A dedicated circuit breaker must be provided within

close proximity to the LD5200 and be clearly marked as

the LD5200’s disconnecting device. Engage a certied

electrician to run a 110 or 220 VAC power supply from a

dedicated circuit breaker (following all state and local electrical codes)

and conduit to the device to support your cabling needs.

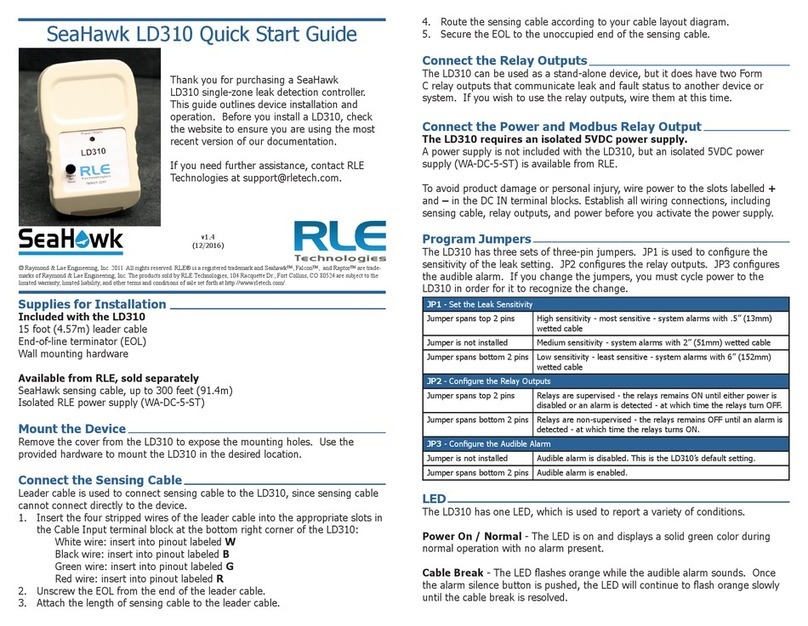

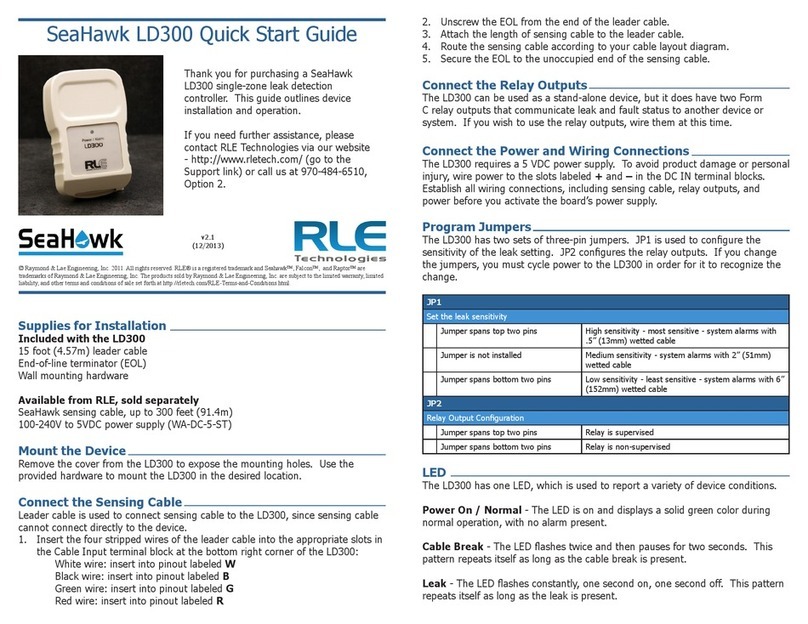

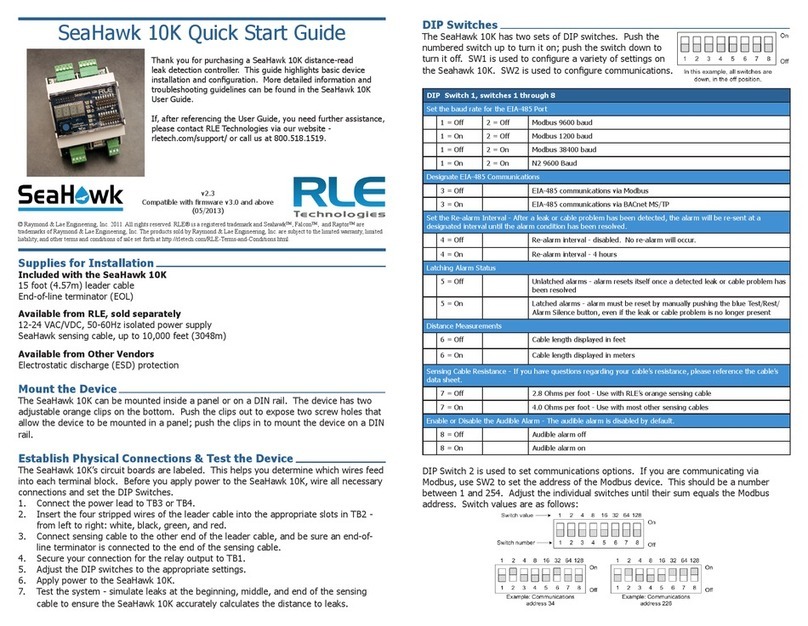

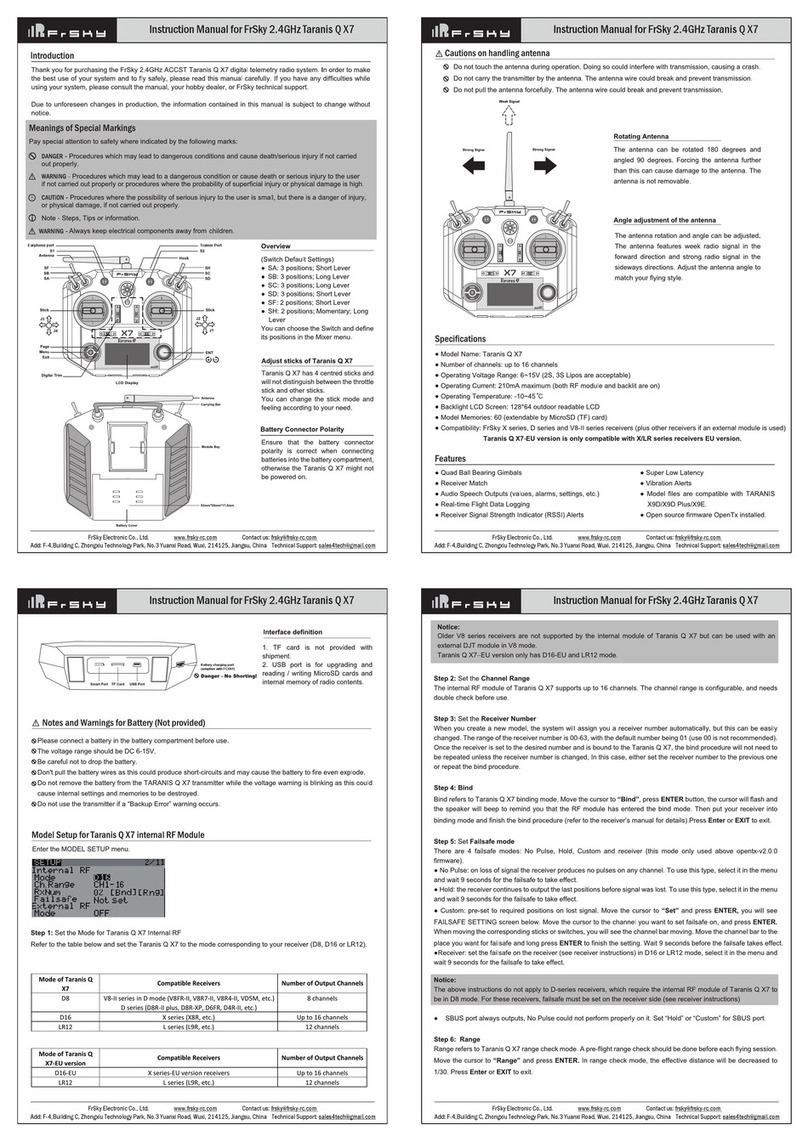

Install the Sensing Cable

Leader cable is used to connect sensing cable to the LD5200,

since sensing cable cannot connect directly to the controller.

1. Insert the four stripped wires of the leader cable into the

appropriate slots in the 4-pin terminal block connector -

from left to right: white, black, green, and red. Tighten

the screws on the terminal block connector to secure the

leader cable. Thread the leader cable through a knockout

on the bottom of the enclosure and plug the terminal

block connector into TB2.

2. Unscrew the EOL from the end of the leader cable.

3. Attach the rst length of sensing cable to the leader cable.

4. Route the sensing cable according to your cable layout diagram.

5. Secure the EOL to the unoccupied end of the sensing cable.

Apply Power to the LD5200

1. Route the power supply through a knockout, into the enclosure, to the power

input terminal block. Insert the wires as noted on the enclosure’s backplate:

Neutral - Line- Ground. Ensure all connections are correct and the screw

terminals are tightened and secure.

2. Apply power. The device will boot. Once diagnostics are complete, the

LCD displays the Main Menu. No alarms should be present. If an alarm is

present, consult the Troubleshooting section of the LD5200 User Guide.

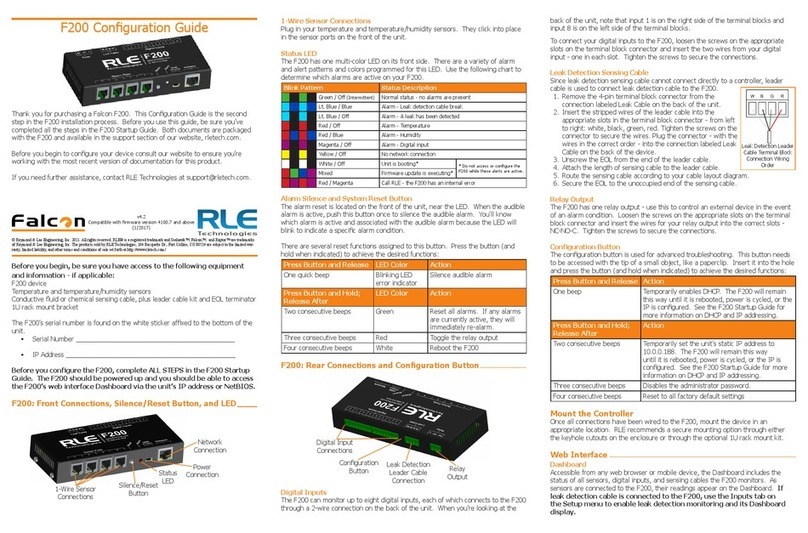

Congure Communications

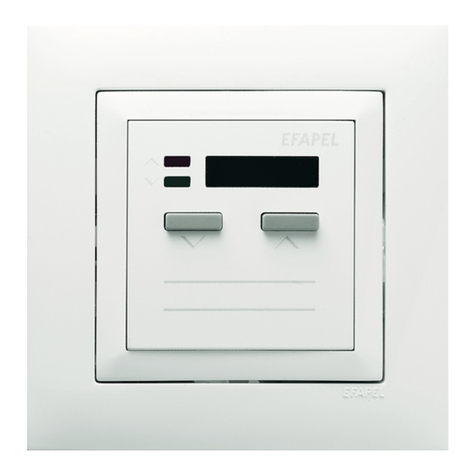

Use the LCD touch screen on the

front of the LD5200 to congure

communications.

1. Push the Setup button on the

LD5200’s LCD.

2. You’ll be prompted to enter a

password. By default, there is no

password congured. Leave the

password eld blank and press the

enter button.

3. Once you’ve accessed the Setup

Menu, press the Down button

until the System Settings option is

highlighted in blue. Press the Select

button to access the System Setup

Menu.

© Raymond & Lae Engineering, Inc. 2011. All rights reserved. RLE® is a registered trademark and Seahawk™, Falcon™, and Raptor™ are

trademarks of Raymond & Lae Engineering, Inc. The products sold by Raymond & Lae Engineering, Inc. are subject to the limited warranty, limited

liability, and other terms and conditions of sale set forth at http://rletech.com/RLE-Terms-and-Conditions.html.

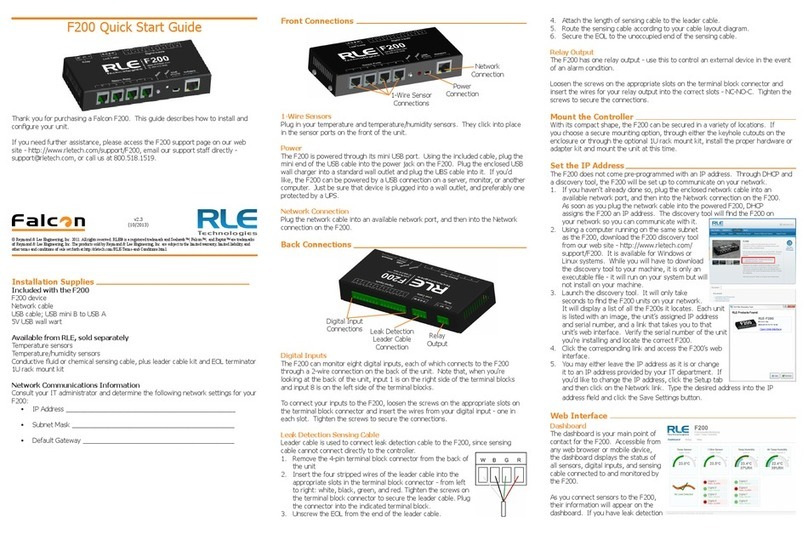

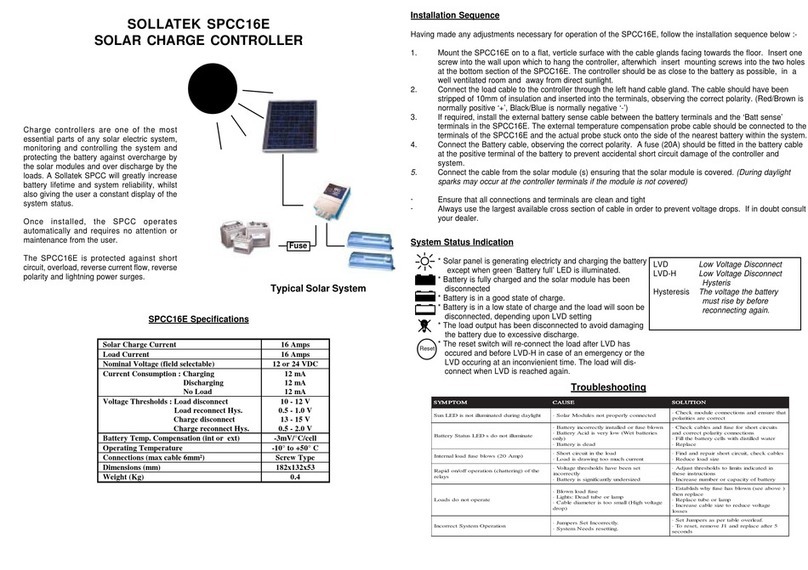

Installation Supplies

Included with the LD5200

LD5200 controller in wall-mount enclosure

15 foot (4.57m) leader cable

End-of-line terminator (EOL)

Available from RLE, Sold Separately

SeaHawk sensing cable - up to 10,00 feet (3048m) of conductive uid sensing

cable or 7,000 feet (12134m) of chemical sensing cable

Network Communications Information

Consult your IT administrator and determine the following LD5200 network

settings:

• IP Address _______________________________________________

• Subnet Mask _____________________________________________

• Default Gateway __________________________________________

Mount the Device

THE LD5200 is a wall mounted device. Use the included wall mount kit and

mount the controller in a convenient location. Once the unit is mounted on the

wall, carefully remove the appropriate knockouts from the enclosure.

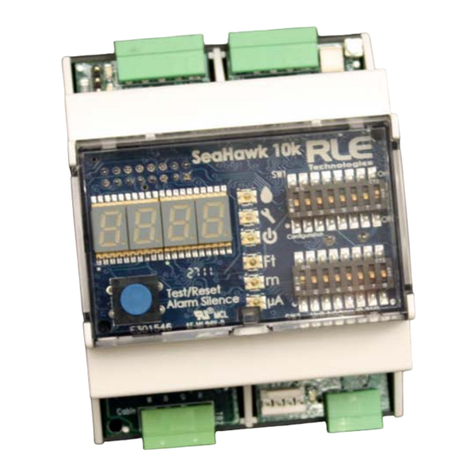

SeaHawk LD5200 Quick Start Guide

Thank you for purchasing a SeaHawk

LD5200 distance-read leak detection

controller. This guide outlines basic LD5200

installation and conguration.

For additional installation and conguration

instructions, download the LD5200 User

Guide from our website - rletech.com.

If you need further assistance, please

contact RLE Technologies via our website -

http://www.rletech.com/ (go to the Support

link) or call us at 970-484-6510, Option 2.

v1.0

(03/2012)