Ssab RR75 User manual

DESIGN AND INSTALLATION MANUAL

This manual deals with driven and jacked SSAB’s RR and RRs piles, shaft grouted driven

CSG-RR piles and drilled RD and RDs piles. It covers all SSAB’s steel pile sizes. The manual is

based on the piling instructions of the Finnish Piling Manual PO-2016 and the Eurocodes system.

The manual describes the basics of the design and dimensioning of SSAB’s steel piles and pile

foundations according to Finnish application of Eurocodes, gives recommendations on the

selection of pile type and size and provides advice on the handling and installation, quality control,

measurements and documentation of piling. The manual includes pre-calculated dimensioning

tables and design and implementation examples to facilitate the design and implementation of

piling. When SSAB steel piles are used outside Finland, national requirements (implementation

and national annexes of Eurocodes) shall be taken into account in design and execution of piles.

SSAB’s RR, RRs, RD and RDs piles have European Technical Assessment ETA 12/0526.

Applications:

• 1 and 2 family houses

• single- and multi-storey commercial, oce, industrial and storage buildings

• multi-storey residential buildings

• sports arenas

• underpinning of foundations

• bridges

• pile slabs and other structures for transport infrastructure and

municipal engineering

• noise barriers and fences

• ports

• wind turbines and other power plants ETA 12/0526

RR®and RD®piles

www.ssab.com/infra

SSAB is a Nordic and US-based steel company. SSAB oers value added products and services developed in close cooperation with its customers to create

a stronger, lighter and more sustainable world. SSAB has employees in over 50 countries. SSAB has production facilities in Sweden, Finland and the US.

SSAB is listed on the NASDAQ OMX Nordic Exchange in Stockholm and has a secondary listing on the NASDAQ OMX in Helsinki. www.ssab.com.

2

CONTENTS

1. GENERAL ......................................................................................................4

2. SSAB’s STEEL PILES ...........................................................................................4

2.1 General....................................................................................................4

2.2 Steel grades and standards ................................................................................4

2.3 Small diameter RR and RRs piles............................................................................5

2.3.1 Structure, steel grades and identification ..............................................................5

2.3.2 Pile sections, pipes and splices........................................................................5

2.3.3 Pile shoes............................................................................................6

2.4 Large diameter RR piles ....................................................................................7

2.4.1 Structure, dimensions and availability of steel grades...................................................7

2.4.2 Pile shoes ...........................................................................................8

2.5 RD and RDs piles ..........................................................................................9

2.5.1 Structure, dimensions, steel grade selection and identification ..........................................9

2.5.2 Splicing and steel grade selection of RD piles .........................................................10

2.6 Shaft grouted RR piles (CSG-RR piles) ..................................................................... 11

2.7 Bearing plates ............................................................................................12

2.8 Pile dimensions and geometrical sectional properties .......................................................12

3. DESIGN STANDARDS AND IMPLEMENTATION CONTROL.........................................................14

4. RECOMMENDATIONS FOR THE SELECTION AND DESIGN OF PILE TYPE, PILE SIZE AND

PILING CLASS FOR DIFFERENT APPLICATIONS .................................................................14

5. STRUCTURAL AND GEOTECHNICAL DESIGN OF PILES...........................................................15

5.1 Limit states of pile foundations to be considered ............................................................15

5.2 Design process of a steel pile foundation ...................................................................15

5.3 Actions and design situations ..............................................................................16

5.4 Geotechnical investigations ...............................................................................16

5.5 Dimensioning methods and analyses of geotechnical resistance.............................................16

5.5.1 Selection of geotechnical dimensioning method for steel piles .........................................16

5.5.2 Stiness of a piled structure .........................................................................16

5.5.3 Resistances determined by stress wave analysis ......................................................17

5.5.4 Resistances determined by dynamic load tests .......................................................17

5.5.5 Resistances determined by pile driving formulas ......................................................17

5.5.6 Resistances determined on the basis of ground test results............................................17

5.5.7 Resistances determined by static load tests ..........................................................19

5.6 Geotechnical dimensioning of tension piles.................................................................19

5.7 Structural resistance ......................................................................................19

5.7.1 Resistance of RR piles during installation..............................................................19

5.7.2 Structural resistance during service ................................................................. 20

5.7.3 Corrosion .......................................................................................... 20

5.8 Vertical displacements of pile foundation.................................................................. 22

5.9 Considering downdrag (negative skin friction) in dimensioning.............................................. 22

5.10 Transversely loaded steel piles............................................................................23

5.11 Short piles ...............................................................................................23

5.12 Dimensioning tables for RR and RRs piles, pile sizes RR75 to RR320/12.5....................................23

5.13 Dimensioning tables for RD and RDs piles, RD/RDs90 to RD320/12.5........................................23

6. DESIGN OF PILE FOUNDATIONS .............................................................................. 26

6.1 Attachment of piles to superstructure ..................................................................... 26

6.2 Centre-to-centre distances between steel piles ........................................................... 26

6.3 Distance between side of pile footing and piles ............................................................ 26

6.4 Distances between piles and other structures ............................................................. 26

6.5 Pile inclinations ...........................................................................................27

6.6. Allowed positional and angular deviations .................................................................27

6.7 Impact of piling on previously installed piles, other foundation structures and immediate surroundings ....... 28

7. PILING ...................................................................................................... 28

7.1 Material needed for piling: working plan and quality plan.................................................... 28

7.2 Storage, handling, inspection and erection of steel piles.................................................... 28

7.3 Installation of RR piles.................................................................................... 29

7.3.1 Piling equipment.................................................................................... 29

7.3.2 Start of installation..................................................................................31

3

7.3.3 Penetration blows and allowed driving stresses........................................................31

7.3.4 Additional installation instructions and splicing of RR75 to RR220 piles ................................32

7.3.5 Additional instructions for the installation of RR270 to RR1200 piles ...................................32

7.3.6 Additional instructions for rock shoes with hollow dowel ...............................................32

7.3.7 End of driving of an end-bearing pile with a drop or hydraulic hammer..................................33

7.3.8 End of driving of an end-bearing pile with a hydraulic ram or pneumatic hammer .......................33

7.3.9 Preparation of end-of-driving instructions for large diameter piles in piling classes PTL3 and PTL2 ......34

7.3.10 Final blows on friction piles..........................................................................34

7.3.11 Project-specific driving instructions..................................................................34

7.3.12 Installation of jacked-RR piles.......................................................................34

7.4. Installation of RD piles ....................................................................................34

7.4.1 Piling equipment and drilling methods ................................................................34

7.4.2 Start of installation..................................................................................35

7.4.3 Drilling of RD piles ...................................................................................35

7.4.4 Handling and installation of threaded RD pile sections and threaded sleeves ...........................37

7.5 Splicing of steel pipe piles by welding.......................................................................38

7.5.1 Welding Plan ........................................................................................38

7.5.2 Welding quality requirements ........................................................................38

7.5.3 Qualification of Welders .............................................................................39

7.5.4 Welding Procedures ................................................................................ 40

7.5.5 Welding Consumables .............................................................................. 40

7.5.6 Welding Conditions................................................................................. 40

7.5.7 Joint Preparation ....................................................................................41

7.5.8 Preheating......................................................................................... 42

7.5.9 Welding ........................................................................................... 42

7.5.10 Inspection of Welded splices ....................................................................... 42

7.6 Pile cut-o ...............................................................................................43

7.7 Pile cleaning ..............................................................................................43

7.8 Reinforcement and concreting of piles .....................................................................43

7.9 Bearing plate installation................................................................................. 44

7.10 Installation of shaft grouted CSG-RR piles................................................................ 44

7.10.1 Installation equipment ............................................................................. 44

7.10.2 Driving of pile into soil and its splicing .............................................................. 44

7.10.3 Grout injection .................................................................................... 44

8. SUPERVISION AND QUALITY CONTROL OF PILING WORK, MEASUREMENTS .....................................45

8.1 Supervision and monitoring of piling work...................................................................45

8.2 Quality control of materials................................................................................45

8.3 Monitoring measurements during installation...............................................................45

8.4 Testing of piles........................................................................................... 46

9. DOCUMENTATION OF PILING WORK .......................................................................... 46

9.1 General.................................................................................................. 46

9.2 Piling records............................................................................................ 46

9.3 Outcome drawing and other piling documents ............................................................. 46

10. WORK SAFETY AND ENVIRONMENTAL PROTECTION.......................................................... 46

11. END-OF-DRIVING TABLES ....................................................................................47

11.1 General ..................................................................................................47

11.2 Drop and hydraulic hammers..............................................................................47

11.2.1 Basics of modelling..................................................................................47

11.2.2 Instructions for use of end-of-driving tables .........................................................47

11.3 Hydraulic rams and pneumatic hammers.................................................................. 48

11.3.1 Principles of modelling.............................................................................. 48

11.3.2 Instructions for use of end-of-driving graphs and tables ............................................. 48

Appendix 1. Rc;max values of driven piles and directive design values Rdof large diameter RR piles.................... 50

Appendix 2. End-of-driving tables and curves for dierent pile driving equipment

(can be downloaded from www.ssab.com/infra)

Appendix 3. Design values for RR and RD piles made of S440J2H steel grade.

(can be downloaded from www.ssab.com/infra)

4

Table 1. Standard steel grades of SSAB’s steel piles, against special order, the piles may also be delivered in X grades ac-

cording to API5L standard.

Steel grade Carbon

equivalent Chemical composition, max. Mechanical properties

Impact strength

CEV max. C Mn P S fymin fuA5min T* KV min

[%] [%] [%] [%] [%] [MPa] [MPa] [%] [°C] [J]

S355J2H 0.45 0.22 1.6 0.03 0.03 355 470-630 20 -20 27

S440J2H 0.45 0.16 1.6 0.02 0.02 440 490-630 17 -20 27

S460MH 0.46 0.16 1.7 0.035 0.03 460 530-720 17 -30 27

S550J2H 0.47 0.12 1.9 0.02 0.02 550 605-760 14 -20 27

*) Testing temperature may also be -40 °C. Demanded impact energy remains the same.

1. GENERAL

This manual deals with driven and jacked SSAB's RR and

RRs piles, shaft grouted driven CSG-RR piles and drilled

RD and RDs piles. It covers all pile sizes from RR75 to RR/

RD1200. This manual describes the basics of the design of

SSAB's steel piles and provides advice on their handling

and installation, quality control, measurements and

documentation. This manual is supplemented by product

brochures on RR and RRs piles and RD and RDs piles,

which describe the applications, materials, structures and

dimensions of steel piles on a general level.

This manual is based on the Finnish Piling Manual PO-

2016 (RIL 254-2016). This manual is used when the site

has been designed according to the Eurocodes system. If

the piling of a site is designed using the maximum allowed

pile loads method, the RR and RD Piling Instructions

are followed in the design of steel piles. The installation,

handling and end-of-driving instructions presented

here can be used where applicable if the site has been

designed based on maximum allowed pile loads.

This manual applies to both individual piles and

pile groups. They can be applied to the design and

implementation of support structures made of SSAB's

steel piles, such as the RD pile wall, various Combi wall

structures, and driven or drilled steel pipe piles used in

other retaining walls.

2. SSAB’S STEEL PILES

2.1 General

SSAB has CE marking, based on European Technical

Assessment (ETA 12/0526), which is the most

comprehensive CE marking to be granted to pile

structures made of structural steel. It covers the entire

pile structure, manifests the requirements and conformity

of the mechanical splices, and establishes that the

product has been manufactured specifically for piling.

The approval is based on detailed load tests, especially

on splices, continuous quality control during the various

phases of production, and traceability of materials.

Use of SSAB's CE marked piles in a construction

project ensures the durability and performance of

foundations. Tested products guarantee problem-free

site installation.

Internal splices of RR piles are not covered by the CE

marking.

SSAB's steel piles meet the requirements presented in

Finnish Piling Manual PO-2016 (RIL 254-2016) for pile

materials and accessories.

SSAB's steel piles have SP Technical Research Institute of

Sweden quality certificate – P-mark (0656/94).

2.2 Steel grades and standards

The steel grades and chemical composition and

mechanical properties of SSAB's steel piles are presented

in Table 1.

The availability of steel grades by pile types and diameter

and wall thickness are presented in Secs. 2.3.1 and 2.4.1.

Against special order, the piles may also be delivered in

X grades according to API5L standard.

The technical delivery terms of the piles comply with

standard EN 10219-1. Dimensions and tolerances

comply with standard EN 10219-2. SSAB's steel piles

with mechanical splices are manufactured to tolerances

stricter than those of standard EN 10219-2. A material

certificate of type 3.1 specified in EN 10204 is provided for

the pile material.

5

2.3 Small diameter RR and RRs piles

2.3.1 Structure, steel grades and identification

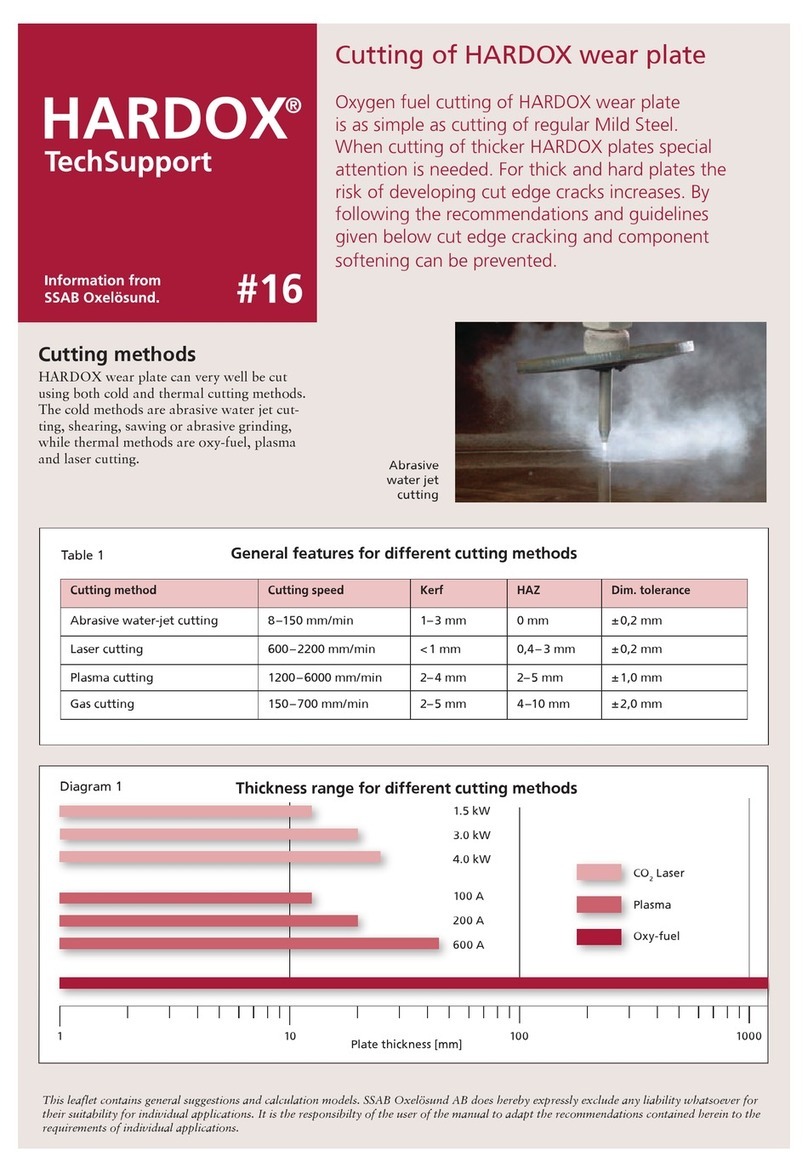

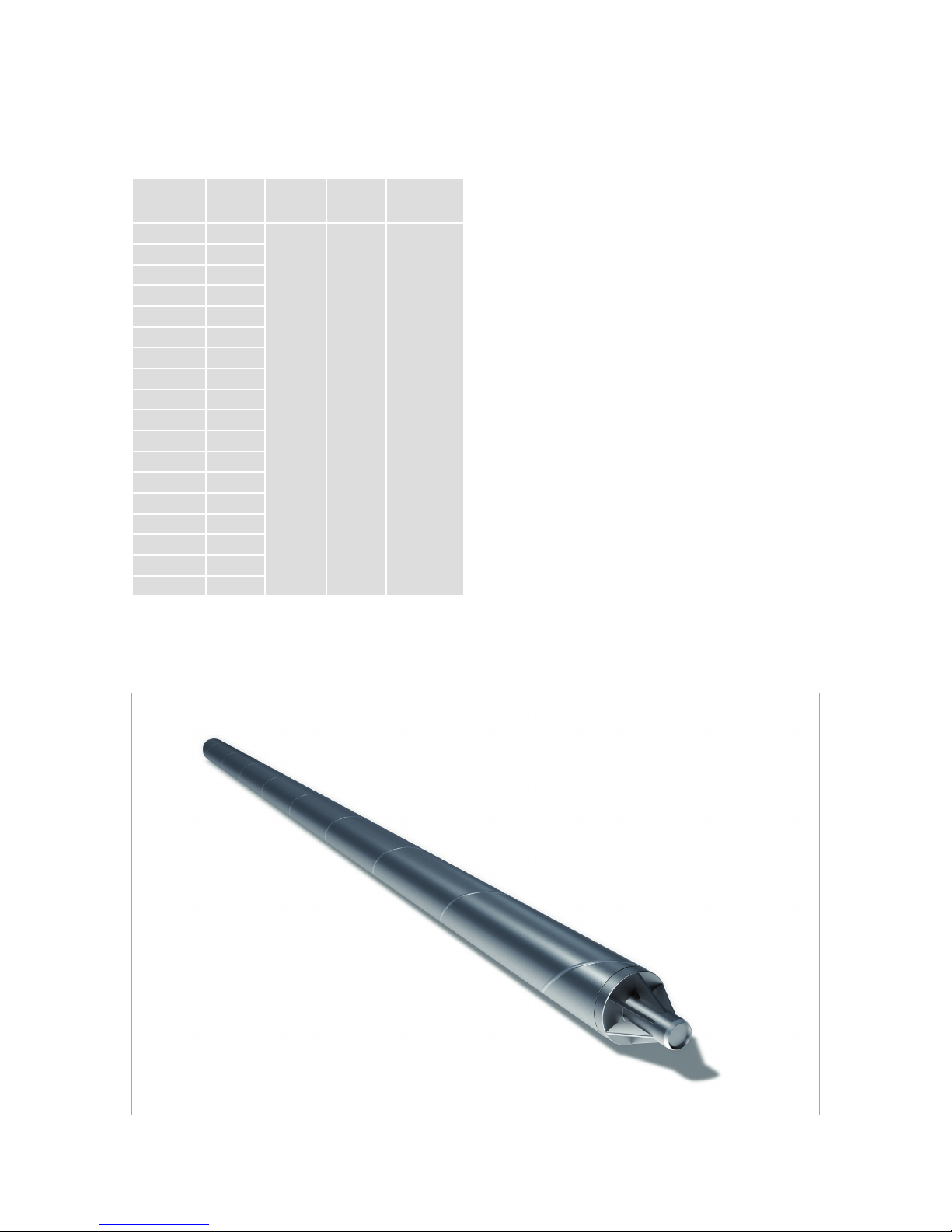

The structure and members of RR and RRs piles are shown

in Figure 1.

The basic steel grade of RR piles is S460MH and that

of RRs piles S550J2H. Against special order, the piles

may also be delivered in S420MH steel grade. RR270

to RR320 piles made of steel grade S355J2H are also

available.

RR and RRs piles have mechanical friction splices and pile

shoes up to pile size RR220/12.5. RR270 and RR320 piles

are spliced, if necessary, by welding, and the pile shoe is

attached by welding.

SSAB's RR small diameter piles are identified by a marking

on the side of the pile. In addition, identification tape is

attached to splices of RR pile sections or next to them.

Pile bundles are delivered with product descriptions that

indicate, besides pile manufacturer and dimensions, the

steel grade of the RR piles.

2.3.2 Pile sections, pipes and splices

A pile section consists of a pile pipe and the attached

external splice sleeve. The mill lengths of RR pile sections

and pile pipes without external splice sleeves are presented

in Table 2.

All pile sizes RR75 to RR220 made of steel grade S460MH

can be spliced using external splice sleeves and pile sizes

RR140 to RR220 by separate internal splices. RRs piles are

manufactured in eight different sizes. All RRs pile sizes can

be joined by external splice sleeves.

External

splice

Internal

splice

Rock shoe

Bottom plate

Bearing

plate

Figure 1. Structure and parts of RR piles, pile sizes RR75

to RR220.

The splices meet the requirements of PO-2016 for rigid

splices and those of the national appendix to Eurocode

EN 1993-5: Design of steel structures, Steel piles (Table

3). Since the splices meet the requirements, pile splices do

not limit the structural capacity of the pile, and piles can be

installed as straight as possible in all soil conditions.

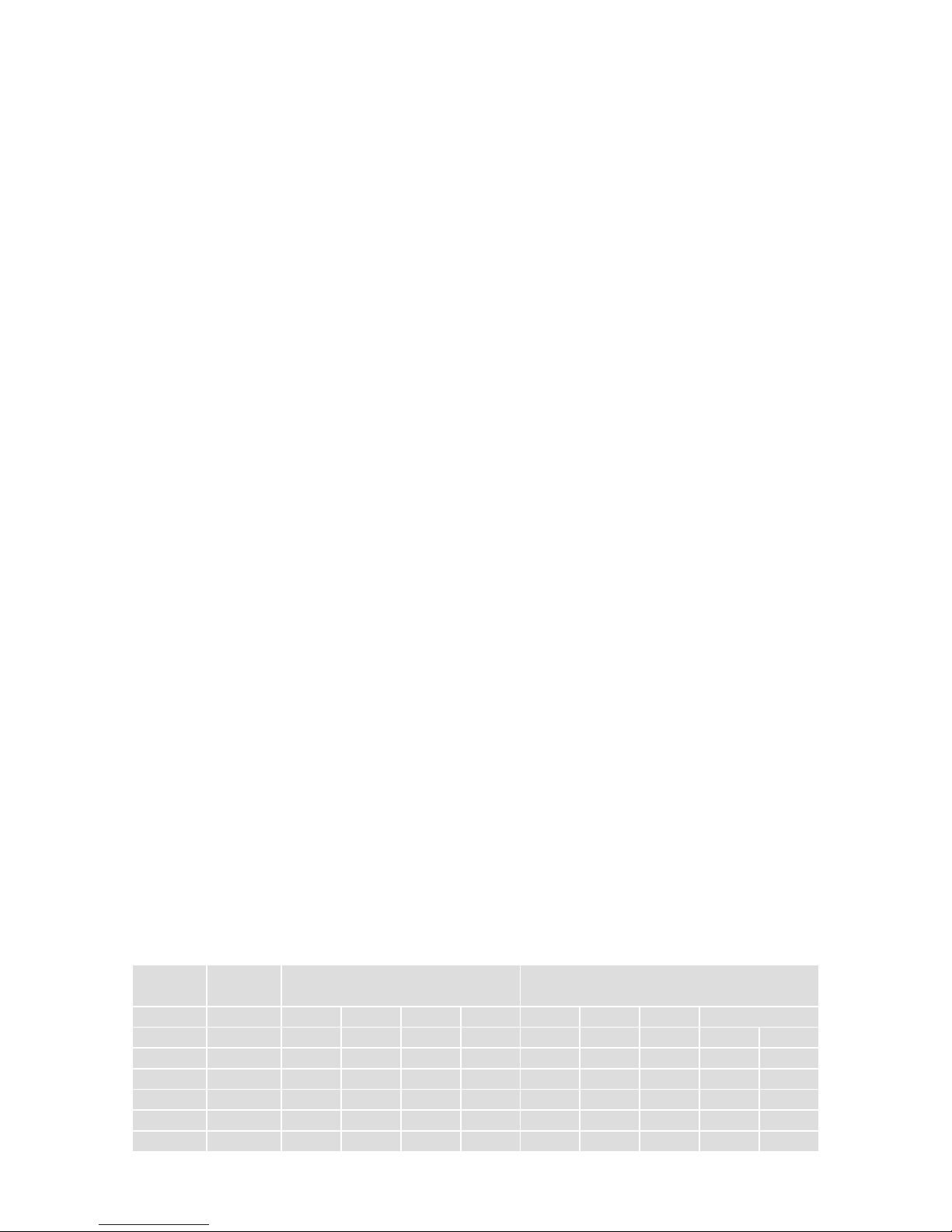

Table 2. Mill dimensions of RR and RRs pile sections and pile pipes.

Length of pile section (incl. splice) Length of pile section (excl. splice)

Pile type 12 m 6 m 4 m 3 m 2 m 1.5 m 1.2 m 1.0 m 6 m 12 m 16 m

RR75 - X O O O O O O X O -

RR90 - X O O O O O O X O -

RR115/6.3 O X O O O O O O X O -

RR115/8 O X O O O O O O O X O

RR140/8 X X O O O O O O O X O

RR140/10 X X O O O O O O O X O

RR170/10 X X O O O O O O O X O

RR170/12.5 X O O O O O O O O X O

RR220/10 X O O O - - - - O X O

RR220/12.5 X O O O - - - - O X O

RRs100/6.3 - X O O O O O O X O -

RRs115/8 O X O O O O O O O X O

RRs125/6.3 X X O O - - - - O X -

RRs140/8 X X O O O O O O O X O

RRs140/10 X O O O O O O O O X O

RRs170/10 X O O O O O O O O X O

RRs220/10 X O O O - - - - O X O

RRs220/12.5 X O O O - - - - O X O

X = stock size O = project-specific size – = not in production

6

Table 3. Minimum strength and stiness requirements of

RR and RRs pile splices

Pile type

Tensile

strength

[kN]

Com-

pression

strength

Yield

moment

M

Flexural

stiffness

EI(0.3-0.8 M)

RR75 95

Ppile Mpile 0.75xEIpile

RR90 113

RRs100/6.3 156

RR115/6.3 147

RR115/8 184

RRs115/8 220

RRs125/6.3 197

RR140/8 228

RRs140/8 273

RR140/10 281

RRs140/10 336

RR170/10 343

RRs170/10 410

RR170/12.5 422

RR220/10 453

RRs220/10 542

RR220/12.5 560

RRs220/12.5 669

2.3.3 Pile shoes

The mechanically attached pile shoes of RR and RRs piles,

bottom plates and rock shoes, meet the requirements

given in PO-2016. The rock shoe dowel is made of

hardened special steel, which ensures good penetration

into bedrock. The foundation engineer chooses the

type of pile shoe according to the conditions. Use of a

rock shoe is always recommended when piles are driven

through to an inclined bedrock surface or a bedrock

surface under thin coarse-grained or moraine soil

layers. Rock shoes make it possible for piles to penetrate

compact or rocky soil layers better and remain straighter.

SSAB's pile shoes are dimensioned to withstand the

stresses from pile installation and use, provided that the

instructions of Sec. 7.3 are observed in installation.

Jacked RR micropiles can be equipped with a special shoe

through which post-grouting can be done after jacking to

improve point, and to some extent, shaft resistance.

The shoes used with RR270 to RR320 piles are rock shoes

with hardened rock dowels. Against special order, the pile

tip can be protected by a bottom plate or a rock shoe

different from the standard rock shoe. All shoes of RR270

to RR320 piles are attached to the pipe pile by welding.

Pipe piles are delivered to site with welded-on rock shoes.

The design resistance values of standard rock shoes for

RR270 to RR320 piles are presented in Table 4. The most

Figure 2. Large diameter RR pile

7

important dimensioning factor for rock shoes are the end

blows and/or dynamic load test. Moreover addition, the

installation instructions of Sec. 7.3 must be followed in

installation, especially if the pile tip encounters a boulder

or an inclined bedrock surface.

RR270 to RR320 rock shoes have the Finnish Transport

Agency’s permission for use (565/090/201, 4.10.2011).

With steel grade S460MH, the calculated resistance of

the rock shoe limits the ultimate geotechnical resistance

Rcof pile sizes RR270/12.5 and RR320/12.5 to that

presented in Table 4 and with steel grade S550J2H and

all pile dimensions RR270 to RR320 to the Rd,L values

presented in Table 4.

Table 4. Structural resistances of RR270 and RR320

standard rock shoes

Pile Rd,L [kN]

RR270 4073

RR320 4777

Rd,L = design value of ultimate limit state of the structural

resistance of a rock shoe for a centric vertical load at

the installation stage (impact and PDA measurement)

2.4 Large diameter RR piles

2.4.1 Structure, dimensions and availability of

steel grades

Large diameter RR piles are made of spirally welded steel

pipes. It is possible to manufacture single-section piles

up to 39 metres long. Piles are usually ordered in specific

lengths. The standard stocked sizes are presented in

Table 5.

Table 5. Large diameter RR piles in stock (L=12 m)

Dimensions

diameter x wall thickness [mm]

Steel grade

406 x 12.5 S440J2H (S355J2H)

508 x 12.5 S440J2H (S355J2H)

610 x 12.5 S355J2H

711 x 12.5 S355J2H

813 x 12.5 S355J2H

The main steel grades used for RR large diameter piles

are S355J2H, S440J2H and S550J2H. Against special

order, the piles may also be delivered in MH steel grades

according to standard EN10219 or X grades according to

API5L. Standard dimensions and the availability of steel

grades are presented in Table 6. The diameters primarily

recommended for design are RR400, RR500, RR600,

RR700, RR800, RR900, RR1000 and RR1200. In the case

of end-bearing piles, the recommended minimum wall

thickness to ensure easy installation is 10 mm for piles

RR400 to RR800 and 12.5 mm for RR900 to RR1200.

Besides the standard dimensions presented in Table

6, RR piles can also be made with other diameters

and customer-specific wall thicknesses selectable at

0.1 mm intervals. The selection of wall thicknesses and

steel grades allows accurate optimisation of structures.

Customer- or project-specific deviations from standard

dimensions require a quite large project, and optimisation

is particularly useful with combi wall or RD pile wall

structures, but also in end-bearing pile projects.

RR large diameter piles are recognised from a marking

on the side. Pile bundles are delivered with product

descriptions that indicate, besides pile manufacturer and

dimensions, the steel grade of the RR piles.

Table 6. Standard dimensions and availability of steel grades of large diameter steel pipe piles.

Pile Diameter Wall thickness [mm]

[mm] 8 10 12.5 14.2 16 18 20 21 22 23

RR400 406.4

RR450 457.0

RR500 508.0

RR550 559.0

RR600 610.0

RR650 660.0

RR700 711.0

RR750 762.0

RR800 813.0

RR900 914.0

RR1000 1016.0

RR1200 1220.0

Steel grades S440J2H, S550J2H and S355J2H

Steel grades S440J2H and S355J2H

Check availability from SSAB sales.

8

structure used as a wharf where the penetration level of

the piles is close to the bottom of the waterway and piles

are subject to considerable horizontal loads. There, rock

dowels drilled through the hollow dowel ensure the stability

of the retaining structure. Rock shoes with a hollow dowel

are also used at sites where piles are subject to tension

forces. A pull anchor can be installed through the hole.

In conditions of no or few stones, where the pile tip is

designed to bear on soil layers, the tip of the pile can be

protected by a so-called reinforced bottom plate. The

recommended solution for such conditions, however, is to

use standard rock shoes with structural steel dowels.

Open ended piles are often equipped with a so-called

reinforcement ring to protect the lower end. The

reinforcement ring is usually a 150 to 500 mm wide steel

band welded onto the lower end of the pile. The sheet

thickness of the steel band is usually 10, 15 or 20 mm.

Both reinforcement rings and reinforced bottom plates

are manufactured to the client’s project-specific designs.

Rock shoes are preheated before welding and assembly

welding is carried out by robots. The rock shoes are

numbered to ensure the traceability of the manufacture

and raw-materials of the shoes.

The design resistance values of standard rock shoes for

RR large diameter piles are presented in Table 7. The

most important criterion for rock shoes are the end blows

and/or the dynamic load test. Project specific rock shoes

with different capacities are analyzed numerically by the

requirements of Finnish Transport Agency. Moreover, the

installation instructions of Sec. 7.3 must be followed in

installation, especially if the pile tip encounters a boulder

or an inclined rock surface.

At the design stage, however, the maximum impact

resistance of each pile size should be limited to its/the Rd,L

value.

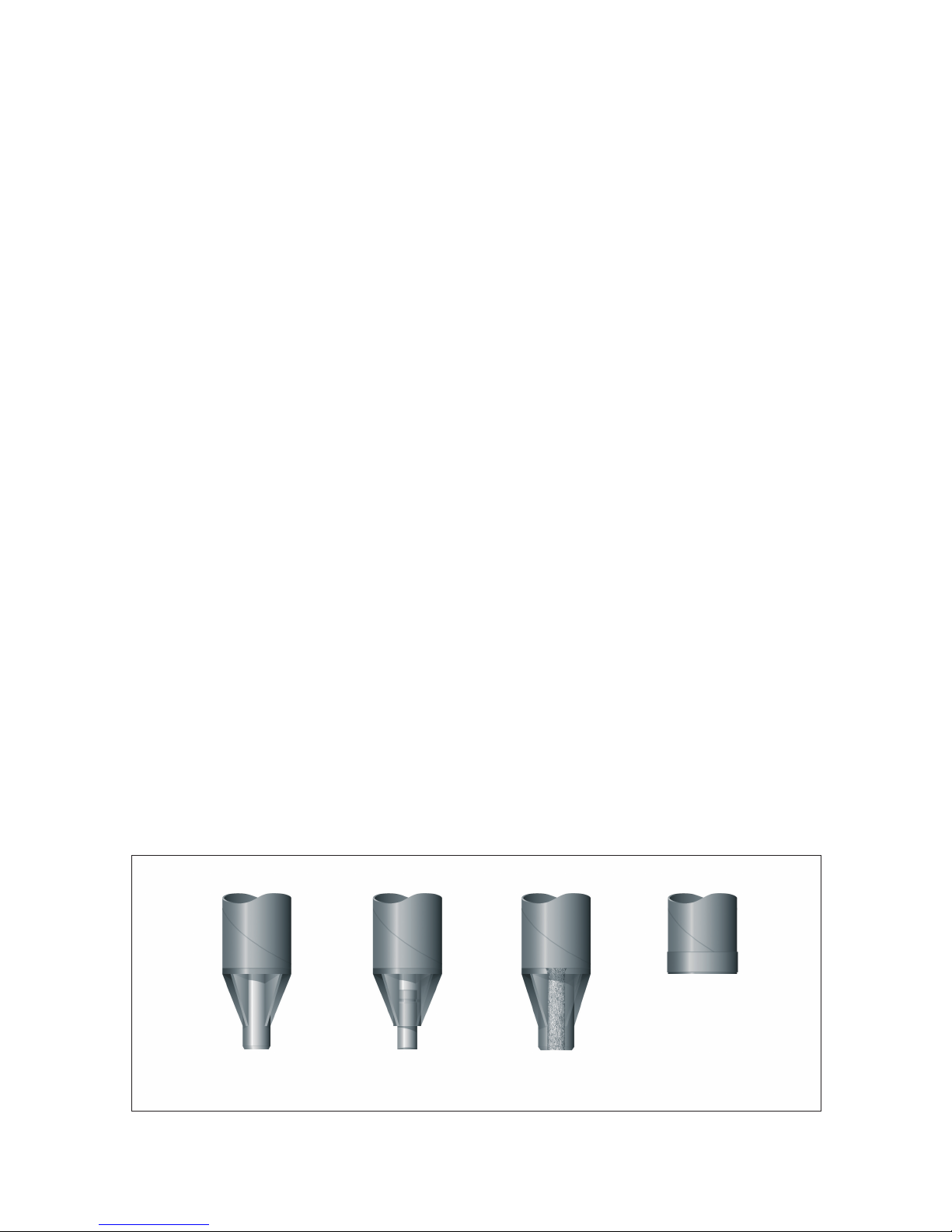

Figure 3. Shoe types of large diameter RR piles.

Rock shoe with structural

steel dowel

Rock shoe with hardened

steel dowel

Rock shoe with

hollow dowel

Toe

reinforcement

2.4.2 Pile shoes

In soil conditions typical of the Nordic countries,

RR large diameter piles are usually equipped with

RR rock shoes. SSAB's standard rock shoes were

granted the Finnish Transport Agency’s use permission

(565/090/201, 4 October 2011) and the manufactured

rock shoes are CE marked. Rock shoes are used to protect

the lower end of the pile against installation stresses, to

centre the stresses on the pile tip as evenly as possible

across the pile pipe cross-section, and to prevent lateral

sliding of the pile tip.

There are three types of RR rock shoes (Figure 3). The most

common ones are rock shoes fitted with a structural steel

dowel or a hardened rock dowel. SSAB also delivers rock

shoes fitted with a hollow dowel, which allows drilling, for

example, a dowel bar to be grouted to bedrock through the

concrete filled hollow dowel of the rock shoe.

A rock shoe with a structural steel dowel is used in

conditions where the target level of the piles is within

coarse-grained or moraine soil layers, or in conditions

where the bedrock surface is relatively even and there

are supporting compact soil layers on top of the bedrock.

A rock shoe with a structural steel dowel endures well

penetration to the surface of the bedrock and into it.

A rock shoe with a hardened rock dowel is used in

conditions where the bedrock surface is inclined or there

are no compact coarse-grained or moraine soil layers on

top of the bedrock – or the soil layers are thin and the

pile tip is to be driven to the bedrock surface. Rock shoes

with a hardened rock dowel can prevent lateral sliding of

the pile tip in most conditions.

Rock shoes with a hollow dowel can be used in conditions

where it is desired to ensure the staying in place of the pile

tip by a grouted steel dowels drilled through the hollow

dowel into bedrock. A typical application is a combi-wall

9

Table 7. Design values of ultimate limit state of the structural

resistance of a rock shoes for a centric vertical load at the

installation stage (impact and PDA measurement)

Pile Structural

steel dowel

Rd,L [kN]

Hardened

steel dowel

Rd,L [kN]

Hollow

dowel

Rd,L [kN]

RR400 5033 4982

RR450 6057 6032

RR500 7672 7545

RR550 7994 7940

RR600 9677 9681 9285

RR650 10084 10062

RR700 11993 11605 11370

RR750 12387 12342

RR800 12653 12610 12188

RR900 14910 14887 14512

RR1000 18751 15691 18371

RR1200 19317 19260

2.5 RD and RDs piles

2.5.1 Structure, dimensions, steel grade selection

and identification

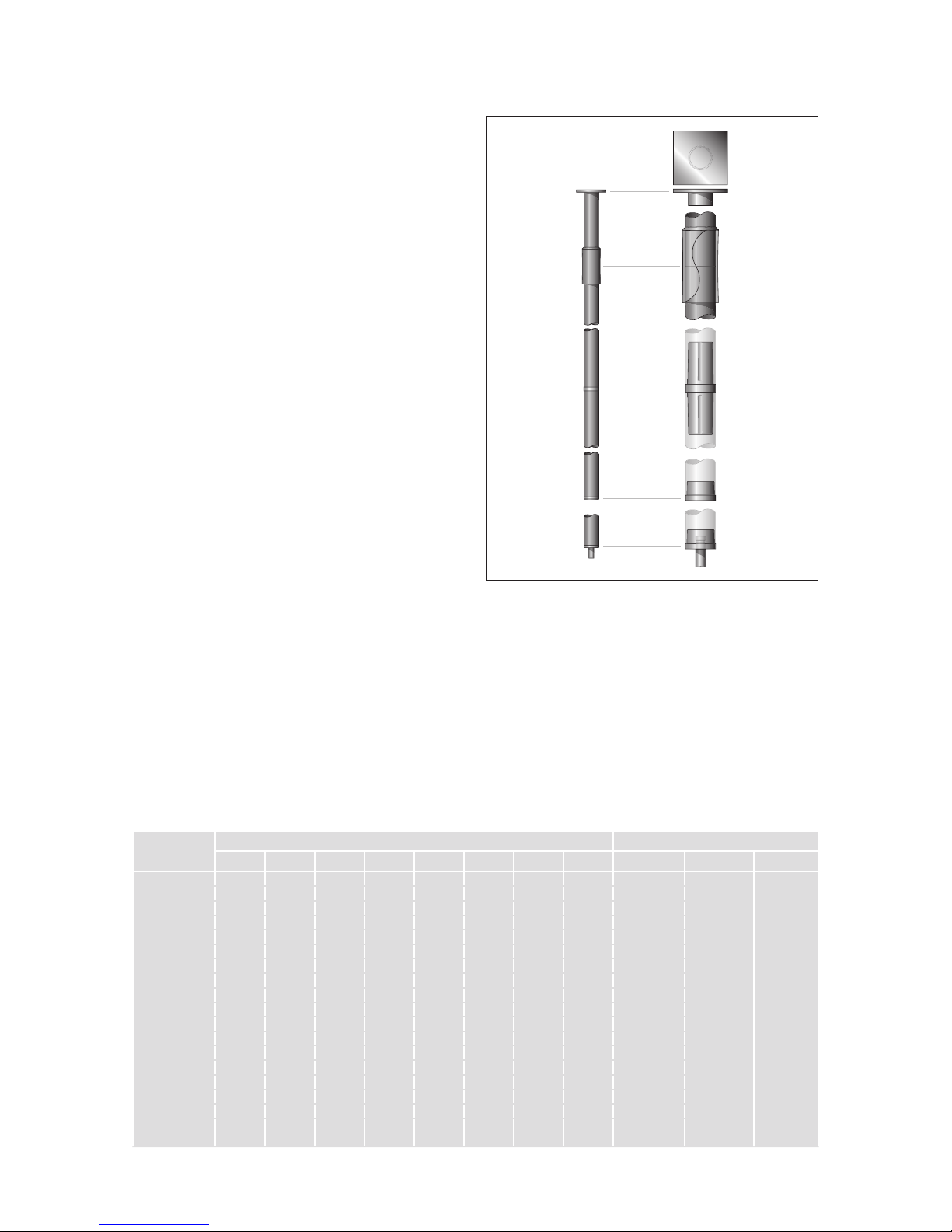

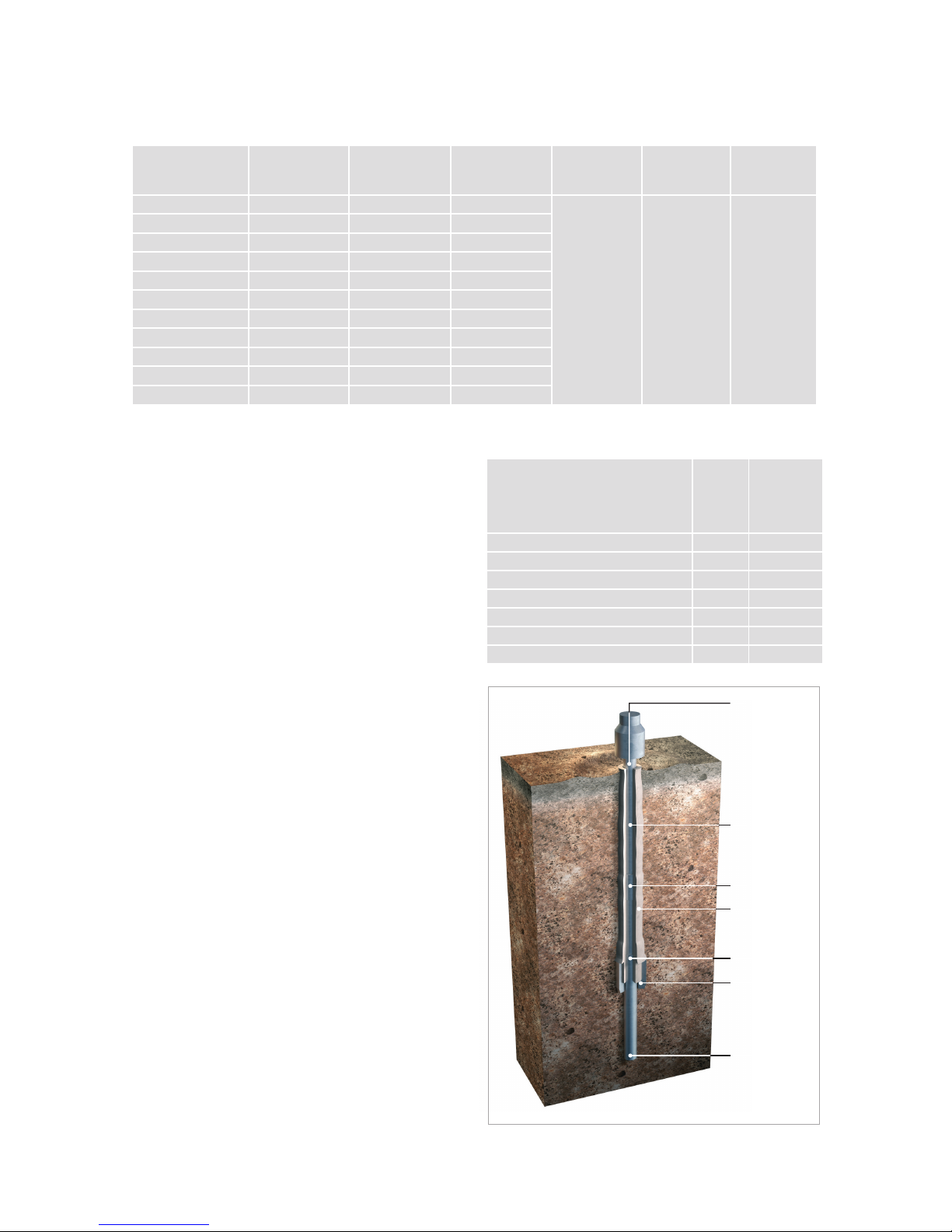

The structure of the RD pile is shown in Figure 4. The

standard steel grade of RD90 to RD220 piles is S460MH.

The steel grade of RDs piles is S550J2H. Against special

order, the piles may also be delivered in S420MH steel

grade. RD270 to RD320 piles made of S355J2H steel

grade are also available. All steel grades of SSAB's steel

pile products can be used as steel grades of RD400 to

RD1200 piles. The pile sizes and availability of steel grades

Threaded

pile section

Threaded

splice sleeve

Bearing plate

Welded splice

(beveled ends)

Casing shoe /

ring bit

Figure 4. Structure of RD micropile.

of RD piles are presented in Table 8. Dimensions RD400,

RD500, RD600, RD700, RD800, RD900, RD1000 and

RD1200 are recommended for RD large diameter piles.

Table 8. Standard dimensions and availability of steel grades of RD piles.

Pile Diameter Wall thickness [mm]

[mm] 6.3 8 10 12.5 14.2 16 18 20 21 22 23

RD90 88.9

RDs100 101.6

RD115 114.3

RDs125 127.0

RD140 139.7

RD170 168.3

RD220 219.1

RD270 273.0

RD320 323.9

RD400 406.4

RD450 457.0

RD500 508.0

RD550 559.0

RD600 610.0

RD650 660.0

RD700 711.0

RD750 762.0

RD800 813.0

RD900 914.0

RD1000 1016.0

RD1200 1220.0

Steel grades S440J2H and S550J2H

Steel grades S550J2H

Steel grades S460MH, S550J2H and S355J2H

Steel grades S440J2H, S550J2H and S355J2H

Steel grades S440J2H and S355J2H

Check availability from SSAB sales.

10

Figure 5. Structure of large diameter RD piles.

a top hammer is used. Instructions for the handling and

installation of splices, as well as the dimensions of threaded

sleeves and recommended types and dimensions of ring

bits are presented in Sec. 7.4.4 of these instructions. The

sleeves meet the requirements for rigid splices of Piling

Manual PO-2016 and the National Annex to Eurocode

1993-5, Design of steel structures, Steel piles (Table 10).

The splice is guaranteed a tensile strength that is 50 % of

the compressive strength of the pile when the handling and

installation of the splice are done according to Secs. 7 and 8.

All RD piles may also be spliced by welding.

The piles are delivered either as pile pipes or RD pipe sections

with threaded ends. The lengths of pile pipes and sections are

shown in Table 9. The inside burr of the longitudinal seam of

RD90-RD320 piles can be removed in individual projects to

order. With the most commonly used pilot bits the removal

of the inside burr is usually not necessary, but the pilot bit

should be selected considering the effect of the burr.

RD piles can be identified by the marking on their side.

Pile bundles are delivered with product descriptions that

indicate, besides pile manufacturer and dimensions, the

steel grade of the RD piles. If these markings are missing,

the pile pipe must not be used in RD piles.

2.5.2 Splicing and steel grade selection of RD piles

RD-piles are spliced using external threaded sleeves (t≥8mm

and D≤220mm) (Figure 6), by threaded and welded splice

pieces (RD270/10, RD270/12,5, max fy= 460 MPa ;

RD320/10, RD320/12,5, max fy= 550 MPa) or by welding.

Mechanized welding is used specially in underpinning

projects. When using a DTH hammer, the threads of the pile

pipe and the sleeve are left-handed, but right-handed when

RD®RDs®

Figure 6. Splice sleeves of RD and RDs piles

Table 9 a. and table 9 b. Length range of RD and RDs piles

Pile type Lenght of pile pipe without threads

1 m 1.2 m 1.5 m 2 m 3 m 4 m 6 m 12 m 12-16 m 16-34 m

RD90 O O O O O O X - - -

RD115/6.3 O O O O O O X O - -

RD115/8 O O O O O O O X O -

RD140-RD320 O O O O O O O X O -

RD400-RD1200 O O O O O O O X O O

RDs90 O O O O O O O - - -

RDs100 O O O O O O O - - -

RDs115/6.3 O O O O O O O O - -

RDs115/8 O O O O O O O X O -

RDs125/6.3 O O O O O O O X - -

RDs140-RDs320 O O O O O O O X O -

X = stock sizes

O = project-specific size

-= not available

Pile type

Length of pile section with threaded ends

1 m 1.2 m 1.5 m 2 m 3 m 4 m 6 m 12 m

RD115/8 O O O O X O O O

RD140/8 O O O O O O O O

RD140/10 O O O O O O X O

RD170/10 O O O O O O X O

RD170/12.5 O O O O O O X O

RD220/10 O O O O O O O O

RD220/12.5 O O O O O O X O

RDs115/8 O O O O O O O O

RDs140/8 O O O O O O O O

RDs140/10 O O O O O O O O

RDs170/10 O O O O O O O O

RDs170/12.5 O O O O O O X O

RDs220/10 O O O O O O O O

RDs220/12.5 O O O O O O X O

Pile type

Length of pile section with threaded splice pieces

6 m 12 m

RD270/10 O O

RD270/12.5 O O

RD320/10 0 O

RD320/12.5 0 O

RDs320/10 0 O

RDs320/12.5 0 O

11

Grouting,

pressurised

if necessary

RR pile

section

Splice

Grout mantle

Grouting holes

Collar

Pile toe

2.6 Shaft grouted RR piles (CSG-RR piles)

Shaft grouted RR®piles are for the most part shaft-

bearing micropiles where the geotechnical bearing

capacity of the pile shaft is improved by Continuous

Shaft Grouting using cement grout. Shaft grouted piles

are suitable for use in friction soil layers where their

high shaft resistance can be used to shorten pile length

considerably.

Shaft grouted RR piles have all the mechanical

components of RR micropiles as well as a so-called

collar. The splice type is the external RR pile splice

sleeve. The length of a pile section is usually 6 metres,

but the other section lengths presented in Table 2 are

also possible. The most common shaft grouted pile sizes

are RR90 to RR140. The standard steel grade of shaft

grouted RR piles is S460MH. RRs100/6.3, RRs115/8,

RRs125/6.3, RRs140/8, RRs140/10 and RRs170/10 pile

sections of steel grade S550J2H may also be used. The

pile structure is shown in Figure 7.

Shaft grouted driven RR piles are equipped either with

a bottom plate or a rock shoe, usually a bottom plate. A

rock shoe is used especially to ensure contact between

the pile tip and bedrock or penetration of compact soil/fill

layers in top soil. The lower end of a shaft grouted driven

RR pile has a collar larger than the pile pipe. The purpose

of the collar is to keep the grouting holes open during

installation and to make a hole larger than the pile pipe in

the ground. A guide device directs the tip of the pile and

protects the collar from possible obstructions. The length

of the guide device is usually 0.5 to 1.0 m. Table 11 shows

the diameters of pre-dimensioned shoe collars. The collar

of a pre-dimensioned shoe is detachable and installed

in the shoe at the beginning of the installation stage. If

necessary, the collars and shoes can be designed case by

case. It is recommended that the outer diameter of the

collar is at least 40 mm larger than the diameter of the

pile pipe.

Table 10. Strengths of threaded sleeves and threaded M/F splices.

Figure 7. Grouted RR pile (CSG-RR pile)

Table 11. Diameters of CSG-RR pile collars.

Pile size

Pile

diameter

d[mm]

Diameter of

standard

collar

[mm]

CSG-RR75 76.1 127.0

CSG-RR90 88.9 139.7

CSG-RRs100/6,3 101,6 152,4

CSG-RR115/6.3 and CSG-RR115/8 114.3 159

CSG-RRs125/6.3 127.0 168.3

CSG-RR140/8 and CSG-RR140/10 139.7 193.7

CSG-RR170/10 and CSG-RR170/12.5 168.3 219.1

Pile Tensile strength

[kN] Pile Tensile

strength [kN]

Compression

strength

Bending

strength

Flexural

stiness

EI

(0.3 –0.8 M)

RD115/8 620 RDs115/8 750

Ppile Mpile 0.75 x EIpile

RD140/8 770 RDs140/8 910

RD140/10 940 RDs140/10 1120

RD170/10 1150 RDs170/10 1370

RD170/12.5 1410 RDs170/12.5 1680

RD220/10 1520 RDs220/10 1810

RD220/12.5 1870 RDs220/12.5 2230

RD270/10 1900

RD270/12.5 2350

RD320/10 2270 RDs320/10 2720

RD320/12.5 2820 RDs320/12.5 3370

12

2.7 Bearing plates

Usually a bearing plate is installed at the upper end of RR/

RRs, RD/RDs and CSG-RR micropiles to transfer loads

from the superstructure to the pile. Standard bearing

plates are centralized on the pile shaft by an internal

sleeve, which serves to keep the bearing plate in place

during the construction phase. It is not designed to

withstand possible horizontal loads of the pile. The plate

of standard bearing plates is made of steel S355J2. The

standard sizes of bearing plates are shown in Table 12.

Table 12 presents the suggested design strengths Rdof

the bearing plates. It is recommended that the strength of

the bearing plate be verified both as to the steel structure

of the bearing plate and the compressive strength and

punching shear capacity of the concrete on top of the

bearing plate when the design value of load is about 90

to 100% of the design value of the strength of the bearing

plate and when using concrete strengths C30/37 to

C35/45.

Bearing plates may also be made based on specific site

designs in dimensions and shapes different from standard

bearing plates, for example, with a hole.

2.8 Pile dimensions and geometrical sectional

properties

The dimensions and geometrical sectional properties of

longitudinally welded RR and RD micropiles are presented

in Table 13 and those of spirally welded large diameter RR

and RD piles in Table 14.

Table 13. Dimensions and geometrical sectional properties of RR®and RD®micropiles.

A

Au

Ab

= Area of steel cross-section

= Pile surface area

= Area of pile toe

Z

I

Wel

= Pile impedance

= Moment of inertia

= Elastic modulus

Sectional properties incl. corrosion allowances

of 1.2 mm and 2.0 mm

D

[mm]

t

[mm]

M

[kg/m]

A

[mm2]

Au

[m2/m]

Ab

[mm2]

Wel

[cm3]

I

[cm4]

EI

[kNm2]

Z

[kNs/m]

A1,2

[mm2]

A2,0

[cm4]

I1,2

[cm4]

I2,0

[cm4]

EI1,2

[kNm2]

EI2,0

[kNm2]

76.1 6.3 10.8 1382 0.24 4548 22.3 84.8 178 56.1 1099 916 65.0 52.8 137 111

88.9 6.3 12.8 1635 0.28 6207 31.6 140.2 295 66.4 1304 1089 108.4 88.7 228 186

101.6 6.3 14.8 1886 0.32 8107 42.3 215.1 452 76.6 1508 1260 167.4 137.4 351 289

114.3 6.3 16.8 2138 0.36 10261 54.7 312.7 657 86.8 1711 1432 244.5 201.4 514 423

114.3 8.0 21.0 2672 0.36 10261 66.4 379.5 797 108.5 2245 1966 311.3 268.2 654 563

127.0 6.3 18.7 2389 0.40 12667 68.7 436.2 916 96.9 1914 1603 342.3 282.7 719 593

139.7 8.0 26.0 3310 0.44 15328 103.1 720.3 1513 134.4 2788 2445 595.1 515.2 1250 1082

139.7 10.0 32.0 4075 0.44 15328 123.4 861.9 1810 165.4 3553 3210 736.7 656.8 1547 1379

168.3 10.0 39.0 4973 0.53 22246 185.9 1564.0 3284 201.9 4343 3928 1344.1 1202.7 2823 2526

168.3 12.5 48.0 6118 0.53 22246 222.0 1868.4 3924 248.4 5488 5073 1648.5 1507.1 3462 3165

219.1 10.0 51.6 6569 0.69 37703 328.5 3598.4 7557 266.7 5748 5205 3110.9 2794.7 6533 5869

219.1 12.5 63.7 8113 0.69 37703 396.6 4344.6 9124 329.4 7292 6749 3857.0 3540.9 8100 7436

273.0 10.0 64.9 8262 0.86 58535 524.1 7154.1 15024 335.5 7238 6560 6207.9 5590.9 13037 11741

273.0 12.5 80.3 10230 0.86 58535 637.2 8697.4 18265 415.3 9205 8527 7751.2 7134.2 16278 14982

323.9 10.0 77.4 9861 1.02 82397 750.7 12158.3 25533 400.4 8645 7839 10574.7 9538.5 22207 20031

323.9 12.5 96.0 12229 1.02 82397 916.7 14846.5 31178 496.5 11012 10206 13262.9 12226.7 27852 25676

Table 12. Dimensions of standard bearing plates,

suggested design strengths of bearing plates.

Pile

Bearing plate

dimensions

[mm x mm x mm]

Suggested

design

resistance

Rd[kN]

RR75** 150 x 150 x 15 380

RR/RD90** 150 x 150 x 15 450

RRs100/6,3 200 x 200 x 20

200 x 200 x 25 700

780

RR/RD115/6.3** 200 x 200 x 20 780

RR/RD115/8** 250 x 250 x 25 910

RRs125/6.3 200 x 200 x 20

250 x 250 x 25

950

1080

RR/RD140/8 and

RR/RD140/10** 250 x 250 x 25 1240

RR/RD170/10 and

RR/RD170/12.5** 300 x 300 x 30 1810

RR/RD220/10** 300 x 300 x 30 2090

RR/RD220/12.5 300 x 300 x 30 2090

RRs/RDs220/12.5 350 x 350 x 35 2700

RR/RD270/10 350 x 350 x 35* 2700

RR/RD270/12.5 350 x 350 x 35* 2700

RR/RD320/10 400 x 400 x 30* 3480

RR/RD320/12.5 400 x 400 x 30* 3480

RR/RD270/10 S550J2H 400 x 400 x 30* 2950

RR/RD270/12.5

S550J2H 450 x 450 x 40* 3750

RR/RD320/10 S550J2H 450 x 450 x 40* 4050

RR/RD320/12.5

S550J2H 500 x 500 x 40* 4520

*) Product not in stock

**) Pile sizes RR75 to RR220/10 of steel grades S440J2H

and S550J2H with same bearing plates

13

Table 14. Dimensions and geometrical sectional properties of RR®and RD®large diameter piles

A

Au

Ab

= Area of steel cross-section

= Pile surface area

= Area of pile toe

Z

I

Wel

= Pile impedance

= Moment of inertia

= Elastic modulus

Sectional properties incl. corrosion allowances

of 1.2 mm and 2.0 mm

D

[mm]

t

[mm]

M

[kg/m]

A

[mm2]

Au

[m2/m]

Ab

[mm2]

Wel

[cm3]

I

[cm4]

EI

[kNm2]

Z

[kNs/m]

A1,2

[mm2]

A2,0

[cm4]

I1,2

[cm4]

I2,0

[cm4]

EI1,2

[kNm2]

EI2,0

[kNm2]

406.4 8.0 78.6 10013 1.28 129717 978.0 19873.9 41735 406.5 8485 7472 16738.8 14679.5 35151 30827

406.4 10.0 97.8 12453 1.28 129717 1204.5 24475.8 51399 505.6 10926 9912 21340.7 19281.4 44815 40491

406.4 12.5 121.4 15468 1.28 129717 1477.9 30030.7 63064 628.0 13941 12927 26895.6 24836.3 56481 52156

457.0 8.0 88.6 11285 1.44 164030 1244.9 28446.4 59737 458.2 9566 8426 23984.0 21048.1 50366 44201

457.0 10.0 110.2 14043 1.44 164030 1535.7 35091.3 73692 570.2 12325 11184 30628.9 27693.0 64321 58155

457.0 12.5 137.0 17455 1.44 164030 1888.2 43144.8 90604 708.7 15737 14597 38682.4 35746.5 81233 75068

508.0 8.0 98.6 12566 1.60 202683 1546.5 39280.0 82488 510.2 10656 9387 33145.8 29104.6 69606 61120

508.0 10.0 122.8 15645 1.60 202683 1910.2 48520.2 101893 635.2 13735 12466 42386.1 38344.9 89011 80524

508.0 12.5 152.7 19458 1.60 202683 2352.6 59755.4 125486 790.0 17548 16279 53621.3 49580.1 112605 104118

508.0 14.2 172.9 22029 1.60 202683 2645.6 67198.6 141117 894.4 20118 18849 61064.5 57023.3 128235 119749

508.0 16.0 194.1 24731 1.60 202683 2949.2 74909.0 157309 1004.1 22820 21551 68774.9 64733.7 144427 135941

559.0 8.0 108.7 13848 1.76 245422 1880.7 52564.9 110386 562.3 11745 10348 44386.4 38992.4 93211 81884

559.0 10.0 135.4 17247 1.76 245422 2325.6 65001.1 136502 700.3 15144 13748 56822.5 51428.6 119327 108000

559.0 12.5 168.5 21461 1.76 245422 2868.0 80161.8 168340 871.4 19358 17961 71983.2 66589.3 151165 139837

559.0 14.2 190.8 24304 1.76 245422 3228.3 90230.7 189485 986.8 22201 20804 82052.1 76658.2 172309 160982

559.0 16.0 214.3 27294 1.76 245422 3602.3 100683.0 211434 1108.2 25191 23794 92504.4 87110.5 194259 182932

610.0 8.0 118.8 15130 1.92 292247 2247.6 68551.4 143958 614.3 12835 11310 57918.1 50898.9 121628 106888

610.0 10.0 148.0 18850 1.92 292247 2781.9 84846.6 178178 765.3 16554 15029 74213.3 67194.1 155848 141108

610.0 12.5 184.2 23464 1.92 292247 3434.6 104754.7 219985 952.7 21169 19644 94121.5 87102.3 197655 182915

610.0 14.2 208.6 26579 1.92 292247 3869.0 118003.9 247808 1079.2 24284 22759 107370.6 100351.4 225478 210738

610.0 16.0 234.4 29858 1.92 292247 4320.7 131781.4 276741 1212.3 27563 26038 121148.2 114129.0 254411 239671

610.0 18.0 262.8 33477 1.92 292247 4812.8 146790.8 308261 1359.2 31182 29657 136157.5 129138.3 285931 271190

660.0 8.0 128.6 16387 2.07 342119 2639.0 87087.9 182885 665.3 13903 12252 73613.7 64712.5 154589 135896

660.0 10.0 160.3 20420 2.07 342119 3268.8 107870.5 226528 829.1 17937 16286 94396.3 85495.1 198232 179540

660.0 12.5 199.6 25427 2.07 342119 4039.6 133306.4 279943 1032.4 22944 21293 119832.2 110931.0 251648 232955

660.0 14.2 226.2 28810 2.07 342119 4553.4 150263.1 315552 1169.7 26326 24675 136788.9 127887.6 287257 268564

660.0 16.0 254.1 32371 2.07 342119 5088.5 167921.2 352634 1314.3 29887 28237 154447.0 145545.7 324339 305646

660.0 18.0 285.0 36304 2.07 342119 5672.4 187188.3 393095 1474.0 33821 32170 173714.1 164812.9 364800 346107

711.0 8.0 138.7 17668 2.23 397035 3070.7 109162.2 229241 717.4 14992 13214 92310.2 81170.3 193851 170458

711.0 10.0 172.9 22023 2.23 397035 3805.9 135301.4 284133 894.2 19347 17568 118449.4 107309.5 248744 225350

711.0 12.5 215.3 27430 2.23 397035 4707.3 167343.2 351421 1113.7 24754 22975 150491.3 139351.4 316032 292638

711.0 14.2 244.0 31085 2.23 397035 5309.0 188735.2 396344 1262.1 28409 26630 171883.3 160743.4 360955 337561

711.0 16.0 274.2 34935 2.23 397035 5936.4 211039.8 443184 1418.4 32259 30480 194187.9 183047.9 407794 384401

711.0 18.0 307.6 39188 2.23 397035 6621.9 235410.0 494361 1591.1 36512 34733 218558.1 207418.2 458972 435578

711.0 20.0 340.8 43417 2.23 397035 7295.4 259350.9 544637 1762.8 40741 38962 242498.9 231359.0 509248 485854

762.0 8.0 148.8 18950 2.39 456037 3535.0 134683.0 282834 769.4 16082 14175 113931.3 100205.7 239256 210432

762.0 10.0 185.5 23625 2.39 456037 4383.9 167028.4 350760 959.2 20757 18850 146276.7 132551.0 307181 278357

762.0 12.5 231.0 29433 2.39 456037 5426.0 206731.0 434135 1195.0 26565 24658 185979.3 172253.7 390557 361733

762.0 14.2 261.9 33360 2.39 456037 6122.6 233271.2 489870 1354.5 30492 28585 212519.5 198793.9 446291 417467

762.0 16.0 294.4 37498 2.39 456037 6849.7 260973.3 548044 1522.5 34630 32723 240221.6 226496.0 504465 475642

762.0 18.0 330.3 42072 2.39 456037 7645.1 291276.4 611680 1708.2 39204 37297 270524.7 256799.1 568102 539278

762.0 20.0 366.0 46621 2.39 456037 8427.4 321082.8 674274 1892.9 43753 41846 300331.1 286605.4 630695 601871

813.0 8.0 158.8 20232 2.55 519124 4032.0 163900.5 344191 821.4 17171 15136 138689.6 122006.2 291248 256213

813.0 10.0 198.0 25227 2.55 519124 5002.8 203363.9 427064 1024.3 22167 20131 178153.0 161469.6 374121 339086

813.0 12.5 246.8 31436 2.55 519124 6195.8 251860.3 528907 1276.3 28375 26340 226649.4 209966.0 475964 440929

813.0 14.2 279.7 35635 2.55 519124 6994.2 284314.9 597061 1446.8 32575 30539 259103.9 242420.6 544118 509083

813.0 16.0 314.5 40062 2.55 519124 7828.3 318221.7 668266 1626.6 37001 34966 293010.8 276327.4 615323 580288

813.0 18.0 352.9 44956 2.55 519124 8741.7 355350.0 746235 1825.3 41896 39861 330139.1 313455.7 693292 658257

813.0 20.0 391.1 49826 2.55 519124 9641.1 391909.3 823010 2023.0 46765 44730 366698.4 350015.0 770067 735032

813.0 23.0 448.1 57083 2.55 519124 10964.2 445694.2 935958 2317.7 54022 51987 420483.2 403799.9 883015 847980

914.0 10.0 222.9 28400 2.87 656118 6349.0 290147.2 609309 1153.1 24959 22670 254307.1 230570.4 534045 484198

914.0 12.5 277.9 35402 2.87 656118 7871.1 359708.4 755388 1437.4 31961 29672 323868.3 300131.7 680124 630277

914.0 14.2 315.1 40141 2.87 656118 8891.6 406344.5 853323 1629.8 36699 34410 370504.4 346767.8 778059 728212

914.0 16.0 354.3 45138 2.87 656118 9959.3 455141.8 955798 1832.7 41697 39408 419301.7 395565.1 880534 830687

914.0 18.0 397.7 50668 2.87 656118 11130.5 508664.8 1068196 2057.2 47226 44937 472824.7 449088.1 992932 943085

914.0 20.0 440.9 56172 2.87 656118 12285.8 561461.2 1179068 2280.7 52731 50441 525621.1 501884.5 1103804 1053957

914.0 23.0 505.4 64381 2.87 656118 13989.2 639308.0 1342547 2614.0 60939 58650 603467.9 579731.3 1267283 1217436

1016.0 10.0 248.1 31604 3.19 810732 7871.1 399849.7 839684 1283.2 27779 25233 350602.3 317964.5 736265 667725

1016.0 12.5 309.3 39407 3.19 810732 9766.2 496123.1 1041858 1600.0 35582 33036 446875.7 414237.9 938439 869899

1016.0 14.2 350.8 44691 3.19 810732 11038.6 560762.0 1177600 1814.5 40865 38320 511514.6 478876.8 1074181 1005641

1016.0 16.0 394.6 50265 3.19 810732 12371.6 628479.4 1319807 2040.9 46440 43894 579232.0 546594.2 1216387 1147848

1016.0 18.0 443.0 56436 3.19 810732 13835.7 702854.2 1475994 2291.4 52610 50064 653606.9 620969.0 1372574 1304035

1016.0 20.0 491.3 62581 3.19 810732 15282.0 776323.9 1630280 2540.9 58755 56209 727076.6 694438.7 1526861 1458321

1016.0 23.0 563.2 71751 3.19 810732 17418.3 884847.4 1858180 2913.2 67925 65380 835600.1 802962.2 1754760 1686221

1220.0 10.0 298.4 38013 3.83 1168987 11405.5 695737.9 1461050 1543.4 33419 30360 610420.2 553821.4 1281883 1163025

1220.0 12.5 372.2 47418 3.83 1168987 14169.3 864326.6 1815086 1925.3 42824 39765 779008.9 722410.0 1635919 1517061

1220.0 14.2 422.3 53791 3.83 1168987 16028.9 977764.6 2053306 2184.0 49197 46139 892446.9 835848.1 1874139 1755281

1220.0 16.0 475.1 60520 3.83 1168987 17980.7 1096821.7 2303325 2457.2 55925 52867 1011504.0 954905.2 2124158 2005301

1220.0 18.0 533.6 67971 3.83 1168987 20128.6 1227843.9 2578472 2759.8 63377 60319 1142526.3 1085927.4 2399305 2280448

1220.0 20.0 591.9 75398 3.83 1168987 22254.8 1357545.0 2850845 3061.3 70803 67745 1272227.4 1215628.5 2671677 2552820

1220.0 23.0 679.0 86491 3.83 1168987 25403.9 1549638.8 3254242 3511.7 81896 78838 1464321.2 1407722.3 3075074 2956217

The table shows the pile dimensions of standard products. Other dimensions defined in standard EN 10219-2 are also available against order.

14

3. DESIGN STANDARDS AND

IMPLEMENTATION CONTROL

The Eurocode standards are followed in building

construction projects according to the decrees of the

Ministry of the Environment. In civil engineering projects,

the Eurocode standards are applied according to the

instructions of the Finnish Transport Agency. Instructions

of other authorities (such as municipalities/cities) are

observed where necessary.

The geotechnical class (GL1, GL2, GL3) of the site is

selected according to PO-2016 and RIL 207 (Application

Eurocode 7). The foundation engineer responsible for the

site determines the geotechnical class.

GL1 sites do not normally require piling. Most soil

conditions and sites belong to geotechnical class GL2.

Owing to the good and versatile properties of steel piles,

they have many applications at geotechnical class GL3

sites.

Piling class (PTL1, PTL2 or PTL3) is determined on the ba-

sis of consequence class (CC1 to CC3, cf. EN 1990 National

Annex) and geotechnical class.

4. RECOMMENDATIONS FOR THE

SELECTION AND DESIGN OF PILE TYPE,

PILE SIZE AND PILING CLASS FOR

DIFFERENT APPLICATIONS

Various applications and advantages of different SSAB's

steel pile types are presented in brochures on RR and RRs

piles, RD and RDs piles and RD pile walls.

The selection of a suitable pile type should be based

primarily on soil conditions, but superstructures and

ambient structures also play a major role. Some

instructions and recommendations for the selection of

pile type, pile size and piling class are given below.

Pile loads

SSAB's steel piles can be divided according to pile sizes

and applications based on pile loads, for example, as

follows:

RR75–RR/RD140/8 1 & 2 family houses and other struc-

tures subject to relatively light loads

RR/RD140/8–RR/RD270 multi-storey buildings of about 3 to

8 storeys

RR/RD220–RR/RD500 heavy multi-storey buildings

(>5 storeys) or industrial building

projects

RR/RD140–RR/RD270 pile slab projects

RR/RD220–RR/RD400 noise barrier piles

(single pile foundations)

RR/RD500–RR/RD1200 bridge and harbour construction and

buildings of more than 10 to 15 storeys

When selecting between RR and RD pile sizes, it should be

noted that the design strength of RD piles bearing on solid

bedrock is typically clearly higher (about 1.2 to 2.0 times)

than that of an RR pile of corresponding size. Owing to

the comprehensive pile size range, foundation structures

can always be optimised by using several (typically two or

three) pile sizes at a site.

Installability of piles

RD piles can be installed in all soil conditions. In very

exacting conditions, such as those involving thick fill

layers containing large boulders, the smallest RD piles

(pile sizes around RD90 to RD140) may pose the risk

of slightly higher pile bending in comparison to large

diameter RD piles. If the bedrock surface is particularly

inclined, close to ground level (<3 to 5 m), and in

conditions where there are no supporting friction soil

layers on top of the bedrock surface, an RD pile is a risk-

free solution in terms of support for the lower end of the

pile.

The penetrability of driven RR and RRs piles increases

with increasing pile size. When the amount/size of

stones and boulders in soil and fill layers – or the density

or thickness of the soil layer – increases, the risk of

deviations in the positions and verticality of driven piles

increases. The risk that piles bend or fail to reach a load-

bearing soil layer also increases. RR large diameter piles

have successfully penetrated rock fills several metres

thick, even ones over 20 metres thick. An RR170 or

RR220 pile is often rigid enough to penetrate relatively

thick layers of rocky fill and moraine all the way to a

bearing basal formation, provided that the size and

amount of stones and boulders is not exceptionally

large. A rock shoe improves the penetrability of a pile.

When building 1 & 2 family houses on thick moraine soils

containing stones it is recommended to use at least pile

size RR115/6.3.

Positional and verticality tolerances of piles

When a structure is set strict positional and verticality

tolerances, like, for instance, railway bridges built using

the bridge-moving technique, where a large diameter

pile is attached to the deck and also acts as a column,

the RD pile is the least risky alternative. It is also the

most recommendable alternative for corresponding

building construction projects where the pile also acts

as a column. Strict tolerances may also be required in

foundation underpinning or industrial building projects.

Environmental impacts of piling and nearby

structures

The environmental impacts of piling and issues related

to the selection of pile type are discussed in Sec. 6.7 of

these instructions.

15

Selection of piling class

In most projects, the piling class can be either PTL2

or PTL3. In consequence class CC3 projects related to

geotechnical classes GL2 and GL3, piling class PTL3 is

always required.

Piling class PTL2 is recommended for 1 & 2 family house

projects to ensure correct pile loads and geotechnical

resistance. PTL3 may be applicable to these projects if

the soil conditions are exceptional and/or the number

of piles is large (a project involving several 1 & 2 family

houses).

PTL3 should be considered with RR and RRs piles, when

the number of piles is at least moderate and it is desired

to minimise the environmental impacts of the piling. Then,

the number of piles can be reduced due to the higher

design value of pile strength by a maximum of 15 to 20%

compared to PTL2. With large diameter piles, load-

bearing capacity must always be ensured by dynamic load

tests. In their case it is often recommendable to choose

piling class PTL3 to optimise the structures.

With RD piles, the lowest piling class allowed by

the consequence class and geotechnical class is

recommended.

Considering installation equipment in design and

selection of pile size

RR/RRs piles can be installed using light basic equipment

(<20 to 25 t) up to a pile size of about RR170, and

RD/ RDs piles up to about RD270 to RD320. Light

basic equipment allows using essentially thinner piling

platforms, especially in very soft subsoils, compared to

heavy (>40 to 60 t) piling equipment. The environmental

impacts of light installation equipment (mainly vibration)

also remain low.

5. STRUCTURAL AND GEOTECHNICAL

DESIGN OF PILES

5.1 Limit states of pile foundations to be considered

The limit states specified in PO-2016, Sec. 4.1, should be

considered in the design of a pile foundation, considering

the properties of the site.

5.2 Design process of a steel pile foundation

At conventional sites, where the piles are mainly subject

to axial loading, the design of a steel pile foundation

includes:

1) Selection of pile type suitable for the site:

• soil conditions; pile drivability/installability and

functioning of the pile foundation

• loads from the superstructure and actions due to

ground displacement

• structures and conditions in the piling area and its

surroundings

2) Selection of piling class PTL1 to 3 based on

geotechnical class (GL1 to 3) and consequence

class (CC1 to 3)

3) Determination of the geotechnical resistance of piles

Rd,geo according to Sec. 5.5

• with RR75 to RR320 end-bearing piles, apply Table

22, end-of-driving instructions, and with PTL3 also

dynamic load tests

• with RD piles, geotechnical resistance is usually not

a dimensioning factor

• RR large diameter piles, dynamic load tests

• stiffness of structure (non-stiff or stiff structure)

4) Determination of the design value Rd,str of structural

resistance of piles according to Sec. 5.7

• determination of corrosion allowance

• RR75 to RR320 and RD90 to RD320 normal cases,

Tables 22 and 23

• dimensioning program for RR and RD piles

(www.ssab.com/infra)

• end-of-driving instructions (Sec. 11) are observed

with driven piles to ensure that impact stresses stay

within allowed limits

• the structural resistance of rock shoes for RR270 to

RR1200 piles (Tables 4 and 7) may determine the

maximum impact and structural resistance

5) Determining the design value for resistance

to an action

• the design value of resistance Rdis the smaller of

geotechnical Rd,geo and structural resistance Rd,str

6) Calculation of pile foundation displacements,

if necessary (Sec. 5.8)

• vertical displacement of an individual pile and

displacements of pile groups

7) Assessment of and preparation for environmental

impacts of piling

• assessment of vibration, soil displacement, increase

in pore water pressure and compaction of subsoil

due to piling

• preparation for environmental impacts

- selection of pile type

- piling sequence

- monitoring measurements

- special measures

16

8) Structural design of a pile foundation

• Pile foundations are always designed together with

the structures to be supported on it, which allows

selecting the most suitable shape, dimensions

and stiffness for the entire structure. Things to

be considered in the structural design of the pile

foundation include

- joints between piles and superstructure

- determination of positional and verticality

tolerances on the basis of pile type, soil conditions

and superstructure

- elevation of pile group foundation

- centre-to-centre pile spacing

- pile inclinations

- distances of piles to nearby structures

- distance from side of the foundation to side of

the pile

- other structural aspects to be considered

9) Foundation engineering print-outs

• Building specification (work schedule)

- soil conditions

- geotechnical works

°Work stages prior to piling and measures

affecting the work phases, piling platforms,

excavations, etc.

°Site-specific instructions related to piling, such

as instructions for installation, piling sequence,

quality control measurements, special measures

- Foundation structures

• Pile foundation drawings

• Geotechnical and structural dimensioning calculations

- normally dimensioning calculations for the

structure of an axially loaded pile can be made

and printed out easily using the pile dimensioning

program for RR and RD piles

• As-built drawing

5.3 Actions and design situations

The design actions of loads must correspond to those

specified in standard EN 1991 and the national annex to

it. They are included in publication RIL 201-1-2008 with

their application instructions. Actions caused by subsoil

displacement, such as downdrag (negative skin friction),

are treated in dimensioning as permanent actions on the

pile (for more details, see 5.9).

5.4 Geotechnical investigations

Geotechnical investigations for the design of steel piles

are generally regulated by the Finnish Building Code

and Eurocodes EN 1997-1 and EN 1997-2. PO-2016

presents the general requirements for geotechnical

investigations in building construction, requirements and

recommendations for different geotechnical classes and

foundation underpinning sites, as well as requirements

and instructions for the presentation of geotechnical

information. Valid guidelines of the Finnish Transport

Agency are observed in infrastructure construction.

Geotechnical investigations must be complemented with

sufficiently extensive investigations of nearby structures

(ducts, pipes, cables, underground structures, etc.), their

location and condition, foundation methods, as well as

sensitivity to displacement and vibration.

Geotechnical information and its assessment are

presented in the ground investigation report according to

PO-2016, Ch 1, Sec. 3.3. The ground investigation report

should indicate the following points most essential for the

design and dimensioning of steel piles:

• the characteristic value of the undrained shear

strength of soil used in dimensioning – by soil

layers, if necessary, and/or with the site divided

into different zones if the site is large and/or the

undrained shear strength of soil varies considerably

• corrosion allowance used in dimensioning

• estimated pile length and basis of estimate

• estimate of subsoil properties affecting piling, such

as the quality, stoniness and thickness of fills, dense/

stony intermediate layers, density and stoniness of

moraine, inclination of bedrock surface

• shoe type of driven pile used at site

• estimate of the occurrence of downdrag (negative

skin friction) and determination of the design value

of downdrag for different pile dimensions and

different areas of the site, if necessary

Depending on the site, the following may also be needed:

• axial spring constant of pile for service state

displacement analysis (see Sec. 5.8), is in principle

always required in PTL3 but also in PTL2 in the case

of long piles

• geotechnical parameters of soil layers to determine

extreme values of modulus of subgrade reaction

and lateral resistance, when piles are subject to a

horizontal load and/or moment.

5.5 Dimensioning methods and analyses of

geotechnical resistance

5.5.1 Selection of geotechnical dimensioning

method for steel piles

The geotechnical compressive strength of steel piles can

be determined according to PO-2016 in several ways,

whose applicability is shown in Table 15.

5.5.2 Stiness of a piled structure

The stiffness of a piled structure is taken into account

in building construction projects according to the

instructions of PO-2016 and in civil engineering projects

according to those of NCCI7. The correlation coefficients

presented in these instructions and the design values

based on them assume that the structures are not so-

called rigid structures.

17

5.5.3 Resistances determined by stress wave

analysis

Determining end-of-driving criterias by stress wave

analysis is the preferred method for driven RR75 to

RR320 piles in piling classes PTL1 and PTL2.

Sec. 11 of these instructions and Appendix 3 present end-

of-driving criterias for different pile driving equipments,

piles and pile lengths (10, 20 and 30 m) based on the

one-dimensional stress wave theory using the GRLWEAP

program. Correlation factor ξ5is 1.47 (1.40 x 1.05) according

to PO-2016 Part 1 Sections 4.5.2.4 and 4.5.2.6. The end-

of-driving tables present the targeted geotechnical

ultimate resistance at different piling class, design values

of geotechnical resistance Rdcorresponding to the

ultimate resistance, and end-of-driving criterias for each

pile driving equipment/pile combination. The design value

Rdis obtained as follows:

Rd= Rc/(ξ5xt)= Rc/(1.47 x 1.20) = Rc/1.764 (1)

The Rdvalues presented in the end-of-driving conditions

and Table 22 can be used directly in design for piling class

PTL1 and PTL2, and the geotechnical resistance of the pile

is ensured when the end-of-driving criterias are met.

In Table 22 the design values of geotechnical resistance for

PTL3 are calculated according to Formula (1). The design

values can be used as input values for design, and geo-

technical resistance must be ensured by dynamic load tests.

5.5.4 Resistances determined by dynamic load tests

Resistances determined by dynamic load tests are

suitable for friction and end-bearing piles at pile sizes

RR75 to RR1200 in all piling classes. Dynamic load tests

must always be used at building construction sites where

driven piles are used and the piling class is PTL3. In the

case of large diameter piles, dynamic load tests are

always recommended even with PTL2.

Correlation coefficients and related model coefficients

are presented in PO-2016. The dimensioning program

for RR and RD piles calculates correlation coefficients

automatically on the basis of input data.

Dimensioning based on dynamic load tests can in

principle be performed in two different ways.

1) The design value of geotechnical resistance Rdis

selected on the basis of piling class from Table 22, and

is used to calculate the minimum and average targets

for dynamic load tests.

2) The ultimate geotechnical resistance of the pile type

in question reliably achievable in the soil conditions of

the site is assessed considering the highest allowable

impact resistance of the piling class (Appendix 1),

and the design value of geotechnical compressive

resistance is calculated on the basis of this assessment

and dynamic load tests.

Table 15. Suitability of geotechnical dimensioning methods for dierent steel pile types.

Pile

static load test

dynamic load test

based on ground test results

end-of-driving criterias/

measurements based on pile

driving formulas

end-of-driving instructions

based on stress wave

analysis

based on the behaviour of

a corresponding foundation

RR small diameter piles/end-bearing piles PTL1–2 X XX X XX XXX X

RR small diameter piles/end-bearing piles PTL3 X XXX X XX XX X

RR large diameter piles/end-bearing piles - XXX X XX XX X

RR small diameter piles/friction piles XX XXX XX XX XX X

RR large diameter piles/friction piles - XXX XX XX XX X

CSG-RR piles/friction piles XXX - XX - X XX

Jacked RR-piles XXX X XX - - XX

RD piles X X XXX* X X X

Tension piles xxx x xx - x x

XXX = preferred method

XX = applicable

X = possible, applicability to be assessed case by case

- = technically infeasible or uneconomical

XXX* = RD piles feasible assuming that the bedrock surface has been reliably established or

that the bearing capacity of RD piles based on skin friction is determined by calculations

18

5.5.5 Resistances determined by pile driving

formulas

Pile driving formulas can be used in piling class PTL1 or PTL2,

for example, in situations where, according to the end-

of-driving table, the used pile driver is not able to mobilise

sufficient ultimate geotechnical resistance and geotechnical

resistance is ensured by a separate test loading hammer

without a dynamic load test. The pile driving formulas are used

according to PO-2016, Ch. 1, Sec. 4.5.2.5.

5.5.6 Resistances determined on the basis of ground

test results

Geotechnical resistance is determined on the basis of ground

test results according to PO-2016, Ch. 1, Sec. 4.5.2.3. It is

recommended that the so-called alternative method is

used in design, where a model factor of ≥1.6 is used for

end-bearing and friction piles and ≥1.95 for cohesion piles in

long-term loading and ≥1.40 in short-term loading.

As concerns steel piles, the capacity of both smooth and

grouted friction piles can be determined on the basis of

ground investigation results, but it is recommended that

the capacity is also determined by static or dynamic load

tests. This method is highly suitable for calculating the

geotechnical compressive strength of foundation piles of

lightweight noise barriers.

The point and shaft resistance of piles can be estimated

either on the basis of the angle of friction or cohesion of soil or

directly based on sounding resistance according to PO-2016.

5.5.6.1 Special features of the geotechnical resistance of

open ended steel pipe piles

In preliminary analyses of open ended steel piles with point

reinforcement ring (a steel collar over the shaft), external

shaft resistance can be estimated to decrease by 50 %

in a dense coarse-grained soil layer or moraine layer,

and 25 % in a loose layer compared to the table values

presented in PO-2016 or static capacity formulas. Point

resistance increases with increasing pile-point area.

If no plugging occurs in the pile, internal shaft resistance

can be assumed to be half of external shaft resistance in

preliminary analyses. However, the capacity consisting of

internal shaft resistance and point resistance of the area

of the steel cross-section of the pile must not exceed the

capacity of a plugged pile of corresponding size due to

point resistance.

5.5.6.2 Geotechnical resistance of grouted CSG-RR piles

bearing on a soil layer

The dimensioning geotechnical diameter of shaft grouted

piles (dd) may be larger than the diameter of the collar

(d0) used with the pile. The increase in diameter is caused

by the pressurising effect of grout with this installation

method, which makes the grout both displace and mix

with the soil layers surrounding the pile.

The dimensioning geotechnical diameter can be

determined, for example, by measurements on a test pile

or by using information on shaft grouted micropiles in

corresponding soil conditions. The magnitude of

the dimensioning diameter can be evaluated using

Formula 2.

dd = a ·d0 (2)

where ddis the dimensioning geotechnical diameter;

ais the coefficient that depends on soil type, grout

pressure, etc. and

d0is the diameter of the collar used with the pile in

question