Srne MD Series User manual

Manual version: V1.02 Subject to change without notice

User Manual of MPPT DC Charge

Controller for Solar Energy and Generator

Code: 108260

Dear users:

Thank you for choosing our products!

Safety Instructions

1. Since the applicable voltage of the controller exceeds the safety limit of human body,

please read the manual carefully before operation and operate it only after the safety

operation is trained.

2. Since no part is required to be maintained or repaired inside the controller, please do

not disassemble and repair the controller.

3. Please install the controller indoors to avoid exposure of components and keep water

away from the controller.

4. Since the cooling fin will be very hot during operation, please mount the controller in a

well-ventilated place.

5. Suitable fuse or circuit breaker is recommended to be equipped outside the controller.

6. Before installing and adjusting the wiring of the controller, be sure to disconnect the

wiring of the photovoltaic array and the fuse or circuit breaker near the accumulator

battery terminals.

7. After installation, check whether all wiring is tightly connected to avoid the danger of

heat accumulation due to loose connection.

Warning: Indicating dangerous operation, and safety preparation is required

before operating.

!

Contents

01 02

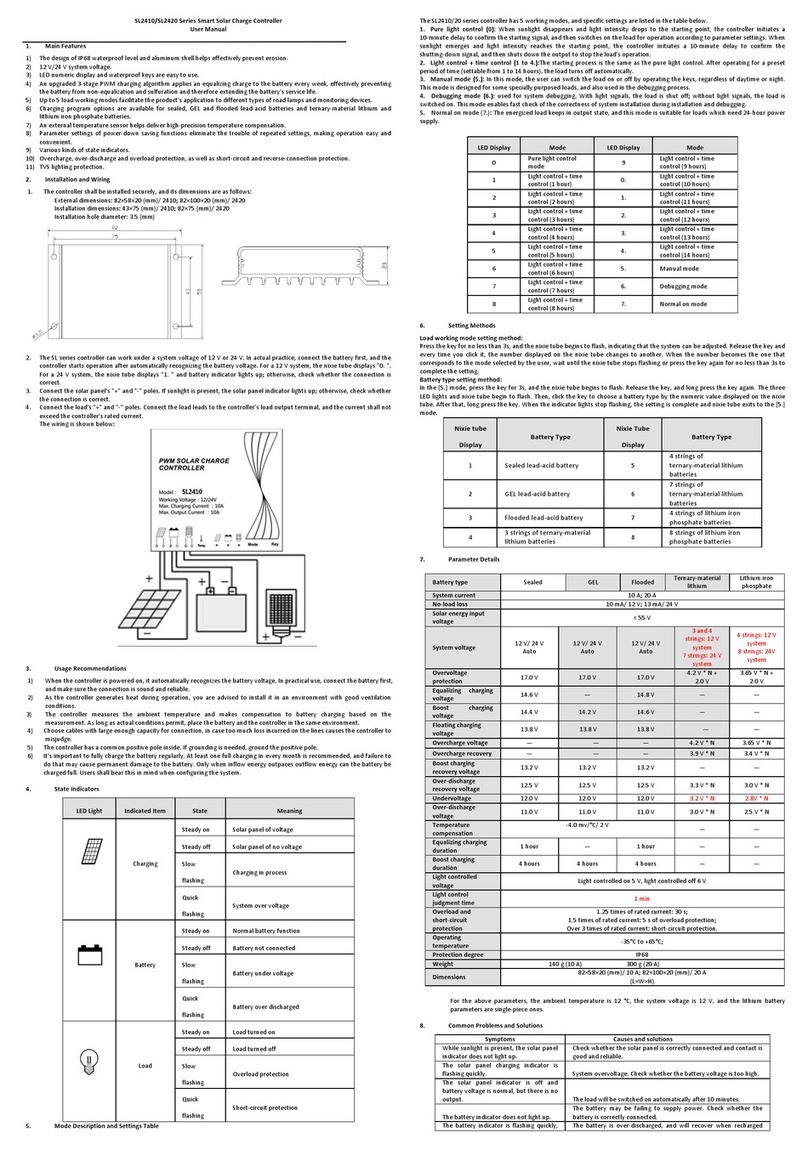

1. Product Introduction------------------------------------------------------------------------------

1.1 Product overview------------------------------------------------------------------------------

1.2 Product features-------------------------------------------------------------------------------

1.3 Interface description--------------------------------------------------------------------------

1.4 Introduction of maximum power point tracking--------------------------------------------

1.5 Introduction of charging stage---------------------------------------------------------------

1.5.1 Charging for lead-acid battery--------------------------------------------------------

1.5.2 Charging for lithium battery-----------------------------------------------------------

2. Product Applications----------------------------------------------------------------------------

2.1 Specification and parameter-----------------------------------------------------------------

2.2 Default parameters of battery type----------------------------------------------------------

2.3 Definition and description of indicator lights-----------------------------------------------

2.3.1 Status description of indicator lights-------------------------------------------------

2.3.2 Indicator light of solar panel-----------------------------------------------------------

2.3.3 Indicator light of generator------------------------------------------------------------

2.3.4 Indicator light of backup battery------------------------------------------------------

2.3.5 Indicator light of backup battery types-----------------------------------------------

2.4 Button-------------------------------------------------------------------------------------------

2.5 RS485 communication --------------------------------------------------------------

2.6 CAN communication interface

----

-----------------------------------------------------------

2.7 Bluetooth communication --------------------------------------

2.8 CAN communication -------------------------------------

2.9 TTL communication interface- -- -----------------------------------------------------------

3. Common Problems and Solutions------------------------------------------------------------

4. Installation-----------------------------------------------------------------------------------------

4.1 Installation precautions-----------------------------------------------------------------------

4.2 Reference for wire and fuse selection------------------------------------------------------

4.3 Installation and wiring-------------------------------------------------------------------------

5. Product Dimensions-----------------------------------------------------------------------------

Attention: Indicating destructive operation.

Tips: Indicating suggestions and tips to the operator.

03

03

03

04

04

06

06

07

08

08

09

09

09

09

10

10

10

10

11

11

11

11

12

12

13

13

13

14

16

2.10 Voltage compensation interface of backup battery- -------------------------------------

2.11 Temperature sampling interface of backup battery--------------------------------------

2.12 Ignition signal interface --------------------------------------------------------------------

12

12

12

--------

------------------------------

-

--

--

-------------------------------------

03

1. Product Introduction

03 04

1.1 Product overview

Based on multi-phase synchronous rectification technology and advanced MPPT control algorithm,

the MD Series MPPT DC charge controller for solar energy and generator adopts fully digital and

intelligent design. Thus, it achieves advantages such as great response speed and reliability and

reaches high industrialization standards. The multi-phase synchronous rectification technology ensures

super conversion efficiency at any charging power, significantly improving the energy utilization of the

system. The PowerCatcher maximum power point tracking technology leads the industry and achieves

the maximum energy tracking of solar panels. That makes it possible for the panel to rapidly and

precisely track the maximum power point of solar battery in any condition and obtain the maximum

energy of solar panels in real-time.

The product belongs to the DC/DC intelligent charger that applies to vehicle or ship systems. It is

applied to a dual battery system integrating the respective advantages of generator and photovoltaic

power generation. In this case, the system adopts the combination of charging methods with ingenious

design, which effectively ensures enough power at any time. The backup battery could be charged by

either or both of the solar energy and generator.

1.4 Introduction of maximum power point tracking

The MPPT (Maximum Power Point Tracking) system is an advanced charging technology, which

achieves more energy output from the solar batteries by adjusting the operating state of the electrical

modules. Due to the nonlinearity of the solar battery array, there is a maximum energy output point

(maximum power point) on its curve. The traditional controller (switching charging technology and

PWM charging technology) cannot charge the battery continuously at the point, so it cannot obtain the

maximum energy of the solar panel. Instead, the solar controller with MPPT can always track the

maximum power point of the array, so as to charge the battery with the maximum energy. For

example, for the 12V solar system, since the peak-to-peak voltage (Vpp) of the solar battery is about

17V, while the battery voltage is about 12V, therefore, when the charge controller is charging the

battery, the voltage of the solar battery is generally about 12V, that is, the solar battery does not fully

exert its maximum power. The MPPT controller can overcome the problem. It could adjust the input

voltage and current of the solar panel in real-time to reach the maximum input power. Compared with

the traditional PWM controller, the MPPT controller can exert the maximum power of the solar battery,

so it can provide a larger charging current. Generally, the MPPT controller can improve the energy

utilization rate by 15%~20% more than the PWM controller.

Applied with the PowerCatcher maximum power point tracking technology, the controller could still

track the maximum power point of the solar battery in complex conditions. Compared with traditional

MPPT technology, it has better response speed and tracking efficiency, and its efficiency could reach

up to 99.9%.

Applied with the design of multi-phase synchronous rectification for step-up/down circuitry, the

controller owns great DC/DC conversion efficiency whether in high/low power, which could reach up to

98%.

Various types of backup batteries are supported such as sealed, gel, flooded, lithium, and custom.

Various types of generators are supported such as intelligent and traditional generators, and the

controller could automatically identify the generator types by the ignition signal.

Applied with various charging modes such as photovoltaic charging the backup battery individually,

generator charging the backup battery individually, and photovoltaic and generator charging the backup

battery at the same time.

Applied with cable drop compensation for charging voltage of the backup battery, so that the controller

controls the charging voltage in a more accurate way.

Applied with temperature sampling for the backup battery, and temperature compensation for the

lead-acid battery, effectively extending the service life of batteries.

Applied with automatic derating while charging in high temperature.

Applied with TTL communication, providing technical support of communication protocol to facilitate

applications for secondary development.

The parameters could be monitored and set via mobile APP and PC monitoring and setting

applications.

Applied with potting of smidahk, the controller has IP65 grade of protection, which ensures reliable

and efficient operation in various working conditions.

Applied with high-quality aluminum radiator and high-temperature derating technology, which ensures

reliable and efficient operation in various working conditions.

1.2 Product features

1. The solar battery, generator (startup battery), and backup battery adopt the common negative pole

design.

2. See the description below for the definitions of the indicator light and interface, button function,

interface description, etc.

No. Name

1LED indicator light

2TTL communication interface

3 CAN and RS485

communication interfaces

4Voltage sampling interface for

backup battery

5Temperature sampling interface for

backup battery

6Ignition signal interface

7

8

9

No. Name

Operating button

Positive interface for solar battery

Positive interface for generator

(startup battery)

Common negative interface

Positive interface for backup battery

fixed hole

1.3 Interface description

10

11

12

05 06

1.5 Introduction of charging stage

Fast charging (BULK)

During the fast charging stage, when the battery voltage has not yet reached the setting

value (i.e. equalizing/boost voltage) of full voltage, the controller will perform MPPT to charge the

battery with the maximum solar power. When the battery voltage reaches the default value,

constant-voltage charging will be applied.

PWM

charging

U(V)

I(A)P(W)

VP curve

VI curve

94. 5

81. 0

67. 5

54. 0

27. 0

40. 5

13. 5

0. 0

19. 616. 814. 011. 28. 45. 62. 80. 0

0. 5

1. 0

1. 5

2. 0

2. 5

3. 0

3. 5

4. 0

4. 5

5. 0 MPPT point

Output characteristic curve of battery panel

Due to the different ambient temperature and lighting conditions, the maximum power point

often changes. And our MPPT controller could adjust the parameters in real-time under different

conditions, thus making the system status always near the maximum operating point. The whole

process is completely automatic without any adjustment.

As light intensity decreases,

current decreases

U( V )

I(A)

20 ℃

50 ℃

70 ℃

60 ℃

40 ℃

30 ℃

Solar panel temperature

I (A)

U( V)

As temperature decreases,

current remains and power

increases

Relationship between output characteristic

of battery panel and temperature

Relationship between output characteristic

of battery panel and light intensity

The controller charges the backup battery for lead-acid type in three stages. A complete

charging process consists of: fast charging (BULK), sustaining charging (EQUALIZE/BOOST),

and floating charging (FLOAT). The charging curve is as down below:

Sustaining charging (EQUALIZE/BOOST)

When the battery voltage reaches the setting value of the sustaining voltage, the controller

will perform constant-voltage charging. In this process, the MPPT charging will not work,

meanwhile, the charging current gradually decreases over time. The sustaining charging

consists of equalizing charging and boost charging, which are not repeated during one complete

charging process. And the equalizing charging is performed once a month (30 days) (default).

Charging curve of lead-acid battery

Charging voltage

Time

Equalizing charging voltage

A

Fast

charging

BC

Boost

Bulk

Boost charging voltage

Floating charging voltage

Boost restoring voltage

Sustaining

charging

Floating

charging

Present current

Charging current

Time

Equalizing charging (EQUALIZE)

Regular equalizing charging is applied in certain types of batteries, which could stir up the

electrolyte and balance the battery voltage to complete the chemical reaction. During the

equalizing charging stage, the charging voltage is increased beyond the standard complement

voltage, which could gasify the electrolyte. This stage will last for 120 minutes (default). Equalizing

charging and boost charging are not repeated during a single full charging process to avoid

excessive gas evolution or overheating of the battery.

1.5.1 Charging for lead-acid battery

As light intensity decreases,

open-circuit voltage decreases As temperature increases,

open-circuit voltage decreases

07

Equalizing charging

Warning: Explosion risk!

Attention: Device damage!

Excess charging and gas evolution may damage the battery panel, resulting in falling

off of the active substances on the battery panel. Over voltage of equalizing charging or too long

duration of this stage will damage the battery. Please carefully and strictly follow the technical

specifications of the battery.

!

08

1.5.2 Charging for lithium battery

The controller charges the backup battery of lithium type in two stages. The first one is the fast

charging (BULK) stage, which maximizes the utilization of solar energy and generator energy

with the limited maximum charging current, and rapidly increases the battery voltage to the setting value

of charging. Then, it switches to the second stage, constant-voltage charging, until the battery is fully

charged. And, the charging current gradually drops during this stage.

A

Fast

charging

B

Sustaining charging

Time

Time

Charging voltage

Schematic diagram for charging stages of lithium battery

Charging current

Boost charging voltage

Present current

2. Product Applications

System voltage of backup battery

Voltage range of backup battery

Back up battery types

Rated charging current

Maximum PV input voltage

Maximum power point voltage range

Charging method for solar panel

MPPT tracking efficiency

12/24/48V

9~60V DC

12/24/48V

Lead-acid battery

Voltage range of

generator

Traditional generator

Intelligent (EURO 6)

generator

120A

12~16 V DC (*2/24 V generator; *4/48 V generator)

Charging method for generator boost,buck,boost-buck

12 V backup battery

Maximum input

power of generator 24 V backup battery

48 V backup battery

Temperature compensation factor -3 mV/°C/2 V (default, while it could be set for lead-acid

battery). No temperature compensation for lithium battery

Communication method TTL、RS485、CAN、BLE

Protection function

Overcharge protection, overcurrent protection,

overtemperature protection, reverse connection protection

of generator, reverse connection protection of solar panel,

reverse charging protection at night. No reverse connection

protection for backup battery (external fuse is needed)

Operating temperature

Altitude

Protection grade

-35°C~65°C

≤3000 meters

400W

800W

1600W

<19mA

No-load loss

Maximum charging conversion efficiency

Maximum PV input current

60V DC

Product dimensions 233*262*100mm

IP65

Product model MD4830N06

Net weight

5.3kg

Boost charging (BOOST)

Generally, the default duration of the boost charging stage is 2h, while customers could also adjust

the duration and the default value of boost voltage point according to actual needs. When the duration

reaches the setting value, the system will be switched to floating charging.

Floating charging (FLOAT)

This stage could maintain the battery voltage near the floating charging voltage. In this stage, the

battery is charged with a very weak current to maintain the battery in a fully-charged state.

During the stages of equalizing charging, boost charging, and float charging, when the battery

voltage drops to “boost recovery voltage”, the system will exit the current stage and re-enter the BULK

fast charging stage. Then, the battery voltage slowly increases and the current drops as the charging

goes, the system will enter the constant-voltage stage again.

2.1 Specification and parameter

400W

800W

1600W

The gas could be generated during the equalizing charging stage. So the battery compartment

shall be well ventilated and not be covered by foreign objects.

Sealed, gel, flooded, lithium iron phosphate, and

custom battery

30A

60V DC

17~42V

100A

>99%

Step-down MPPT, step-up MPPT, step-up/down MPPT

Maximum PV

input power

12 V backup battery

24 V backup battery

48 V backup battery

System voltage of generator (startup battery)

Type of startup battery

Maximum input voltage of generator

Maximum input current of generator

13.2~16 V (*2/24 V generator; *4/48 V generator)

98%

09 10

No. Definition of indicator light

①Indicator light of solar panel

②Indicator light of generator

③Indicator light of backup battery

④Indicator light of backup battery types

!

2.2 Default parameters of battery type

Default parameters of battery types

Battery type

Parameter

Sealed lead-

acid battery

SLD (default)

Gel lead-acid

battery, GEL

Flooded lead-

acid battery,

FLD

Lithium iron

phosphate

battery, LFP

Custom battery USER

(SLD default)

Overvoltage disconnect

voltage 16.0V

Overvoltage recovery

voltage

Equalizing voltage

Boost voltage 14.4V

Boost voltage

Boost restoring voltage

Over-discharge restoring

voltage

Undervoltage recovery

voltage

Undervoltage alarming

voltage

Over-discharge voltage

Boost charging duration —— 10~600 minutes

Equalizing charging

duration

Equalizing charging

interval

Temperature

compensation mV/°C/2V -3 -3 -3 0 0、-3、-4、-5

Note: Please strictly follow the technical specifications and the safety recommendations

from the battery manufacturer for setting relevant parameters

2.3.1 Status description of indicator lights

2.3.2 Indicator light of solar panel

Color of indicator light Indicating method Description

Red

Normal ON MPPT charging

Slow flash Boost charging

Single flash Floating charging

Fast flash Equalizing charging

Double flash Current-limited charging

OFF Not in charging

2.3.3 Indicator light of generator

2.3.4 Indicator light of backup battery

2.3.5 Indicator light of backup battery types

2.4 Button

Button function I: set battery type

Hold down the button for 8 seconds, and the indicator light of battery type starts to flash (the

controller turns off charging now). In this situation, each press switches the color of the indicator,

indicating a battery type. When the battery type is set, hold down for 3 seconds or no operation for 10

seconds, and the controller will automatically save the current battery type, cancel the setting

mode, and perform the normal working mode.

2.3 Definition and description of indicator lights

Custom

battery

default

120 minutes

-3

Flooded lead-acid

battery

(Red)

Gel lead-acid battery

(Yellow)

Sealed lead-acid battery

(Green)

12V lithium battery

(Blue)

24V lithium

battery

(Purple)

48V lithium

battery

(Cyan)

Custom battery

(White)

Button function II: restore to factory defaults

Hold down the button for 20 second, and the four red indicator lights start to flash, and the factory

defaults are restored.

30 days —— 30 days —— 0~250 days

30 days

120 minutes —— 120 minutes —— 0~600 minutes

120 minutes

120 minutes

16.0V

15.0V

——

14.2V

13.8V

13.2V

12.6V

12.2V

12.0V

11.1V

120 minutes 120 minutes

16.0V

15.0V

14.6V

14.4V

13.8V

13.2V

12.6V

12.2V

12.0V

11.1V

16.0V

15.0V

14.8V

14.6V

13.8V

13.2V

12.6V

12.2V

12.0V

11.1V

——

13.2V

12.6V

12.3V

12.1V

11.1V

——

15.0V

16.0V

15.0V

14.6V

14.4V

13.8V

13.2V

12.6V

12.2V

12.0V

11.1V

9.0 ~ 17.0V

——

9.0 ~ 17.0V

9.0 ~ 17.0V

9.0 ~ 17.0V

9.0 ~ 17.0V

9.0 ~ 17.0V

——

9.0 ~ 17.0V

9.0 ~ 17.0V

Color of indicator

light Indicating method Description

Red

Normal ON Backup battery charged by generator

Fast flash Generator over-voltage

OFF Not in charging

Color of

indicator light Indicating method Description

Green Normal ON Battery fully charged

Yellow Normal ON Normal battery voltage (>12.0 V)

Red

Normal ON Battery undervoltage (<12.0 V)

Slow flash Battery over-discharge (<11.1 V)

Fast flash Battery overvoltage (>16.0 V)/ battery

over-temperature

Color of

indicator light Indicating method Description

Red Normal ON Flooded lead-acid battery, FLD

Yellow Normal ON Gel lead-acid battery, GEL

Green Normal ON Sealed lead-acid battery, SLD (default)

Blue Normal ON 12 V lithium battery, LI (default lithium

iron phosphate)

Purple Normal ON 24 V lithium battery, LI (default lithium

iron phosphate)

Cyan Normal ON 48 V lithium battery, LI (default lithium

iron phosphate)

White Normal ON Custom (default 12 V sealed lead-acid)

11 12

2.10 Voltage compensation interface of backup battery

With large charging power and small wire diameter, the collected voltage by the controller is higher than

the battery voltage, causing the battery to be undercharged. The battery voltage sampling wire can collect

the battery voltage more accurately, so as to compensate the output voltage difference in time to get a more

reasonable charging voltage. Connect the battery positive and negative electrodes to the corresponding

position of the battery voltage sampling terminals ④ by the voltage compensation wire. The positive

electrode is on the left and the negative electrode is on the right.

VBAT

No. Definition

① +

②_

2.11 Temperature sampling interface of backup battery

Connect the temperature sensor to the interface ⑤ to sample the real-time temperature of the battery.

The default temperature is 25℃ when the temperature probe is not connected. When a temperature sensor

is connected, by sampling battery temperature, it can provide high/low temperature protection for batteries

or temperature compensation for lead-acid battery charging voltage.

Wiring method: connect the temperature sensor terminal to interface ⑤ and fix the temperature sensor

on the battery surface.

2.12 Ignition signal interface

The charging voltages of the smart generator and general generator are different. If using a smart

generator, the ignition signal wire should be connected to the IGN terminal. When using general generator,

the charging voltage is 13.2V. When using smart generator, the charging voltage is 12.0V. It is also

allowed to connect only one wire on the positive electrode.

The interface is defined as follows:

IGN

No. Definition

① +

②_

3. Common Problems and Solutions

Phenomenon Possible reasons Troubleshooting

Power the backup

battery, the indicator

does not light.

A. Incorrect or loose wiring of backup

battery

B. Lithium battery protection

A1. Please check whether the connection wire of the

backup battery is correct.

B1. Connect the solar panel or generator to activate the

lithium battery by charging.

The backup battery

cannot be charged by

the solar panel through

the controller in the

daytime.

A. Incorrect or loose wiring of solar panel

B. The solar panels are blocked

C. The voltage class of the backup battery

system is set incorrectly

A1. Please check whether the connection wire of the solar

panel is correct.

B1. Ensure that the solar panels are not blocked.

C1. The system voltage class set by the controller is

consistent with the actual battery voltage class in use.

The backup battery

cannot be charged by

the generator while

driving.

A. Incorrect or loose wiring of generator

B. The voltage class of the backup

battery system is set incorrectly

A1. Please check whether the connection wire of the

generator is correct.

B1. The system voltage class set by the controller is

consistent with the actual battery voltage class in use.

(1) Default baud rate: 9,600 bps, check bit: none, data bit: 8 bit, stop bit: 1 bit

(2) Interface type: RJ45, communication power supply output specification: 5VDC/200mA

(3) RS485 communication line sequence is defined as follows, and the interface integrates CAN

communication interface.

The isolated power

supply is positive 5.0VDC

Definition

D+

D-

Power ground

-

-

CANH

CANL

S/N

①

②

③

④

⑤

⑥

⑦

⑧

2.5 RS485 communication

2.9 TTL communication interface

Users can use the Modbus protocol for controller data monitoring, parameter setting, and other operation

through this port.

The interface is defined as follows:

TTL-COM

No. Definition

①Output voltage+14.8V

②Controller receiver (RX)

③Controller sender (TX)

④GND

2.6 CAN communication interface

It is an isolated CAN communication interface. According to the communication protocol, the user can

make customized development for controller data monitoring, parameter setting, and other operation.

2.7 Bluetooth communication

Built-in Bluetooth communication function, real-time monitoring of the controller's operating data, fault

status, and adjustment of the controller's operating parameters through the mobile APP.

2.8 CAN communication

Built-in CAN communication function, RV-C protocol, real-time monitoring of the controller's operating

data, fault status, adjustment of the controller's operating parameters, etc. See 2.5 for the pin definition of

CAN communication interface.

The interface is defined as follows:

13 14

Step 1: Select an installation location

Do not install the controller in a place with direct sunlight, high temperature, or where water can

easily enter, and make sure the controller is well ventilated.

Step 2: Fix suspension screws

According to the mounting dimensions of the controller, mark the mounting positions, then drill

two mounting holes of suitable size at the two marks and fix the screws on them.

Step 3: Fix the controller

Align the controller fixing holes with the two pre-fixed screws to hang the controller up, and then

fix the two screws below.

Fix the controller

215

4.3 Installation and wiring

Warning: Danger of explosion! Never install

the controller and the flooded battery in the

same confined space or a place where battery

gas may be accumulated.

Warning: Danger of high voltage! The PV

array may generate high open-circuit voltage.

Disconnect the circuit breaker or fuse before

wiring, and be careful during wiring.

!

Note: When installing the controller, make sure

that there is enough air to flow through the

cooling fins of the controller, and leave at least

150mm space above and below the controller to

ensure natural convection heat dissipation. If the

controller is installed in a sealed box, the heat

dissipation of the controller shall be reliable.

≥150mm Hot air

≥150mm Cold air

Installation and heat dissipation

Warning: Danger of electric shock! We

strongly recommend that fuses or circuit

breakers should be connected to the PV array,

generator and battery terminals.

!

4. Product Installation

4.1 Installation precautions

Be careful when installing battery. Wear protective goggles when installing a flooded lead-acid battery.

4.2 Reference for wire and fuse selection

Voltage of

PV at the

maximum

power

point

(Vmp)

System

voltage

of

generat

or (V)

System

voltage

of

backup

battery

(V)

Maximum

input

current of

PV (A)

Wire

diameter

of PV

(mm²/

AWG)

Fuse

specification

of PV (A)

Maximum

input

current of

generator

(A)

Wire

diameter

of

generator

terminal

(mm²/

AWG)

Fuse

specificatio

n of

generator

(A)

Current

of

backup

battery

(A)

Wire

diameter of

backup

battery

terminal

(mm²/AWG)

Fuse

specificati

on of

backup

battery (A)

17

12

12 25 6/9 40~50 30 8/8 50~60

30 8/8 50~60

24 50 12/6 75~100 60 15/5 90-120

48 100 25/3 150~200 120 30/2 180-240

24

12 25 6/9 40~50 17 4/11 26-34

24 50 12/6 75~100 34 9/7 51-68

48 100 25/3 150~200 68 17/5 102-136

48

12 25 6/9 40~50 92/14 14-18

24 50 12/6 75~100 18 5/10 27-36

48 100 25/3 150~200 36 9/7 54-72

1. The data above is only part of the application of the controller and the actual application differs from the site

configuration;

2. The current density of wire should be around 4A/mm2;

3. The specification of the fuse at the input terminal should be 1,5 to 2 times of the actual maximum current

Wiring and installation must meet the requirements of national and local electrical codes.

The wiring specifications of PV(Photovoltaic), generator and battery shall be selected y as per their

rated current. Please refer to the table below for wire and fuse specifications:

The false connection and corroded cables may produce extreme heat to melt the cable insulation

and burn surrounding materials, even causing a fire. Make sure that the connections are tightened.

The cables are fixed with ties to avoid loose connection when wobbled in transportation.

When connecting the system, the output voltage of the components may exceed the human body

safety voltage, therefore, use insulated tools and keep your hands dry.

The battery terminals on the controller can be connected either to a single battery or a battery

pack. The subsequent instructions are for a single battery, but they are also applicable to systems

with a battery pack.

Please follow the safety recommendations of the battery manufacturer.

The current density of the system connection wire should be no more than 4A/mm2.

Ground the ground terminal of the controller.

When installing the battery, it is forbidden to reverse the battery connection, which may cause

irreversible damage.

Once in contact with the battery acid, please rinse with water immediately.

Stay away from metal objects to prevent battery short-circuit.

The battery may produce acid gas when charging. Ensure the ambient environment is well ventilated.

The battery may produce combustible gas. Stay away from sparks.

When installing outdoors, avoid direct sunlight and rain seeping.

Warning: Danger of electric shock! We strongly recommend that fuses or circuit breakers

should be connected to the PV array, loading and battery terminals to prevent the risk of

electric shock during wiring or misoperation, and make sure that the fuse or circuit breaker is

disconnected before wiring.

Warning: Danger of high voltage! The PV array may generate high open-circuit voltage.

Disconnect the circuit breaker or fuse before wiring, and be careful during wiring.

Warning: Danger of explosion! Once the positive and negative battery terminals and the

connected wires are short-circuited, it will cause fire or explosion. Please be careful when

operating.

Connect the battery first, then the solar panel and finally the load. Please connect the positive

electrode first when wiring.

When all power lines are connected firmly and reliably, check again whether the wiring is

correct and make sure that the positive and negative electrodes are not reversed. After

confirming, connect the battery fuse or circuit breaker first, then observe whether the LED

indicator lights up. If not, please immediately cut off the fuse or circuit breaker and check

whether the wire is well-connected.

After the battery is normally energized and then connected to the solar panel, the charging

indicator of the controller will always light or blink and start charging the battery if there is

enough sunlight.

15 16

wiring diagram

5. Product Dimensions

Product dimensions: 233*262*100mm

Mounting dimension: 215*132mm

Fixing hole position: φ6mm

60,53

100,00

Step 4: Wiring

4.4.1 Crimping. According to the system configuration, select the proper wire specification and

fix one wire end to the standard copper tip SC35-8 with a professional crimping tool;

4.4.2 Wiring. Connect the wiring hole of copper terminal SC35-8 to the corresponding bolt of

the controller, and fasten the M8 mounting nut with a hexagon socket. The size of the hexagon

socket is 14mm.

Wiring

terminals

Cross-sectional area

35mm²

Diameter of crimping hole

8,5mm

Wiring tool Hexagon socket with

14mm diameter of the

opposite side

4.4.3 The specific wiring method is shown in the system wiring diagram:

Inner diameter 14mm

!

Notice: the installation position of the battery fuse should be close to the controller,

and the recommended installation distance is no more than 150 mm.

!

FUSE

BATTERY

BATTERY

FUSE

FUSE

215.00

202.40

233.00

172.00

φ6.00

262.08

131. 92 mm

This manual suits for next models

1

Table of contents

Other Srne Controllers manuals

Popular Controllers manuals by other brands

GOK

GOK ES2000 Assembly and operating instructions

Nortek Security & Control

Nortek Security & Control GoControl WI15VZ-1 instructions

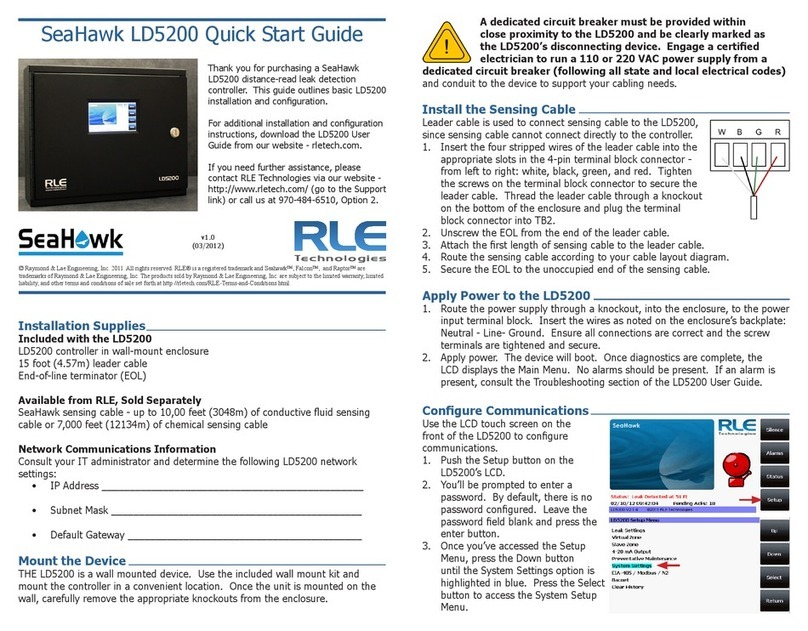

RLE Technologies

RLE Technologies SeaHawk LD5200 quick start guide

Brightlink

Brightlink 4U manual

Johnson Controls

Johnson Controls Hitachi C4IRK01 Operation manual

RECO

RECO RM-BV4 Micro DP Documentation

Danfoss

Danfoss AMEi 6 iSET operating guide

Sunlight Supply

Sunlight Supply TITAN Controls Saturn 4 instruction manual

Elko

Elko iNels BPS3-02M quick start guide

Gardena

Gardena Select 1891 Operator's manual

B&B Electronics

B&B Electronics RS-232 Digital Relay I/O 232DRIO user manual

Eaton

Eaton OPTE9 installation manual