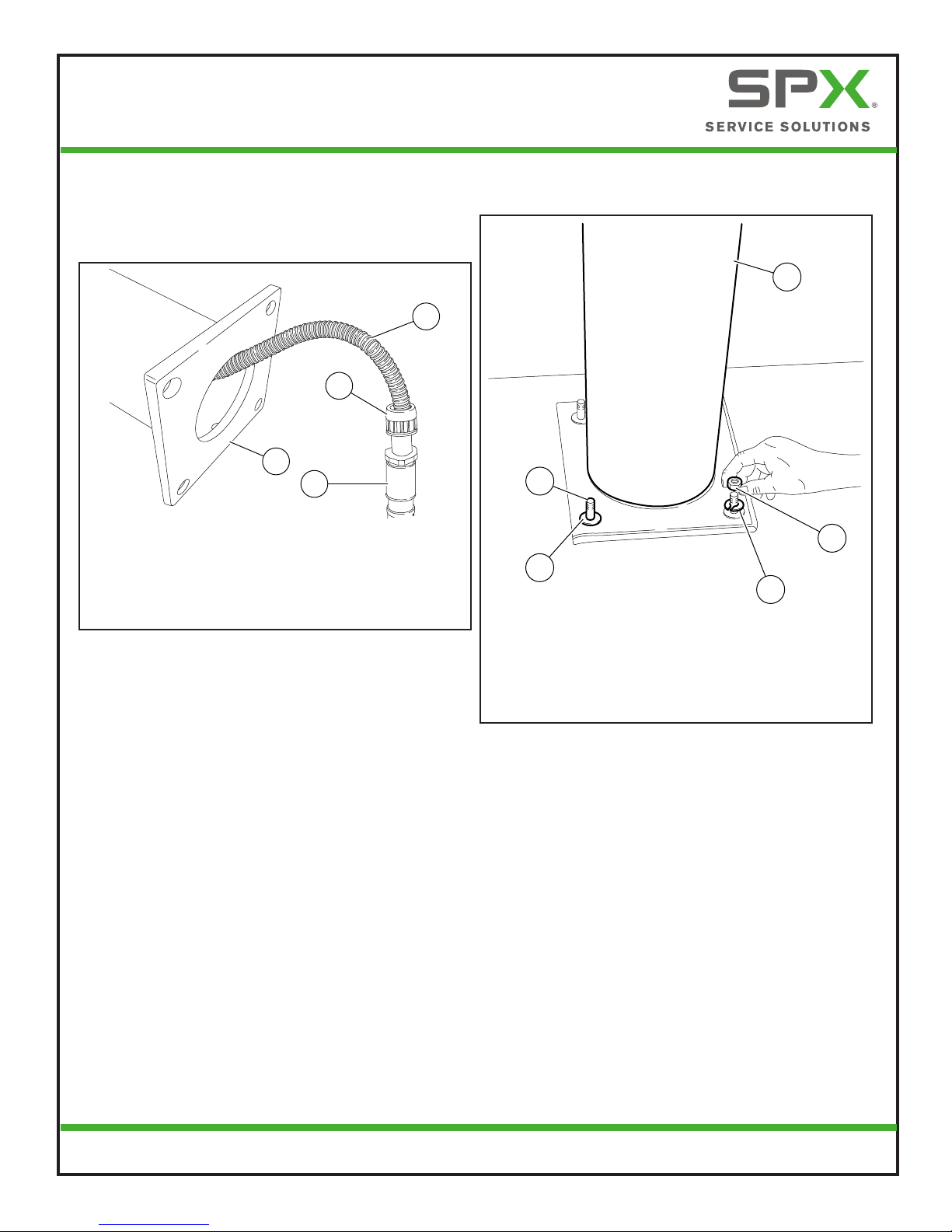

5. Place the bollard on its side.

6. Gently guide the conduit through the bottom

of the bollard and position the bollard over the

bolts and onto the base.

C

B

D

A

A. 1/2-in. liquid-tight exible conduit

B. Liquid-tight tting

C. Adapter

D. Bollard base plate

Figure 14. Guide Conduit into Bollard

7. Use a level on two sides (90° apart) of the

bollard to check whether the bollard is standing

straight.

8. If the bollard is not plum and level, remove the

bollard and place washers on the lag bolts as

needed to level the bollard.

9. Repeat Steps 7 and 8 until the bollard is level.

NOTE: Alternately, double-nut leveling installation

is acceptable.

10. Install a washer, lock washer, and nut on each

bolt.

A

B

E

D

C

A. Bollard

B. Nut

C. Lock washer

D. Flat washer

E. Lag Bolt

Figure 15. Install Washers and Nuts

11. Tighten the nuts evenly around the bollard.

Any gap between the bollard base and the

mounting surface may be lled with caulk

suitable for the installation environment.

16

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

12. Position the conduit on the left side of the

bollard (opposite the open metal slot side).

A

B

A. Tapered EVSE guide bracket

B. 1/2-in. liquid-tight exible conduit

Figure 17. Conduit Positioned on Left

13. Gently guide the EVSE body down through the

bollard until it rests on the top of the tapered

guide bracket.

A

B

C

A. EVSE

B. Tapered EVSE guide bracket

C. 1/2-in. liquid-tight exible conduit

Figure 18. EVSE Resting on Bracket

14. Mark 1/2-in. liquid-tight exible conduit for

length based on the required radius bend to

attach to the top of the EVSE.

A

B

C

A. Location to cut conduit

B. Precut hole in top of EVSE

C. 1/2-in. liquid-tight exible conduit

Figure 19. Location to Cut Conduit

15. Cut 1/2-in. liquid-tight exible conduit to

length. Do not cut wires.

16. Install approved, liquid-tight ttings to attach

1/2-in. liquid-tight exible conduit to top of

EVSE.

A

B

A. 1/2-in. liquid-tight exible conduit

B. Liquid-tight tting

Figure 20. Fittings Installed

17

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

NOTE: All connections must be liquid-tight.

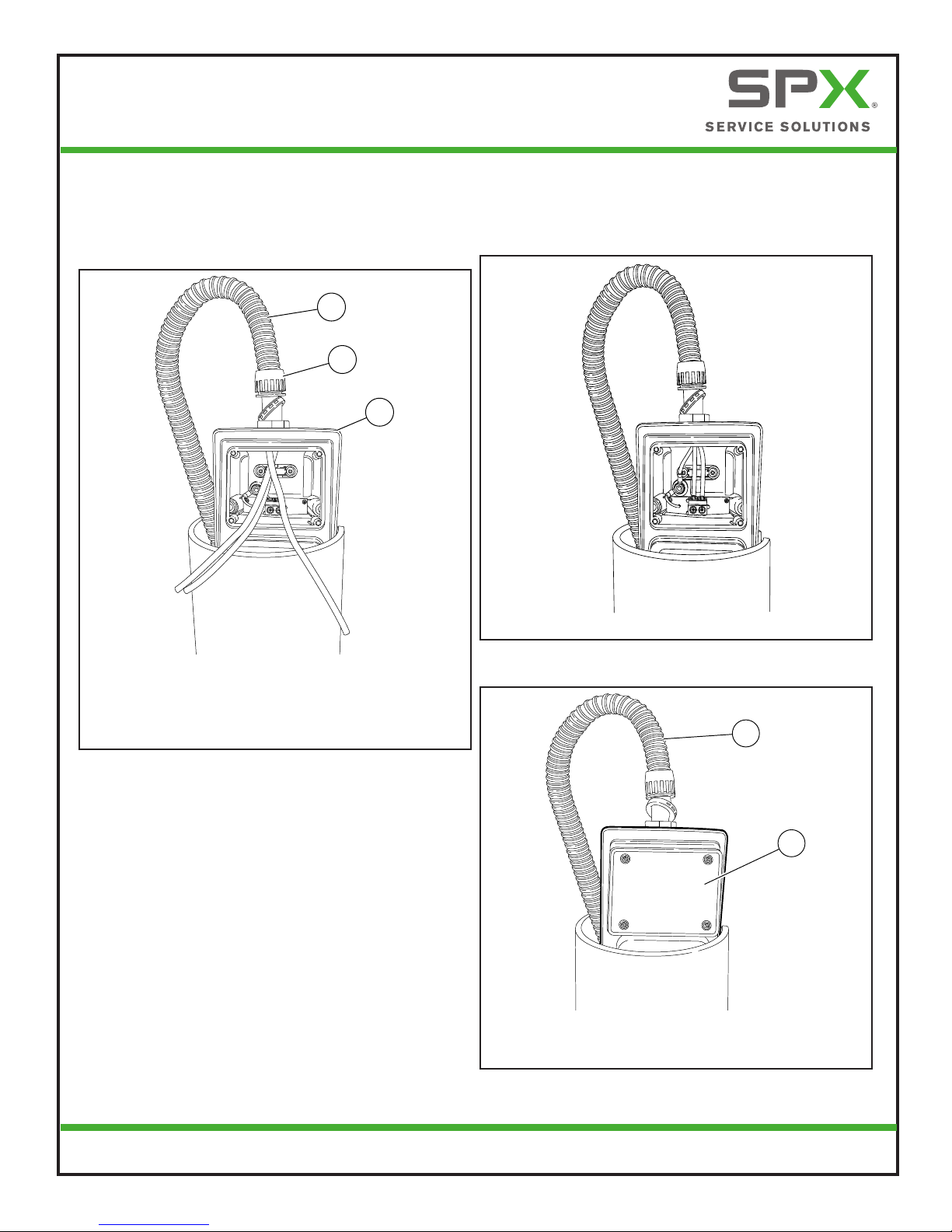

17. Feed wires into the hole in the top of the EVSE

and attach 1/2-in. liquid-tight exible conduit

with a liquid-tight tting.

A

B

C

A. 1/2-in. liquid-tight exible conduit

B. Liquid-tight tting

C. EVSE

Figure 21. Wires Inserted into EVSE and

Conduit Installed

18. Cut wires to length.

19. Strip wires and wire them into the EVSE. Refer

to label on inside of EVSE cover or details on

circuit board. Torque terminal screws to 10.62

± 1 in-lb (1.2 ± 0.12 Nm).

Figure 22. Wires Installed into EVSE

20. Install EVSE cover.

A

B

A. 1/2-in. liquid-tight exible conduit

B. EVSE cover

Figure 23. EVSE Cover Installed

18

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

21. Apply decal to the front of the EVSE cover.

22. Continue lowering the EVSE until the front

edge of the EVSE bottom cover rests on the

ledge in the bollard front opening.

B

A

A. EVSE bottom cover

B. Ledge in bollard front opening

Figure 24. EVSE Lowered into Position

WARNING: The lower edge of the EVSE

bottom cover must rest on the ledge

of the bollard. Failure to position the

EVSE correctly in the opening will cause

damage to the EVSE when the locating

set screw is tightened.

WARNING: Never use any other size set

screw to secure the EVSE in place. If

the set screw is too long, it will prevent

installation of the upper cover.

23. Push any excess conduit down into the bollard.

A loop will extend above the bollard and t in

the top cover.

Figure 25. Excess Conduit Pushed into Bollard

24. Install the locating set screw to 50 ± 5 in-lb

(5.5 ± 0.55 Nm).

Figure 26. Tightening the Locating Set Screw

19

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

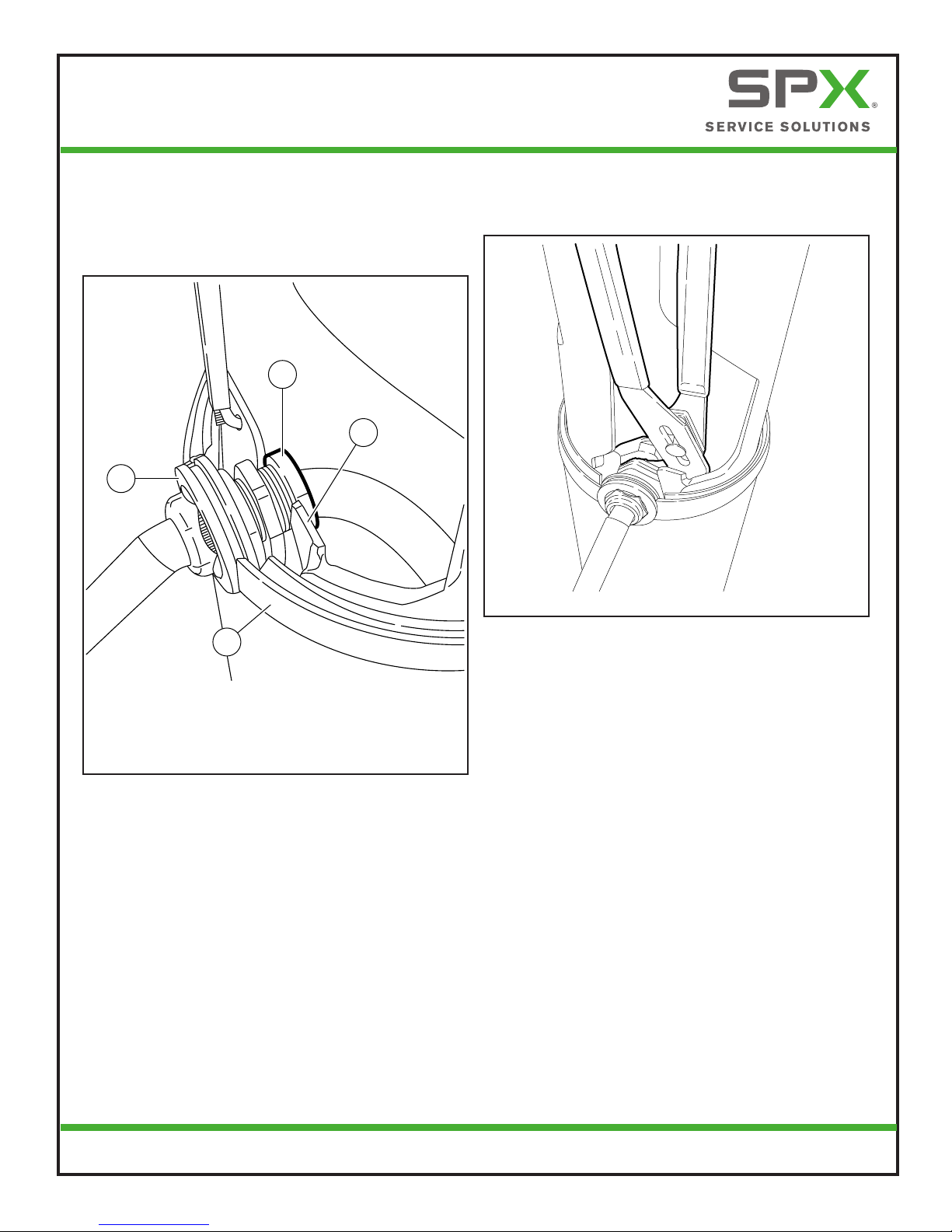

25. Position the strain relief at the bottom of the

side slot metal mounting bracket in the steel

bollard. Position such that the rubber grommet

(D) seats on the opening of the lower plastic

bollard cover.

D

C

A

B

A. Inner strain-relief nut

B. Metal mounting bracket

C. Seal

D. Rubber grommet

Figure 27. Strain Relief Placement

26. Tighten the inner strain-relief nut (A) inside the

bollard hand tight. Using expandable pliers,

tighten the nut an additional 1/4 turn.

Figure 28. Tightening the Strain-Relief Nut

NOTE: Do not overtighten the strain-relief nut. The

grommet may pull through.

20

Power Xpress™ Bollard Charge Station

Installation Guide

EL-50600-17 Rev. A

27. Carefully lower the upper plastic cover down

onto the bollard base.

A

B

A. Upper plastic cover

B. Metal bollard

Figure 29. Upper Bollard Lowered into Place

28. Use a small at-blade screwdriver or similar

tool to guide the upper plastic cover into the

seal.

WARNING:

WARNING:

RED STATUSLIGHT ILLUMINATED - SEE OPERATINGMANUAL FOR

FAULTINDICATION AND OPERATINGINSTRUCTIONS.

8.RETURN CABLE AND COUPLER BACKTO STOWABLEPOSITION AT EVSE.

NOTE: EVSEWILL RESUME CHARGING UPON RESTORATION OF INTERRUPTED GRID POWER.

7.UNPLUGVEHICLE COUPLER (CONNECTOR) FROM VEHICLE INLET (RECEPTACLE)- STATUS

INDICATOR CHANGES BACKTO AMBER ILLUMINATION STATE.

6.POST COMPLETION OF CHARG - STATUSLIGHT RETURNS TOSOLID GREEN ILLUMINATION

STATUS.

5.AFTER SAFETYTEST VERIFICATION - STATUSLIGHT BEGINS TO FLASH GREEN,INDICATING

VEHICLE IS CHARGING.

LA LUMIERE DE STATUTROUGE ECLAIREE - VOITLE MANUEL

OPERANT POUR L’INDICATIONDE FAUTEET LES

INSTRUCTIONS OPERANTES.

Sl appareil ne fonctionne pas selon les instructions

EMPLOI Ne pas utiliser ce peripherlque, contactez

TECHNICIEN QUALIFIEpour entretien ou reparation.

IFUNIT FAILSTO OPERATEPER THE OPERATINGINSTRUCTIONSDO NOTUSE

THISDEVICE, CONTACTQUALIFIEDTECHNICIANFOR SERVICEOR REPAIR.

AVERTISSEMENT:

AVERTISSEMENT:

FOR USE WITH ELECTRICVEHICLES ONLY

VENTILATION NOTREQUIRED

A

B

C

D

A. Upper plastic cover

B. Seal

C. Lower plastic cover

D. Small at-blade screwdriver

Figure 30. Seal Installation

29. While gently pressing down on the upper

plastic cover, carefully slide the screwdriver

around the bollard to extend the upper lip

of the seal over the upper plastic cover. The

upper cover may need to be tapped gently to

fully seat it in the seal.

CAUTION: Use care not to cut or damage the

seal during this procedure.

NOTE: When the upper plastic bollard cover is fully

seated, the rear cable-management holes

will be in line with the threaded holes in

the steel portion of the bollard base and the

rubber cable grommet will be centrally lo-

cated with respect to the rubber seal.

Verify the cable-management holes and the

rubber cable grommet are each properly

aligned.

30. Use a 5/16-in. hex-head wrench to install the

rear cable-management hook with the two

cable-management retaining screws. The

torque on the cable-management retaining

screws should be 60 ± 5 in-lb (6.8 ± 0.55 Nm).

Table of contents

Other SPX Batteries Charger manuals