SPX Hankison HPRP Series User manual

1

HPRP Series

Refrigerated Type Compressed Air Dryers

Models: HPRP100, HPRP125, HPRP150, HPRP200, HPRP250, HPRP300, HPRP400, HPRP500, HPRP600, HPRP750

FORM NO.: 5002730 REVISION: 01/2012 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

2

CONTENTS

GENERAL SAFETY INFORMATION .................................... 2

RECEIVING, MOVING, AND UNPACKING .......................... 2

1.0 INSTALLATION........................................................... 3

2.0 OPERATION.............................................................. 5

3.0 MAINTENANCE ........................................................ 9

SIZING.............................................................................. 9

ENGINEERING DATA

Models 100-250.......................................................... 10

Models 300-750.......................................................... 11

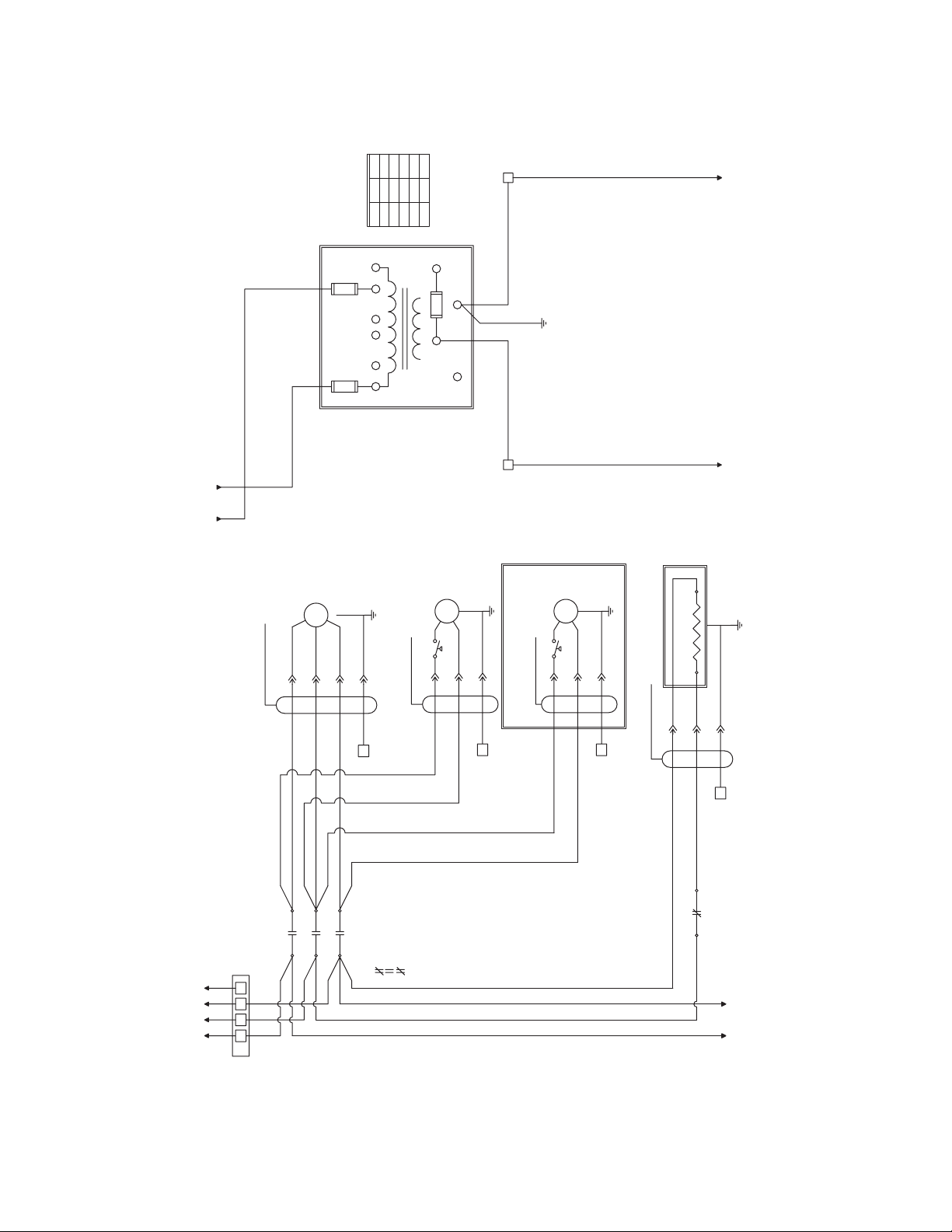

WIRING DIAGRAM

Model 100: 120/230 VAC........................................... 12

Models 125-150: 120/230 VAC.................................. 13

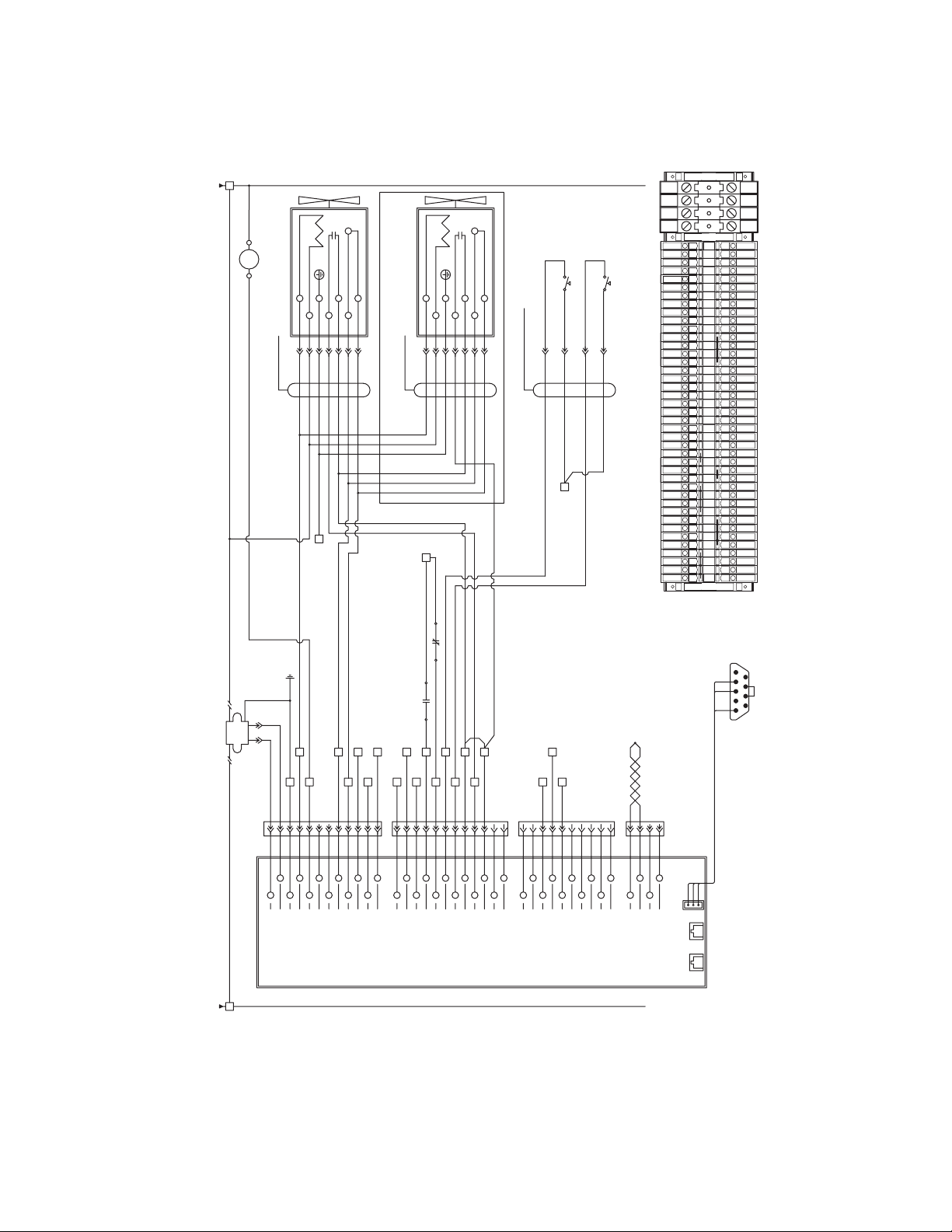

Models 200-600: 460 VAC ......................................... 14-15

Model 750: 460 VAC .................................................. 16-17

Models 200-750, 575-460/3/60 Transformer Pack ... 18

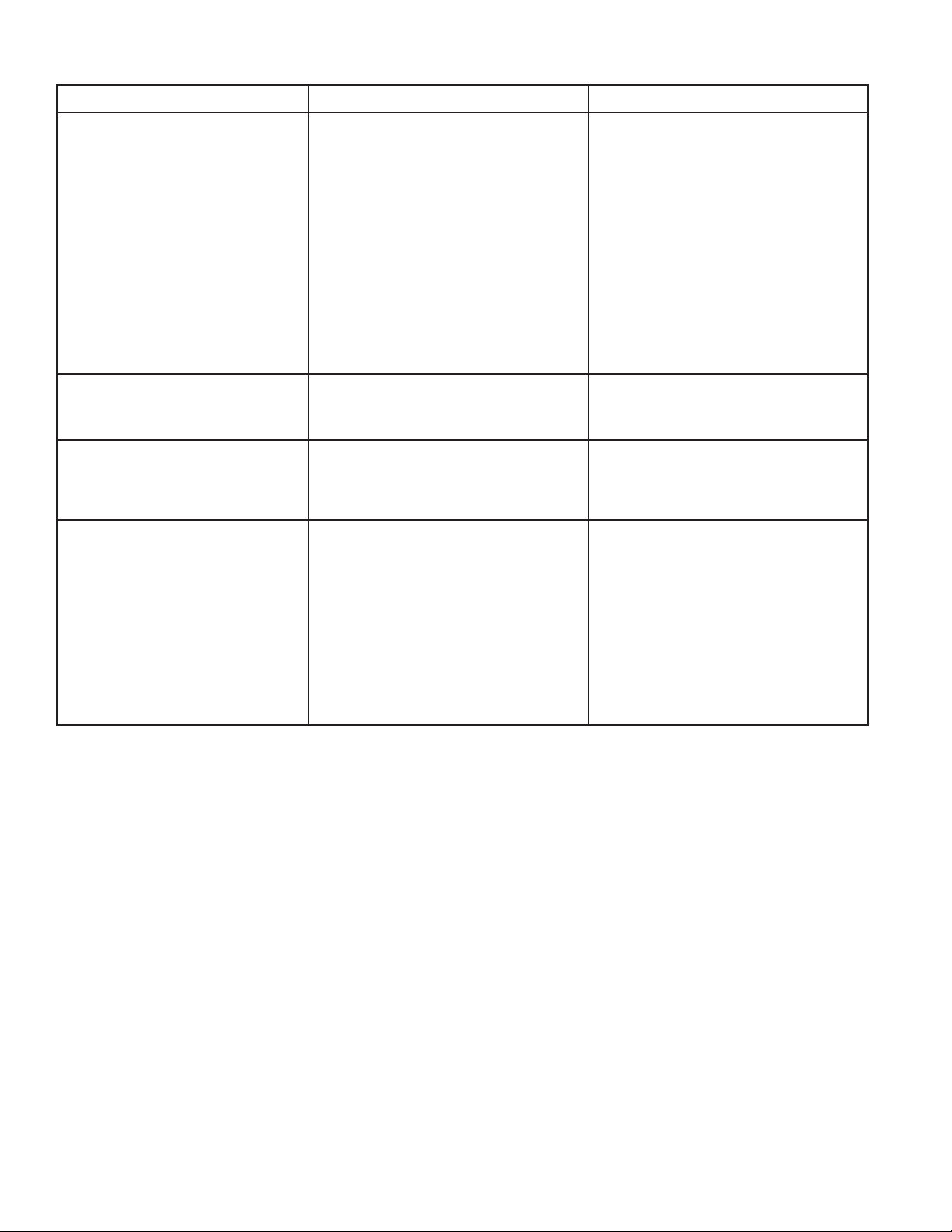

DIMENSIONS / WEIGHTS.................................................. 19

TROUBLESHOOTING GUIDE

Models 100-150.......................................................... 20

Models 200-750.......................................................... 21

PARTS LIST....................................................................... 22

WARRANTY ..................................................................... 23

GENERAL SAFETY INFORMATION

1. PRESSURIZED DEVICES:

This equipment is a pressure containing

device.

• Donotexceedmaximumoperating

pressure as shown on equipment

serial number tag.

• Make sure equipment is depressurized before

working on or disassembling it for service.

2. ELECTRICAL:

This equipment requires electricity to

operate.

• Installequipmentincompliancewith

all applicable electrical codes.

• Standard equipment is supplied with electrical

enclosuresnotintendedforinstallationinhazardous

environments.

• Disconnect power supply to equipment when

performing any electrical service work.

3. BREATHING AIR:

• Air treated by this equipment may

not be suitable for breathing without

further purification.

Refer to applicable standards and

specifications for the requirements

for breathing quality air.

RECEIVING, MOVING, AND UNPACKING

A. RECEIVING

This shipment has been thoroughly checked, packed and

inspected before leaving our plant. It was received in

good condition by the carrier and was so acknowledged.

Check for Visible Loss or Damage. If this shipment shows

evidence of loss or damage at time of delivery to you,

insist that a notation of this loss or damage be made on

the delivery receipt by the carrier’s agent.

B. UNPACKING

Check for Concealed Loss or Damage. When a shipment

has been delivered to you in apparent good order, but

concealed damage is found upon unpacking, notify the

carrier immediately and insist on his agent inspecting

the shipment. Concealed damage claims are not our

responsibility as our terms are F.O.B. point of shipment.

C. MOVING

In moving or transporting dryer, do not tip dryer onto

its side.

D. STORAGE/SHUT DOWN

Dryer should not be stored outside (either

packedorunpacked)orexposedtotheweather.Damage

to electrical and control components may result.

IMPORTANT: WATER-COOLED UNITS - If unit is shut down

belowfreezingtemperatures,thewater-cooledcondenser

mayfreezeandcausepermanentdamage.Condensermust

be drained when the unit is shut down.

IMPORTANT: Do not store dryer in temperatures above

130°F, 54.4°C.

3

IMPORTANT: READ PRIOR TO STARTING THIS EQUIPMENT

1.0 INSTALLATION

1.1 Location

A. For typical placement in a compressed air system, see

drawing.

B. Air compressor intake – Locate air compressor so that

contaminants potentially harmful to the dryer (e.g.

ammonia) are not drawn into the air system.

C. Clearances Free air flow

Front 36 inches (914 mm)

Back 6 inches (152 mm)

Sides 36 inches (914 mm)

Service - To facilitate maintenance leave 36 inches

(914 mm) of clearance in front of dryer.

D. Standard units are designed to operate in ambients:

Air-cooled: 40 to 110°F (4 to 43°C).

Water-cooled: 40 to 130°F (4 to 54°C).

E. Installations in altitudes above 4500 feet (1370 meters) –

Dryer is adjusted to operate in altitudes up to 4500 feet

(1370 meters). If dryer is installed in an altitude above

this, and has not been preset at the factory for this

altitude, contact manufacturer’s Service Department.

F. The installation of a exible connection prior to the

dryer is recommended to prevent possible damage from

vibration.

NOTE: Outdoor installation – Standard units are designed

for indoor installation. Contact manufacturer if installing

outdoors.

Aftercooler

Separator

Dryer

Oil Removal

Filter

Compressor

Moisture Separator

Coalescing Filter

(Option)

Float Drain

(Standard)

Condenser

Drain Outlet

Electrical Entry

(230 VAC)

Air Outlet

Air Inlet

Control Panel

Models 100, 125, & 150

Electric Demand Drain (EDD)

3-Way Valve

Moisture Separator

Coalescing Filter

(Option)

Control Panel

RS232 Entry

Electrical Entry

Air Outlet

Air Inlet

Condenser

Drain Outlet

Models 200, 250, 300, 400, 500, 600, & 750

4

1.2 Mounting

Mount the dryer on a level solid surface. Holes are provided

in the dryer base to permanently mount the dryer to the

floor.

1.3 Piping connections

A. Air Inlet - Connect compressed air line from air source

to air inlet. (Reference markings on dryer for air inlet/

outlet connection locations.)

RefertoSerialNumberTagformaximumworking

pressure.Donotexceeddryer’sMaximumWorkingPressure.

NOTE: Install dryer in air system at highest pressure possible

(e.g. before pressure reducing valves).

NOTE: Install dryer at coolest compressed air temperature

possible.Maximuminletcompressedairtemperature:120°F

(49°C).Ifinletairexceedsthistemperature,precooltheair

with an aftercooler.

B. Air Outlet – Connect air outlet to downstream air lines.

C. Bypass piping – If servicing the dryer without

interrupting the air supply is desired, piping should

include inlet and outlet valves and an air bypass valve.

D. Water cooled models – cooling water inlet and outlet

1. Connect cooling water supply to cooling water inlet.

2. Connect cooling water return line to cooling water

outlet connection.

NOTE: Strainer and water regulating valve are supplied on

water cooled models.

1.4 Electrical connections

IMPORTANT: Use copper supply wires only.

A. Dryer is designed to operate on the

voltage, phase, and frequency listed on

the serial number tag.

B. If dryer is supplied with a cord and plug,

install in a receptacle of proper voltage.

C. Electrical entry on larger dryers is through a hole in

the cabinet. It is located on the right side panel when

facing the front of the unit. Connect power source to

terminal strip in electrical enclosure as shown on the

wiring diagram included with the dryer.

NOTE: Refrigeration condensing unit is designed to run

continuously and should NOT be wired to cycle on/off with

the air compressor.

NOTE: ON MODELS 500, 600, and 750, CHECK FOR CORRECT

PHASING OF UNIT. After starting the dryer, if an unusual

noise is heard, or if the discharge line does not get hot, the

refrigeration compressor may be running in the reverse

direction. Immediately stop the dryer, reverse two of the

power leads, restart the dryer, and verify the unusual noise is

corrected and the refrigerant discharge line is hot. FAILURE

TO DO SO MAY DAMAGE THE COMPRESSOR AND VOID THE

WARRANTY.

1.5 Moisture separator

A. Models 100-150:

Separator (and Oil Removal Filter where

applicable) has an internal drain which

automatically discharges condensate.

Models 200-750:

Separator (and Oil Removal Filter where applicable) has

an electronic demand drain (EDD) which automatically

discharges condensate.

NOTE: It may be desirable to pipe the condensate from the

Automatic Drain outlet to a suitable drain.

B. Models 100-150:

Separatorhasaknurledttingwithexibledraintubing

attached. Be sure knurled fitting is tightened by turning

counter-clockwise before operating dryer.

TO CLOSE

TURN COUNTERCLOCKWISE

C. Models 200-750

Formanualdraining,convenientdryerdepressurization,

and EDD service, a three-way valve assembly has been

installed at the bottom of the moisture separator (and

cold coalescing filter where applicable). Review the

following for proper drain function:

• Automatic Draining - Valve handle should be

positioned parallel to the valve body (as shown),

with the arrow on the handle pointing toward the

EDD. In this position, condensate will flow from the

bowl to the EDD.

• DrainIsolation (Shutdown)- Valvehandleshall be

turned perpendicular to the valve body (rotate 90°).

In this position, condensate flow is shutoff.

• ManualDraining-Drainvalvehandleshallberotated

slightly past the drain isolation position to allow

throttling through the valve for manual discharge

anddepressuruzation.

• NOTE: The quick disconnect fitting allows removal

of the entire drain assembly. However, the unit

must be depressurized prior to disassembly or

serious injury may occur.

NOTE:Discharge is at system pressure. Drain line should be

anchored.

NOTE:Condensate may contain oil. Comply with applicable

laws concerning proper disposal.

5

1.6 Operation

A. Verify that isolation valves are open. If the drain fails to

discharge after the valve is energized, the electronic

controlcircuitwillrepeatedlyenergizethevalveinan

attempt to clear the discharge port. If, after 60 seconds,

the drain still fails to discharge, the control circuit then

switches to the alarm mode. In this mode the valve is

de-energized and the red alarm light is activated on

the drain and the dryer controller. The valve is then

automaticallyenergizedevery4minutesfor5seconds.

Check the drain operation. Push drain (push-to-test)

button on the Energy Management Monitor control

boardtoenergizedrain.Aowofcondensateand/orair

should be present at the drain outlet. The alarm mode

automatically clears after the drain returns to normal

operation.

B. Condensate enters the reservoir (1) through the inlet

port. When the condensate level in the reservoir covers

the capacitance sensor, an electronic signal is sent to the

solid state countdown processor. The processor delays

the opening of the solenoid valve for a given period

of time. Once the time has elapsed, the solid state

processortransmitsinformationtoenergizethecoilin

the solenoid valve (2). The magnetic force of the coil

causes the solenoid core (3) to move, closing the pilot

air supply line and opening the pilot air exhaust line.

After the pilot air above the diaphragm (4) is vented,

pressure in the reservoir opens the discharge port and

forces the condensate through the discharge port and

outlet piping.

2.0 OPERATION

2.1 Minimum/Maximum operating conditions

A. Maximuminletairpressure:refertodryerserialnumber

tag

B. Minimum inlet air pressure: 30 psig (2.1 kgf/cm

2

)

C. Maximuminletairtemperature:120°F(49°C)

D. Maximumambienttemperature:

Air-cooled models: 110°F (43°C)

Water-cooled models: 130°F (54°C)

E. Minimum ambient temperature: 40°F (4°C)

2.2 Start-up

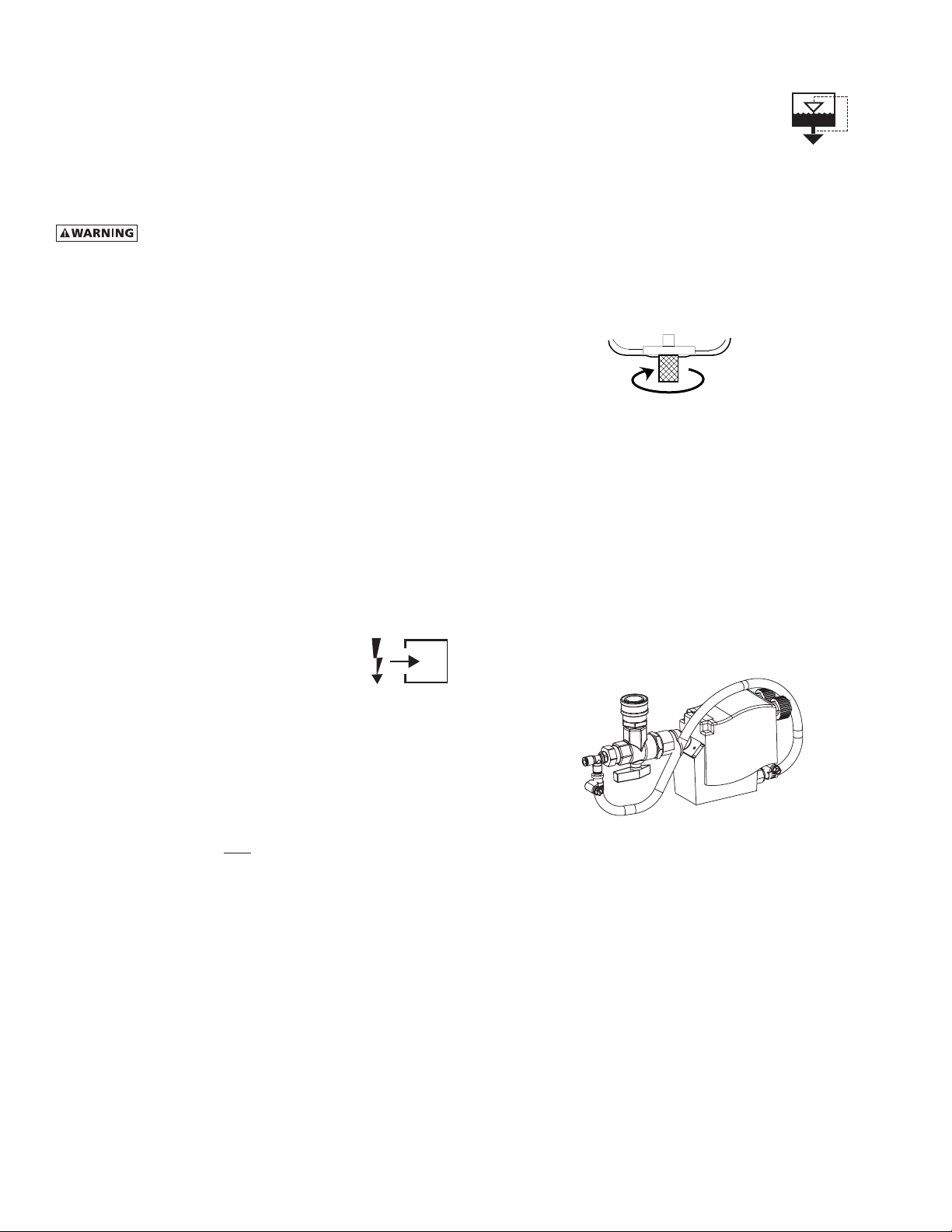

A. Models 100-150:

Energizecompressorbypositioningtheon/offswitchin

the on (I) position. Compressor on light will illuminate.

On/Off Switch Power-On Light Dewpoint Indicator (Green)

B. Models 200-750:

Energizedryer.Greenpoweronlightwillilluminate.

IMPORTANT:Energizedryerdisconnectswitch(providedby

others, see NEC) 24 hours before refrigeration compressor

is started! Never use the disconnect switch to shutdown

thedryerforaextendedperiodoftime(exceptforrepair).

Failure to follow these instructions may result in a non-

warrantable compressor failure.

NOTE: If there is no power to the control board for a period

of two weeks or more, it may return to the default mode.

C. Program Monitor

Press and hold Program Mode button until Main Menu screen

appears. Use the Up and Down arrow buttons to scroll

through the list of submenu choices. Press Enter button

toviewthesubmenuthatisdisplayed.PressESCtoexitthe

Main Menu and return to Display mode.

1. Language selection

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll

through the list of languages (choice of 10 available:

English, Deutsch, Francais, Espanol, Italiano, Polski,

Dansk, Dutch, Norsk and Suomi).

b. Press ‘Enter’ button to select the language that is

displayed.

c. Push ‘ESC’ at any time to return to the Main Menu.

2. Setting Date & Time

a. Use the ‘Up’ and ‘Down’ arrow buttons to set minutes

(00 to 59). Press ‘Enter’ to accept new value.

b. Use the ‘Up’ and ‘Down’ arrow buttons to set hours

(00 to 23). Press ‘Enter’ to accept new value.

c. Use the ‘Up’ and ‘Down’ arrow buttons to set year

(00 to 99 representing 2000 to 2099). Press ‘Enter’

to accept new value.

d. Use the ‘Up’ and ‘Down’ arrow buttons to set month

(three letter abbreviation). Press ‘Enter’ to accept

new value.

e. Use the ‘Up’ and ‘Down’ arrow buttons to set day

(01tomaximumforthemonthandyearselected).

Press ‘Enter’ to accept new value.

f. Push ‘ESC’ at any time to return to the Main Menu.

1

2

3

4

6

1. Temperature Indicator

2. Operator Interface Display

3. Power-on Light

4. Compressor-on Light

5. Alarm / Service Light

6. Schedule On/Off and Enter Button

a. In display mode: Press to toggle between

SCHEDULE RUNNING and MANUAL OVERRIDE.

b. In program mode:

i. Press to move to a lower level menu.

ii. Press to accept a value that has been edited.

7. Program Mode (i) and Esc

a. In display mode: Press and hold to enter pro-

gram mode.

b. In program mode: Press to move to a higher

level menu.

8. Up Arrow

a. In display mode: No function

b. In program mode:

i. Presstoviewthenextiteminalistorto

increment a variable to a higher value. Press

and hold for accelerated incrementing.

ii. When the top of the list (or highest value) is

displayed, pressing the up button will cause

the display to wrap to the bottom of the list

(or lowest value).

9. Down Arrow

a. In display mode: No function

b. In program mode:

i. Press to view the previous item in a list or to

increment a variable to a lower value. Press

and hold for accelerated incrementing.

ii. When the bottom of the list (or lowest value)

is displayed, pressing the down button will

cause the display to wrap to the top of the

list (or highest value).

10. 1/0: Press at any time to turn the dryer on/off.

11. Drain test: Press at any time to momentarily the

open drains (like the current emm).

12. Reset: Press at any time to clear the alarm/service

message (if shown) and the alarm LED.

CONTROL PANEL

1234 5

6789 10 11 12

3. Setting Schedule

a. Use the ‘Up’ and ‘Down’ arrow buttons to select

desired “Day of week + on/off”. Press ‘Enter’ to

accept new value

b. Use the ‘Up’ and ‘Down’ arrow buttons to set hour

(00 to 23). Press ‘Enter’ to accept new value

NOTE: If the hour setting is ‘IGNORE’, Press ‘Enter’

again to move the cursor under the “Day of week +

on/off”. Repeat steps a through b (or c) as needed.

c. Use the Up and Down arrow buttons to set minutes

(00, 10, 20, 30, 40, 50; not shown if hour setting is

‘IGNORE’). Press ‘Enter’ to accept new value and

return to “Day of week + on/off”. Repeat steps a

through c as needed.

d. Push ‘ESC’ at any time to return to the Main Menu.

NOTE: Scheduler will ignore programmed commands

for10minutesafterexitingprogrammode.

4. Hours To Service

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll

through the range of permissible values (0 to 8760)

before service reminder is initiated. Press ‘Enter’

to accept new value. (Only hours that refrigeration

compressor is operating are counted).

b. Press ‘ESC’ at any time to return to the Main Menu.

NOTE: On dryers with air-cooled condensers, regular

condenser cleaning is recommended. Dirtiness

of ambient air at installation site will determine

frequency of service. Typically once a month is

recommended. Dryers contain an integral 3 micron

filter. As the filter element accumulates solid

contaminants, differential pressure increases. Solid

particulate load in the compressed air supply will

determine frequency of service. Typically element

changeout is recommended at least annually.

5. PushESCbuttontoexitprogrammode

NOTE: If after 60 seconds no button is pressed while in

Program Mode, the audible alarm sounds for five (5)

seconds. Dryer will resume previous operating mode.

6. Manual Operation

a. To manually turn the refrigeration system on or off

use ‘On/Off’ button; Push ‘Schedule On/Off and

Enter’ button to return to schedule.

NOTE:Afterpowerinterruptiondryerwillreenergize

in Manual override, refrigeration system off. To

restart Schedule: Push ‘Schedule On/Off and Enter’

button.

D. Starting dryer

IMPORTANT: Dryer must be energized 24 hours before

starting refrigeration compressor.

NOTE: It is recommended that dryer be started 15 minutes

before compressed air flow begins.

1. On water-cooled models: after 24 hours, begin cooling

water flow.

2. Check for proper electrical voltage.

3. Slowlypressurizeunitairsidebyopeninginletisolation

valve. Check for leaks.

7

4. After 15 minutes, open outlet isolation valve slowly.

5. Close air bypass valve.

6. Dryer may be operated in Manual or Scheduled modes.

NOTE: ON MODELS 500, 600, and 750, CHECK FOR CORRECT

PHASING OF UNIT. After starting the dryer, if an unusual

noise is heard, or if the discharge line does not get hot, the

refrigeration compressor may be running in the reverse

direction. Immediately stop the dryer, reverse two of the

power leads, restart the dryer, and verify the unusual noise is

corrected and the refrigerant discharge line is hot. FAILURE

TO DO SO MAY DAMAGE THE COMPRESSOR AND VOID THE

WARRANTY.

Manual mode - push On/Off button - refrigeration

compressor will start and run, green Compressor-on

light will illuminate. In this mode compressor will run

continuously and will not be turned on and off by the

monitor. MANUAL OVERRIDE will appear on interface

panel.

Schedule mode - push Schedule On/Off and Enter button.

SCHEDULE RUNNING will appear on the interface panel.

The refrigeration compressor will continue to be on or

off (as selected in the Manual Override Mode) until the

nextscheduledevent.Thecompressorwillthenturnon

or off as programmed.

NOTE: Schedule may be returned to the manual mode at

any time using the ‘Schedule On/Off and Enter’ button.

MANUAL OVERRIDE will appear on interface panel. To

reinstitute Schedule, push the ‘Schedule On/Off and Enter’

button again.

NOTE: Restart after the power interruption. Unit will be

in MANUAL OVERRIDE mode, refrigeration compressor, off

when power is restored after power interruption.

7. To reinstitute SCHEDULE RUNNING, push ‘Schedule On/

Off and Enter’ button.

IMPORTANT: Dryer must be energized 24 hours before

refrigeration compressor is started.

E. Operating check points

1. Check that green Power-on light is illuminated

2. Check that green Compressor-on light is illuminated if

dryer is on in the manual mode or it is a scheduled on

time

IMPORTANT: Refrigeration compressor must be restarted

after power interruption.

3. Check interface panel

NOTE: Interface panel will scroll through three screens

(Current Time/Operating Status, Hours to Service and Total

Operating Hours).

a. Verify that current time is correct

b. Check HRS TO SERVICE: this indicates time remaining

until service is required; allow time for required

maintenance items to be ordered

c. Check operating status:

MANUAL OVERRIDE - Dryer is either running

continuously (not being controlled by the scheduled

on/off times) or the refrigeration compressor has

been shut off using the ‘On/Off’ button.

SCHEDULE RUNNING - Refrigeration compressor

is being turned on and off by the monitor per-

programmed schedule (see B.3. to set schedule).

d. Check Temperature indicator - indicator should read

in the green area.

e. Check Alarm/Service light If illuminated, check

Interface panel.

1) If SERVICE DRYER appears, scheduled maintenance

time has elapsed (HRS TO SERVICE is 0). Perform

needed service and reset service interval (see B.3.).

2) If ALARM appears, a dryer fault is indicated; see

Troubleshooting Guide for possible remedies.

After fault correction push Reset button to turn

Fault alarm off.

Type of FAULTS:

LOW PRESSURE - the refrigeration compressor

control circuit has opened because of low suction

pressure.

HIGH PRESSURE - the refrigeration compressor

control circuit has opened because of high head

pressure. The high pressure switch must be reset

manually once the fault is corrected. Red reset

button is located on pressure switch inside unit.

HIGH TEMPERATURE - compressed air temperature

is above the set point.

COMPRESSOR - Normally open (NO) auxiliary

contact on the compressor contactor is open

when the dryer is on.

HEATER- Normallyclosed(NC) auxiliarycontact

on the compressor contactor is open when the

dryer is off.

TEMP SENSOR - Occurs if the temperature sensor

circuit is open or shorted. If open, the left-most

LED in the temperature display will be illuminated.

If shorted, all the LEDs in the temperature display

will be illuminated.

DRAIN - electric drain contains a high water level

alarm that activates if drain fails to discharge.

f. Check drain operation - push Drain (push-to-

test) button to energize electric drain. A ow of

condensate and/or air should be present at the drain

outlet.

8

F. Using the RS-232 port

The RS-232 port is used to monitor dryer operation from a

host computer. A (1 to 1) DB-9 cable is required to connect

dryer and computer. For PC connections, data is transmitted

on pin 2, received on pin 3, ground is pin 5, pins 7 and 8 are

jumpered at dryer.

Operationisatxedbaudrateof9,600;asynchronousformat

is 8 bit, no parity, 1 stop bit (“8,N,1”). No check sum or error

correction values are provided. If required, request status

string two (or more) times and compare for agreement.

Request data by sending ASCII ? character (3FH). Response

may take up to two seconds as certain processing functions

may require completion before serial port is acknowledged.

Dryer responds with line feed (0AH), carriage return (0DH),

and character string: (1), (2), (3), (4), (5), (6), (7), (8), (9)

(1) =STX(start-of-textcharacter,mayappearasasmiley

face or some other character

(2) = 108, Control board ID

(3) = 0 or 1, Compressor running status (0=off, 1=on)

(4) = M or S, Operating Mode (M= MANUAL OVERRIDE, S

= SCHEDULE RUNNING)

(5) =xxxx,HOURSTOSERVICE

(6) =xxxxxx,TOTALHOURS

(7) = xx, Alarm or Service Code (0=no alarm, 30=LOW

PRESSURE ALARM, 31=HIGH PRESSURE ALARM,

32=COMPRESSOR ALARM, 36=HIGH EVAP TEMP ALARM,

37=HEATER ALARM, 38=DRAIN ALARM, 39=SERVICE

DRYER, 41=TEMP SENSOR ALARM)

(8) =xx.x,Evaporatortemperature(°F)

(9) =ETX,(end-of-textcharacter,mayappearasaheart

or some other character)

9

SIZING

Determining dryer capacity at actual operating conditions

Todeterminethemaximuminletowcapacityofadryer

at various operating conditions, multiply the rated capacity

from Table 1 by the multipliers shown in Table 2.

Example: How many scfm can an air-cooled model 400

handle when compressed air to be dried is at 200 psig and

100°F; ambient air temperature is 80°F?

Answer:400x1.22x1.12 = 547 scfm.

TABLE 1

Rated capacity (scfm) and pressure drop @ 100 psig inlet

pressure, 100°F inlet temperature, and 100°F ambient

temperature

MODEL 100 125 150 200 250

Rated capacity

of air-cooled

models (scfm)

60Hz

50Hz

100

84

125

105

150

125

200

170

250

210

MODEL 300 400 500 600 750

Rated capacity

of air-cooled

models (scfm)

60Hz

50Hz

300

250

400

340

500

420

600

540

750

630

TABLE 2

Air capacity correction factors (Multipliers)

INLET COMPRESSED AIR CONDITIONS

INLET

PRESSURES

INLET TEMPERATURES

80°F 90°F 100°F 110°F 120°F

psig kgf/cm227°C 32°C 38°C 43°C 49°C

50

80

100

125

150

175

200

3.5

5.6

7.0

8.8

10.5

12.3

14.0

1.35

1.50

1.55

1.63

1.70

1.75

1.80

1.05

1.17

1.23

1.31

1.37

1.42

1.47

0.84

0.95

1.00

1.07

1.13

1.18

1.22

0.69

0.79

0.82

0.91

0.95

0.99

1.03

0.56

0.66

0.70

0.74

0.80

0.84

0.89

COOLING MEDIUM*

AMBIENT

TEMPERATURE

MULTIPLIER

°F °C

80

90

100

110

27

32

38

43

1.12

1.06

1.00

0.94

*Air-cooled models; water-cooled models use 1.15 multiplier if cooling

water is below 35°C, 95°F.

3.0 MAINTENANCE

3.1 Condenser coil – Clean off accumulated dust

and dirt monthly.

3.2 Moisture separator – Replace filter element

when pressure drop across dryer is excessive

or annually.

3.3 Check separator daily to be sure automatic

drain is discharging.

3.4 Blow down separator weekly by pushing test

button on control panel.

3.5 Rebuild drain mechanism annually.

To facilitate service, maintenance kits are available.

Models 100-150

Drain Line

PTC Swivel Elbow

Element

Wave Spring

Float Drain

Element O-Ring

Bowl O-Ring

Head

Models 200-750

Head

Element O-Ring

Bowl O-Ring

Element

Bowl

Drain Quick Disconnect

Bowl Support

*Models 500-750 Only.

10

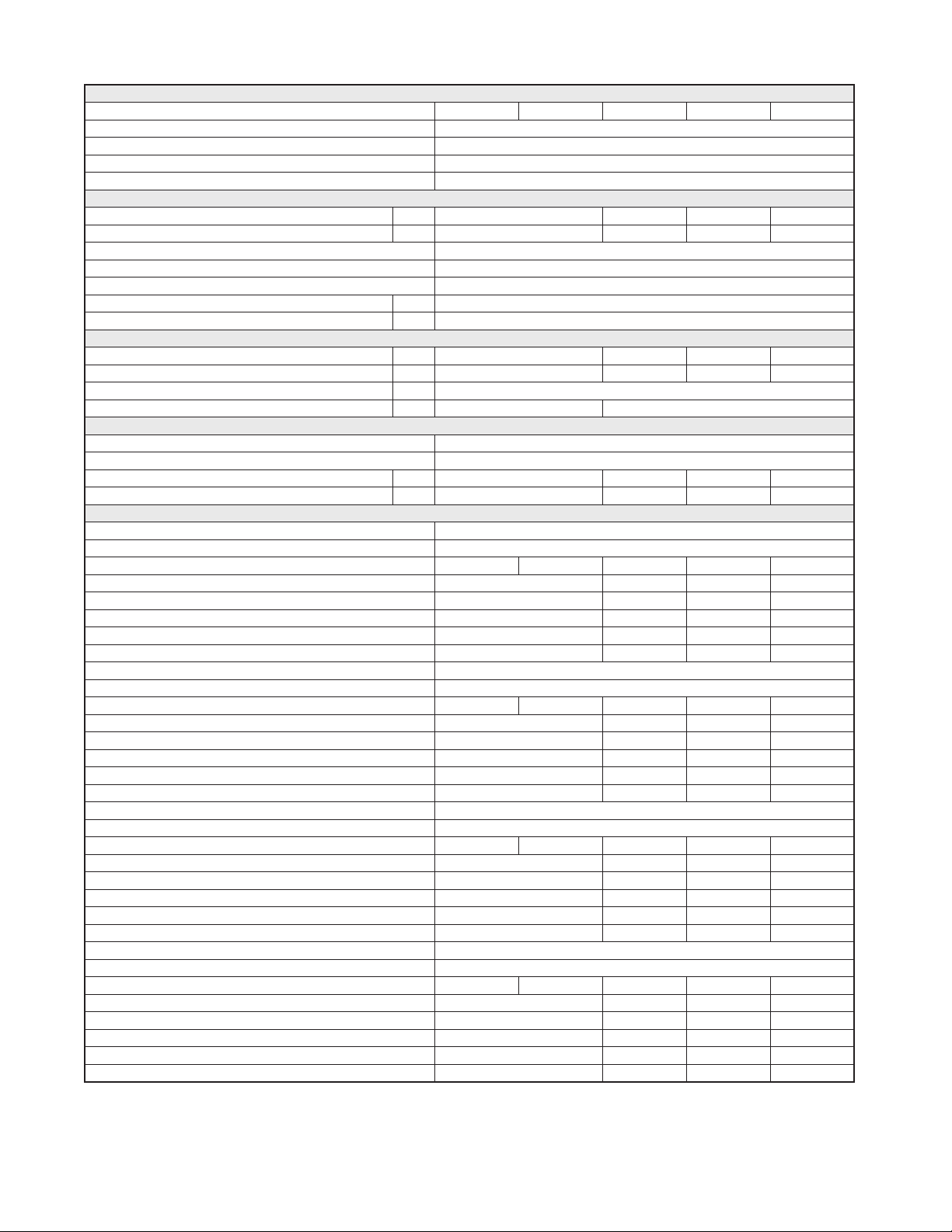

ENGINEERING DATA (MODELS 100-250)

Air System Data

Rated Flow Capacity at 100°F, 100 psig Inlet, 100°F Ambient Temperature 100 125 150 200 250

Maximum / Minimum Inlet Air Pressure (compressed air at inlet to dryer) 232 psig (16 barg) / 30 psig (2 barg)

Maximum / Minimum Inlet Air Temperature (compressed air at inlet to dryer) 120°F (49°C) / 40°F (4°C)

Maximum / Minimum Ambient Temperature 110°F (43°C) / 40°F (4°C)

Outlet Air Temperature (nominal at rated conditions) 85°F (29°C)

Refrigeration System Data

Refrigeration Capacity @ 35°F Evaporator & 100°F Ambient (BTU/hr) 60 Hz 4820 7130 8900 15200

50 Hz 4020 7340 7420 12700

Refrigerant Type R-134A

Refrigerant Charge See Data Tag on Dryer

Suction Pressure Setting - Hot Gas Bypass Valve (psig) 30.5 psig (2.1 barg

Compressor Control Ranges (out-in) High N/A 281 - 190 psig (19.4 - 13.1 barg)

Low N/A 22 - 34 psig (1.5 - 2.3 barg)

Air-Cooled Condensers

Air Flow Across Condenser (cfm) (air-cooled models) 60 Hz 300 450 710 1070

50 Hz 250 370 590 890

Condenser Fan Switch Setting (in-out) Fan 1 110 - 70 psig (7.6 - 4.8 barg) 113 - 78 psig (7.8 - 5.4 barg)

Fan 2 N/A

Water-Cooled Condensers

Water Regulating Valve Setting 135 psig (9.3 barg)

Required Available Water Pressure Differential 40 psig (2.8 barg) - minimum

Flow Required with 85°F Cooling Water (gallons per minute) 60 Hz N/A 1.1 2.0

50 Hz N/A 0.9 1.7

Electrical Data

Nominal Voltage 115/1/60 208-230/3/60

Min. - Max. Voltage 104 - 127 187 - 253

Input Power @ Rated Flow (watts) 932 1280 1298 1255 1962

Rated Load Amps** 10.2 13.0 7.5 10.4

Locked Rotor Amps** 51.0 70.0 51.0 66.0

Minimum Circuit Ampacity 13.6 18.0 10.5 15.9

Branch Circuit Fuse Size (amps) 20 25 15 20

Resistance (ohms) 4.3 S / 0.7 R 3.2 S / 0.4 R 1.8 1.3

Nominal Voltage 208-230/1/60 460/3/60

Min. - Max. Voltage 187 - 253 414 - 506

Input Power @ Rated Flow (watts) 932 1280 1298 1255 1962

Rated Load Amps** 5.4 6.5 3.6 4.7

Locked Rotor Amps** 30.0 35.0 25.0 33.0

Minimum Circuit Ampacity 7.3 9.1 5.2 7.5

Branch Circuit Fuse Size (amps) 15 15 15 15

Resistance (ohms) Main/Start 9.0 S / 2.3 R 7.9 S / 1.6 R 7.4 5.0

Nominal Voltage 100/1/50 575/3/60

Min. - Max. Voltage 90 - 110 518 - 633

Input Power @ Rated Flow (watts) 680 1019 991 1255 1962

Rated Load Amps 10.2 13.0 3.6 4.7

Locked Rotor Amps 51.0 70.0 25.0 33.0

Minimum Circuit Ampacity 13.6 18.0 4.2 6.0

Branch Circuit Fuse Size (amps) 20 25 15 15

Resistance (ohms) 4.3 S / 0.7 R 3.2 S / 0.4 R 7.4 5.0

Nominal Voltage 240/1/50 380-420/3/50

Min. - Max. Voltage 216 - 264 342 - 462

Input Power @ Rated Flow (watts) 680 1019 991 1002 1613

Rated Load Amps** 4.5 5.0 3.6 4.7

Locked Rotor Amps** 21.0 30.0 25.0 33.0

Minimum Circuit Ampacity 6.2 7.3 5.2 7.5

Branch Circuit Fuse Size (amps) 15 15 15 15

Resistance (ohms) 19.5 S / 3.3 R 10.5 S / 1.8 R 7.4 5.0

* For 60 Hz, 35°F Evaporator, 100°F Ambient; for 50Hz, 35°F Evaporator, 77°F Ambient

** Compressor Only

11

ENGINEERING DATA (MODELS 300-750)

Air System Data

Rated Flow Capacity at 100°F, 100 psig Inlet, 100°F Ambient Temperature 300 400 500 600 750

Maximum / Minimum Inlet Air Pressure (compressed air at inlet to dryer) 232 psig (16 barg) / 30 psig (2 barg)

Maximum / Minimum Inlet Air Temperature (compressed air at inlet to dryer) 120°F (49°C) / 40°F (4°C)

Maximum / Minimum Ambient Temperature 110°F (43°C) / 40°F (4°C)

Outlet Air Temperature (nominal at rated conditions) 85°F (29°C)

Refrigeration System Data

Refrigeration Capacity @ 35°F Evaporator & 100°F Ambient (BTU/hr) 60 Hz 15200 19200 22000 30500

50 Hz 12700 16000 18300 25400

Refrigerant Type R-134A

Refrigerant Charge See Data Tag on Dryer

Suction Pressure Setting - Hot Gas Bypass Valve (psig) 30.5 psig (2.1 barg

Compressor Control Ranges (out-in) High 281 - 190 psig (19.4 - 13.1 barg)

Low 22 - 34 psig (1.5 - 2.3 barg)

Air-Cooled Condensers

Air Flow Across Condenser (cfm) (air-cooled models) 60 Hz 1070 2470 1680 2170

50 Hz 890 2060 1400 1810

Condenser Fan Switch Setting (in-out) Fan 1 113 - 78 psig (7.8 - 5.4 barg)

Fan 2 N/A 183 - 124 psig (12.6 - 8.6 barg)

Water-Cooled Condensers

Water Regulating Valve Setting 135 psig (9.3 barg)

Required Available Water Pressure Differential 40 psig (2.8 barg) - minimum

Flow Required with 85°F Cooling Water (gallons per minute) 60 Hz 2.0 2.1 4.9 6.8

50 Hz 1.7 1.8 4.1 5.6

Electrical Data

Nominal Voltage 208-230/3/60

Min. - Max. Voltage 187 - 253

Input Power @ Rated Flow (watts) 1999 2031 2680 2910 4120

Rated Load Amps** 10.4 11.4 13.9 22.1

Locked Rotor Amps** 66.0 75.0 88.0 115.0

Minimum Circuit Ampacity 15.9 20.0 19.7 30.4

Branch Circuit Fuse Size (amps) 20 25 30 45

Resistance (ohms) 1.3 1.1 1.0 0.7

Nominal Voltage 460/3/60

Min. - Max. Voltage 414 - 506

Input Power @ Rated Flow (watts) 1999 2031 2680 2910 4120

Rated Load Amps** 4.7 5.1 7.1 9.6

Locked Rotor Amps** 33.0 40.0 44.0 63.0

Minimum Circuit Ampacity 7.5 9.6 10.4 15.2

Branch Circuit Fuse Size (amps) 15 15 15 20

Resistance (ohms) Main/Start 5.0 4.1 4.0 2.7

Nominal Voltage 575/3/60

Min. - Max. Voltage 518 - 633

Input Power @ Rated Flow (watts) 1999 2031 2680 2910 4120

Rated Load Amps 4.7 5.1 7.1 9.6

Locked Rotor Amps 33.0 40.0 44.0 63.0

Minimum Circuit Ampacity 7.5 7.7 8.3 12.2

Branch Circuit Fuse Size (amps) 15 15 15 20

Resistance (ohms) 5.0 4.1 4.0 2.7

Nominal Voltage 380-420/3/50

Min. - Max. Voltage 342 - 462

Input Power @ Rated Flow (watts) 1622 1667 1992 2040 2860

Rated Load Amps** 4.7 5.1 7.1 9.6

Locked Rotor Amps** 33.0 40.0 44.0 63.0

Minimum Circuit Ampacity 7.5 8.1 10.4 15.2

Branch Circuit Fuse Size (amps) 15 15 15 20

Resistance (ohms) 5.0 4.1 4.0 2.7

* For 60 Hz, 35°F Evaporator, 100°F Ambient; for 50Hz, 35°F Evaporator, 77°F Ambient

** Compressor Only

12

COMPRESSOR HARNESS

PE

T2

T1

FAN 1 HARNESS

IO

PE

GROUND

STUD

L2

L1

L2

230 VAC

CUSTOMER SUPPLIED

L1 PE

PILOT LIGHT

POWER ON

T2

T2

T2

T1

T1

A

PE

T2

T1 T1

FPS 1

FAN 1

MTR2

START RELAY

SR

SR

L3

L3

M6

5

S

CAPACITOR

4

OVERLOAD

31 3

MTR1

COMPRESSOR

R

C

S

POWER CORD SUPPLIED

120 VAC

WIRING DIAGRAM

Model 100: 120/230 VAC

13

WIRING DIAGRAM

Models 125-150: 120/230 VAC

RC - RUN CAPACITOR

SC - START CAPACITOR

SR - START RELAY

COMPRESSOR CONTACTOR

POWER ON

PILOT LIGHT

CONT 1

PE

PE

L1

CONT 1

6

L2

GROUND STUD

L2

L1

PE

230 VAC

CUSTOMER SUPPLIED

L1 L2

L2

L2

L1

L2

L1

L1

T2

T2

T1

T1

CONT 1

L1

N

4

5 5

A

PE

6

FAN 1 HARNESS

HEATER HARNESS

PE

L2

T2

T1 FPS 1

H1 H2

HEATER 1

MTR2 FAN 1

COMPRESSOR HARNESS

PE

1

C

4

COMPRESSOR

MTR1

120 VAC

POWER CORD SUPPLIED

-2NC

-1NC

L3

L2

L1

T3

T2

T1

O I

A1

SR

A2

C

R

S

RC

SC

1 2 5

14

COMPRESSOR

Optional Fan

(for 500-600 models only)

TO LINE 22

21

20

18

19

17

16

15

14

13

L1 L3

L2 CONT 1

-1NC

PE

HEATER HARNESS

-2NC 1L2

L3

TB2

TB2

PE

T3

T2

H1 H2

HEATER 1

FAN 2 HARNESS

FPS 2

MTR3 FAN 2

REF SHEET 02 LINE 11

REF SHEET 02 LINE 10

REF SHEET 01 LINE 20

03

10

11

12

09

08

07

06

05

04

L3

L3

L3

L2

L2

L3

L2

T3

T2

02

01

00

PETB1 L1 L2 L3

L1

L1

460 VAC

3 PHASE 60 Hz

L1 L2 L3

L1

CONT 1

T1

PE

TB2

T1

T2

T3

T3

T2

T3

TB2

PE

T2

T3

T2

FAN 1 HARNESS

FPS 1

MTR2 FAN 1

MTR1

T1

T1

T1

COMPRESSOR HARNESS

TO SHEET 02

43

42

X

40

41

39

38

37

36

35

TO SHEET 02

N

XF

25

(4 Terminal Blocks)

TB2

32

33

34 X

31

30

X

29

28

27

26

X1

FU3

X3

X2

FU2

H6 H5

FU1

H4 H3 H2 H1

FROM LINE 21

L3

24

23 L1

22 L3

L1

L3

L1

(4 Terminal Blocks)

FACTORY SET TO 460V

N

460V

575V

400V

H6

H6

H6

TB2

N

H2

H1

H3

L2

230V

208V

H6

H6

L1

H4

H5

WIRING DIAGRAM

Models 200-600, (460 VAC)

Sheet 1 of 2

15

Drain Alarm #2 Input

13 21

W36

W28

W37

W34

W32

W30

FMD #1 In (RJ-11)

FMD #2 In (RJ-11)

J2 RS-232

RED

BLACK

WHITE

22

21

20

19

18

17

16

15

14

W38

Evaporator Thermistor

Evaporator Thermistor

Phase B xfmr Input

Phase A xfmr Input

Phase Com. xfmr Input

W4

N/A

N/A W7

W6

W5

N/A

W35

Gnd. (W28 thru W32)

Remote/Local Input

Remot Start/Stop Input

N/A

N/A

W33

W31

N/A

N/A

N/A

W29

W12

30

37

35

36

34

35

34

33

32

31

TCI

TB2

TB2

25

29

28

27

26

28

27

26

24

23

22

23

22

TB2

28

26

27

EMM INSTRUMENT BOARD

W20

W24

W26

W22

12

11

10

09

07

08

06

05

04

Gnd (W8 thru W14)

Drain Alarm #1 Input

Low Pressure Sw. Input

Heater #1 ON Input

High Pressure Sw. Input

Alarm A Com.

Compressor #1 ON Input

Alarm A N/C

Alarm A N/O

W15

W13

W14

W11

W10

W9

W8

W21

W19

Alarm B N/C

Alarm B Com.

Drain Test Output

Alarm B N/O

Drain Test Output

Compressor #1 Output

Compressor #1 Output

W27

W18

W17

W16

N/A

N/A W25

W23

FROM SHEET 01

01

03

02

00

Chassis Gnd.

TB2

X

24VAC IN

24VAC IN W3

W2

W1

X

TB2

3X

REMOVE JUMPER IF OPTIONAL DRAIN INSTALLED

-4NO

TB2

TB2

TB2

TB2

TB2

19

20

21

18

17

19

20

21

18

17

14

16

15

13

12

14

16

15

13

12

16 TB2

TB2

TB2

20

18

19

17

TB2

TB2

14

12

15 15

13

TB2

TB2

TB2

10

11

9

8

10

11

9

8

7

6

4

5

7

4

TB2

TB2

10

8

11

9

TB2

4

7

X

-3NO

CONT 1 19

16 -1NC

20

19

18

17

CONT 1 -2NC 19

4

8

7

BLU

TB2

CONNECTOR

PE

2

1

PE

2

1

PE

BRN

RED BRN

F1

LOAD

LINE WHITE

PE

BLU

TERMINAL BLOCK LAYOUT

TB2

19

18

19

TB2

HPS/LPS SENSOR HARNESS

17

19

HPS

TB1

LPS

HPS

L1 L1

8

X

X

4

N

X

X

N

N

N

4

4

4

8

7

7

19

15

11

10

9

14

13

12

18

17

16

19

19

19

26

21

20

28

27

PE

PE

PE

PE

L3

L2

PE

L3

L2

PE

4

6

3

1

1

3

6

4

TB2

19

TB2 PE

OPTIONAL DRAIN

DRAIN 2 HARNESS

X

N

20

19

7

8

5

3

2

8

7

19

20

N

X

5

3

2

DRAIN 1 HARNESS

4

24VAC

ALM

TEST

TEST

ALM

24VAC

CONTACTOR

COMPRESSOR

CONT 1

A1 A2 N

FROM SHEET 01

TB2 N

BLACK

WHITE

(Mounted in Enclosure)

DB9 MALE CONNECTOR

3

89

5

RED

4

67

21

WIRING DIAGRAM

Models 200-600, (460 VAC)

Sheet 2 of 2

16

COMPRESSOR

TO LINE 22

21

20

18

19

17

16

15

14

13

L1 L3

L2

CONT 1

-1NC

PE

HEATER HARNESS

-2NC 1L2

L3

TB2

TB2

PE

T3

T2

H1 H2

HEATER 1

FAN 2 HARNESS

FPS 2

MTR3 FAN 2

REF SHEET 02 LINE 11

REF SHEET 02 LINE 10

REF SHEET 01 LINE 20

03

10

11

12

09

08

07

06

05

04

L3

L3

L3

L2

L2

L3

L2

T3

T2

02

01

00

PE

L1

L1

L1

L2

L3

460 VAC

3 PHASE 60 Hz

TB1 L1 L3L2

L1

CONT 1

T1

DISCONNECT SWITCH

PE

TB2

T1

T2

T3

T3

T2

T3

TB2

PE

T2

T3

T2

FAN 1 HARNESS

FPS 1

MTR2 FAN 1

MTR1

T1

T1

T1

COMPRESSOR HARNESS

TO SHEET 02

43

42

X

40

41

39

38

37

36

35

TO SHEET 02

N

XF

25

(4 Terminal Blocks)

TB2

32

33

34 X

31

30

X

29

28

27

26

X1

FU3

X3

X2

FU2

H6 H5

FU1

H4 H3 H2 H1

FROM LINE 21

L3

24

23 L1

22 L3

L1

L3

L1

(4 Terminal Blocks)

FACTORY SET TO 460V

N

460V

575V

400V

H6

H6

H6

TB2

N

H2

H1

H3

L2

230V

208V

H6

H6

L1

H4

H5

WIRING DIAGRAM

Model 750, (460 VAC)

Sheet 1 of 2

17

Drain Alarm #2 Input

13

21

W36

W28

W37

W34

W32

W30

FMD #1 In (RJ-11)

FMD #2 In (RJ-11)

J2 RS-232

RED

BLACK

WHITE

22

21

20

19

18

17

16

15

14

W38

Evaporator Thermistor

Evaporator Thermistor

Phase B xfmr Input

Phase A xfmr Input

Phase Com. xfmr Input

W4

N/A

N/A W7

W6

W5

N/A

W35

Gnd. (W28 thru W32)

Remote/Local Input

Remot Start/Stop Input

N/A

N/A

W33

W31

N/A

N/A

N/A

W29

W12

30

37

35

36

34

35

34

33

32

31

TCI

TB2

TB2

25

29

28

27

26

28

27

26

24

23

22

23

22

TB2

28

26

27

EMM INSTRUMENT BOARD

W20

W24

W26

W22

12

11

10

09

07

08

06

05

04

Gnd (W8 thru W14)

Drain Alarm #1 Input

Low Pressure Sw. Input

Heater #1 ON Input

High Pressure Sw. Input

Alarm A Com.

Compressor #1 ON Input

Alarm A N/C

Alarm A N/O

W15

W13

W14

W11

W10

W9

W8

W21

W19

Alarm B N/C

Alarm B Com.

Drain Test Output

Alarm B N/O

Drain Test Output

Compressor #1 Output

Compressor #1 Output

W27

W18

W17

W16

N/A

N/A W25

W23

FROM SHEET 01

01

03

02

00

Chassis Gnd.

TB2

X

24VAC IN

24VAC IN W3

W2

W1

X

TB2

3X

REMOVE JUMPER IF OPTIONAL DRAIN INSTALLED

-4NO

TB2

TB2

TB2

TB2

TB2

19

20

21

18

17

19

20

21

18

17

14

16

15

13

12

14

16

15

13

12

16 TB2

TB2

TB2

20

18

19

17

TB2

TB2

14

12

15 15

13

TB2

TB2

TB2

10

11

9

8

10

11

9

8

7

6

4

5

7

4

TB2

TB2

10

8

11

9

TB2

4

7

X

-3NO

CONT 1 19

16 -1NC

20

19

18

17

CONT 1 -2NC 19

4

8

7

BLU

TB2

CONNECTOR

PE

2

1

PE

2

1

PE

BRN

RED BRN

F1

LOAD

LINE WHITE

PE

BLU

TERMINAL BLOCK LAYOUT

TB2

19

18

19

TB2

HPS/LPS SENSOR HARNESS

17

19

HPS

TB1

LPS

HPS

L1 L1

8

X

X

4

N

X

X

N

N

N

4

4

4

8

7

7

19

15

11

10

9

14

13

12

18

17

16

19

19

19

26

21

20

28

27

PE

PE

PE

PE

L3

L2

PE

L3

L2

PE

4

6

3

1

1

3

6

4

TB2

19

TB2 PE

OPTIONAL DRAIN

DRAIN 2 HARNESS

X

N

20

19

7

8

5

3

2

8

7

19

20

N

X

5

3

2

DRAIN 1 HARNESS

4

24VAC

ALM

TEST

TEST

ALM

24VAC

CONTACTOR

COMPRESSOR

CONT 1

A1 A2 N

FROM SHEET 01

TB2 N

BLACK

WHITE

(Mounted in Enclosure)

DB9 MALE CONNECTOR

3

89

5

RED

4

67

21

WIRING DIAGRAM

Model 750, (460 VAC)

Sheet 2 of 2

18

WIRING DIAGRAM

Models 200-750, 575-460/3/60 Transformer Pack

19

DIMENSIONS / WEIGHTS

NOTE: Dimensions and Weights are for reference only. Request certified drawings for construction purposes.

FRONT VIEW

BOTTOM VIEW

RIGHT SIDE VIEW

BACK VIEW

DETAIL A

A

“B”

“A”

“D”

“E” “F”

“G”

“H”

“I” “J”

“C”

Ø “K” MOUNTING HOLE

4-PLACES TYP.

“L” - I/O CONNECTIONS

2.500

CONDENSER AIR FLOW

6-FT (1.8 Meters) POWER CORD

MODELS 100-150 (115 VOLT)

ELECTRICAL ENTRY

MODELS 100-150 (230 VOLT)

0.25-NPT DRAIN CONNECTION

MODELS 100-150

ELECTRICAL ENTRY

MODELS 200-750

RS-232 ACCESS

MODELS 200-750

0.25-NPT DRAIN CONNECTION

MODELS 200 - 600

0.25-NPT DRAIN CONNECTION

MODEL 750 ONLY “N”

“M”

“O” 1/2-18 FPT I/O WATER CONNECTIONS

MODELS 200 - 750 ONLY

Dimensions, inches (mm)

Model 100 125 150 200 250 300 400 500 600 750

A 37.56 (954) 37.56 (954) 37.56 (954) 38.60 (980) 38.60 (980) 45.38 (1153) 45.38 (1153) 58.06 (1475) 58.06 (1475) 58.06 (1475)

B 25.62 (651) 25.62 (651) 25.62 (651) 32.15 (817) 32.15 (817) 32.15 (817) 32.15 (817) 32.15 (817) 32.15 (817) 32.15 (817)

C 1.63 (41) 1.63 (41) 1.63 (41) 1.88 (48) 1.88 (48) 2.63 (67) 2.63 (67) 2.77 (70) 2.77 (70) 2.77 (70)

D 23.62 (600) 23.62 (600) 23.62 (600) 30.15 (766) 30.15 (766) 30.15 (766) 30.15 (766) 30.15 (766) 30.15 (766) 30.15 (766)

E 17.62 (448) 17.62 (448) 17.62 (448) 30.15 (766) 30.15 (766) 30.15 (766) 30.15 (766) 39.62 (1006) 39.62 (1006) 39.62 (1006)

F 19.62 (498) 19.62 (498) 19.62 (498) 32.15 (817) 32.15 (817) 32.15 (817) 32.15 (817) 41.62 (1057) 41.62 (1057) 41.62 (1057)

G 9.58 (243) 9.58 (243) 9.58 (243) 7.64 (194) 7.64 (194) 13.51 (343) 16.25 (413) 20.44 (519) 20.44 (519) 20.44 (519)

H 14.96 (380) 14.96 (380) 14.96 (380) 15.80 (401) 15.80 (401) 21.82 (554) 25.68 (652) 27.79 (706) 27.79 (706) 27.79 (706)

I 28.54 (725) 28.54 (725) 28.54 (725) 30.19 (767) 30.19 (767) 29.98 (761) 36.89 (937) 49.06 (1246) 49.06 (1246) 49.06 (1246)

J 25.02 (636) 25.02 (636) 25.02 (636) 26.04 (661) 26.04 (661) 25.74 (654) 32.82 (833) 44.78 (1137) 44.78 (1137) 44.78 (1137)

K 0.31 (7.9) 0.31 (7.9) 0.31 (7.9) 0.31 (7.9) 0.31 (7.9) 0.31 (7.9) 0.31 (7.9) 0.63 (16) 0.63 (16) 0.63 (16)

L 1 MPT 1 MPT 1 MPT 1.5 MPT 1.5 MPT 1.5 MPT 2 MPT 2.5 MPT 2.5 MPT 2.5 MPT

M N/A N/A N/A 4.56 (116) 4.56 (116) 4.56 (116) 4.56 (116) 4.81 (122) 4.81 (122) 4.81 (122)

N N/A N/A N/A 9.84 (250) 9.84 (250) 9.84 (250) 9.84 (250) 20.82 (529) 20.82 (529) 20.82 (529)

O N/A N/A N/A 3.13 (80) 3.13 (80) 3.13 (80) 3.13 (80) 3.13 (80) 3.13 (80) 3.13 (80)

Weight

lbs (kg) 251 (114) 273 (124) 279 (127) 425 (193) 463 (210) 527 (239) 571 (259) 684 (310) 691 (313) 734 (333)

20

TROUBLESHOOTING GUIDE (MODELS 100-150)

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

A) Water downstream of dryer 1. Residual free moisture remaining in

downstream pipelines

2. Air bypass system is open

3. Inlet and Outlet connections are reversed

4. Airlinesdownstreamofdryerareexposed

to temperatures below the dew point.

5. Excessivefreemoisture(bulkliquid)at

dryer inlet.

6. Condensate not being drained

Drain mechanism is clogged or

inoperative.

Drainlineisrestrictedorfrozen.

Electric drains-timer not set to allow for

sufficient condensate removal.

7. Dryer overloaded resulting in elevated

dew point.

8. Refrigeration system not functioning

Blow out system with dry air

Check valve positions

Check for correct connection

Insulateorheattraceairlinesexposedtolow

ambients or dry air to lower dew point

Install separator ahead of dryer

Replace drain mechanism if inoperative.

Open drain line.

Electric drains-reset time so that all liquid is

discharged

Check inlet air temperature and pressure,

flow rate (compressor capacity) and ambient

air or water temperature.

See D below

B) High pressure drop across dryer 1. Excessiveairow

2. Freezingofmoistureinevaporator

because of refrigeration system fault

3. Separator filter element clogged

Check flow rate

See D below

Replace filter element

C) Dew point indicator in red area 1. Dryer overloaded resulting in high air

outlet temperature

2. Refrigeration system not functioning

properly resulting in high air outlet

temperature

See A 7

See D below

D) Refrigeration system not

functioning properly

1. Power on light off

2. Refrigeration compressor cycles

on and off

a. Power failure

b. Line disconnect switch open

c. Blown fuses, open breaker

d. Faulty wiring, loose terminals

a. High or low ambient conditions

b. Air-cooled - Dirty, clogged condenser fins,

obstructed flow across condenser, faulty

fan motor or fan control switch.

Check for power to unit

Close disconnect switch

Check for continuity

Have electrician check electrical connections.

Checkmin./max.temperatureranges

Clean condenser and check for free air

flow, if problem persists contact qualified

refrigeration repairman or manufacturer’s

service department.

This manual suits for next models

10

Table of contents

Other SPX Dehumidifier manuals

SPX

SPX HPD Series User manual

SPX

SPX Hankison HPRplus Series User manual

SPX

SPX Pneumatic Products IBP500 User manual

SPX

SPX HCD Series User manual

SPX

SPX RDH-HP Series User manual

SPX

SPX HANKISON HES Series User manual

SPX

SPX Hankison GCU Series User manual

SPX

SPX HANKISON HIT Series User manual

SPX

SPX DELAIR QD 90 User manual

Popular Dehumidifier manuals by other brands

ecozone

ecozone Dehumidier user manual

International Refrigeration Products

International Refrigeration Products DH470 user manual

Kenmore

Kenmore 25851 owner's manual

GEAppliances

GEAppliances ADEL30 owner's manual

Timco Tools

Timco Tools 102611934 Operation manual

Ingersoll-Rand

Ingersoll-Rand TZ730 user manual