SPX RDH-HP Series User manual

RDH-HP Series

Pressure-Swing Desiccant Type Compressed Air Dryers

Models: RDH-HP-715G, RDH-HP-1550G, RDH-HP-5200G

FORM NO.: 3245430 REVISION: 04/2014 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

MODELS RATED

FLOW

REFER

AS

MODELS

RDH-HP-715G 715 SCFM 715

RDH-HP-1550G 1550 SCFM 1550

RDH-HP-5200G 5200 SCFM 5200

2

WARRANTY

The manufacturer warrants the product manufactured by it, when properly installed, operated, applied, and maintained in accordance with

procedures and recommendations outlined in manufacturer’s instruction manuals, to be free from defects in material or workmanship for a period

of one (1) year from the date of shipment to the buyer by the manufacturer or manufacturer’s authorized distributor, or eighteen months from the

date of shipment from the factory, whichever occurs first, provided such defect is discovered and brought to the manufacturer’s attention within

the aforesaid warranty period. The manufacturer will repair or replace any product or part determined to be defective by the manufacturer within

the warranty period, provided such defect occurred in normal service and not as a result of misuse, abuse, neglect or accident.

The warranty covers parts and labor for the warranty period. Repair or replacement shall be made at the factory or the installation site, at

the sole option of the manufacturer. Any service performed on the product by anyone other than the manufacturer must first be authorized by

the manufacturer. Normal maintenance items requiring routine replacement are not warranted. Unauthorized service voids the warranty and

any resulting charge or subsequent claim will not be paid. Products repaired or replaced under warranty shall be warranted for the unexpired

portion of the warranty applying to the original product. The foregoing is the exclusive remedy of any buyer of the manufacturer’s product. The

maximum damages liability of the manufacturer is the original purchase price of the product or part.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR STATU-

TO RY, AND IS EXPRESSED IN LIEU OF THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE. THE MANUFACTURER SHALL NOT BE LIABLE FOR LOSS OR DAMAGE BY REASON OF STRICT LI-

ABILITY IN TORT OR ITS NEGLIGENCE IN WHATEVER MANNER INCLUDING DESIGN, MANUFACTURE OR INSPECTION OF THE EQUIP-

MENT OR ITS FAILURE TO DISCOVER, REPORT, REPAIR, OR MODIFY LATENT DEFECTS INHERENT THEREIN. THE MANUFACTURER,

HIS REPRESENTATIVE OR DISTRIBUTOR SHALL NOT BE LIABLE FOR LOSS OF USE OF THE PRODUCT OR OTHER INCIDENTAL OR

CONSEQUENTIAL COSTS, EXPENSES, OR DAMAGES INCURRED BY THE BUYER, WHETHER ARISING FROM BREACH OF WARRANTY,

NEGLIGENCE OR STRICT LIABILITY IN TORT.

The manufacturer does not warrant any product, part, material, component, or accessory manufactured by others and sold

or supplied in connection with the sale of manufacturer’s products.

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY

BEFORE MATERIAL IS RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

CONTENTS

1.0 DESCRIPTION................................................................ 4

2.0 INSTALLATION................................................................ 6

3.0 OPERATION ................................................................. 12

4.0 MAINTENANCE ............................................................ 16

5.0 TROUBLESHOOTING .................................................. 18

6.0 REPLACEMENT PARTS ............................................... 19

3

IMPORTANT:

READ PRIOR TO STARTING THIS EQUIPMENT

A. UNPACKING

This shipment has been thoroughly checked, packed and inspected

before leaving our plant. It was received in good condition by the car-

rier and was so acknowledged.

1. Check for Visible Loss or Damage. If this shipment shows evidence of

loss or damage at time of delivery to you, insist that a notation of this

loss or damage be made on the delivery receipt by the carrier’s agent.

2. Check for Concealed Loss or Damage. When a shipment has been

delivered to you in apparent good order, but concealed damage is

found upon unpacking, notify the carrier immediately and insist on his

agent inspecting the shipment. Fifteen days from receipt of shipment

is the maximum time limit for requesting such inspection. Concealed

damage claims are not our responsibility as our terms are F.O.B. point

of shipment.

B. MOVING CAUTION:

Do not lift by piping. Use lifting lugs or fork lift.

GENERAL SAFETY

INFORMATION

1. Pressurized devices: This equipment is a pressure

containing device. Do not exceed maximum operating

pressure as shown on equipment serial number tag.

Make sure equipment is depressurized before working

on or disassembling it for service.

2. Electrical: This equipment requires electricity to operate.

Install equipment in compliance with national and local

electrical codes. Standard equipment is supplied with

NEMA 4, 4x electrical enclosures and is not intended for

installation in hazardous environments.

Disconnect power supply to equipment when performing

any electrical service work.

3. Breathing Air: Air treated by this equipment may not be

suitable for breathing without further purification. Refer

to OSHA standard 1910.134 for the requirements for

breathing quality air.

4. Noise: Do not operate dryer without mufflers installed.

5. High Velocity Air: Do not stand near mufflers during

tower depressurization.

I. INSTALLATION

1. Install on level surface.

2. Ambient temperature range: 35 to 120°F (1.7 to 49°C)

[ if low ambient package supplied: -10 to 120°F (-23 to 49°C) ]

3. Install purge mufflers if shipped separately.

4. Connect air from compressor to inlet.

• Maximum compressed air temperature: 120°F (49°C)

• Maximum compressed air pressure: Refer to serial number

tag.

• Minimum compressed air pressure: 100 psig (6.9 barg)

5. Connect outlet to air system.

6. Refer to serial number tag for correct voltage. Make electrical

connection to terminal strip in control panel. Connect line to

position 5, neutral to position 6 and ground to position 7.

7. Verify voltage selector switch (115V or 230V). Position should

match voltage on Serial Number Tag.

II. START UP

1. Set or verify controller settings. See section 3.1.1.

2. SLOWLY pressurize unit.

3. Energize dryer by turning on/off switch on. (“I” is on; “O” is off)

4. Adjust purge air flow rate. Turn purge rate valve until Purge

Pressure Gauge reads as shown in the following table.

NOTE: One tower must be purging when setting purge pressure.

MINI INSTRUCTIONS

For complete instructions on installation, operation and maintenance, consult manual.

III. OPERATIONAL CHECKPOINTS

1. Check that dryer is energized (indicating lights are illumi-

nated)

2. MOISTURE INDICATOR - Indicator should be green (Allow

4 hours after start up for indicator to turn green).

3. TOWER PRESSURE GAUGES -

• Tower on line should read line pressure

• Tower off line should read 2 psig (0.14 barg)or less while

purging. If pressure exceeds 2 psig (0.14 barg) replace

purge muffler elements.

NOTE: An extra set of elements is shipped with dryer.

4. PURGE PRESSURE GAUGE - Verify proper setting.

5. CHECK FOR ALARM CONDITION.

IV. DEPRESSURIZATION

Isolate dryer. Run timer until both tower pressure gauges read

0 psig (0 kgf/cm

2

)(test mode may be used to speed up cycle).

4

1.0 DESCRIPTION

Desiccant is regenerated by driving off (desorbing) the water collected

on its surface. Pressure-swing (also called heatless or heaterless

because no outside heat is added) dryers regenerate by expanding a

portion (approximately 14 - 15% at 100 psig, 7 barg) of the dried air to

atmospheric pressure. This “swing in pressure” causes the expanded air

to become very dry (have a very low vapor pressure). This very dry air

(called purge air) plus the stored heat of adsorption allows the moisture

to desorb from the desiccant. The purge air then carries the desorbed

water out of the dryer.

1.1 Function

1.1.1 Dryer

Dual tower regenerative desiccant dryers are an economical and reliable

way to dry compressed air to dew points below the freezing point of wa-

ter (dew points as low as -150°F (101°C) [1 ppb @ 100 psig, 7.0 barg]

are possible) or reduce the moisture content of compressed air when

used in critical process applications.

These dryers continuously dry compressed air by using two identical

towers, each containing a desiccant bed. While one tower is on-stream

drying the compressed air, the other tower is off-stream being regener-

ated (reactivated, i.e., dried out). The towers are alternated on- and

off-stream so that dry desiccant is always in contact with the wet

compressed air. In this way a continuous supply of dry air downstream

is possible.

Desiccant dryers lower the dew point of compressed air by adsorbing the

water vapor present in the compressed air onto the surface of the desic-

cant. Desiccant is a highly porous solid containing extensive surface

area.

Adsorption occurs until the partial pressure of the water vapor in the

air and that on the surface of the desiccant come into equilibrium. As

adsorption occurs, heat is released (referred to as the heat of adsorption)

and is stored in the bed for use during regeneration.

5

8

1

5C 5D 8

7 ) (

2

61

5A

10A 9A 3A 3B 9B 10B

5B

11

INLET

TOWER

4B

TOWER

4A

OUTLET

FIGURE 1A

TOWER 4A DRYING: TOWER 4B REGENERATING

Purge Stream

Process Stream

FIGURE 1B

TOWER 4B DRYING: TOWER 4A REGENERATING

1.2 Description of Operation

1.2.1 Dryer (Refer to Figure 1A.)

Compressed air flows through inlet switching valve (3A) (normally open)

to tower (4A) where the air is dried. After the air is dried it flows through

check valve (5A) and then to the dryer outlet.

A portion of the dry air, the purge stream, branches off from the main air

stream prior to the outlet. The purge stream flow rate is controlled by the

adjustable purge rate valve (6) and the purge orifice (7).

The purge flow, which has been throttled to near atmospheric pressure,

is directed through check valve (5D) to tower (4B). As the purge flow

passes over the desiccant in tower (4B), it removes the water vapor

which was deposited there while the tower was on-line drying. The purge

air then passes through purge and repressurization valve (9B) (normally

closed) and purge muffler (10B) to the atmosphere.

After regeneration, purge and repressurization valve (9B) (normally

open) closes allowing tower (4B) to repressurize slowly. Adequate

repressurization time is allowed so that tower 4B is fully repressurized

before switchover. After a controlled time period, air inlet switching valve

(3B) (normally open) opens and inlet switching valve (3A) (normally

open) closes, purge and repressurization valve (9A) (normally closed)

then opens.

(Refer to Figure 1B.) Tower (4B) is now drying the main air stream while

tower (4A) is being regenerated by the purge air stream. The operation

of the inlet switching (normally open) and purge and repressurization

valves (normally closed) is sequenced by the control system located in

the electrical box.

8

1

5C 5D 8

7 ) (

2

61

5A

10B

9B

3B

3A

9A

10A

5B

11

INLET

TOWER

4B

TOWER

4A

OUTLET

1. Pressure Gauges

2. Purge Pressure Gauge

3. Inlet Switching Valves

4. Desiccant Drying Towers

5. Check Valves

6. Adjustable Purge Rate Valve

7. Purge Orifice

8. Pressure Relief Valves

9. Purge / Repressurization Valves

10. Purge Mufflers

11. Moisture Indicator

6

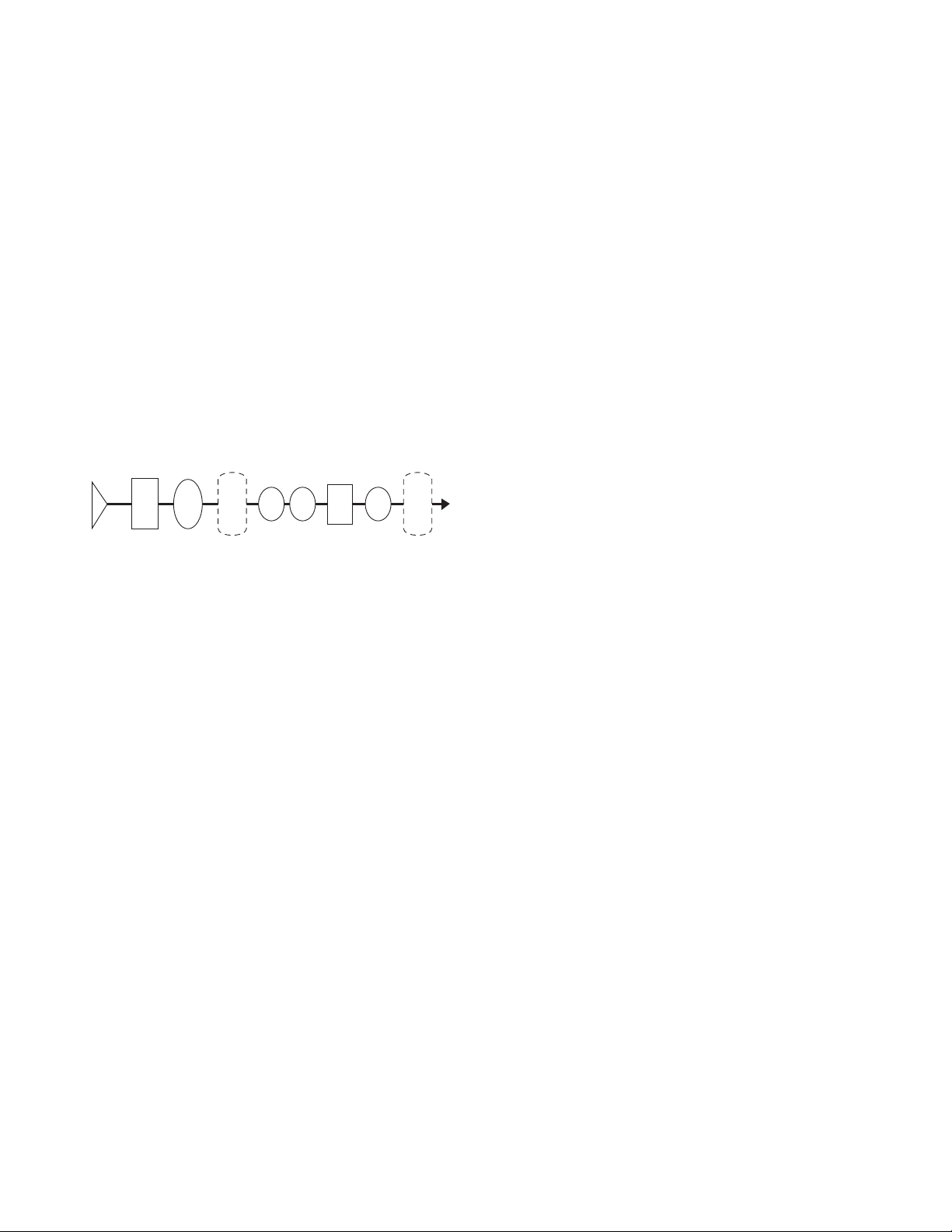

BC E

D

Desiccant

Dryer

Compressor

Aftercooler

Separator

A

Prefilter(s) Afterfilter

A

Receiver Receiver

(B & C) PREFILTERS - Adequate filtration is required upstream of the

dryer in order to protect the desiccant bed from contamination. The fol-

lowing filtration is recommended:

B - Particulate/Gross Liquid Removal - On heavily contaminated sys-

tems use a gross contaminant filter to remove solids and high inlet liquid

concentrations.

C - Oil Aerosol Removal -On systems with lubricated compressors,

use an oil removal filter to remove oil aerosols and protect desiccant bed

from oil contamination.

(D) DESICCANT DRYER

(E) AFTERFILTER - To ensure downstream air purity (prevent desiccant

dust from traveling downstream) adequate filtration downstream of the

dryer is required. Typically 1 micron filtration is specified although finer

filtration is available.

OR

Oil Vapor Adsorber - Use as an afterfilter to remove oil vapor and its

subsequent taste and odor and to protect down-stream components

from solid particles 0.01 micron and larger.

NOTE: By-pass lines and isolation valves are recommended so that

maintenance work can be performed without shutting off the air supply.

2.2 Physical Location

Dryer must be installed with suitable overhead protection.

2.1 Location in the compressed air system.

NOTE: Air Compressor should be adequately sized to handle air system

demands as well as purge loss. Failure to take this into account could

result in overloading air compressors and/or insufficient air supply

downstream.

NOTE: It is desirable to install dryer where compressed air is at the

lowest possible temperature (downstream of aftercoolers) and the high-

est possible pressure (upstream of pressure reducing valves) without

exceeding the maximum working pressure. (Refer to Figure 2A)

(A) AFTERCOOLER/SEPARATOR - Compressed air entering dryer must

be cooled to at least 120°F (49°C). Use aftercooler and separator if

higher temperatures are present.

NOTE: Installation of a refrigerated dryer ahead of a pressure-swing

desiccant dryer does not increase desiccant dryer capacity or reduce

purge flow requirements. However a cooling unit installed ahead of the

desiccant dryer reduces the inlet air temperature and outlet air dew point.

2.0 INSTALLATION

2.3 Minimum & Maximum Operating Conditions

The compressed air supply inlet should be checked periodically to ensure

that equipment design specifications are not exceeded. Normally the

compressor installation includes intercoolers, aftercoolers, separators,

receivers, or similar equipment which adequately pretreat the com-

pressed air supply in order to avoid excessively high air temperatures

and liquid slugging of downstream equipment.

2.3.1 Compressed air conditions

2.3.1.1 Maximum working pressure: Refer to Serial Number Tag.

WARNING

Do not operate the dryer at pressures above the maximum pressure

shown on the tag.

2.3.1.2 Minimum working pressures: 100 psig (7 barg)

2.3.1.3 Maximum inlet compressed air temperature:

120°F (49°C)

NOTE: If inlet air is higher than 120°F (49°C) the air must be pre-

cooled with an aftercooler.

2.3.2 Ambient temperatures:

Minimum:

Standard units: 35°F (1.7°C)

Units with optional low ambient package: - 10°F (-23°C)

Maximum: 120°F (49°C)

NOTE: If dryer is installed in ambients below 35°F (1.7°C) heat tracing

of the prefilters and inlet piping and valves is necessary to prevent con-

densate from freezing. If installing heat tracing, observe electrical class

code requirements for type of duty specified.

2.4 Mounting

Install dryer on a level pad on floor. Holes are provided in

the floor stand base angles for floor anchors if desired.

NOTE: Floor anchors must be used if area is subject to vibrations.

2.5 Piping

2.5.1 Inlet and Outlet connections

Observe location of inlet and outlet connections as indicated in Figure

2C or 2D and connect inlet and outlet piping.

NOTE: All piping must be supported so as not to bear on the dryers or

filters.

2.5.2 Isolation valves

If isolation valves are installed, it is recommended that gate valves be

used to ensure that dryer is pressurized slowly. This is particularly true

if isolation valves are placed before and after pre- and afterfilters where

rapid pressurization could cause excessive pressure drop across filter

elements.

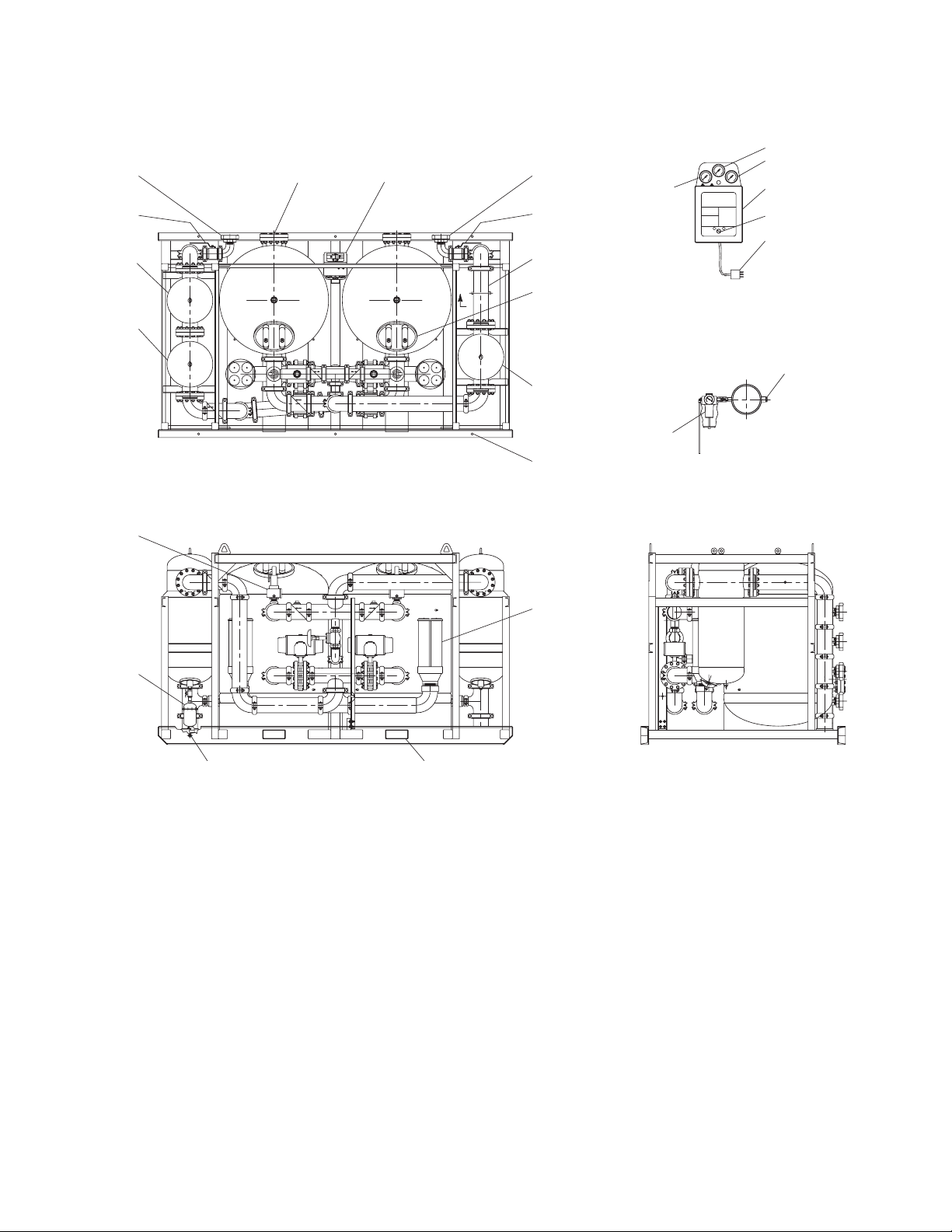

FIGURE 2A

7

Icon idenification

Air Inlet

Air Outlet

Left Tower Pressure Gauge

Right Tower Pressure Gauge

Purge Pressure Gauge

Electrical Entry

Inlet Pressure Gauge

Outlet Pressure Gauge

Automatic Condensate Drain

Purge Muffler

FIGURE 2B

8

FIGURE 2C Model 715G

3.1/4" X 9.1/4" FORKLIFT TUBE

OPENINGS (83mm X 235mm)

3 PLACES

DESICCANT DRAIN

PORT

MOUNTING HOLES

7/8" DIA.

HIGH EFFICIENCY OIL

REMOVAL PREFILTER

AIRLINE AFTERFILTER

AIRLINE PREFILTER

PROCESS AIR OUTLET

NPS 3 BOSS FITTING

TOP VIEW

ELECTRICAL ENCLOSURE

SEE DETAIL

SIDE VIEW

(SEE AC SIDE DETAIL)

RIGHT TOWER

PRESSURE GAGE

PURGE PRESSURE GAGE

PURGE PRESSURE

ADJUSTMENT VALVE

DESICCANT FILL PORT

FRONT VIEW

LEFT TOWER

PRESSURE GAGE

MOISTURE INDICATOR

TOWER PRESSURE

RELIEF VALVE

PROCESS AIR INLET

NPS 3 BOSS FITTING

PURGE MUFFLER

ENCLOSURE DETAIL

(ENLARGED)

3 PRONG MALE

ELECTRICAL PLUG

POWER SWITCH

ELECTRICAL ENCLOSURE

NEMA CLASS 4/4X

9

FIGURE 2D Model 1550G

ELECTRICAL ENCLOSURE

SEE DETAIL A

AIRLINE AFTERFILTER HIGH EFFICIENCY OIL

REMOVAL PREFILTER

SEPARATOR PREFILT ER

TOP VIEW

MOUNTING HOLES

7/8" DIA.

DESICCANT FILL PORT

DESICCANT DRAIN

PORTS

LEFT TOWER

PRESSURE GAUGE

PURGE PRESSURE GAUGE

RIGHT TOWER

PRESSURE GAUGE

ELECTRICAL ENCLOSURE

NEMA CLASS 4/4X

POWER SWITCH

3 PRONG MALE

ELECTRICAL PLUG

DETAIL A

TOWER PRESSURE

RELIEF VALVE

PURGE MUFFLER

PROCESS AIR INLET

NPS 3 BOSS FITTING

CONDENSATE DRAIN

3/4 NAT. HOSE

MALE THREAD

3.1/4" x 9.1/4" FORKLIFT TUBE

OPENINGS (83mm X 235mm)

SIDE VIEW

REAR VIEW OF DRYER

PROCESS AIR OUTLET

NPS 3 BOSS FITTING

MOISTURE INDICATOR

LIFTING LUGS

10

FIGURE 2E Model 5200G

SIDE VIEW

MOISTURE INDICATOR

SECTION B

(ENLARGED)

PILOT AIR REGULATOR

DETAIL A

3 PRONG MALE

ELECTRICAL PLUG

POWER SWITCH

ELECTRICAL ENCLOSURE

NEMA CLASS 4/4X

PURGE PRESSURE GAGE

RIGHT TOWER

PRESSURE GAGE

LEFT TOWER

PRESSURE GAGE

PROCESS AIR OUTLET

NPS 3 BOSS FITTING

4 PLACES

OUTLET SHUT OFF

VALVE NPS 3

4 PLACES

SEE SECTION B

DESICCANT FILL PORT

AIRLINE AFTERFILTER

HF7-76-6F-S

MOUNTING HOLES

1 INCH DIA.

6 PLACES

PURGE MUFFLER

3.1/2" X 9.1/2" FORKLIFT

OPENINGS (90mm X 241mm)

2 PLACES

CONDENSATE DRAIN

3/4 NPS MALE

PIPE THREAD

REAR VIEW

TRIP-L-TRAP

TOWER PRESSURE

RELIEF VALVE

TOP VIEW

B

HIGH EFFICIENCY OIL

REMOVAL PREFILTER

SEPARATOR PREFILTER

PROCESS AIR INLET

NPS 3 BOSS FITTING

4 PLACES

INLET SHUT OFF

VALVE NPS 3

4 PLACES

DESICCANT DRAIN

PORT ELECTRICAL

ENCLOSURE

SEE DETAIL A

11

2.6 Electrical Connections

Standard and Automatic Purge Saving

2.6.1 Power Connections

NOTE: Check Serial Number Tag for correct voltage.

Connect wires to terminal strip. Connect L1 (line) to position 5, L2 (neu-

tral) to position 6, and ground to position 7. Do not make connections to

terminals labeled with grounding symbol or labeled with RS.

Set the voltage selection switch located at the lower edge of the control

board for the proper supply voltage.

Electrical entry is 7/8” dia. hole for 1/2” nominal conduit entry.

2.6.2 Alarm Connections -

Dry contacts for a remote alarm are supplied at terminals 20, 21, 22.

When the unit is energized and no alarms are in effect, continuity should

exist between terminals 20 and 21, with no continuity between terminals

21 and 22. Alarm contact is common for switching failure alarm and

optional high humidity alarm.

Maximum contact rating is:

240 VAC - 5.0 amps

50 VDC - 1.0 amps

NOTE: Check Serial Number Tag for electrical values.

2.7 Provisions for Purge Exhaust

Purge exhaust must be routed through the factory supplied mufflers or

piped to a remote location.

2.7.1 Purge mufflers - If shipped separately, install purge exhaust muf-

flers in the locations shown in Figure 2C, 2D, or 2E.

2.7.2 If purge exhaust is piped to a remote location, choose a pipe size

large enough so that back pressure through the piping is not

created.

WARNING

Do not operate dryer without one of the above measures.

Exhausting air will result in noise levels above OSHA

permissible levels and exhausting gas could potentially

cause harm to persons or property.

2.8 Initial Desiccant Charge

The dryer is shipped complete with desiccant and ready to operate after

piping and electrical connections are made.

FIGURE 2E Electrical Schematic (Standard Dryers)

CUSTOMER

POWER

CONNECTIONS

(SEE NOTE 1)

GROUND

NEUTRAL

LINE 1

2TB-7

2TB-6

2TB-5

1TB-41SS

1TB-3

1TB-2

1FU

125mA

250V

1TB-1

12

T

LOW VOLTAGE

SUPPLY TO SOLID

STATE TIMER AND

CONTROL CIRCUITS

3TB-8 3TB-9

3TB-10

4TB-12

4TB-13

3TB-11

4TB-14

4TB-15

5TB-16

5TB-17 5TB-18

5TB-19

7TB-23

7TB-24

7TB-25

6TB-20

6TB-21

6TB-22

8TB-26

8TB-27

8TB-28

8TB-29

1PS

2PS

CR

CR

CR

POWER OFF/ON SWITCH

SPARE LOAD CONNECTIONS

SOLID STAT E

TIMER AND

CONTROL CIRCUIT

STEP DOWN

TRANSFORMER

120/240 VAC

CONTROL BOARD

INLET VOLTAGE

SELECTOR SWITCH

(SEE NOTE 1)

SOLENOID CIRCUIT FUSE

RIGHT TOWER

INLET SWITCHING

SOLENOID

LEFT TOWER

PURGE/

REPRESSURIZATION

SOLENOID

RIGHT TOWER

PURGE/

REPRESSURIZATION

SOLENOID

LEFT TOWER

INLET SWITCHING

SOLENOID

SPARE GROUND

CONNECTIONS

1SST

1SST

1SOL

2SOL

3SOL

4SOL

1Q

2Q

3Q

4Q

GATE

2FU

1.6A

250V

TO SOLID

STATE

TIMER

AND

CONTROL

CIRCUITS

TO SOLID

STATE

TIMER

AND

CONTROL

CIRCUITS

RIGHT TOWER

SWITCHING FAILURE ALARM

PRESSURE SWITCH

LEFT TOWER

SWITCHING FAILURE ALARM

PRESSURE SWITCH

COMMON ALARM

CONTACTS

(SEE NOTE 2)

2SS

10

9

71

3

4

6

(120) (240)

CUSTOMER

COMMON

ALARM

CONNECTIONS

(SEE NOTE 2)

COMMON ALARM

RELAY

(SEE NOTE 2)

GATE

GATE

GATE

(SEE NOTE 1)

(SEE NOTE 1)

(SEE NOTE 1)

(SEE NOTE 1)

CONTROL CIRCUIT FUSE

12

FIGURE 3B

Standard Control Board

3.0 OPERATION

3.1 Start-up

3.1.1 Controller Settings- Set or verify settings on controller

3.1.1.1 Standard Control Board

WARNING

Enclosure may have live electric parts.

De-energize dryer before opening enclosure.

3.1.1.1.1 Voltage Selection -

Set the voltage selection switch located at the lower edge of the power

board for the proper voltage.

3.1.1.1.2 Dip Switch Settings - (Refer to Table 3A)

NOTE: For ON DIP switch is up; OFF DIP switch is down

To select Test Mode - place switch 5 and 6 in ON position

Right Inlet Solenoid Energized LED

Left Purge/Repressurization Solenoid Energize LED

Right Purge/Repressurization Solenoid Energized LED

Left Inlet Solenoid Energized LED

DIP Switches for Economizer Setting,

Standard or HP selection,

Cycle/Mode selection

Alarm Hook-up

Power Hook-up

Voltage Selection Switch

Soleniod circuit fuse

1.25A 250V

Control circuit fuse

125m A 250V

Tower Pressure Switches Open @40 psig

Close @45 psig

RESET/STEP

BUTTON

HIGH HUMIDITY

ALARM

SWITCHING

FAILURE ALARM

FIXED CYCLE

MODE INDICATORS

LEFT TOWER

REGENERATING

INDICATOR

TEST MODE

INDICATOR

OFF ON

FIGURE 3A

Standard Control Panel

LEFT TOWER

DRYING INDICATOR

RIGHT TOWER

REGENERATING

INDICATOR

RIGHT TOWER

DRYING INDICATOR

PURGE

ECONOMIZER

SETTING

POWER

SWITCH

60 %

50 %

40 %

30 %

100 %

90 %

80 %

70 %

13

3.1.2 SLOWLY pressurize dryer to full line pressure (open inlet isola-

tion valve, outlet isolation valve remains closed).

NOTE: During initial start-up check entire system for leaks. If neces-

sary, depressurize and correct any leaks.

3.1.3 Energize dryer using the power switch located on the control

panel.

NOTE: Switching failure alarm: alarm (light) may be activated if unit is

energized before it is pressurized. To deactivate alarm, allow dryer to

cycle to next step and press the reset button.

3.1.4 Adjust the purge rate valve.

3.1.4.1 Determine:

1) Maximum working pressure (MWP) of dryer from the dryer serial

number tag

2) Air pressure at inlet to dryer

3.1.4.2 Refer to Table 3A for proper purge rate pressure setting at the

conditions found in 3.1.4.1

3.1.4.3 Adjust purge rate valve until purge flow indicator reads re-

quired pressure setting.

NOTE: Adjustment must be made while a tower is purging (air exhaust-

ing from muffler).

IMPORTANT

INSUFFICIENT PURGE AIR WILL EVENTUALLY RESULT IN SATURA-

TION OF DESICCANT BED AND WET AIR DOWNSTREAM. MAKE CER-

TAIN THAT CYCLE TIME, PURGE ECONOMIZER SWITCH, AND PURGE

PRESSURE ARE CORRECTLY SET.

3.1.5 Establish normal flow through dryer (open outlet isolation

valve). Close air by-pass valve if present.

NOTE: When dew points below -40°F (-40°C) are required, the dryer

must be run with an inlet flow rate of less than 50% of maximum until

the desired dew point is attained. Depending on the initial dryness of

the desiccant, this can take as long as 2 to 3 days. This stabilization

period is required on initial startup, after dryer has been shutdown

for extended periods of time, or after dryer maintenance (desiccant

change, etc.).

3.1.6 With the inlet pressure to the dryer at its minimum level, read-

just the purge pressure as determined in 3.1.4.

NOTE: Adjustment must be made while a tower is purging (air exhaust-

ing from muffler).

3.2 Operational Check Points

3.2.1 Standard Unit

3.2.1.1 Power to unit -

Check periodically that there is power to the unit (indicating lights il-

luminated).

3.2.1.2 Moisture Indicator -

Every four hours check moisture indicator. Indicator should be green.

Outlet relative humidity of the desiccant dryer is indicated by the color

change humidity indicator. Green indicates a R.H. below 3% and yellow

indicates a R.H. above 3%. Table 3C (page 16) indicates outlet dew point

when moisture indicator changes from green to yellow at various inlet

temperatures.

NOTE: During start-up the indicator may be yellow, however, it should

begin to change to green within four hours.

3.2.1.3 Purge Flow Indicator -

Every four hours check the purge pressure and adjust as required. Ad-

justment should be made when the inlet pressure to the dryer is at its

minimum level.

NOTE: Adjustment must be made while a tower is purging (air exhaust-

ing from muffler).

Units with Standard Board Operation

3.2.1.4 Alarms

Periodically check for flashing red alarm light. Alarm light will flash if

either tower fails to pressurize or depressurize to the required levels at

the proper time or if optional high humidity alarm indicates high exiting

dewpoint.

NOTE: Alarm will activate if dryer is energized without being pressur-

ized. If this occurs allow dryer to cycle to next step and press reset

button.

NOTE: Alarm light will continue to flash even if fault clears. To clear

alarm, press reset button.

NOTE: If the tower being regenerated fails to repressurize, the dryer

will not switch towers. The switching failure alarm will be activated and

the dryer will remain in this mode until the tower repressurizes.

Switching Failure

The switching failure alarm operates by sensing tower pressures after

tower changeover. If towers have failed to pressurize or depressurize to

the required levels, an alarm condition exists. The alarm light blinks while

the alarm condition exists. Depressing the reset switch will extinguish the

light, but will not interrupt the drying cycle.

If the tower being regenerated fails to repressurize, the dryer will not

switch towers. The switching failure alarm will be activated and the dryer

will remain in this mode until the tower repressurizes.

3.2.1.5 Tower Status Lights -

Illuminated light indicates which tower is on-line drying or off-line re-

generating.

3.2.1.6 Tower pressure gauges

3.2.1.6.1 Periodically check tower pressure gauges to verify that tower

pressure gauge of tower on-line reads line pressure and tower

pressure gauge of tower off-line reads below 2 psig.

NOTE: Read off-line tower gauge when tower is purging (air exhaust-

ing from muffler)

3.2.1.6.2 Check mufflers for back pressure

Excessive back pressure may result due to the accumulation of dust in

the muffler. This sometimes occurs after start-up because of dusting of

the desiccant during tower filling and dryer transport.

If the tower pressure gauge of the off-stream tower rises out of the black

area on the gauge dial, muffler elements should be replaced. A set of

purge exhaust muffler replacement elements is supplied with the dryer.

14

3.2.3 All MODELS - Determine if air control valves are operating and

sequencing correctly.

3.2.3.1 Inlet switching and purge/repressurization valves.

1) Tower pressure gauge of tower on-line should read line pressure. No

air should be leaking from purge/repressurization valve of the on-line

tower.

2) Tower pressure gauge of tower off-line should read below 2 psig while

tower is purging. If excessive purge air is exhausting during purge

cycle, inlet valve may have failed to close or a check valve may be

sticking.

3.2.3.2 Check valves

Check valve sticking will result in excessive air discharge through a muf-

fler. If excessive air is discharged through the muffler on the left, check

if valve 5a or 5d is sticking. If excessive air is discharged through the

muffler on the right, check if valve 5b or 5c is sticking.

3.3 Shut Down

3.3.1 Depressurize dryer

3.3.1.1 Open by-pass valve (if one is installed) and close inlet and

outlet isolation valves.

3.3.1.2 Run timer through a tower change cycle until pressure gauges

on both towers read 0 (test mode may be used to speed this

up).

3.3.2 De-energize dryer

Turn dryer off using on-off switch (indicating lights extinguished).

3.4 Loss of Power

Control valves are designed so that upon loss of power the air dryer

is capable of drying air until the desiccant exposed to the air flow is

saturated.

3.5 Verify that dryer is operating within design parameters

3.5.1 Maximum working pressure:

Refer to Serial Number Tag to determine maximum working pressure

of dryer.

WARNING

Do not operate dryer at pressures above the maximum pressure shown

on the tag.

3.5.2 Minimum working pressures: 100 psig (7 barg)

15

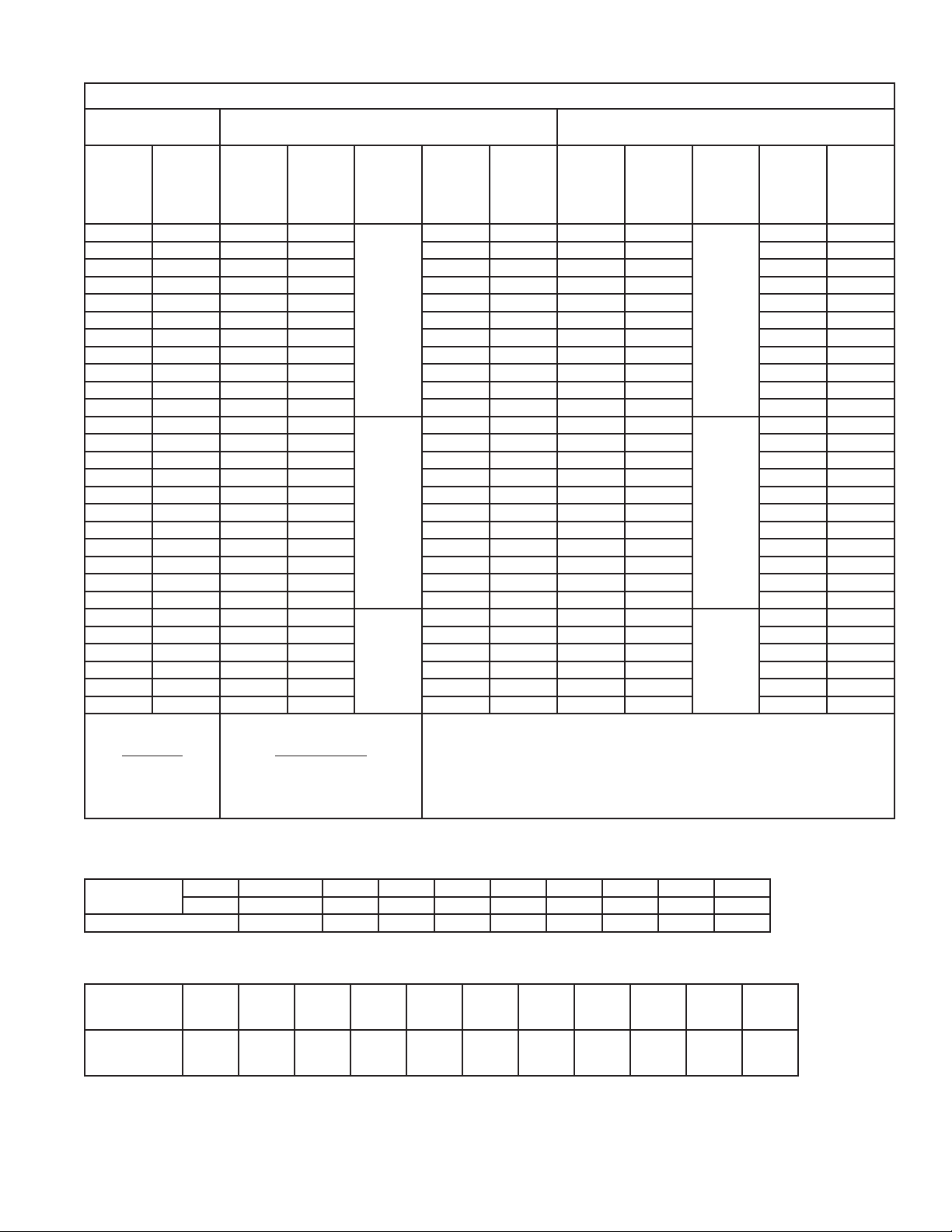

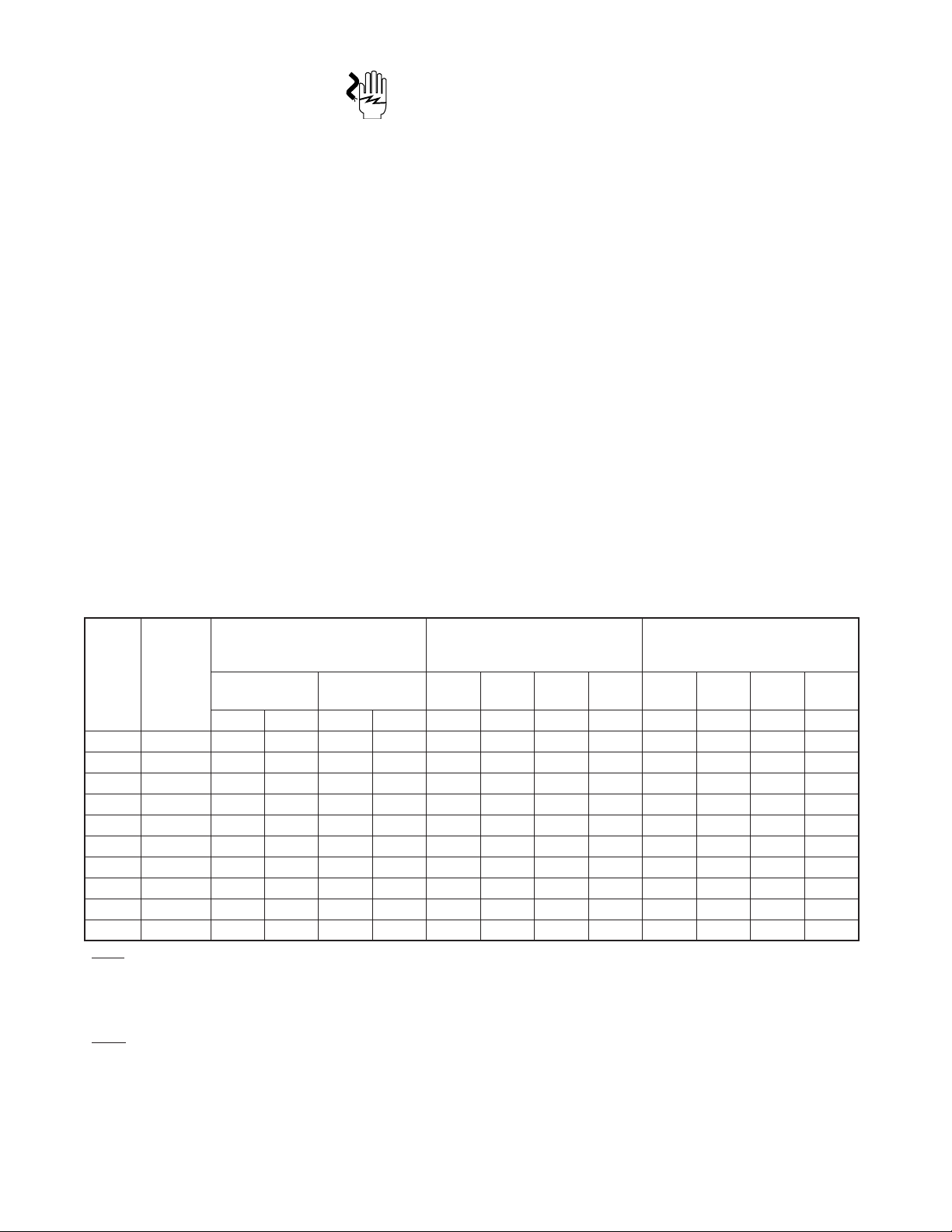

TABLE 3A

Model RDH-HP

Inlet Temperature

100°F

Outlet Pressure Dew Point: -40°F

10 Minute Cycle

Outlet Pressure Dew Point: -100°F

4 Minute Cycle

Inlet

Pressure

(psig)

Inlet

Pressure

Correction

Factor

*

Purge

Time

(seconds)

Repress

Time

(seconds)

Timer

board DIP

Switch

Settings

Purge

Orifice

Pressure

(psig)

Maximum

Purge

Flow

Factor

**

Purge

Time

(seconds)

Repress

Time

(seconds)

Timer

board DIP

Switch

Settings

Purge

Orifice

Pressure

(psig)

Maximum

Purge

Flow

Factor

**

350 1.78 139 155

1 = OFF

2 = ON

3 = OFF

4 = ON

5 = OFF

6 = ON

42 0.166 29 85

1 = ON

2 = ON

3 = OFF

4 = ON

5 = ON

6 = OFF

89 0.318

340 1.76 139 155 43 0.168 29 85 90 0.322

330 1.73 139 155 44 0.170 29 85 92 0.327

320 1.71 139 155 44 0.173 29 85 93 0.333

310 1.68 139 155 45 0.176 29 85 95 0.337

300 1.66 139 155 46 0.178 29 85 97 0.342

290 1.63 139 155 47 0.181 29 85 98 0.348

280 1.60 139 155 48 0.184 29 85 100 0.353

270 1.58 139 155 49 0.188 29 85 102 0.360

260 1.55 139 155 50 0.191 29 85 104 0.366

250 1.52 139 155 51 0.194 29 85 106 0.373

250 1.52 174 120

1 = OFF

2 = OFF

3 = OFF

4 = ON

5 = OFF

6 = ON

39 0.155 42 72

1 = OFF

2 = OFF

3 = OFF

4 = ON

5 = ON

6 = OFF

70 0.257

240 1.49 174 120 40 0.158 42 72 72 0.262

230 1.46 174 120 41 0.162 42 72 74 0.268

220 1.43 174 120 42 0.165 42 72 75 0.273

210 1.40 174 120 43 0.169 42 72 77 0.279

200 1.37 174 120 44 0.172 42 72 79 0.286

190 1.34 174 120 46 0.177 42 72 81 0.293

180 1.30 174 120 47 0.181 42 72 84 0.300

170 1.27 174 120 48 0.186 42 72 86 0.308

160 1.23 174 120 50 0.191 42 72 89 0.317

150 1.20 174 120 52 0.197 42 72 92 0.326

150 1.20 234 60 1 = OFF

2 = OFF

3 = OFF

4 = OFF

5 = OFF

6 = ON

36 0.146 66 48 1 = OFF

2 = OFF

3 = OFF

4 = OFF

5 = ON

6 = OFF

55 0.208

140 1.16 234 60 38 0.151 66 48 57 0.214

130 1.12 234 60 39 0.156 66 48 59 0.222

120 1.08 234 60 41 0.162 66 48 62 0.230

110 1.04 234 60 43 0.168 66 48 65 0.239

100 1.00 234 60 45 0.175 66 48 68 0.249

Dryer Model

RDH-HP-715

RDH-HP-1550

RDH-HP-5200

Inlet Flow Rating

@ 100 psig (scfm)

715

1550

5200

* (Inlet Flow rating @ P) =

(Inlet Pressure Correction factor @ P) X (Inlet Flow Rating @ 100 psig)

** (Maximum Purge Flow @ P) =

(Maximum Purge Flow Factor @ P) X (Inlet Flow Rating @ 100 psig)

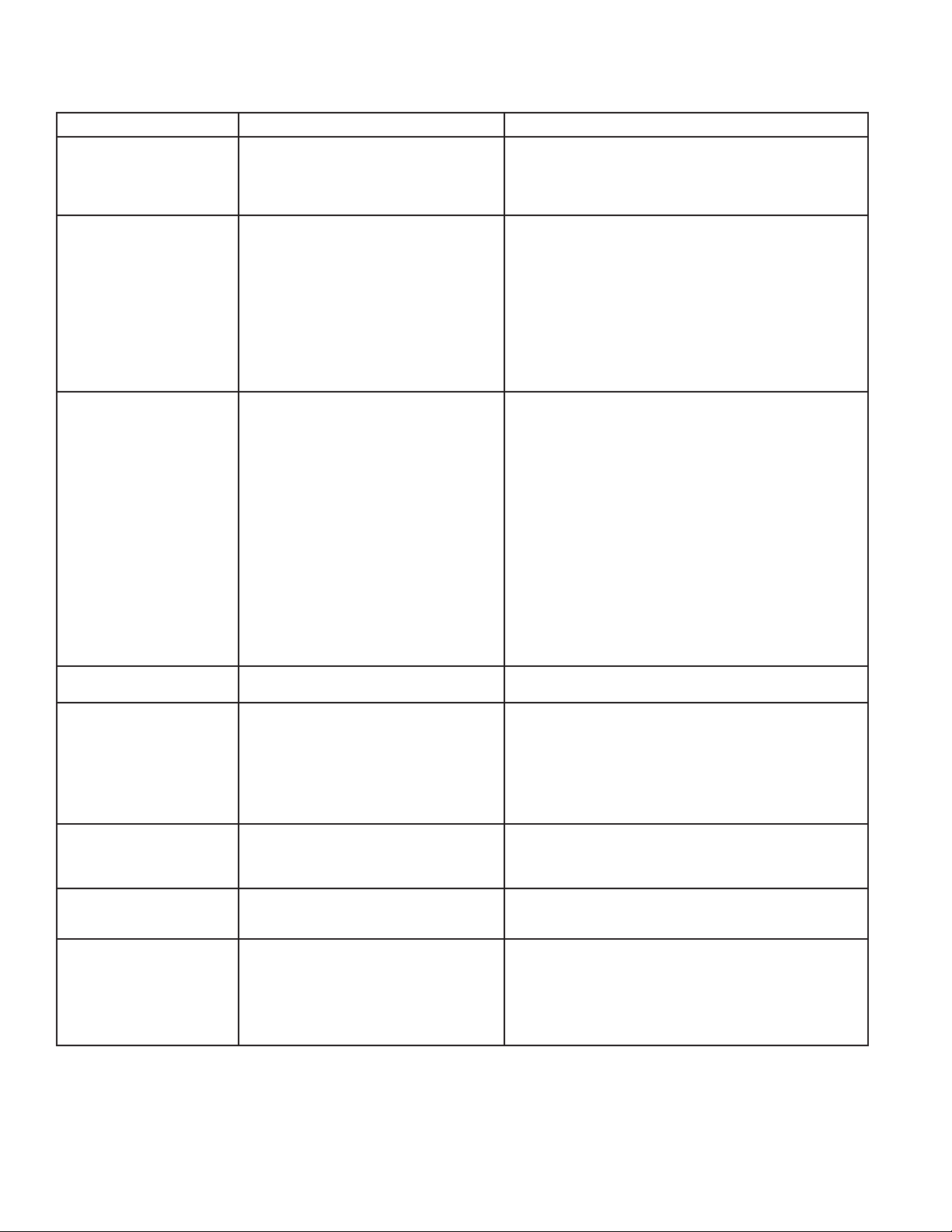

TABLE 3C Outlet pressure dew points at moisture indicator color change

INLET

TEMPERATURE

°F

°C

35

1.7

40

4.4

50

10.1

60

15.6

70

21.1

80

26.7

90

32.2

100

37.8

110

43.3

120

48.9

OUTLET P.D.P. °F

°C

-34

-36.7

-28

-33.4

-22

-30.0

-16

-26.7

-10

-23.4

-4

-20.0

3

-16.1

9

-12.8

15

-9.5

21

-6.1

TABLE 3B Inlet Temperature Correction Factor

INLET

TEMPERATURE

°F 100 and below 105 110 115 120 125 130 135 140

°C 38 and below 41 43 46 49 52 54 57 60

MULTIPLIER 1.0 0.98 0.96 0.93 0.91 0.85 0.81 0.76 0.70

16

4.2 Pilot Air Filter - Element Replacement -

Models 370 scfm and larger

4.2.1 Frequency of replacement -

Pilot air filter contains a filter element which should be changed yearly

or sooner if pressure drop across cartridge prevents valves from actu-

ating. Pilot air pressure must not drop below 60 psig (4.2 kgf/cm2).

4.2.2 Procedure for element replacement.

Follow instructions supplied with replacement element.

WARNING

THIS SEPARATOR IS A PRESSURE CONTAINING DEVICE. DEPRES-

SURIZE BEFORE SERVICING. IF SEPARATOR HAS NOT BEEN DEPRES-

SURIZED BEFORE DISASSEMBLY, AN AUDIBLE ALARM WILL SOUND

WHEN THE BOWL BEGINS TO BE REMOVED FROM THE HEAD. IF THIS

OCCURS, STOP DISASSEMBLY, ISOLATE AND COMPLETELY DEPRES-

SURIZE SEPARATOR BEFORE PROCEEDING.

1. Shut off air supply.

2. Depressurize Dryer.

3. Remove bowl.

a. Push bowl up, turn bowl

1/8th turn to your left,

and pull bowl straight down

4. Clean filter bowl

5. Replace element

a. Pull off old element and

discard

b. Make certain o-ring inside

top of replacement element

is in place and push element

onto filter head.

NOTE: Make certain o-ring is generously lubricated.

6. After making certain that bowl o-ring is in place, reassemble bowl

to head.

NOTE: Wave spring ends should be pointed down to prevent the wave

spring from interfering with reassembly.

4.3 Fuse Replacement

4.3.1 Fuses are located on board in electrical enclosure. See figure

3B for Standard Control Board and 3C for Automatic Purge Sav-

ing System.

4.0 MAINTENANCE

FIGURE 4B

Element O-ring

Replacement

Element

Bowl O-ring

Wave Spring

Spacer

WARNING

The heatless desiccant dryer is a pressure containing device. Depressurize

before servicing. (See Section 3.3)

4.1 Desiccant Replacement

NOTE: The use of the correct replacement desiccant is necessary for

proper dryer operation. Never use hygroscopic salts of the type com-

monly used in “deliquescent” type dryers.

4.1.1 Frequency of desiccant replacement

Desiccant should be replaced whenever the required dew point cannot

be maintained while the dryer is being operated within its design condi-

tions and there are no mechanical malfunctions. Refer to section 5.0 for

troubleshooting hints.

NOTE: Desiccant life is determined by the quality of the inlet air. Proper

filtering of the inlet air will extend the life of the desiccant.

Typically desiccant life is 3 to 5 years.

4.1.2 Procedure for Desiccant Charge Replacement

4.1.2.1 Depressurize and de-energize the dryer. (See section 3.3)

4.1.2.2 Remove the fill and drain plugs

from desiccant tower and drain

the spent desiccant. Place a

container at the base of the

vessel to collect the desiccant.

If necessary tap the sides of the

vessels with a rubber mallet to

loosen desiccant.

4.1.2.3 Replace the drain plug using

teflon tape sealant or equivalent.

4.1.2.4 Fill the desiccant drying tower as

full as possible with dry desic-

cant. Do not tamp desiccant.

4.1.2.5 Replace the fill plug using teflon

tape sealant or equivalent.

4.1.2.6 Repeat this procedure for the

other tower.

4.1.3 Insuring desiccant dryness

4.1.3.1 Replacement desiccant is shipped in air tight containers. Keep

the covers on these containers tightly closed until use to avoid

moisture contamination. If desiccant is exposed to air it can be

heated in an oven at 400°F (204°C) for four hours before use,

or the procedure in 4.1.3.2 can be used.

4.1.3.2 If the dryer is not refilled with dry desiccant, it will be necessary

to operate the dryer with an inlet flow rate of less than 50% of

maximum to dry the desiccant. To do this, set the Economizer

Switch for 100%, and the purge pressure for 45 psig. (3.2 kgf/

cm2)

4.1.3.3 Purge mufflers should be changed annually.

4.1.3.4 Valve(s) should be checked annually.

DRAIN

PLUGS

FILL

PLUG

FIGURE 4A

DRAIN

PLUGS

17

Test Mode

TABLE 4B

TOWER STATUS VALVE POSITION SOLENOID/TERMINALS

ENERGIZED

(light illuminated)

STEP

NUMBER

WHAT

OCCURS

MODE PRESSURE L

P/R

L

IN

R

P/R

R

IN

L

P/R

L

IN

R

P/R

R

IN

LT RT LT RT

Start D D LP LP C O C O

1 R IN closes D - LP LP C O C C E

2 (1) R P/R opens D R LP <2 C O O C E E

3 No change D R LP <2 C O O C E E

4 (2) (3) R P/R closes D - LP REP C O C C E

5 R IN opens D D LP LP C O C O

6L IN closes - D LP LP C C C O E

7 (1) L P/R opens R D <2 LP O C C O E E

8 No change R D <2 LP O C C O E E

9 (2) (3) L P/R closes - D REP LP C C C O E

NOTES:

(1) Close purge rate valve during this step to check for any valve leaks. No air should exhaust through the muffler. If air is exhausting through the muffler, check all valves for leaks.

After testing for leaks or fixing any leaks, be sure to open the purge pressure valve and reset the purge pressure.

(2) Do not go to the next step until the tower is repressurized.

(3) Switching failure alarm circuit is energized during this step (alarm light should flash until pressure exceeds 40 psig).

CODES:

R IN - Right inlet valve D - Drying E - Energized

R P/R - Right purge/repressurization valve R - Regenerating

L IN - Left inlet valve LP - Line Pressure

L P/R - Left purge/repressurization valve <2 - Less than 2 psig

LT - Left tower REP - Repressurizing

RT - Right tower C - Closed

O - Open

4.4 Test Mode

WARNING

Enclosure contains electricity.

Use caution when working inside box.

4.5.1 Test Mode - Standard Control Panel

4.5.1.1 Wait until point in cycle when right tower is drying and left

tower has completed regeneration and repressurization (both

towers at full line pressure).

4.5.1.2 De-energize dryer (on/off switch off, “O”); Select Test Mode by

placing DIP switches 5 and 6 (found inside enclosure) in the ON

(up) position; Re-energize dryer (1) (2).

4.5.1.3 Use Reset/step button to step through the operating cycle in the

order shown in Table 4B.

4.5.1.4 Complete all 9 steps, allow the left tower to fully repressurize

and de-energize dryer. (1) (3).

4.5.1.5 Reset DIP switches 5 and 6 to operating mode desired (10 min.

cycle - 5 is OFF, 6 is ON or 4 min. cycle - 5 is ON, 6 is OFF); Re-

energize dryer.

(1) Do not de-energize dryer unless both towers are at line pressure.

(2) If Test Mode is selected without de-energizing dryer, Test Mode light

will blink until tower on line has completed drying. Dryer will then enter

Test Mode and light will glow steadily.

(3) If another operating mode is selected without de-energizing dryer and

before all 9 steps are completed, selected mode light will blink and dryer

will automatically complete a cycle. Dryer will then operate in selected

mode and light will glow steadily. You may also use the Reset/step but-

ton to manually step through the cycle until the left tower drying light

illuminates and pressing the Reset/step button will not advance through

further steps.

18

5.0 TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE(S CORRECTIVE ACTION

5.1 Indicator lights not illuminated No power to unit

On/Off Switch off

Switch malfunctioning

Check voltage at terminal board.

Turn on.

Replace switch.

5.2 Moisture Indicator turns yellow

(elevated outlet dew points)

Maximum flow being exceeded

Design conditions being exceeded

Desiccant not adsorbing

a. Useful service life has ended

b. Desiccant is contaminated

(e.g. with oil)

c. Premature exhaustion (saturated with water)

Refer to Table 3A to determine maximum flow.

Refer to Section 3.5 to determine if dryer is being operated within its design

limitations.

Change desiccant.

Take corrective action. Refer to Section 2.1 to determine proper prefiltration

then change desiccant.

Refer to 5.3 for corrective action. Desiccant beds may be reactivated by running

at reduced flow until desired outlet dewpoint is achieved.

5.3 Desiccant being exhausted

prematurely

Insufficient purge rate

a. Improper purge rate

b. Tower not completely depressurized during

purge cycle (Tower pressure gauge should read

lower than 2 psig)

1. Clogged exhaust muffler

2. Purge valve won’t open

3. Check valve stuck open

Insufficient purge time

a. Improper set points

b. Faulty Timer

Refer to Section 3.1.4 to determine correct Purge Pressure Indicator Setting.

Replace muffler inserts.

Check power to valve to determine if valve or timer at fault.

Check pilot air line for obstruction.

Repair valve.

Refer to Section 3.1.1 to determine correct Economizer Switch and Cycle Set-

tings.

Refer to Section 3.2.3 to verify proper time sequence.

5.4 Tower fails to pressurize to line

pressure

Purge repressurization valve won’t close

Excessive downsteam air demand

Check valve for obstruction. This valve is normally closed.

Check pilot solenoid valve and pilot air line for obstruction.

5.5 Tower fails to depressurize to less

than 2 psig

Purge rate valve open too far

Clogged muffler

Check valve stuck open

Purge repressurization valve won’t open

Check Section 3.1.4 for purge rate indicator setting.

Replace muffler.

Repair valve.

Check power to valve to determine if valve or timer is at fault. Check pilot valve,

pilot air line, and purge repressurization valve for obstruction.

5.6 Excessive purge air is discharged

during purge cycle

Inlet valve won’t close

Check valve sticking

Check power to valve to determine if valve or timer is at fault.

Check valve for obstruction. Check pilot valve and pilot air line for obstruction.

Repair Valve

5.7 Excessive desiccant dust

downstream

Faulty timer

Purge rate valve closed

Refer to Section 3.2.3 to verify proper time sequence.

Refer to Section 3.1.4 to determine Correct Purge Pressure setting.

5.8 Switching Failure

Unit did not depressurize in time

(24 sec) or below 10#

Unit did not repressurize in time

(24 sec) or not above 40#

Clogged mufflers, faulty check valve, faulty inlet valve or

purge valve, or faulty pressure switch.

Make sure dryer has air pressure, check purge pressure

setting, faulty purge valve, or faulty pressure switch.

Replace mufflers or defective parts.

Provide proper air pressure. Replace defective parts. Set purge pressure per

section 3.1.4.

19

Description Model HP-715G Model HP-1550G Model HP-5200G Quantity

Power On/Off Selector Switch 3158486 3158486 3158486 1

Pressure Switch 7417131 7417131 7417131 1

Switching Valve Pilot Solenoid Valve (coil only) 4009808 4009808 4009808 2

Purge Pilot Solenoid Valve (coil only) 4009808 4009808 4009808 2

Switching Valve Pilot Solenoid Valve Rebuild Kit 3153703 3153703 3153703 1

Moisture Indicator 4003167 4003167 4003168 1

Pressure Gauge, 0 - 400PSIG 4011115 4011115 4011115 3

Pressure Gauge, 0 - 100PSIG 4011100 4011100 4011100 1

Purge Muffler Replacement Core 3097672 — — 1

Purge Muffler Replacement Core — 72378 72378 8

Aftercooler Air Filter-Silencer Replacement Core 3211091 3211091 3211091 1

Aftercooler Temperature Gauge 4011137 4011137 4011137 1

Packaged Oil (for Aftercooler option) 3164064 3164064 3164064 1

Filtration Replacement Elements Quantity per Dryer

3174776, High Efciency Oil Removal Prelter (Grade 5) 2 3 11

3174855, Air Line Afterfilter (Grade 7) 2 3 11

3174934, Separator Prefilter (Grade 9) 2 3 11

Desiccant Quantity per Dryer

3153517, 10# container 2 — —

7405937, 17# container 2 2 —

3146257, 50# container 2 — —

3146259, 150# container — 12 4

3146260, 350# container 2—4

3146261, 2000# sack — — 2

6.0 REPLACEMENT PARTS

RDH-HP SERIES

Pressure-Swing

Desiccant Type

Compressed Air Dryers

Models: RDH-HP-715G

RDH-HP-1550G

RDH-HP-5200G

SPX

1000 Philadelphia Street

Canonsburg, PA 15317-1700 U.S.A.

P: (724) 745-1555

F: (724) 745-6040

www.rentaldryers.com

Improvements and research are continuous at SPX.

Specifications may change without notice.

ISSUED 04/2014 Form No.: 3245430 Revision: A

COPYRIGHT ©2014 SPX Corporation

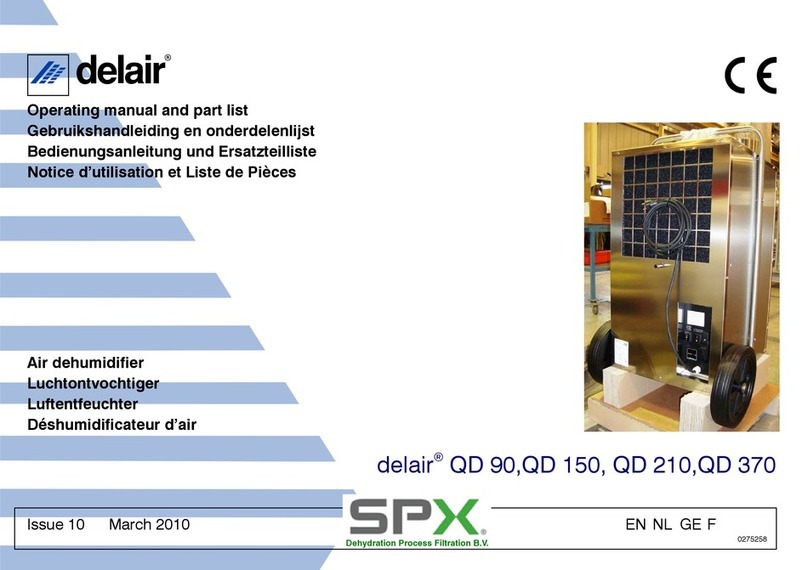

This manual suits for next models

3

Table of contents

Other SPX Dehumidifier manuals

SPX

SPX DELAIR QD 90 User manual

SPX

SPX Hankison GCU Series User manual

SPX

SPX HANKISON HES Series User manual

SPX

SPX HPD Series User manual

SPX

SPX HCD Series User manual

SPX

SPX HANKISON HIT Series User manual

SPX

SPX Hankison HPRP Series User manual

SPX

SPX Hankison HPRplus Series User manual

SPX

SPX Pneumatic Products IBP500 User manual

Popular Dehumidifier manuals by other brands

Seaira Global

Seaira Global WatchDog 900c Installation and operation manual

LG

LG D451WH owner's manual

ICP

ICP iDRY Instructions for installation and operation

Trotec

Trotec TTK 24 E operating manual

Olimpia splendid

Olimpia splendid SeccoReale Instructions for installation, use and maintenance

omi

omi ED HP40 Instruction and maintenance manual