SPX HANKISON HES Series User manual

SERVICE DEPARTMENT: (724) 746-1100

5006820 Rev. A 5/10

INSTRUCTION MANUAL

HES Series

Models: HES90, HES120, HES140, HES190,

HES240, HES280, HES360, HES450,

HES540, HES675

REFRIGERATED

TYPE

COMPRESSED

AIR DRYERS

CONTENTS

GENERAL SAFETY INFORMATION .................................... 2

RECEIVING, MOVING, AND UNPACKING .......................... 2

1.0 INSTALLATION........................................................... 3

2.0 DRYER OPERATION .................................................. 5

3.0 MAINTENANCE ........................................................ 9

SIZING.............................................................................. 9

ENGINEERING DATA

MODELS 90-240 .......................................................... 10

MODELS 280-675 ........................................................ 11

WIRING DIAGRAMS - STANDARD CONTROLLER

MODELS 90-140: 115/1/60 ......................................... 12

MODELS 90-140: 230/1/60 ......................................... 13

MODELS 190-540 ........................................................ 14-15

MODEL 675 ................................................................. 16-17

WIRING DIAGRAMS - ADVANCED CONTROLLER

MODELS 190-540 ........................................................ 18-19

MODEL 675 ................................................................. 20-21

WIRING DIAGRAM: 575-460/3/60 TRANSFORMER PACK

MODELS 190-675 ........................................................ 22

DIMENSIONS / WEIGHTS.................................................. 23

TROUBLESHOOTING GUIDE

STANDARD CONTROLLER: MODELS 90-675................. 24

ADVANCED CONTROLLER: MODELS 190-675 .............. 25

PARTS LIST....................................................................... 26

WARRANTY ..................................................................... 28

2

GENERAL SAFETY INFORMATION

1. PRESSURIZED DEVICES:

This equipment is a pressure

containing device.

• Donotexceedmaximumoperating

pressure as shown on equipment

serial number tag.

• Makesureequipmentisdepressurizedbefore

workingonordisassemblingitforservice.

2. ELECTRICAL:

This equipment requires electricity to

operate.

• Installequipmentincompliancewith

all applicable electrical codes.

• Standardequipmentissuppliedwithelectrical

enclosuresnotintendedforinstallationinhazardous

environments.

• Disconnectpowersupplytoequipmentwhen

performinganyelectricalservice

work.

3. BREATHING AIR:

• Airtreatedbythisequipmentmay

notbesuitableforbreathingwithout

furtherpurication.

Refertoapplicablestandardsandspecicationsfor

therequirementsforbreathingqualityair.

RECEIVING, MOVING, AND UNPACKING

A. RECEIVING

Thisshipmenthasbeenthoroughlychecked,packed

andinspectedbeforeleavingourplant.Itwas

received in good condition by the carrier and was so

acknowledged.

CheckforVisibleLossorDamage.Ifthisshipment

showsevidenceoflossordamageattimeofdelivery

toyou,insistthatanotationofthislossordamagebe

made on the delivery receipt by the carrier’s agent.

B. UNPACKING

Checkforconcealedlossordamage.Whena

shipment has been delivered to you in apparent

goodorder,butconcealeddamageisfoundupon

unpacking,notifythecarrierimmediatelyandinsist

on his agent inspecting the shipment. Concealed

damage claims are not our responsibility as our terms

areF.O.B.pointofshipment.

C. MOVING

In moving or transporting dryer, do not tip dryer onto

its side.

D. STORAGE/SHUT DOWN

Dryer should not be stored outside (either

packedorunpacked)orexposedtotheweather.Damage

to electrical and control components may result.

IMPORTANT: WATER-COOLEDUNITS-Ifunitisshutdown

inbelow-freezingtemperatures,thewater-cooled

condensermayfreezeandcausepermanentdamage.

Condenser must be drained when the unit is shut down.

IMPORTANT: Do not store dryer in temperatures above

130°F(54.4°C)orbelow20°F(-7°C).

3

IMPORTANT: READ PRIOR TO STARTING THIS EQUIPMENT

1.0 INSTALLATION

1.1 Location

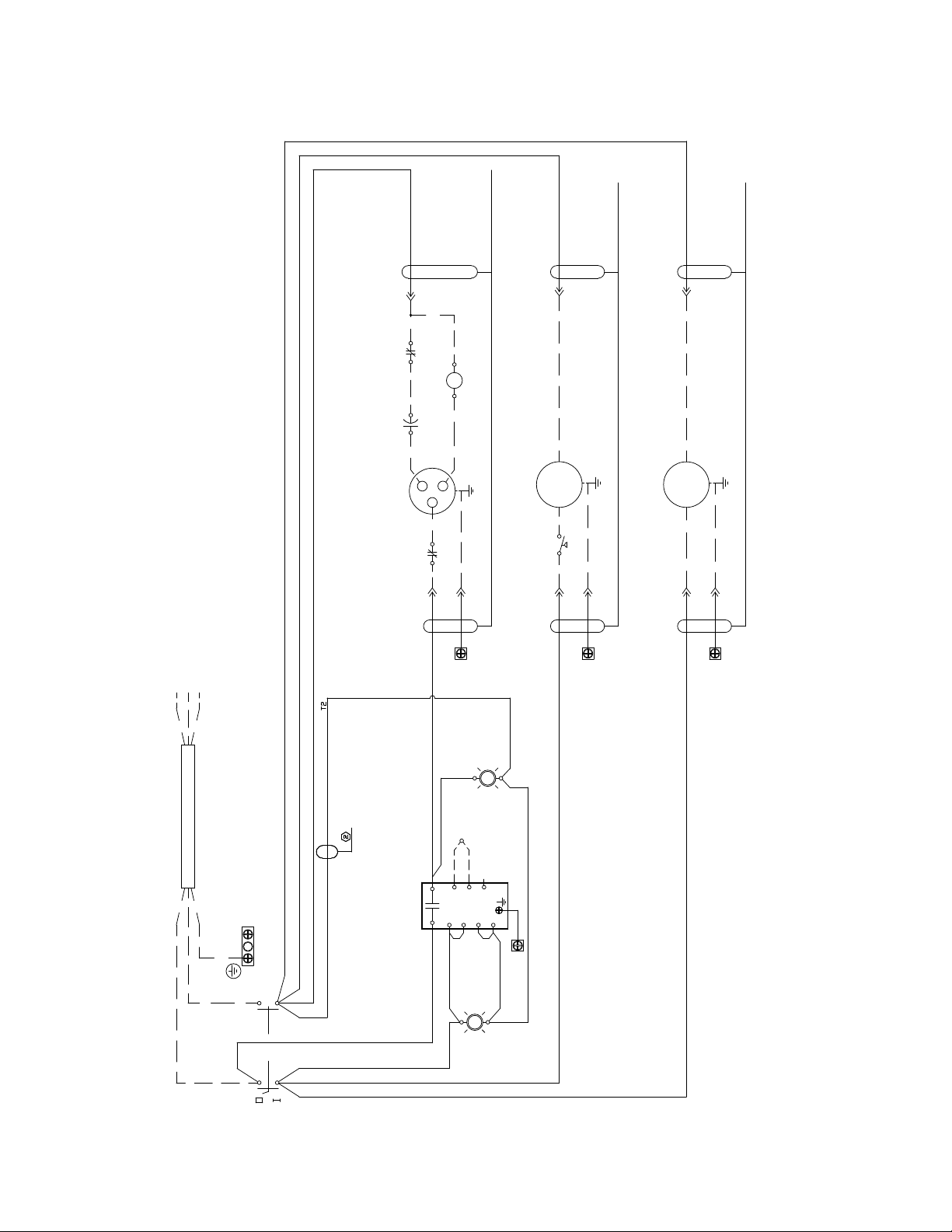

A. For typical placement in a compressed air system, see

drawing.

B. Aircompressorintake–Locateaircompressorsothat

contaminantspotentiallyharmfultothedryer(e.g.

ammonia)arenotdrawnintotheairsystem.

C. Clearances Free air flow

Front36inches(914mm)

Back6inches(152mm)

Sides36inches(914mm)

Service-Tofacilitatemaintenanceleave36inches

(914mm)ofclearanceinfrontofdryer.

D. Standard units are designed to operate in ambients:

Air-cooled:40to110°F(4to43°C).

Water-cooled:40to130°F(4to54°C).

E. Theinstallationofaexibleconnectionpriortothe

dryerisrecommendedtopreventpossibledamagefrom

vibration.

NOTE:Outdoorinstallation–Standardunitsaredesigned

forindoorinstallation.Contactmanufacturerifinstalling

outdoors.

Aftercooler

Separator

Dryer

Oil Removal

Filter

Compressor

Moisture Separator

Float Drain

(Standard)

Coalescing Filter

(Option)

Condenser

Drain Outlet

Electrical Entry

(230 VAC)

Air Outlet

Air Inlet

Control Panel

Models 90, 120, & 140

Electric Demand Drain (EDD)

3-Way Valve

Moisture Separator

Coalescing Filter

(Option)

Control Panel

RS232 Entry

Electrical Entry

Air Outlet

Air Inlet

Condenser

Drain Outlet

Models 190, 240, 280, 360, 450, 540, & 675

4

1.2 Mounting

Mountthedryeronalevelsolidsurface.Holesare

provided in the dryer base to permanently mount the

dryer to the floor.

1.3 Piping connections

A. AirInlet-Connectcompressedairlinefromairsourceto

airinlet.(Referencemarkingsondryerforairinlet/outlet

connectionlocations.)

RefertoSerialNumberTagformaximum

workingpressure.Donotexceeddryer’sMaximumWorking

Pressure.

NOTE: Install dryer in air system at highest pressure

possible(e.g.beforepressurereducingvalves).

NOTE: Install dryer at coolest compressed air temperature

possible.Maximuminletcompressedairtemperature:

130°F(54°C).Ifinletairexceedsthistemperature,precool

theairwithanaftercooler.

B. AirOutlet–Connectairoutlettodownstreamairlines.

C. Bypasspiping–Ifservicingthedryerwithoutinterrupting

the air supply is desired, piping should include inlet and

outlet valves and an air bypass valve.

D. Watercooledmodels–coolingwaterinletandoutlet

1. Connect cooling water supply to cooling water inlet.

2. Connect cooling water return line to cooling water

outlet connection.

NOTE: Strainer and water regulating valve are supplied on

water cooled models.

1.4 Electrical connections

IMPORTANT: Use copper supply wires only.

A. Dryer is designed to operate on the

voltage,phase,andfrequencylistedon

the serial number tag.

B. Ifdryerissuppliedwithacordandplug,installina

receptacleofpropervoltage.

C. Electrical entry on larger dryers is through a hole in the

cabinet.Itislocatedontherightsidepanelwhenfacing

thefrontoftheunit.Connectpowersourcetoterminal

strip in electrical enclosure as shown on the wiring

diagram included with the dryer.

NOTE: The dryer should NOTbewiredtocycleon/offwith

the air compressor.

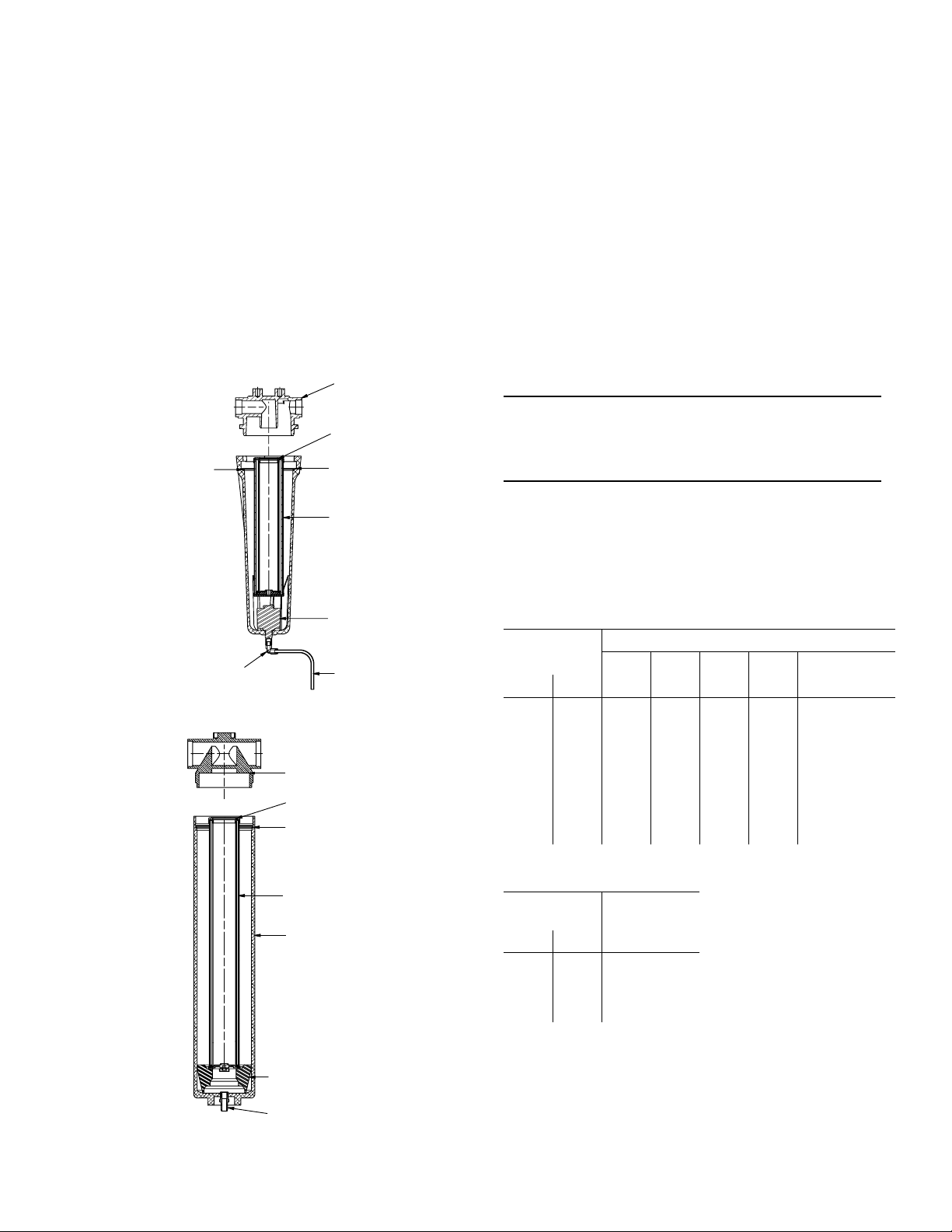

1.5 Moisture separator

A. Models 90-140:

Separator (and Oil Removal Filter where

applicable)hasaninternaldrainwhich

automatically discharges condensate.

Models 190-675:

Separator(andOilRemovalFilterwhereapplicable)has

anelectronicdemanddrain(EDD)whichautomatically

discharges condensate.

NOTE:Itmaybedesirabletopipethecondensatefrom

the Automatic Drain outlet to a suitable drain.

B. Models 90-140:

Separatorhasaknurledttingwithexibledrain

tubingattached.Besureknurledttingistightened

byturningcounter-clockwisebeforeoperatingdryer.

TO CLOSE

TURN COUNTERCLOCKWISE

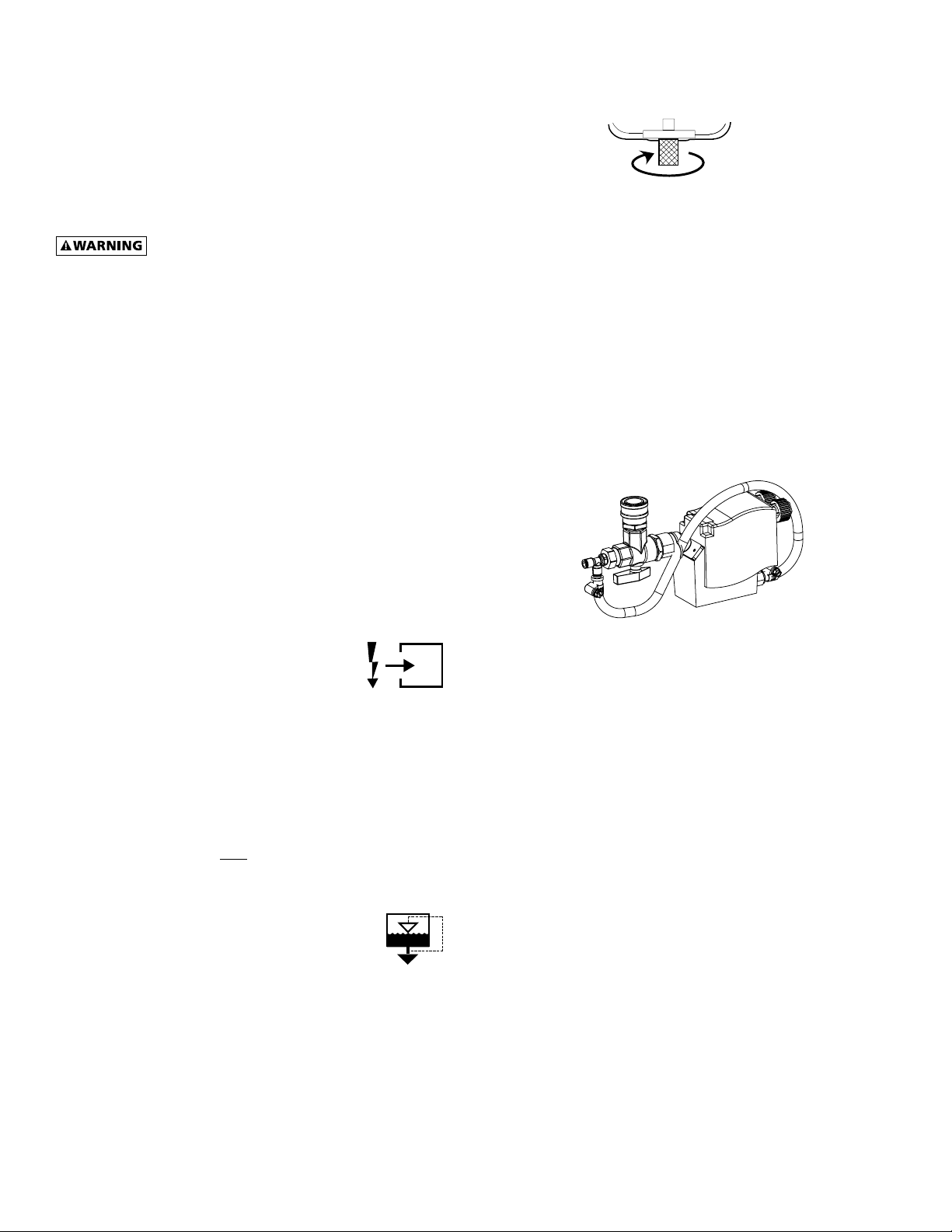

C. Models 190-675

For manual draining, convenient dryer

depressurization,andEDDservice,athree-wayvalve

assemblyhasbeeninstalledatthebottomofthe

moistureseparator(andcoldcoalescinglterwhere

applicable).Reviewthefollowingforproperdrain

function:

• AutomaticDraining-Valvehandleshouldbe

positionedparalleltothevalvebody(asshown),with

the arrow on the handle pointing toward the EDD.

Inthisposition,condensatewillowfromthebowl

to the EDD.

• DrainIsolation(Shutdown)-Valvehandleshallbe

turnedperpendiculartothevalvebody(rotate90°).

Inthisposition,condensateowisshutoff.

• ManualDraining-Drainvalvehandleshallberotated

slightly past the drain isolation position to allow

throttlingthroughthevalveformanualdischarge

anddepressurization.

• Note:Thequickdisconnectttingallowsremoval

oftheentiredrainassembly.However, the unit

must be depressurized prior to disassembly or

serious injury may occur.

NOTE: Discharge is at system pressure. Drain line should

be anchored.

NOTE: Condensate may contain oil. Comply with

applicable laws concerning proper disposal.

1.6 EDD Operation

A. Verifythatisolationvalvesareopen.Ifthedrainfailsto

dischargeafterthevalveisenergized,theelectronic

controlcircuitwillrepeatedlyenergizethevalveinan

attempttoclearthedischargeport.If,after60seconds,

thedrainstillfailstodischarge,thecontrolcircuitthen

switches to the alarm mode. In this mode the valve is

de-energizedandtheredalarmlightisactivatedonthe

drain.Thevalveisthenautomaticallyenergizedevery4

minutesfor5seconds.Checkthedrainoperation.Push

drain(push-to-test)buttononthedrainortheElectronic

Controller(ifequipped)toenergizedrain.Aowof

condensate and/or air should be present at the drain

outlet.Thealarmmodeautomaticallyclearsafterthe

drain returns to normal operation.

5

B. Condensate enters the reservoir (1) through the inlet

port. When the condensate level in the reservoir covers

the capacitance sensor, an electronic signal is sent to the

solid state countdown processor. The processor delays

theopeningofthesolenoidvalveforagivenperiod

oftime.Oncethetimehaselapsed,thesolidstate

processortransmitsinformationtoenergizethecoilin

the solenoid valve (2).Themagneticforceofthecoil

causes the solenoid core (3) to move, closing the pilot air

supplylineandopeningthepilotairexhaustline.After

the pilot air above the diaphragm (4) is vented, pressure

inthereservoiropensthedischargeportandforces

the condensate through the discharge port and outlet

piping.

2.0 DRYER OPERATION

BasicTheoryofOperation:Thisenergysavingsdryer

operatesusingaglycol/airheatexchangertoabsorb

heatfromtheairstream.Arefrigerationcompressoris

usedtocooltheglycolmixtureandwhenthedryerload

isreduced,theexcesscoolingfromthecompressoris

usedtolowerthetemperatureoftheglycol.Whenthe

glycol reaches a minimum temperature, the compressor is

turnedofftosaveenergy.Thedryercontinuestooperate

byusingtheglycolmixturetocooltheairstreamuntilthe

glycolreachesamaximumtemperaturesetpointatwhich

time the compressor again turns on to cool the glycol

mixture.

2.1 Minimum/Maximum operating conditions

A. Maximuminletairpressure:refertodryerserialnumber

tag

B. Minimuminletairpressure:30psig(2.1kgf/cm

2

)

C. Maximuminletairtemperature:130°F(54°C)

D. Maximumambienttemperature:

Air-cooledmodels:110°F(43°C)

Water-cooledmodels:130°F(54°C)

E. Minimumambienttemperature:40°F(4°C)

2.2 Start-up

A. Models 90-140: Standard Controller

Energizecompressorbypositioningtheon/offswitch

intheon(I)position.Poweronlightwillilluminate.

Compressor on light will illuminate. Compressor will

rununtilglycolmixtureiscooled.Therefrigerationunit

willthenturnoff,andthecompressoronlightwillbe

extinguished.

SLOWLYpressurizethedryerwithcompressedair.Fully

open the inlet and outlet valves. Dryer will operate

automatically and the compressor will cycle in response

to the air load.

On/Off DryerOn Dewpoint CompressorOn

Switch Light Indicator Light

B. Models 190-675: Standard Controller

Energizedryerbyapplyingpowertotheunit.Thegreen

dryerenergizedlightwillilluminate.

NOTICE: Energize dryer for 24 hours prior to starting

refrigerationcompressor!Failuretofollowthesenotices

mayresultinanon-warrantablecompressorfailure.

Energizecompressorbypositioningtheon/offswitch

intheon(I)position.Poweronlightwillilluminate.

Compressor on light will illuminate. Compressor will

rununtilglycolmixtureiscooled.Therefrigerationunit

willthenturnoff,andthecompressoronlightwillbe

extinguished.

NOTE:Checkforcorrectphasingofunit.

Onair-cooledmodels:checkfanrotation(airmustbe

pulledthroughthecondenser).Fansmaynotstart

immediatelyormaycycleonandoff.Ifrotationisinthe

wrongdirectionfollowtheprocedurebelow.

Onwater-cooledmodels:Afterstartingdryerifan

unusual noise is heard and the discharge line does not

get hot, stop the dryer, reverse two power leads, restart,

andverifydischargelinegetshot.

SLOWLYpressurizethedryerwithcompressedair.Fully

open the inlet and outlet valves. Dryer will operate

automatically and the compressor will cycle in response

to the air load.

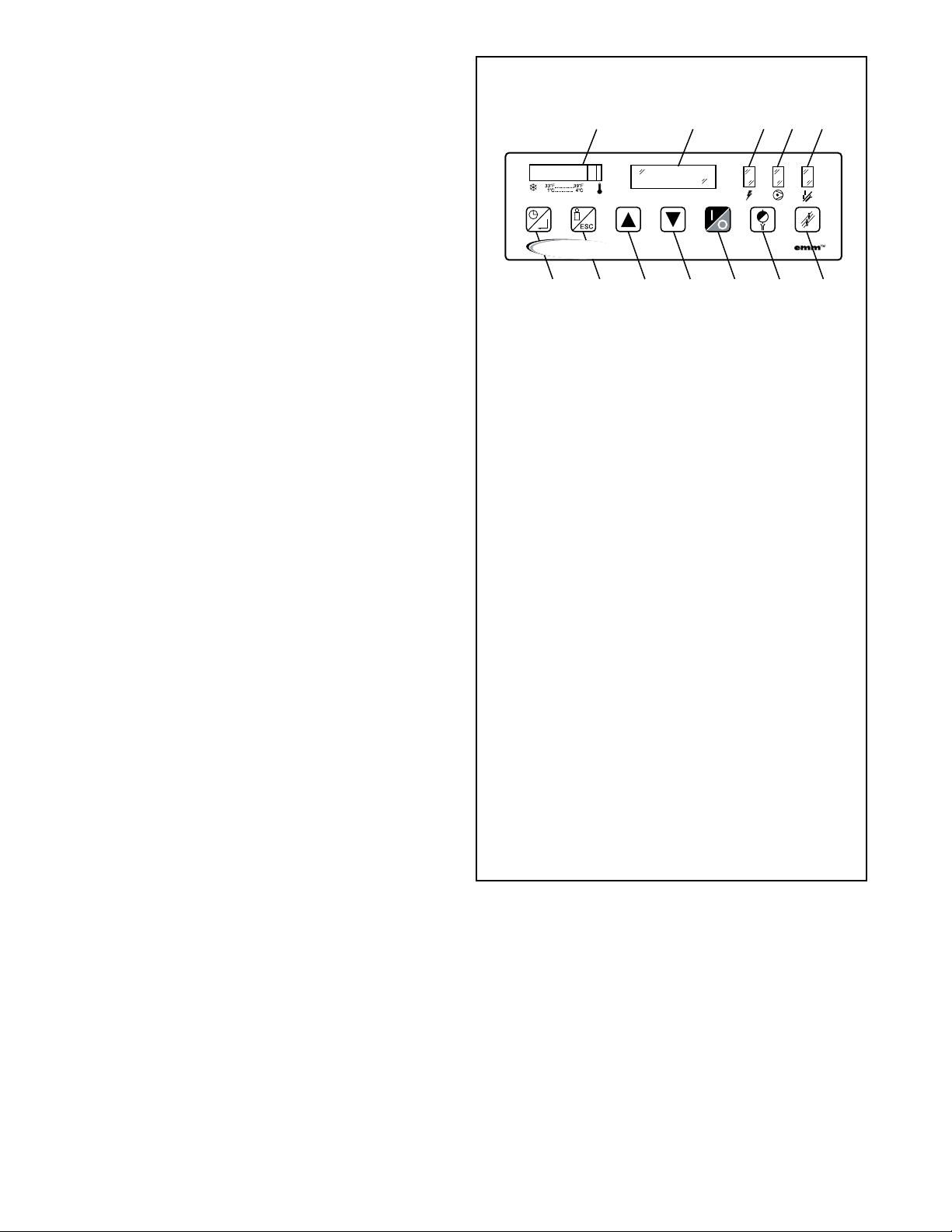

On/Off Power-On Dewpoint Dryer Compressor

Switch Light Indicator Energized On

Light Light

C. Models190-675:AdvancedController(EMM)

Energizedryer.Greenpoweronlightwillilluminate.

NOTICE: Energize dryer for 24 hours prior to starting

refrigerationcompressor!Failuretofollowthesenotices

mayresultinanon-warrantablecompressorfailure.

NOTICE:Donotusedisconnectswitchtoremovepowerfrom

dryerforextendedperiodsexceptfordryerrepair.

1

2

3

4

6

D. AdvancedController(EMM)Setup

Press and hold Program Mode button until Main Menu

appears. Use the Up and Down arrow buttons to scroll

through the menu choices. Press Enter button in order

todisplaytheselectedmenuitem.PressESCtoexitthe

Main Menu and return to Display mode.

1. Language selection

a. Use the ‘Up’ and ‘Down’ arrow buttons to scroll

through available languages.

b. Press ‘Enter’ button to apply the current language

selection.

c. Push ‘ESC’ button to return to the Main Menu.

2. Setting Date & Time

a. Use the ‘Up’ and ‘Down’ arrow buttons to change

theselectedeld.Press‘Enter’buttontoaccept

newvalueandmovetothenexteld.

b. Push ‘ESC’ to return to the Main Menu.

NOTE: The selected value is indicated by a ‘_’.

3. Setting Schedule

a. Use the ‘Up’ and ‘Down’ arrow buttons to select the

dayofweekandoperation.Press‘Enter’toaccept

newvalueandmovetothenexteld.

b. Use the ‘Up’ and ‘Down’ arrow buttons to select

hours. Press ‘Enter’ to accept the hours and move

tothenexteld.

NOTE:‘IGNORE’allowsyoutoskipperformingthe

speciedaction.

c. Use the Up and Down arrow buttons to select

minutes. Press ‘Enter’ to accept the minutes and

returnto“Dayofweek/operation”selection.

d. Push ‘ESC’ when the schedule setup is complete to

return to the Main Menu.

4. Alarm History

a. Use the ‘Up’ and ‘Down’ arrow buttons to

scroll through the last 10 dryer alarms sorted in

chronological order.

b. Press ‘ESC’ to return to the Main Menu.

NOTE: Hold the alarm reset button to clear the alarm

history..

5. Energy Cost

a. Use the ‘Up’ and ‘Down’ arrow buttons to select the

desired currency. Press ‘Enter’ to accept the new

valueandmovetothenexteld.

b. Use the ‘Up’ and ‘Down’ arrow buttons to select the

energy cost. Press ‘Enter’ to accept the new value

andmovetothepreviouseld.

c. Press ‘ESC’ to return to the Main Menu.

6. Service Interval

a. Use the ‘Up’ and ‘Down’ arrow buttons to program

the desired service interval. Press ‘Enter’ to accept

the new service interval value.

b. Press ‘ESC’ to return to the Main Menu.

1. Glycol Temperature Indicator

2. TextDisplay

3. Power LED

4. Compressor LED

5. Alarm / Service LED

6. Schedule / Enter Button

a. In Display Mode: Toggle between manual and

scheduled dryer operating modes.

b. InSetupMode:Enterasub-menuorconrma

value.

7. Setup Mode / Escape Button

a. In Display Mode: Hold to enter setup mode.

b. InSetupMode:Presstoexitcurrentmenu.

8. Up Arrow

a. In Display Mode: Move to previous display

screen.

b. In Program Mode: Increment current menu/

value selection.

9. Down Arrow

a. InDisplayMode:Movetonextdisplayscreen

b. In Program Mode: Decrement current menu/

value selection.

10. On/OffButton:Presstotogglethedryeron/off

forcesdryertoentermanualmode.

11. Drain test: Press to momentarily open the

electronic demand drains.

12. Reset: Press to clear the current alarm message and

alarm/service LED.

CONTROL PANEL

1234 5

67891011 12

energy saving

AIR TREATMENT

7

7. Auto-Restart

a. Use the ‘Up’ and ‘Down’ arrow buttons to enable/

disable auto-restart. Press ‘Enter’ to accept the new

selection.

b. Press ‘ESC’ to return to the Main Menu.

E. Dryer Startup

NOTICE:EnergizeDryerfor24hourspriortostarting

refrigerationcompressor!Failuretofollowthesenoticesmay

resultinanon-warrantablecompressorfailure.

1. Start dryer 15 minutes prior to compressed air flow.

2. On water-cooled models: begin cooling water flow prior

to compressor startup.

3. Checkforproperelectricalvoltage.

4. Slowlypressurizeunitairsidebyopeninginletisolation

valve.Checkforleaks.

5. After15minutes,openoutletisolationvalveslowly.

6. Close air bypass valve.

7. Select dryer operating mode with Manual/Schedule

mode button.

NOTE:Checkforcorrectphasingofunit.

Onair-cooledmodels:checkfanrotation(airmustbepulled

throughthecondenser).Fansmaynotstartimmediatelyor

maycycleonandoff.Ifrotationisinthewrongdirection

followtheprocedurebelow.

Onwater-cooledmodels:Afterstartingdryerifanunusual

noise is heard and the discharge line does not get hot,

stopthedryer,reversetwopowerleads,restart,andverify

discharge line gets hot.

F. Dryer Operation

1. ManualMode-PushingtheOn/Offbuttonwillcausethe

dryertoturnonorturnoff.Dryerstatusisindicatedon

thetextdisplay.Thecompressorwillbegincyclingbased

on the glycol temperature. The compressor LED will

reectthestateofthecompressor.

2. Scheduled Mode - Pressing the Schedule Mode button

will cause the dryer to toggle between scheduled and

manual modes. In scheduled mode the dryer will turn

on/offbasedonthescheduleenteredduringthedryer

setup. The compressor will cycle based on the glycol

temperature when the dryer is on.

3. Remote Mode - By closing the remote mode contact the

dryerwillenteraremotecontrolmode.Thestateofthe

dryerwillbebasedontheremotecontrolcontact.Ifthe

contactisclosedthedryerwillrun,ifthecontactisopen

thedryerwillremainoff.

NOTE: The dryer may be returned to manual mode at any

time by pressing the schedule button. Manual Mode will

appearontextdisplay.Tore-enablescheduledoperation,

press the schedule button again.

Auto-Restart

Disabled(FactoryDefault)-Followingapowerinterruption

the dryer will begin operation in manual mode with the dryer

off.

Enabled - Following a power interruption the dryer will return

to the previous operating mode and will turn the dryer on or

offbasedonthemode.

Manual Mode - Dryer will return to state it was in prior to

powerfailure.

ScheduledMode-Dryerwillbeonoroffbasedonthe

programmed schedule.

RemoteMode-Dryerwillbeonoroffbasedonremote

control contact.

G. Dryer Display

1. Operating Mode - Displays the current date/time and

operating mode.

2. DryingStatus-Displaysthestatusofthedryer(on/off)

3. HourstoService-Displaysthehoursremainingbefore

dryer service is required.

4. Total Hours - Displays the total hours the dryer has been

operating.

5. Daily Run Time - Displays the average dryer load over the

last 24 hours.

6. Average Run Time - Displays the average dryer load over

the last 30 days.

7. Energy Savings - Displays the estimated annual energy

savings based on the average dryer load over the last 30

days.

8. Glycol Temperature - Displays the glycol temperature

reading.

H. Dryer Alarms

SERVICE DRYER - Indicates that the service interval

forthedryerhasexpired.Performrequireddryer

maintenance and reset using the alarm reset button.

HIGH DISCHARGE PRESSURE - Indicates that the

refrigerationcompressorcontrolcircuithasopened

becauseofhighheadpressure.Thehighpressure

switchmustberesetmanually.Afterxingthefaultand

resetting the pressure switch the alarm can be cleared

using the alarm reset button.

COMPRESSOR–Indicatesthatthecompressorcontactor

hasnotengaged.Checkthecompressorcontactor.

Oncethefaulthasbeencorrectedthealarmcanbe

manually cleared using the alarm reset button.

TEMPERATURESENSORFAILURE–Indicatesaproblem

withthe10kOhmNTCThermistor.Checktomakesure

the thermistor is properly connected to the control

board and the resistance across the Thermistor is correct.

Oncethefaulthasbeencorrected,thealarmcanbe

manually cleared using the alarm reset button.

HIGH TEMPERATURE -

HIGHGLYCOLTEMPERATURE–

Indicates that the dryer is overloaded or there is a

problemwiththerefrigerationsystemleadingtopoor

dryerperformance.Oncethefaulthasbeencorrected

the alarm can be manually cleared using the alarm reset

button.

HEATER–Indicatesaproblemwiththecrankcaseheater.

Thecrankcaseheatershouldenergizeanytimethe

dryerisoff.Checktomakesurethecrankcaseheateris

energized.Oncethefaulthasbeencorrectedthealarm

can be manually cleared using the alarm reset button.

DRAIN–Indicatesaproblemwiththeelectronicdemand

drain.Refertotheelectronicdemanddrainmanualfor

furtherinformationonhowtocorrectthedrainfault.

Oncethefaulthasbeencorrectedthealarmcanbe

manually cleared using the alarm reset button.

8

I. Using the RS-232 port

TheRS-232portisusedtomonitordryeroperationfrom

ahostcomputer.A(1to1)DB-9cableisrequiredto

connect dryer and computer. For PC connections, data

is transmitted on pin 2, received on pin 3, ground is pin

5, pins 7 and 8 are jumpered at dryer.

Operationisatxedbaudrateof9,600;asynchronous

formatis8bit,noparity,1stopbit(“8,N,1”).Nocheck

sumorerrorcorrectionvaluesareprovided.Ifrequired,

requeststatusstringtwo(ormore)timesandcompare

foragreement.

RequestdatabysendingASCII?character(3FH).

Responsemaytakeuptotwosecondsascertain

processingfunctionsmayrequirecompletionbefore

serialportisacknowledged.

Dryerrespondswithlinefeed(0AH),carriagereturn(0DH),

andcharacterstring:(1),(2),(3),(4),(5),(6),(7),(8),(9)

(1) =STX(start-of-textcharacter,mayappearasasmi-

leyfaceorsomeothercharacter

(2) =108,ControlboardID

(3) =0or1,Compressorrunningstatus(0=off,1=on)

(4) =MorS,OperatingMode(M=MANUALOVERRIDE,S

=SCHEDULERUNNING)

(5) =xxxx,HOURSTOSERVICE

(6) =xxxxxx,TOTALHOURS

(7) =xx,AlarmorServiceCode(0=noalarm,30=LOW

PRESSUREALARM,31=HIGHPRESSUREALARM,

32=COMPRESSORALARM,36=HIGHEVAPTEMP

ALARM,37=HEATERALARM,38=DRAINALARM,

39=SERVICEDRYER,41=TEMPSENSORALARM)

(8) =xx.x,Evaporatortemperature(°F)

(9) =ETX,(end-of-textcharacter,mayappearasaheart

orsomeothercharacter)

9

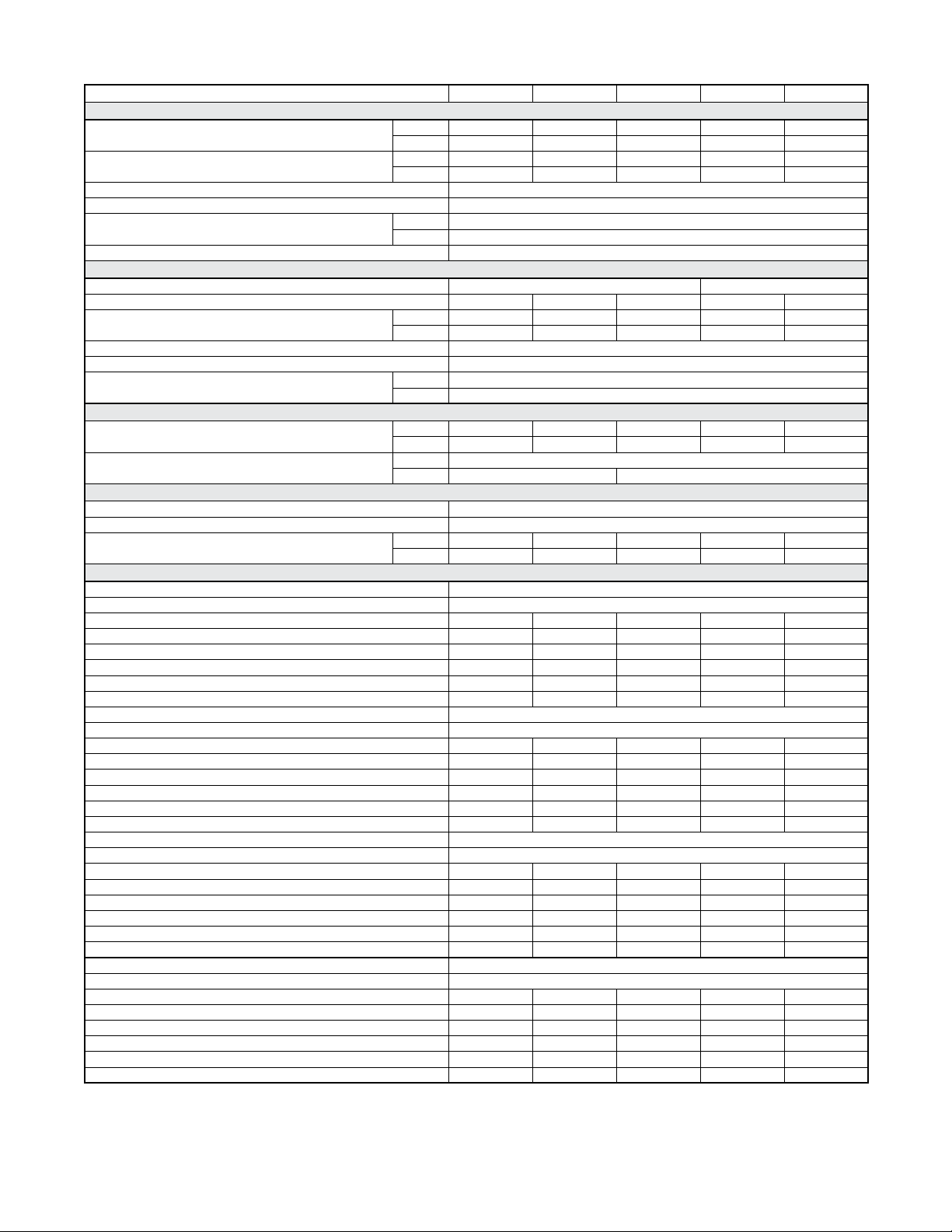

SIZING

Determining dryer capacity at actual operating conditions

Todeterminethemaximuminletowcapacityofadryer

at various operating conditions, multiply the rated capacity

fromTable1bythemultipliersshowninTable2.

Example:Howmanyscfmcananair-cooledmodel360handle

whencompressedairtobedriedisat200psigand110°F;

ambient air temperature is 80°F?

Answer:360x0.95x1.12=383scfm.

TABLE 1

Ratedcapacity(scfm)andpressuredrop@100psiginlet

pressure, 100°F inlet temperature, and 100°F ambient

temperature

MODEL 90 120 140 190 240

Rated capacity

of air-cooled

models (scfm)

60 Hz

50 Hz

90

75

120

100

140

117

190

158

240

200

MODEL 280 360 450 540 675

Rated capacity

of air-cooled

models (scfm)

60 Hz

50 Hz

280

233

360

300

450

375

540

450

675

562

TABLE 2

Aircapacitycorrectionfactors(Multipliers)

INLET COMPRESSED AIR CONDITIONS

INLET

PRESSURES

INLET TEMPERATURES

80°F 90°F 100°F 110°F 120°F 130°F

psig bar 27°C 32°C 38°C 43°C 49°C 54°C

30

50

80

100

125

150

175

200

250

2.0

3.4

5.5

6.9

8.6

10.4

12.1

13.8

17.2

1.24

1.40

1.55

1.61

1.67

1.71

1.75

1.77

1.81

0.92

1.07

1.19

1.25

1.30

1.34

1.37

1.39

1.43

0.71

0.83

0.95

1.00

1.05

1.08

1.11

1.14

1.17

0.56

0.66

0.77

0.82

0.86

0.90

0.92

0.95

0.98

0.44

0.54

0.63

0.68

0.72

0.75

0.78

0.80

0.83

0.35

0.44

0.52

0.56

0.61

0.64

0.66

0.68

0.72

COOLING MEDIUM*

AMBIENT

TEMPERATURE

MULTIPLIER

°F °C

80

90

100

110

27

32

38

43

1.12

1.06

1.00

0.94

*Air-cooled models; water-cooled models use 1.15 multiplier if cooling

water is below 35°C, 95°F.

3.0 MAINTENANCE

3.1 Condenser coil – Clean off accumulated dust

and dirt monthly.

3.2 Moisture separator – Replace filter element

when pressure drop across dryer is excessive,

or annually, whichever occurs first.

3.3 Check separator daily to be sure automatic

drain is discharging.

3.4 Blow down separator weekly.

3.5 Rebuild drain mechanism annually.

Tofacilitateservice,maintenancekitsareavailable.

Models 90-140

Drain Line

PTC Swivel Elbow

Element

Wave Spring

Float Drain

Element O-Ring

Bowl O-Ring

Head

Models 190-675

Head

Element O-Ring

Bowl O-Ring

Element

Bowl

Drain Quick Disconnect

Bowl Support

*Models 500-750 Only.

10

ENGINEERING DATA (MODELS 90-240)

Model 90 120 140 190 240

Air System Data

Rated Air Flow at 100°F & 100 psig Inlet, 100°F Ambient (scfm) 60 Hz, a-c 90 120 140 190 240

60 Hz, w-c n/a n/a n/a 219 276

Rated Air Flow at 95°F & 100 psig Inlet, 77°F Ambient (scfm) 50 Hz, a-c 95 127 148 201 254

50 Hz, w-c n/a n/a n/a 203 257

Minimum / Maximum Inlet Compressed Air Pressure 30 / 232 psig (2.1 / 16.0 barg)

Minimum / Maximum Inlet Compressed Air Temperature 40 / 120°F (4 / 49°C)

Minimum / Maximum Ambient Temperature a-c 40 / 110°F (4 / 43°C)

w-c 40 / 130°F (4 / 54°C)

Outlet Air Temperature (nominal at rated conditions) 85°F (29°C)

Refrigeration System Data

Compressor Type Hermetic, Reciprocating

Refrigeration Compressor Horsepower 0.5 0.75 0.75 1 1.5

Refrigeration Capacity @ Rated Flow (BTU/h) * 60 Hz, a-c 4,820 6,030 6,030 8,900 15,200

50 Hz, a-c 4,760 7,070 7,070 9,130 16,070

Refrigerant Type R-134A

Refrigerant Charge See Serial Tag on Dryer

Compressor Pressure Switch Setting (cut out / cut in) High, a-c N/A 281 - 190 psig (19.4 - 13.1 barg)

High, w-c N/A 200 - 160 psig (13.8 - 11.0 barg)

Air-Cooled Condenser

Air Flow Across Condenser (cfm) 60 Hz 300 450 450 710 1,070

50 Hz 250 370 370 590 890

Condenser Fan Pressure Switch Setting (cut in / cut out) Fan 1 110 / 70 psig (7.6 / 4.8 barg) 113 / 78 psig (7.8 / 5.4 barg)

Fan 2 N/A

Water-Cooled Condenser

Water Regulating Valve Setting 135 psig (9.3 barg)

Minimum Water Pressure Differential 40 psig (2.8 barg)

Cooling Water Flow with 85°F (gallons per minute) * 60 Hz N/A 1.3 1.5

50 Hz N/A 1.2 1.4

Electrical Data

Nominal Voltage 115/1/60 208-230/3/60

Voltage Range 104 - 127 187 - 253

Input Power @ Rated Flow (watts) * 978 1,282 1,293 1,363 1,942

Minimum Circuit Ampacity 13.6 18.3 18.3 10.5 15.9

Maximum Overcurrent Protector (amps) 20 25 25 15 20

Compressor Rated Load Amps 10.2 15.2 15.2 7.5 10.4

Compressor Locked Rotor Amps 51.0 66.3 66.3 51.0 66.0

Compressor Winding Resistance (ohms) 4.3 S / 0.7 R 3.2 S / 0.4 R 3.2 S / 0.4 R 1.8 1.3

Nominal Voltage 208-230/1/60 460/3/60

Voltage Range 187 - 253 414 - 506

Input Power @ Rated Flow (watts) * 978 1,282 1,293 1,363 1,942

Minimum Circuit Ampacity 7.3 10.5 10.5 5.2 7.5

Maximum Overcurrent Protector (amps) 15 15 15 15 15

Compressor Rated Load Amps 5.4 9.0 9.0 3.6 4.7

Compressor Locked Rotor Amps 30.0 33.5 33.5 25.0 33.0

Compressor Winding Resistance (ohms) 9.0 S / 2.3 R 7.9 S / 1.6 R 7.9 S / 1.6 R 7.4 5.0

Nominal Voltage 100/1/50 575/3/60 **

Voltage Range 90 - 110 518 - 633

Input Power @ Rated Flow (watts) * 1,363 1,942

Minimum Circuit Ampacity 13.6 18.3 18.3 4.2 6.0

Maximum Overcurrent Protector (amps) 20 25 25 15 15

Compressor Rated Load Amps 10.2 15.2 15.2 3.6 4.7

Compressor Locked Rotor Amps 51.0 66.3 66.3 25.0 33.0

Compressor Winding Resistance (ohms) 4.3 S / 0.7 R 3.2 S / 0.4 R 3.2 S / 0.4 R 7.4 5.0

Nominal Voltage 240/1/50 380-420/3/50

Voltage Range 216 - 264 342 - 462

Input Power @ Rated Flow (watts) *

Minimum Circuit Ampacity 6.2 9.9 9.9 5.2 7.5

Maximum Overcurrent Protector (amps) 15 15 15 15 15

Compressor Rated Load Amps 4.5 8.3 8.3 3.6 4.7

Compressor Locked Rotor Amps 21.0 53.0 53.0 25.0 33.0

Compressor Winding Resistance (ohms) 19.5 S / 3.3 R 10.5 S / 1.8 R 10.5 S / 1.8 R 7.4 5.0

NOTES:

* For 60 Hz: 35°F Evaporator & 100°F Ambient; for 50Hz: 35°F Evaporator & 77°F Ambient.

** 575/3/60 units use equipment transformers on incoming power. Compressor and fan voltage is 460/3/60.

11

ENGINEERING DATA (MODELS 280-675)

Model 280 360 450 540 675

Air System Data

Rated Air Flow at 100°F & 100 psig Inlet, 100°F Ambient (scfm) 60 Hz, a-c 280 360 450 540 675

60 Hz, w-c 322 414 518 621 776

Rated Air Flow at 95°F & 100 psig Inlet, 77°F Ambient (scfm) 50 Hz, a-c 297 382 477 572 716

50 Hz, w-c 300 385 482 578 722

Minimum / Maximum Inlet Compressed Air Pressure 30 / 232 psig (2.1 / 16.0 barg)

Minimum / Maximum Inlet Compressed Air Temperature 40 / 120°F (4 / 49°C)

Minimum / Maximum Ambient Temperature a-c 40 / 110°F (4 / 43°C)

w-c 40 / 130°F (4 / 54°C)

Outlet Air Temperature (nominal at rated conditions) 85°F (29°C)

Refrigeration System Data

Compressor Type Hermetic, Reciprocating Hermetic, Scroll

Refrigeration Compressor Horsepower 1.5 1.5 2 2.5 3.5

Refrigeration Capacity @ Rated Flow (BTU/h) * 60 Hz 15,200 15,200 19,200 22,000 30,500

50 Hz 16,070 16,070 20,060 21,120 29,650

Refrigerant Type R-134A

Refrigerant Charge See Serial Tag on Dryer

Compressor Pressure Switch Setting (cut out / cut in) High, a-c 281 / 190 psig (19.4 / 13.1 barg)

High, w-c 200 / 160 psig (13.8 / 11.0 barg)

Air-Cooled Condensers

Air Flow Across Condenser (cfm) 60 Hz 1,070 1,070 2,470 1,680 2,170

50 Hz 890 890 2,060 1,400 1,810

Condenser Fan Pressure Switch Setting (cut in / cut out) Fan 1 113 / 78 psig (7.8 / 5.4 barg)

Fan 2 N/A 183 / 124 psig (12.6 / 8.6 barg)

Water-Cooled Condensers

Water Regulating Valve Setting 135 psig (9.3 barg)

Minimum Water Pressure Differential 40 psig (2.8 barg)

Cooling Water Flow with 85°F (gallons per minute) * 60 Hz 1.7 2.1 2.5 3.0 3.6

50 Hz 1.6 2.0 2.3 2.8 3.3

Electrical Data

Nominal Voltage 208-230/3/60

Voltage Range 187 - 253

Input Power @ Rated Flow (watts) * 1,950 2,065 2,496 3,081 4,350

Minimum Circuit Ampacity 15.9 15.9 20.0 19.7 30.4

Maximum Overcurrent Protector (amps) 20 20 25 30 45

Compressor Rated Load Amps 10.4 10.4 11.4 13.9 22.1

Compressor Locked Rotor Amps 66.0 66.0 75.0 88.0 115.0

Compressor Winding Resistance (ohms) 1.3 1.3 1.1 1.0 0.7

Nominal Voltage 460/3/60

Voltage Range 414 - 506

Input Power @ Rated Flow (watts) * 1,950 2,065 2,496 3,081 4,350

Minimum Circuit Ampacity 7.5 7.5 9.6 10.4 15.2

Maximum Overcurrent Protector (amps) 15 15 15 15 20

Compressor Rated Load Amps 4.7 4.7 5.1 7.1 9.6

Compressor Locked Rotor Amps 33.0 33.0 40.0 44.0 63.0

Compressor Winding Resistance (ohms) 5.0 5.0 4.1 4.0 2.7

Nominal Voltage 575/3/60 **

Voltage Range 518 - 633

Input Power @ Rated Flow (watts) * 1,950 2,065 2,496 3,081 4,350

Minimum Circuit Ampacity 6.0 6.0 7.7 8.3 12.2

Maximum Overcurrent Protector (amps) 15 15 15 15 20

Compressor Rated Load Amps 4.7 4.7 5.1 7.1 9.6

Compressor Locked Rotor Amps 33.0 33.0 40.0 44.0 63.0

Compressor Winding Resistance (ohms) 5.0 5.0 4.1 4.0 2.7

Nominal Voltage 380-420/3/50

Voltage Range 342 - 462

Input Power @ Rated Flow (watts) *

Minimum Circuit Ampacity 7.5 7.5 8.1 10.4 15.2

Maximum Overcurrent Protector (amps) 15 15 15 15 20

Compressor Rated Load Amps 4.7 4.7 5.1 7.1 9.6

Compressor Locked Rotor Amps 33.0 33.0 40.0 44.0 63.0

Compressor Winding Resistance (ohms) 5.0 5.0 4.1 4.0 2.7

NOTES:

* For 60 Hz: 35°F Evaporator & 100°F Ambient; for 50Hz: 35°F Evaporator & 77°F Ambient.

** 575/3/60 units use equipment transformers on incoming power. Compressor and fan voltage is 460/3/60.

12

PE

POWER CORD FURNISHED

AND INSTALLED BY MANUFACTURER

115 VAC

N

G BAR

L1

L1

T2

T2

T1 T1 T1 T2

T2

T1 T1

L1

GPOWER ON

PILOT LIGHT

T2

T2 G BAR

T1

T1 T1

G BAR

G

GND

TCB–1

TCB–1

T2 T2

COMPRESSOR ON

PILOT LIGHT

1

2

3

4

TEMPERATURE

CONTROL BOARD

120 VAC

100ΩRTD

+

–

G BAR

G BAR

PUMP

T2

PUMP HARNESS

FAN 1 HARNESS

T2

FAN 1

FPS 1

T1

TCB–1 3 1 3

OVERLOAD

C

S

R

MTR1

COMPRESSOR CAPACITOR

45L3 SR S

6L3

START RELAY

SR M

T2

COMPRESSOR HARNESS

T2

T2

T2

WIRING DIAGRAM - STANDARD CONTROLLER

Models 90/120/140: 115/1/60

13

WIRING DIAGRAM - STANDARD CONTROLLER

Models 90/120/140: 230/1/60

CUSTOMER SUPPLIED

230 VAC

L1 L2 PE

T1 T1 T1

G BAR

T2

T2

T2

L2

G BAR

G BAR

G BAR

G BAR

L1

T1

T1

T2

T2

POWER ON

PILOT LIGHT

G

1

2

3

4

TEMPERATURE

CONTROL BOARD

TCB–1

+

–

GND

T2

TCB–1

G

230 VAC

T1

T1 T1

PUMP

T2

PUMP HARNESS

T2

FAN 1 HARNESS

FAN 1

FPS 1

T1

CR4

OVERLOAD

313C

S

R

MTR1

COMPRESSOR CAPACITOR

45

6L3

START RELAY

SR

L3 SR S

M

CR8

COMPRESSOR HARNESS

CR8

T2

T2

T2

CR8

CR4

L2

L1

6 8

24

POWER

CONTROL RELAY

10 CR

T2

COMPRESSOR ON

PILOT LIGHT

100ΩRTD

14

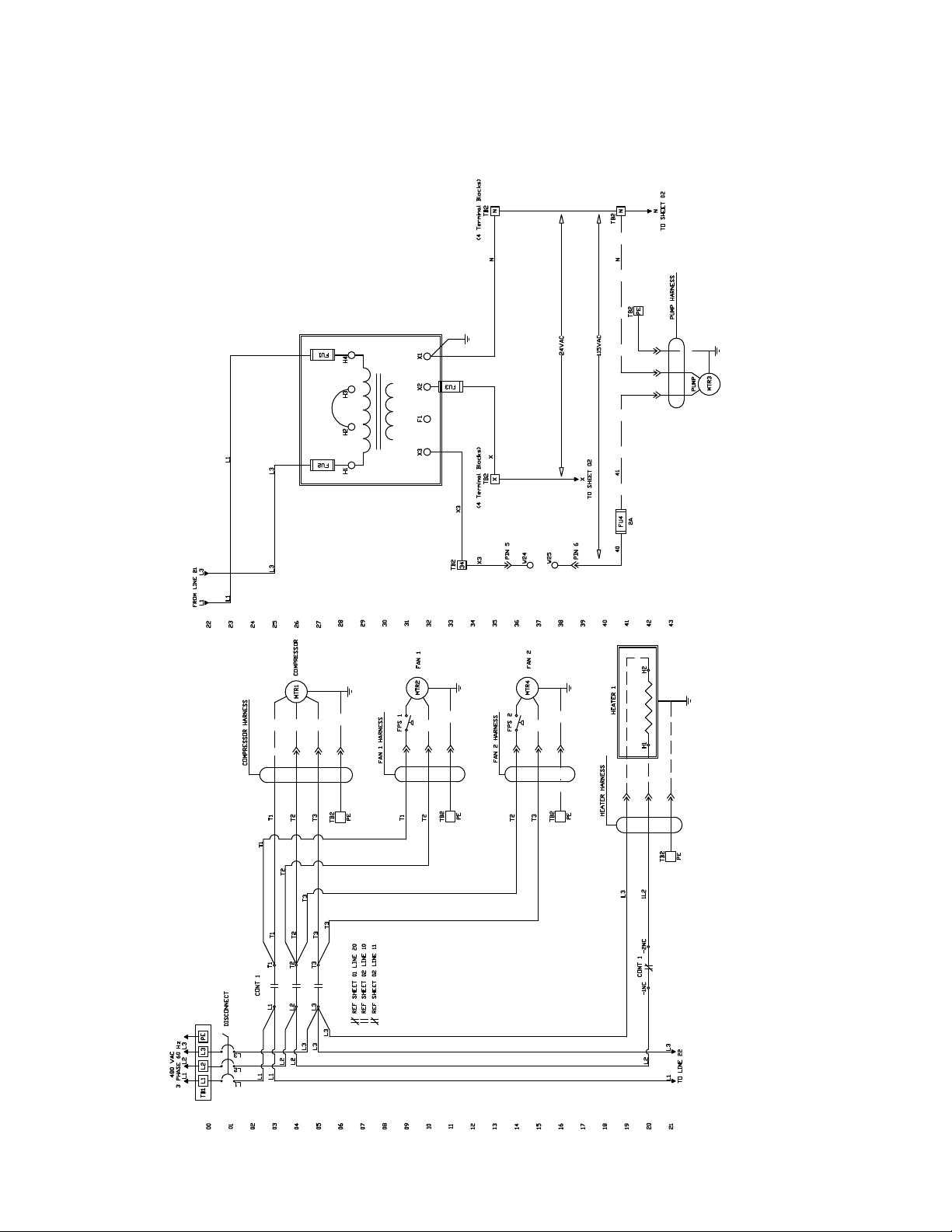

WIRING DIAGRAM - STANDARD CONTROLLER

Models 190/240/280/360/450/540

Sheet1of2

21

20 L2

L3

L1

13

14

15

16

17

18

19

TO LINE 22

12

09

10

11

08

07

06

05

03

04

00

01

02

480 VAC

3 PHASE 60 Hz

L1 L2 L3

L1 L2 L3

TB1 PE

L1

L1

L2

L3

L3

L1

L2

L3

L3

L2

T3

T3

T3

T2

T2

T1

T1

CONT 1

REF SHEET 01 LINE 20

T3

REF SHEET 02 LINE 11

REF SHEET 02 LINE 10

–1NC CONT 1 –2NC

L3

1L2

TB2

PE

T2

T1

T3

T2

T1

TB2

PE

T1

T2

TB2

PE

T3

T2

TB2

PE

HEATER HARNESS

H1 H2

HEATER 1

FPS 2

MTR4 FAN 2

FAN 2 HARNESS

MTR2

FPS 1

FAN 1

FAN 1 HARNESS

MTR1 COMPRESSOR

COMPRESSOR HARNESS

43

42

35

36

37

38

39

40

41

34

31

32

33

30

29

28

27

25

26

22

23

24

X3 N

TO SHEET 02

115VAC

X2

TB2

N

TB2

TB2

X2 TB2

TB2

N

PE

24VAC

X2

N

TB2

X3 FU4 X3

X2

N

FU3

X3 F1 X2 X1

H1 H2 H3 H4

FU2

FU1

L1

L3

L3

L1

L1 L3

FROM LINE 21

L1 L3

H1

H1

H1

H2

H3

H4

208V

230V

460V

FACTORY SET TO 460V

DRAIN 1 HARNESS

PE

N

X2

PE

2

3

5

1

4

6

24VAC

ALM

TEST

24VAC

PE

2

3

5

1

4

6

ALM

TEST

PE

TB2

X

N

DRAIN 2 HARNESS

OPTIONAL DRAIN

Optional Fan

(for 450 – 540 models only)

15

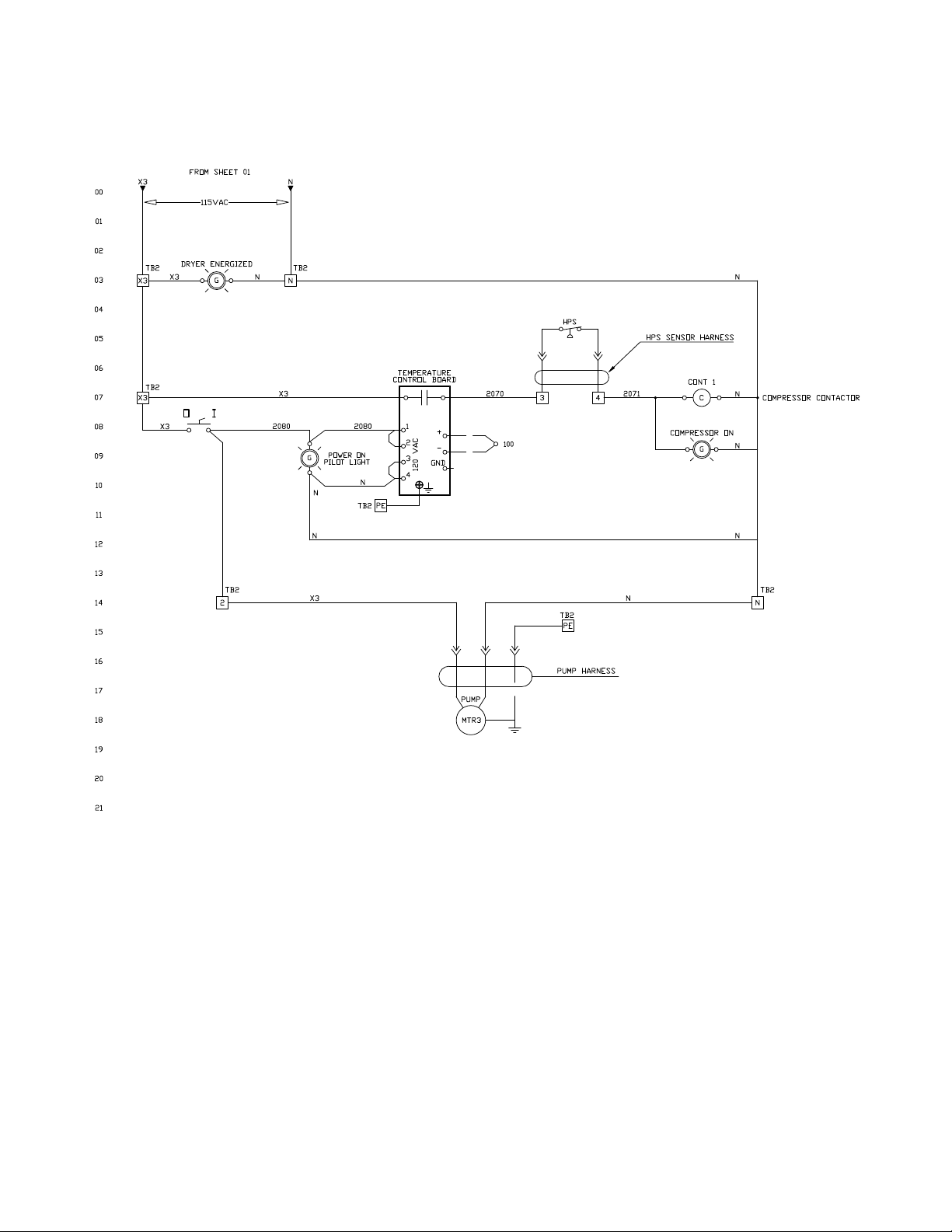

WIRING DIAGRAM - STANDARD CONTROLLER

Models 190/240/280/360/450/540

Sheet2of2

FROM SHEET 01

X3 N

115VAC

00

01

02

03

TB2

X3

DRYER ENERGIZED

X3 GNN

TB2

G

G

TB2 X3

TEMPERATURE

CONTROL BOARD

04

05

06

07

08 X3 2080

X3

2080

POWER ON

PILOT LIGHT

TB2 PE

N

N

N

09

10

11

12

13

14

15

4

3

2

GND

1

–

+

120 VAC

2070 3

100ΩRTD

HPS

HPS SENSOR HARNESS

42071

CONT 1

CN

N

COMPRESSOR ON

COMPRESSOR CONTACTOR

N

N

TB2

N

TB2

PE

PUMP HARNESS

PUMP

MTR3

X3

2

TB2

N

16

17

18

19

20

21

16

WIRING DIAGRAM - STANDARD CONTROLLER

Model 675

Sheet1of2

17

WIRING DIAGRAM - STANDARD CONTROLLER

Model 675

Sheet2of2

Ω RTD

18

WIRING DIAGRAM - ADVANCED CONTROLLER

Models190-540,(460VAC)

Sheet1of2

19

WIRING DIAGRAM - ADVANCED CONTROLLER

Models190-540,(460VAC)

Sheet2of2

20

WIRING DIAGRAM - ADVANCED CONTROLLER

Model675,(460VAC)

Sheet1of2

This manual suits for next models

10

Table of contents

Other SPX Dehumidifier manuals

SPX

SPX HCD Series User manual

SPX

SPX Hankison HPRP Series User manual

SPX

SPX HANKISON HIT Series User manual

SPX

SPX HPD Series User manual

SPX

SPX Hankison GCU Series User manual

SPX

SPX Hankison HPRplus Series User manual

SPX

SPX DELAIR QD 90 User manual

SPX

SPX Pneumatic Products IBP500 User manual

SPX

SPX RDH-HP Series User manual