SSBC A0730 Service manual

INSTALLATION INSTRUCTIONS

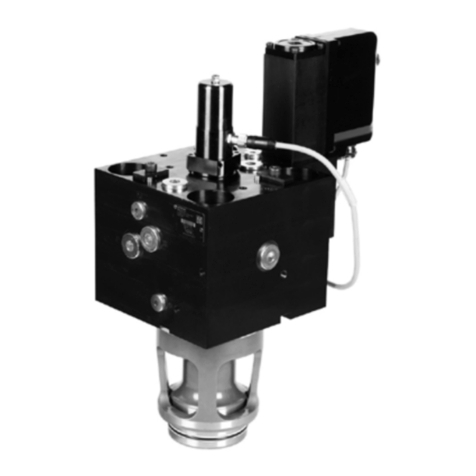

PROP-BLOCK

ADJUSTABLE PROPORTIONING VALVE & DISTRIBUTION BLOCK ALL-IN-ONE

A0730

A0730P

A0730PL

___________________________________________________________

Thank you for choosing STAINLESS STEEL BRAKES CORPORATION for your braking

needs. Pleases take the time to read and carefully follow these instructions to insure the ease of

your installation as well as the proper performance of the complete system.

Before beginning your installation, please verify you have received all the parts indicated on

the packing slip.

To assure your installation will go safely and smoothly, have the following items on hand to

assist you:

JACK & JACK STANDS WRENCH SET

LUG WRENCH TUBE WRENCHES

TORQUE WRENCH MALLET

SOCKET SET BRAKE FLUID

BRAKE CLEANER

1

A0730, A0730P, A0730PL Revision 2

A) Mounting

1) Select a suitable mounting location for the block assembly. In general, the necessary line

connections will be simpler with the block located near the master cylinder. If the vehicle has a

factory combination block bracket, the prop block can be mounted to that, otherwise the block

can be mounted to an inner fender or frame rail.

2) Secure the block using 5/16" hardware of the appropriate length for your specific application.

B) Line Connections

1) All of the in and out connections on the block are 3/8"-24 thread with an SAE flare for a standard

3/16" brake line. The supplied tube nuts can be flared onto any 3/16" brake lines; however, it is

not necessary to use these as long the lines you are using have a 3/8"-24 fitting already flared

on.

2) Connect the front brake outlet of the master cylinder to the port marked "F I" on the top of the

Prop Block. The outlet of the master cylinder for the front brakes will typically be the one for the

larger reservoir. If the reservoirs are the same size, a good rule of thumb is that the front

reservoir feeds the front brakes with GM master cylinders, while the rear reservoir feeds the front

brakes on Ford and Mopar master cylinders.

3) Next connect the two ports marked "F O" on the front and bottom of the Prop Block to the lines

feeding the front brakes of the vehicle. Most vehicles will have two separate brake lines: one

feeding the left (driver) front wheel and one feeding the right (passenger) front. If your vehicle

uses only one front brake line to feed both wheels, it is acceptable to plug the remaining front

outlet port of the Prop Block.

4) Connect the rear brake outlet port of the master cylinder to the port marked "R I" on the top of

the Prop Block.

5) Connect the port marked "R O" on the back of the Prop Block to the line feeding the rear brakes.

If your vehicle is equipped with a 1/4" rear brake line, use the supplied adapter fitting to connect

the line to the outlet of the prop block. SSBC has supplied the 1/4" adapter for the most popular

sizes. In the event that this fitting will not fit your line, you will need to locate a fitting from your

local parts store.

6) Tighten all fittings using a tube wrench and be sure to check for any leaks after the brake system

is bleed.

C) Switch Connections

1) The switch supplied with the Prop Block is a pressure switch designed to activate the brake lights

on the vehicle (and not the brake warning light on your dash). If your vehicle is equipped with a

brake light switch on the brake pedal, the switch in the Prop Block will not be used. If your vehicle

has no other brake light switch, then this switch must be properly connected for the brake lights

to function.

2) Your brake lights should already be connected to a chassis ground. The switch supplied will be

used to send power to the brake lights when pressure is applied to the brake system.

3) Connect the orange wire of the supplied pig tail to a fused constant 12V power supply. A 15-amp

circuit should be appropriate for most vehicles.

4) If your vehicle has separate circuits for the brake lights and turn signals, then the white wire of

the pig tail can be extended to the back of the vehicle and used to power the brake light pig tails

in the tail lights. If your vehicle uses the same circuit for brake lights and turn signals, then the

white wire will be run to your turn signal switch. Refer to the wiring diagram for your specific turn

signal switch for the proper connections.

2

A0730, A0730P, A0730PL Revision 2

D) Brake Bleeding

1) After the installation of the Prop Block is complete, it will be necessary to bleed the brake

system.

2) If the master cylinder is new or went dry at any time during the installation, begin by bench

bleeding the master cylinder.

3) Continue the bleeding process by gravity bleeding the caliper or wheel cylinder at each wheel

until no air bubbles are seen in the escaping brake fluid. Start with the wheel farthest from the

master cylinder and work your way closer bleeding each wheel. Never let the master cylinder go

dry at any time during this process.

4) With all the bleeding complete, a firm consistent pedal feel should be achieved. If the vehicle

already had a functioning brake system prior to the installation of the Prop Block, there should be

no significant change in the pedal feel.

5) With all bleeding complete, check all the fittings for leaks and tighten as necessary.

E) Proportioning Valve Adjustment

1) The proportioning valve in the Prop Block will be used to adjust the rear brake pressure of the

vehicle. The objective is to balance the pressure of the rear brakes to the front so that under hard

braking, the rear brakes do not lock up before the fronts.

2) Start with the valve in the full increase position by turning the knob all the way out in a clockwise

rotation.

3) Find a safe open area such as parking lot and make several hard stops from 30 M.P.H. observing

the function of the rear brakes. If the rear brakes lock up well before the front, begin to decrease

the rear brake pressure by turning the knob in a counter clockwise rotation. Continue these

adjustments until the proper balance is found.

4) When you have found the proper adjustment for your vehicle try the test again at 50 M.P.H. and

make any further adjustments as necessary.

DO NOT DRIVE IN TRAFFIC UNTIL THE BRAKES SAFELY STOP THE CAR IN A SAFE

DISTANCE WITHOUT A SPONGY PEDAL FEEL!

BRAKING TESTS SHOULD ALWAYS BE DONE IN A SAFE OPEN AREA!

NOW ENJOY TRUE PERFORMANCE BRAKING!

Shop for other Replacement Brake Parts on our website.

This manual suits for next models

2

Table of contents

Popular Control Unit manuals by other brands

Emerson

Emerson Anderson Greenwood 727 Series Installation and maintenance instructions

ICP DAS USA

ICP DAS USA EIP-2060 quick start guide

AWG

AWG 30277633 instruction manual

Rothenberger

Rothenberger ROLOC PLUS Instructions for use

Bosch

Bosch Rexroth 2THE5R instruction manual

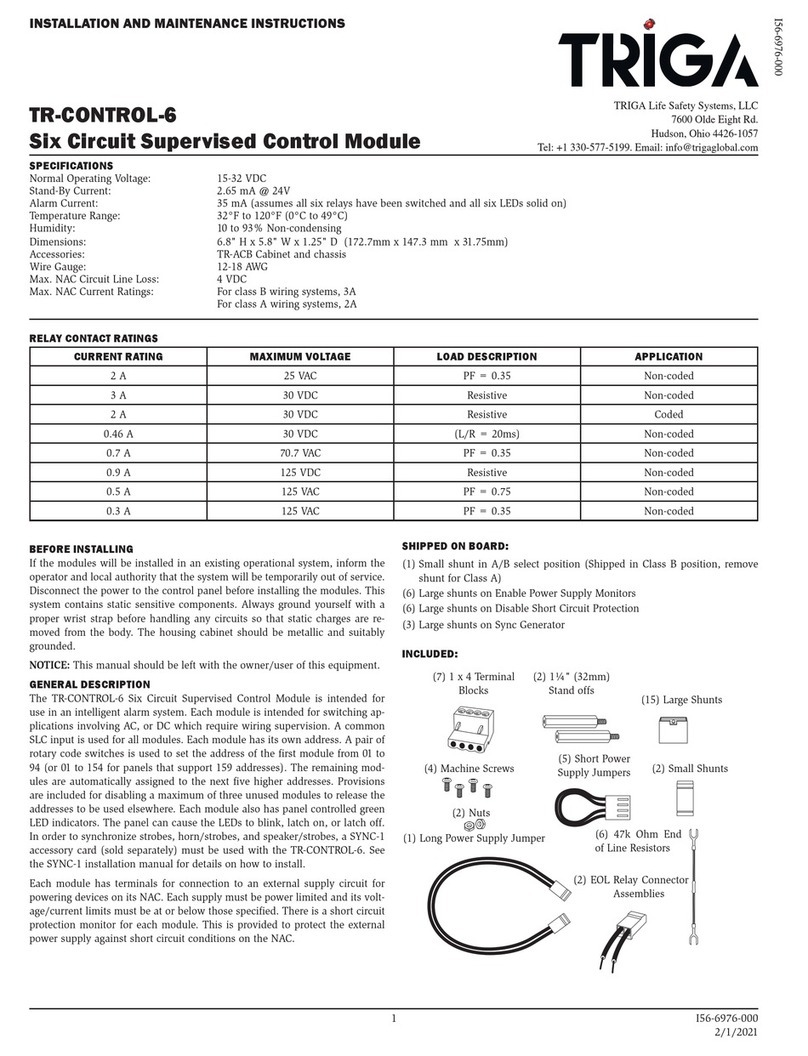

TRIGA

TRIGA TR-CONTROL-6 Installation and maintenance instructions