Srne SR-LG Series User manual

Dear user

:

Many thanks for you choosing our product!

Please read the user instructions carefully before usage.

SR-LG Series Solar charge controller

User manual

Catalogue

1. Attention……………………………………………………………………………..3

2. Product introduction……………………………………………………...........3

3. Panel figure………………………………………………………………………...4

4. Feature……………………………………………………………………...............4

5. Model…………………………………………………………………………………5

6. Installation and connection instruction…………………………….….5

7. LCM indication and instruction……………………………………...........7

7.1Overall figure……………………………………………………………….………..7

7.2Display interface………………………………………………………….………....8

7.3Mode operation and browse parameters……………………………..………....9

8. Controller status………………………………………………….………………10

9. System voltage alternative…………………………………………….……..10

10. System protection function description………………………………..10

10.1 Over temperature protection…………………………………………….10

10.2 Charge protection……… ……………………………… ………………… 11

10.3 Discharge protection……………………………………………………..11

10.4 Short circuit protection…………………………………………………..11

10.5 Over-load protection……………………………………………………..11

10.6 Reverse connection protection…………………………………………11

11. Operating mode………………………………………………………..12

12. Error instruction and description………………………………………12

13. Parameters instruction… …… …… … …… …… … …… … …… …… … .13

14. Accessories………………………………………………………………14

1. Attention

Warning:This controller is a high power device, please read the instruction before use, take

extra care when operating.

Safety notes:

☉read the instruction and attention carefully before use

☉Do not disassembly and repair the controller freely

☉Avoid direct sunlight and pay attention to ventilation When installation

☉Install appropriate fuse or circuit breaker on the outside of the controller

☉Disconnect the external fuse or circuit breaker when wiring

☉Be careful to prevent short-circuit when installing the battery

☉To ensure adopt the correct wire diameter, connect firmly, fasten the wire after connection

☉Temperature resistance should be fixed on the battery,the othe end connect to the controller

2. Product introduction

This controller is designed for DC power supply system, small and medium-sized pv

modules power system, using a dedicated computer chip to realize the intelligent control, all

chips adopt industrial level, can be used in harsh environment. Meanwhile system offers

specific indication for the charge, load , sorts of failure and various protections such as short

circuit, over-load, over charge, particular anti-reversed polarity protection and so on, the

controller used computer chip to sample the parameter of the battery voltage, photovoltaic

cell voltage, discharge current and environment temperature. According to the battery’s

character, realized the accurate control to discharge rate, correction of the temperature

compensation through special control model calculation.charging with the intelligent PWM

dim way and charging compensation in accordance with the current temperature of the

battery, compensation factor is 3mv/℃/unit.LCM could show all of the parameters and modes.

Offer as many as five LED adjust way with lattice pattern to guarantee the battery works in

the best status which could lengthen the service life of the battery. The controller has many

work modes to satisfy different customer’s request. Dial switch need to adjust if adopting

different voltage system.

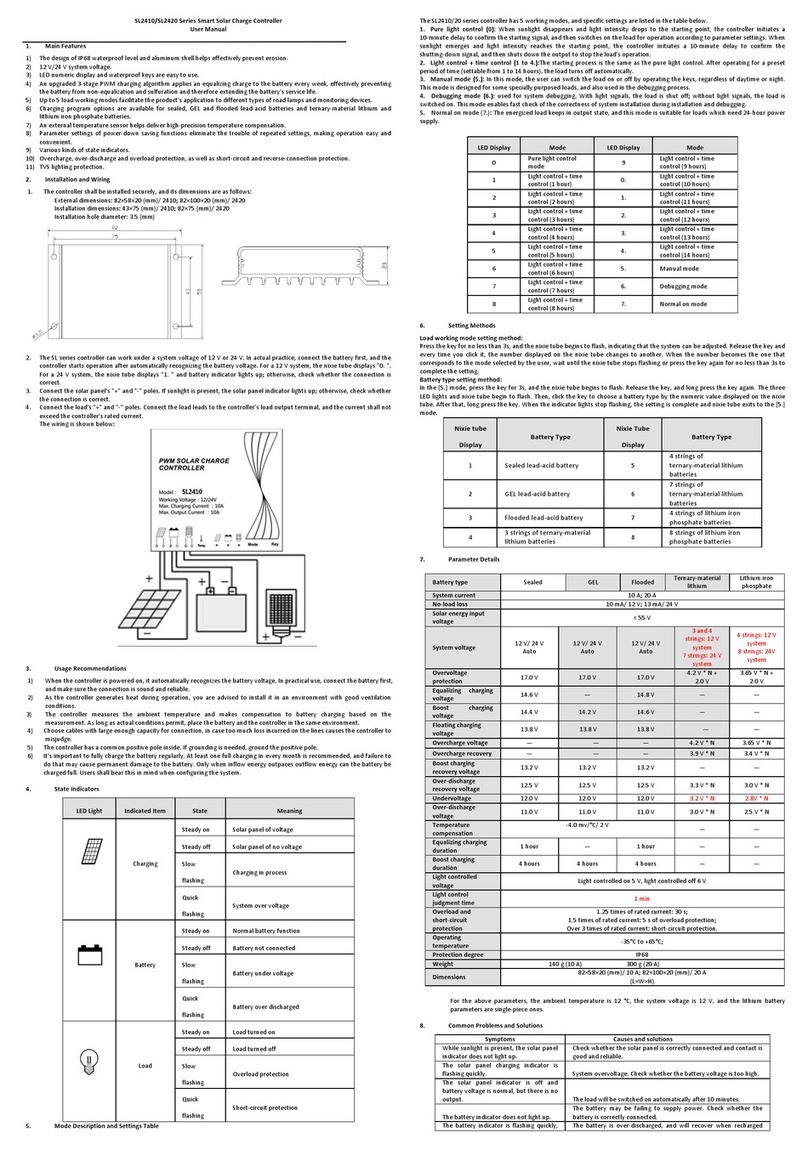

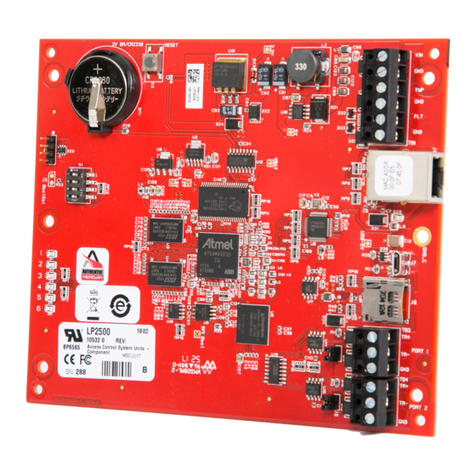

3. Panel figure

4. Feature

4.1、The controller carried with LCM module which can display system status and

parameters

4.2、Begin to ascending charging automatically when the voltage of battery below the

ascending charging recover voltage

4.3、Temperature compensation become more accurate due to Double temperature sensors

design,inner temperature sensor test the inner temperature of the controller,outer

Parameter & Mode

LCM indication

Button

Parameter adjust are

PV Instruction

Load instruction

PV

Battery

Load

Temperature

compensation

PV Instruction

Load instruction

Parameter & Mode

LCM indication

Button

Temperature

compensation

temperature sensor test the outer temperature of the controller.

4.4、The controller could figure out everyday’s power of charge and discharge which make

user assess the controller and entire system more easily

4.5、With the charging current overload protection function, the controller will reduce the

charge current to protect the charging circuit after it surpass the rated current.

4.6、Aequalizing charge every 30 days in order to prevent battery vulcanization

4.7、Industrial-grade chips and precision components makes the controller can operate in

any harsh environment

4.8、Design of double MOS series control circuit and PWM dim control make the charging

efficiency increased greatly

4.9、The setting parameter possess the saving function which makes the parameter won’t

be erased after losing the electricity and system become more reliable.

4.10、Three kinds of load work mode: purely light-operated, light-operated+time controlled,

long-term on mode.

5. Model

SR -LG 48 60

6. Installation and connection instruction

6.1、Installation of controller must be reliable, size is as follows:

6.1.1、45ABoundary and Installation dimension

SHUORI/

SRNE

High power

series

24:Apply to 12V/24V system

48:Apply to 12/24/36/48V system

30:Max current 30A

45:Max current 45A

60:Max current 60A

SETU

P

Temp .

sensor

180.7mm

142.0mm

72.0mm

PWM Solar Charge Controller

100mm

173.7mm

6.1.2、30ABoundary and Installation dimension

SETU

P

Temp .

sensor

180.7mm

115.0mm

72.0mm

PWM Solar Charge Controller

75mm

173.7mm

Controller

+ - + - + -

Load

6.2、Preparation of the wire:

Adopt the wire matching the current,plan the length of wire, strip 5mm insulation of one side of

the controller’s terminal and try to decrease the length of the connected wire so that a reduction in

electrical loss.

6.3、Battery connection

Pay attention to the pole + , - , do not connect reversely. If connect correctly, the controller will

start to work or it’s necessary to check the wire connection and battery’s situation. Users could

connect the system followed by the order showed in the below figure.

6.4、Photovoltaic module connection

Pay attention to the pole + , - ,if sun light is tested, photovoltaic indicator will light on or it’s

necessary to check the connection.

6.5、Load connection

Connect the load wire with the controller’s output terminal, the current can’t surpass the

controller’s rated current and pay attention to the + , - pole, for avoiding damage to the device ,do

not connect reversely

6.6、Temperature sensor connection

Connect one side of the temperature sensor to controller, the other side to the battery. There must

be a good thermal contact with the battery shell.

Attention

:

Connection according to the order showed in the upper figure

7. LCM indication instruction

The controller adopts segmentation LCM indicator which could show 7 items parameters

Solar panel

+ -

Battery

Remark: P is parameter

7.1、Overall figure

7.2、Displayed page

Screen initialize firstly then show kinds of system’s parameters when power on.

7.2.1、Photovoltaic array current

This page shows the pv array real-time current

7.2.2、Battery voltage

This page show the real-time battery voltage

7.2.3、Load current

This page show the real-time load current

7.2.4、Battery temperature

This page show the real-time controller’s inner temperature

7.2.5、Charge power on the day

P 4th

P 3rd

P 2nd

P 1st

Input current

output current

Unit: K/A/H/

℃

Unit: K/V/W/%

Auto recognize indicator

48V system indicator

36V system indicator

24V system indicator

P V

Bat.

Load

Setting

Abnormal

System voltage12V

Solar array sign

Current real time value

PV array current value

Battery sign

Battery voltage real time

value

Battery voltage unit

Load sign

Load current real time value

Load current unit

Battery temperature real

time value

Temperature unit

This page show the real-time charge power on the day

7.2.6、Discharge power on the day

This page show the real-time discharge power on the day

7.2.7、Word mode

This page show the real-time work mode

7.2.8、Fault warning

This page show the corresponding error code when system abnormal occurs, return to normal

display after cancel the error

7.3、Mode operation and parameter browse

7.3.1、Parameter preview

Click the button:switch to next display page

Long press the button:long press the button in non-work mode page start the auto LCM switch

display.

7.3.2、Working mode setting

Positioning the work mode page according to the “parameter preview”

Long press button:long-press in work page,click to user’s required mode after the number

blink,long-press for a period of time to exit with saving the parameter automatically,LCM switch

to display again automatically after exit.

ATTENTION: switch automatically—It’s not necessary to participate for users,LCM will swich

to next page automatically every 3s.

Charge capacity real time value

Battery sign

Charging sign

Energy unit

Discharge sign

Mode display

Error code

Abnormal sign

Mode display(twinkle)

Mode bitmap

8. Controller status

State

Always off

Always on

twinkle Slow

twinkle fast

PV array

instruction

Night

Daytime

In charging

System over

voltage

Load

instruction

Load off

Load on

Overload

Short circuit

9. System voltage alternative

Before setting, please kindly check the system voltage. This controller support 12/24/36/48V

system. Please choose the voltage before use.

System voltage

Dial switch state

Description

12v

Down Down

The right and left gear both turn to

Downward.

24V

Down Up

Turn the left gear to Downward, Turn

the right gear to Upward. .

36V

Up Down

Turn the left gear to Upward, Turn

the right gear to Downward

48V

Up Up

The right and left gear both turn to

Upward.

Please setting firstly before running the system.

10. System protection function description

10.1、Over temperature protection

Controller temperature exceed 90℃will close the load and charging efficiency will decrease.

Led Light

PV working indicator

Load working indicator

Temperature less than 85℃will recover.

Battery temperature exceed 55℃will close the load and charging will closed. Temperature less

than 55℃will recover.

10.2、Charging protection

Decrease the charging efficiency when PV array charging current more than 60A and less then

1.25 times of 60A for 60s.

Decrease the charging efficiency when PV array charging current more than 1.25 and less then

1.5 times of 60A for 5s.

Decrease the charging efficiency when PV array charging current more than 1.5 times of 60A for

1s.

PV array indicator will close.

Recover after decrease charging efficiency for 1min.

10.3、Over discharge protection

The controller will start the over discharge protection and close the load when the battery voltage

is less than over discharge voltage and duration 5s.

The controller will start the over discharge recovery protection when the battery voltage exceed

the over discharge recovery voltage.The next night will remove automatically.

10.4、Short circuit protection

Short circuit:

The first time short circuit in one day will recover after 5s later.

The second time will recover after 10s later.

The third time will recover after 15s later.

The forth time will recover after 20s later.

The fifth time or more than five times will recover after 4hours later.

Also can recover by long press the key!

10.5、Over load protection

Over-load protection:

Close the load when load current more than 1 also less than 1.25 times of 60Afor 60 seconds;

Close the load when load current more than 1.25 also less than 1.5 times of 60Afor30 seconds;

Close the load when load current more than 1.5 also less than 3 times of 60A for 5 seconds;

LED load indicator twinkle slow.

Recovery normal after overload stop 60s later, not have the limited times.

10.6、Reverse connection protection

This controller including the PV array, battery and load reverse connection protection.

11. Operating mode

LED Display

Mode

LED Display

Mode

00

Purely light-operated

08

Light-operated +

time-controlled for 8

hours

01

Light-operated +

time-controlled for 1

hour

09

Light-operated +

time-controlled for 9

hours

02

Light-operated +

time-controlled for 2

hours

10

Light-operated +

time-controlled for 10

hours

03

Light-operated +

time-controlled for 3

hours

11

Light-operated +

time-controlled for 11

hours

04

Light-operated +

time-controlled for 4

hours

12

Light-operated +

time-controlled for 12

hours

05

Light-operated +

time-controlled for 5

hours

13

Light-operated +

time-controlled for 13

hour

06

Light-operated +

time-controlled for 6

hours

14

Light-operated +

time-controlled for 14

hours

07

Light-operated +

time-controlled for 7

hours

15

Always on mode

12. Error instruction and description

If have any short circuit state, the LCM will show the corresponding error instruction.Please

kindly check the error code and description as below.

Error

code

Fault

description

Solutions and recovery condition

LCM

display

Led display

E1

Too high of

controller

temperature

Please ensure the solar panel and

load power not exceeded the rate

power then place the controller to

ventilation environment.Auto

recover after temperature

decrease. Controller will decrease

the charging efficiency and close

discharge.

Bat and

PV

twinkle at

the same

time

--

E2

Battery over

voltage

Please check right connection and

voltage of the battery

Bat

twinkle

Solar panel

indicator

twinkle fast

E3

Battery over

discharge

Ensure the input voltage of the

battery is normal.

Recover auto after full charge

Bat

twinkle

--

E4

Excessive

charging

current

Please check the solar panel power

whether exceed the controller’s

rate power

Pv

twinkle

--

E7

Load short

circuit

Ensure the output line of the load

not have short circuit.

After eliminate the faults then

long press the key or hold on it

will recover automatically.

Load

twinkle

Load

indicator

twinkle fast

E8

Overload

Please check the load power

whether exceed the controller’s

rate power. After decrease the load

then long press the key or hold on

it will recover automatically.

Load

twinkle

Load

indicator

twinkle

slow

E9

Battery

overheat

Please check the battery

temperature overheat or not.

Place the controller to ventilation

environment. Controller will close

charging and auto recover after

temperature decrease.

Bat

twinkle

Solar panel

indicator

twinkle fast

13. Parameters instruction

Parameter

Value

System voltage

12V/24V/36V/48V

Rate charging current

45A/30A

Rate load current

45A/30A

No load loss

<12mA

Charging circuit voltage drop

Less or equal to 0.5V

Discharge circuit voltage drop

Less or equal to 0.5V

Solar input voltage

<140V

Re-entrant boost charge mode voltage

13.2V ×2/24V; ×3/36V; ×4/48V

Over voltage protection

17.0V ×2/24V; ×3/36V; ×4/48V

limited voltage for charging

15.5V ×2/24V; ×3/36V; ×4/48V

Equal charging voltage

Boost charge voltage +0.5V

Equal charging interval

30days

Direct charge voltage

14.4V ×2/24V; ×3/36V; ×4/48V

Float charge voltage

13.6V ×2/24V; ×3/36V; ×4/48V

Over discharge voltage

11.0V ×2/24V; ×3/36V; ×4/48V

Over discharge recover voltage

12.5V ×2/24V; ×3/36V; ×4/48V

Equal charging time

1H

Boost voltage charging time

2H

Temperature compensation

-3.0mv/℃/2V

Light-control voltage

5V ×2/24V; ×3/36V; ×4/48V

Light control delay

10min

Controller over-temperature protection

>90℃

Battery over-temperature protection

>55℃

Working temperature

-35℃to +85℃

Control method

Charging: PWM

Time of lcd back- light auto shut down

30(s)

Data auto transfer time

3(s)

Time of Led lattice closed

25(s)

Weight

1.08Kg/45A 0.9Kg/30A

15. Accessories

Temperature probe

1pcs

Screwdriver.

1pcs

Table of contents

Other Srne Controllers manuals