SSC 2150 Installation instructions

PAGE 1

P52110_MXXXXX_Jan2020 PAGE 1

HELPFUL HINTS

+If your spreader does not spread

evenly, be sure “FRONT” on the GEAR-

BOX points to the front of the spread-

er. The impeller must turn clockwise

when pushing forward. Reversing

the GEARBOX will cause the impeller

to turn counter clockwise. Clean the

impeller plate after each use. Fertilizer

stuck on the impeller blades will cause

uneven spreading.

+

Your spreader is designed to be

pushed at three miles per hour, which

is a brisk walking speed. Clean and

dry your spreader thoroughly after

each use. Coat all metal surfaces

(pay special attention to the inside &

outside of tubing - it’s easiest to do

while assembling) with light oil, Fluid

Film®or silicon spray to help prevent

corrosion. Wash between the shut o

plate and the bottom of the hopper.

Do not use powdered materials.

+Gears are permanently lubricated at

the factory.

Do not open the gearbox

or dirt may enter.

COMMERCIAL BROADCAST SPREADER

Model: 2150 SSC ASSEMBLY & OPERATION

ROCK SALT &

POWDERED MATERIALS

SHOULD NOT BE USED

in this spreader as it will damage

gearbox and can void warranty.

USE ONLY

GRANULAR MATERIALS

P52110_MXXXXX_Jan2020 PAGE 2

ASSEMBLY

1

Remove and identify all loose parts

from carton.

2

Position hopper as shown at the right.

Install FRAME using (4) #14 x 1½” Flat Head Phillips

screws. TIGHTEN THESE NOW .

3

Install impeller onto pin-

ion shaft by pressing the

impeller as shown onto the

pinion shaft and turning

the impeller while holding

the pinion shaft to engage

with the COIN fully, and

press down to secure.

Next, insert Cross Brace

thru the Gearbox Brace

as shown to the right.

FR

O

N

T

Impeller

Cross Brace

GEARBOX ASSEMBLY

Gearbox Brace

Pinion

Shaft

Press & turn

Impeller

to engage

Coin securely

Coin

BOLT

IDENTIFIER

1-1/2”

1”

2”

2-1/4”

2-3/4”

31104

Qty 4

32100

Qty 2

33117

Qty 1

31100

Qty 4 31120

Qty 4

32103

Qty 8

31106

Qty 2

33108

Qty 1

33109

Qty 1

12152

Qty 2

12148

Qty 2

44249

13

16

17

31

24

28

23

25

26

11

12

38

29

9

(Qty 4) #31104

#14 X 1-1/2”

Flat Head Screw

P52110_MXXXXX_Jan2020 PAGE 3

ASSEMBLY

5

4

Install gearbox by inserting the pinion shaft into hole

in center of hoppers bottom. The word “FRONT” on

the gearbox must point to Front of the hopper.

The EarthWay logo is on the front of the hopper.

A - Install LOWER HANDLES onto FRAME to both sides as shown. Insert 2¼” bolt through hole in LOWER HANDLE

and through hole in FRAME install locknut. DO NOT TIGHTEN.

B - Now insert 1½” bolt into the hole in LOWER HANDLE,

then through FRAME brace. Next into threaded connector

in CROSS BRACE.

NOTE: Numbers on frame brace must be facing toward

gear box as shown. Next into threaded connector in cross brace.

DO NOT TIGHTEN.

Install the FOOT into the FRAME and align the bolt holes in the

FOOT and the FRAME (a Phillips screwdriver or large nail is helpful

to align the parts)

C - Next insert 1½” bolt through other end of FRAME BRACE and

through hole in FRAME through the FOOT and install locknut.

Gearbox Assembly

Frame

Brace

Impeller

Cross Brace

Frame

Lower Handle

Shut-Off

1/4-20 x 1-1/2”

Hex Head Bolt

STEP 5B

STEP 5C

1/4-20 x 2-1/4”

Hex Head Bolt

STEP 5A

Foot

Gearbox

FRONT

F

R

O

NT

P52110_MXXXXX_Jan2020 PAGE 4

6

Slide AXLE into the LOWER HANDLE, then the GEAR-

BOX and into the other LOWER HANDLE as shown at

right. Next, install AXLE BEARINGS over the AXLE and

into both LOWER HANDLES as shown at right. NOTE:

Tab on BEARINGS and notches in the LOWER HAN-

DLES you need to align. Now slide the BUSHINGS over

the AXLE (as shown at right) and into the BEARINGS.

7

Install DRIVE WHEEL onto the AXLE and align with the

cotter pin hole nearest to LOWER HANDLE as shown.

Insert 2” cotter pin through wheel and through AXLE.

Bend with pliers to prevent pin from falling out.

8

Install COAST WHEEL onto the AXLE fully, then using

outside cotter pin hole, insert 1” cotter pin through

AXLE (not thru the wheel). Bend with pliers to prevent

pin from falling out.

TURN SPREADER UPRIGHT ON TO WHEELS.

NOW GO BACK AND TIGHTEN ALL NUTS

AND BOLTS STARTING WITH FIRST STEP.

DO NOT OVER TIGHTEN.

9

Insert 2” bolt through Gauge & Lever assembly, next

through upper handle, then the handle shaft and

then the other upper handle and secure with locknut.

TIGHTEN ALL HARDWARE NOW

ASSEMBLY

Bushing

Bushing

Bearing

Bearing

Install the axle

as shown above

Coast wheel side

1” Cotter Pin

Drive wheel side

2” Cotter Pin

Axle Bearing

Flat

Side

Notch

P52110_MXXXXX_Jan2020 PAGE 5

10

Insert pivot rod into shut-o plate as shown below.

TURN TO LOCK IN PLACE.

11

12

Insert other end of pivot rod into pivot and bracket assembly

as shown as shown above. TURN TO LOCK IN PLACE.

14

Install attened end of CONTROL

ROD in to LEVER on GAUGE as

shown. Turn to lock in place.

Next push LEVER forward to

setting “0”. Align CONTROL ROD

with hole in PIVOT BRACKET, pull

LEVER backward to insert CON-

TROL ROD through hole in PIVOT

BRACKET.

Now install 1/4-20 regular nut on

to CONTROL ROD.

Install HANDLE SHAFT to LOWER

HANDLEs and PIVOT & BRACKET

assembly as shown. Using 2” bolts

and locknuts.

TIGHTEN BOLTS & NUTS NOW.

ASSEMBLY

13

Install (1) 1/4-20 Hex nut (not a locknut)

on to control rod as shown.

Shut-Off

Plate

Pivot Rod

with extra bend

Rotate

Pivot Angle

Attaching

Arm

Pivot

Rod

Insert Pivot Rod

into Shut-Off

and rotate to secure

Control Rod

Tabbed Hole

Control Rod

Lever

Tension Nut

Gauge & Lever

30

¼-20

Hex Nuts

Pivot

Bracket Control

Rod

Pivot

Rod

P52110_MXXXXX_Jan2020 PAGE 6

CALIBRATION

15

Pull lever back to setting “30” on gauge and lever assembly. Next push pivot & bracket forward so that the shut o

plate in the hopper is in the full open position.

REMEMBER SETTING “30” ON THE FLOW CONTROL LEVER MUST PLACE THE SHUT-OFF PLATE IN THE FULL OPEN

POSITION TO BE PROPERLY CALIBRATED. Now tighten the nuts against the PIVOT BRACKET to prevent change in

calibration.

16

17

Tension on the ow control LEVER may be

adjusted by tightening or loosening the

tension nut on gauge and lever assembly.

Insert agitator into pinion shaft on inside

of hopper.

NOTE: the position of at side of the agita-

tor in the drawing. The agitator should be

installed as shown.

P52110_MXXXXX_Jan2020 PAGE 7

PARTS

KEY # PART # DESCRIPTION KEY # PART # DESCRIPTION

1 40002 ROUND SCREEN 21 36208 #6 X 3/8” TYPE 25 PHPS S.S.

2 60332 HOPPER ASSEMBLY (2150/2150T) 22 12317SSC New SSC SHUT OFF PLATE

3 33117 AGITATOR 23 25222 LOWER HANDLE SQ (2150’s/2170’s)

4 12220 GEAR BOX BUSHING (2050) 24 25108 FRAME (2150,2170,C22,C24,C25,F-Series)

5 31104 #14 X 1 1/2 TYPE 25 FHPS ZINC 25 44249 FRAME BRACE (2150/2170)

6 32103 1/4-20 NYLON INS LOCKNUT ZINC 26 25228 CROSS BRACE (2150/2170/S25) 11.25 REV908

7 11927 SHUTOFF SUPPORT- LARGE 27 31106 1/4-20 X 2 1/4” HHCS ZINC

8 31120 1/4-20 X 2” HHCS ZINC 28 12110 IMPELLER 9” Round Dished

9 60300 PIVOT & BRACKET ASSEMBLY (2150/2170) 29 25723 FRAME FOOT

10 12274 GRIP (2150/2170) 7.5” LONG 30 70138 PNEUMATIC DRIVE WHEEL STUD (2150/S25)

11 44251 PIVOT ROD (2150/2170/C22/C24) 31 60333 New Floating GEAR BOX (2150/C22)

12 60298 GAUGE & LEVER ASSEMBLY (2150/C22) 32 12148 AXLE BEARING (2130/2150/2170/S25)

13 60175 UPPER HANDLE SQUARE W/GRIP 33 12152 AXLE BUSHING (2130/2150/2170/S25)

14 24500 AXLE COINED 34 33109 3/16” X 2” COTTER PIN ZINC

15 31100 1/4-20 X 1 1/2 HHMS ZINC 35 60027 WING NUT ASSEMBLY BLACK

16 25223 HANDLE SHAFT SQ (2150) 36 37100 1/4-20 X 1” CARRIAGE BOLT ZINC

17 42256 CONTROL ROD (2150/C24SS) 37 12147 SPACER (PIVOT LINK)

18 31138 #8 X 3/8” PMT #8 HD COARSE BLACK

19 33108 3/16” X 1” COTTER PIN ZINC

20 32100 1/4-20 HEX NUT ZINC

44249

23

10

24

7

22

28

21

9

11

20

6

2

3

1

19

30

31

32

33

34

29

23

25

26

8

5

8

6

6

17

20

27

15 25

15

13 35

36

37

14

16

15

27

12

4

18

15

77001

OPTIONAL

Heavy-Duty

Rain Cover

60166R

OPTIONAL

3-Side Salt

Deflector Kit

5

1

0

1

5

3

0

Insert Control Rod

into the Pivot Bracket

Attach 1/4-20 Regular

Hex Nuts at these points.

Notice the position

of the double bend point.

It must be at this location

30

Broadcast Setting Matrix

Calibration Techniques

Shut-Off

Fully Open

Tighten

Screw

Slide Outer

Control Wire

to Calibrate

CABLE TYPE ADJUSTMENT

Loosen/tighten screw on cable clamp then

slide outer cable in/out for calibration

FIG 2

Drop holes shown fully open.

How to ensure your spreader is properly calibrated

Make sure the drop holes in the bottom of the hopper are fully open when the Rate Control handle is on #30. If not,

please adjust control cable or control rod to allow for a full open hopper position at #30.

Rod Type Adjustment

1. Open the shut-o so that the drop holes are completely open as illustrated to the right.

2. Review the Control Lever position - if it is set so that the forward edge is at #30, you are calibrated. If not,

you need to adjust the control rod at the pivot bracket shown in Fig 1.

A. If your shut-o is not able to open fully as in step #1. Loosen the top nut a few turns, then loosen the lower nut

so that it allows you to push the shut-o open fully. Next tighten each nut so that they contact the pivot bracket

without moving it, and then carefully tighten each nut fully so they do not loosen during use. Recheck adjustment

as outlined in #1 above.

B. If your shut-o is able to open fully as in step #1, but the Control Lever is not at #30. Loosen the top nut a few

turns, then loosen the lower nut so that it allows you to push the Control Lever to #30. Next tighten each nut so

that they contact the pivot bracket without moving it. Carefully tighten each nut fully so they do not loosen during

use. Recheck adjust as outlined in #1 above.

Cable Type Adjustment

1. Open the Control Lever so that the shut-o and drop holes are completely open as illustrated in Fig 2.

2. Review the Control Lever position so that the indicator is pointed to #30, if it is your calibration is correct. If not you

need to adjust the control cable at the cable clamp on the underside of the hopper as shown in Fig 2.

A. If your shut-o is not able to open fully as in step #1. Loosen the cable clamp screw slightly so that you can slide

the outer cable out so that the shut-o is fully open. Next tighten the cable clamp screw securely. Recheck

adjustment as outlined in #1 above.

B. If your shut-o is able to open fully as in step #1, but the Control Lever is not at #30. Loosen the cable clamp screw

slightly so that you can slide the outer cable in so that the Control Lever opens to #30. Next tighten the cable clamp

screw securely. Recheck adjustment as outlined in #1 above.

If you have any questions regarding the operation or assembly of your spreader please call us at 574-848-7491

Monday - Friday 9:00am - 4:00pm Eastern. Accessories and Repair Parts are also available at this numbers.

FIG 1

PAGE 8

P52110_MXXXXX_Jan2020 PAGE 9

ESTABLISHING A SETTING RATE

STEP 1: Determine the rate by dividing the bag weight by the coverage of the bag listed (Example:(37lbs/10,000square feet =

.0037), then multiply by 1,000 (.0037x1000 = 3.7lbs/1,000 square feet). That will give the suggested LBS/1,000 square feet rate.

STEP 2: Find the closest LBS/1,000 square feet in Broadcast Setting Matrix below, based on the material particle size. (Example:

2.0 LBS/1,000 square feet = Spreader Setting of 9,11, or 13 based on particle size)

The settings furnished on the Rate Setting Matrix are intended as a guide only. Variations in physical characteristics of ma-

terial applied, walking speed, and roughness of ground surface may require slightly dierent spreader settings. Due to the

above conditions, EPI makes no warranty as to the uniformity of coverage actually obtained from the settings listed.

FULL Rate (one pass) HALF Rate (two passes)

SPREAD PATH

© 2018 Earthway Products, Inc. All rights reserved

SIDEWALK

DRIVEWAYDRIVEWAY

FLOWER

BED

FLOWER

BED

Does not change the setting rate

GRANULAR MATERIAL

PARTICLE SIZES: Fine/Small Medium Large

(1/16" SAND) (3/32") (1/8") ICE MELT

LBS. PER 1,000 SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD

SQUARE FEET SETTING WIDTH FT METERS SETTING WIDTH FT METERS SETTING WIDTH FT METERS

1 LB. 616' 4.9m 10 13.5' 4.1m 11 16' 4.9m

2 LBS. 916' 4.9m 11 13.5' 4.1m 13 16' 4.9m

3 LBS. 12 16' 4.9m 13 13.5' 4.1m 14 16' 4.9m

4 LBS. 14 16' 4.9m 14 13.5' 4.1m 17 16' 4.9m

5 LBS. 16 16' 4.9m 16 13.5' 4.1m 19 16' 4.9m

6 LBS. 19 16' 4.9m 17 13.5' 4.1m 21 16' 4.9m

7 LBS. 22 16' 4.9m 20 13.5' 4.1m 22 16' 4.9m

8 LBS. 25 16' 4.9m 21 13.5' 4.1m 24 16' 4.9m

9 LBS. 28 16' 4.9m 23 13.5' 4.1m 26 16' 4.9m

10 LBS. 30 16' 4.9m 25 13.5' 4.1m 30 16' 4.9m

GRASS SEED

LBS. PER 1,000 FINE SPREAD SPREAD COARSE SPREAD SPREAD

SQUARE FEET SETTING WIDTH FT METERS SETTING WIDTH FT METERS

2 LBS. 11 8.5' 2.6m 16 11' 3.4m

3 LBS. 16 8.5' 2.6m 18 11' 3.4m

4 LBS. 18 8.5' 2.6m 21 11' 3.4m

5 LBS. 20 8.5' 2.6m 24 11' 3.4m

GRANULAR MATERIAL

PARTICLE SIZES: Fine/Small Medium Large

(1.5mm SAND) (2mm) (3mm)

SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD

SETTING WIDTH FT METRES SETTING WIDTH FT METRES SETTING WIDTH FT METRES

5 6 16' 4.9m 10 13.5' 4.1m 11 16' 4.9m

10 916' 4.9m 11 13.5' 4.1m 13 16' 4.9m

15 12 16' 4.9m 13 13.5' 4.1m 14 16' 4.9m

20 14 16' 4.9m 14 13.5' 4.1m 17 16' 4.9m

24 16 16' 4.9m 16 13.5' 4.1m 19 16' 4.9m

29 19 16' 4.9m 17 13.5' 4.1m 21 16' 4.9m

34 22 16' 4.9m 20 13.5' 4.1m 22 16' 4.9m

39 25 16' 4.9m 21 13.5' 4.1m 24 16' 4.9m

44 28 16' 4.9m 23 13.5' 4.1m 26 16' 4.9m

49 30 16' 4.9m 25 13.5' 4.1m 30 16' 4.9m

GRASS SEED

FINE SPREAD SPREAD COARSE SPREAD SPREAD

SETTING WIDTH FT METRES SETTING WIDTH FT METRES

10 11 8.5' 2.6m 16 11' 3.4m

15 16 8.5' 2.6m 18 11' 3.4m

20 18 8.5' 2.6m 21 11' 3.4m

25 20 8.5' 2.6m 24 11' 3.4m

BROADCAST SPREADER SETTING MATRIX for 2150/2170 models with dished impellers

Grams PER Square

Metre

Grams PER Square

Metre

C

C

a

a

l

l

i

i

b

b

r

r

a

a

t

t

i

i

o

o

n

n

:

:

Start by ensuring that your spreader calibration is

correct. Make sure the drop are fully open when the Rate Control

handle is on #30. If not, please adjust control rod at the pivot to

allow for a full open hopper holes with the handle at position at

#30.

C

C

a

a

l

l

i

i

b

b

r

r

a

a

t

t

i

i

o

o

n

n

:

:

Start by ensuring that your spreader calibration is

correct. Make sure the drop holes are fully open when the Rate

Control handle is on #30. If not, please adjust control rod at the

pivot to allow for a full open hopper holes with the handle at

position at #30.

P52110_MXXXXX_Jan2020 PAGE 10

OPERATING INSTRUCTIONS

Before lling hopper, become familiar with the operation of this spreader.

1. Obtain proper setting for material to be used

from the enclosed SETTING MATRIX included

with this spreader, or from our web site under

the MANUALS SECTION.

2. Move stop bolt on rate gauge assembly to the

proper setting.

3. While pushing spreader forward, pull control

lever back to stop bolt.

4. To stop, push lever forward to close ow holes

before you stop moving.

5. When nished, empty any remaining material

from hopper.

6. Thoroughly wash spreader and allow to dry before

storing. A coating of light oil will help prevent corrosion.

7. Keep this manual for future reference

CUSTOMER SERVICE

574.848.7491 | [email protected] | WWW.EARTHWAY.COM

RATE SETTING MATRIX

The settings furnished on the Rate Setting Matrix are

intended as a guide only. Variations in physical charac-

teristics of material applied, walking speed, and rough-

ness of ground surface may require slightly dierent

spreader settings. Due to the above conditions, the

manufacturer makes no warranty as to the uniformity

of coverage actually obtained from the settings listed.

HOW TO ORDER SPARE PARTS

All spare parts listed herein may be ordered direct from

the manufacturer. Be sure to give the following infor-

mation when ordering. (Model Number, Part Number,

Part Description)

EARTHWAY SIDE SPREAD CONTROL TECHNOLOGY OPERATION

The EARTHWAY SIDE SPREAD CONTROL TECHNOLOGY lever is located on the back of the hopper at the bottom. To

operate the EARTHWAY SIDE SPREAD CONTROL TECHNOLOGY, slide the control lever from the left, to the right. This

will activate the EARTHWAY SIDE SPREAD CONTROL TECHNOLOGY for a Partial spread pattern and prevent material

from being spread to the left side of the spreader. Position the left wheel of your spreader 12”-16” from the sidewalk,

owerbed, or driveway and spread as normal. When you have completed this spreading pass, open the EARTHWAY

SIDE SPREAD CONTROL TECHNOLOGY by sliding the control lever from right to left, for a FULL spread pattern.

1-YEAR LIMITED WARRANTY

EPI. warrants this product free of defects in original workmanship and materials for a period of 1-year to the end user with

the original purchase receipt. If a manufacturing non-conformance is found, EPI. at its discretion will repair or replace the

part(s) or product at no charge provided the failure is not the result of incorrect installation, mishandling, misuse, tamper-

ing, or normal wear and tear as determined by EPI. EPI. at its discretion may require that the part(s) or product be returned

along with the original purchase receipt at owners’ expense for examination and compliance with the terms of this warran-

ty. Do not return any product without rst receiving authorization from EPI. To seek remedy under this warranty, contact

EPI. at 574-848-7491, [email protected] or write to EPI. 1009 Maple St., Bristol, Indiana 46507 and describe the na-

ture of the manufactur defect. SPECIFIC LIMITATIONS: This warranty covers only the part(s) or product; any labor charges

associated with repair or replacement of non-conformances are specically excluded. Due to the corrosive nature of most

fertilizers and ice melt products, EPI.. makes no warranty against and specically excludes part(s) or product degradation or

failure due to corrosion or its eects, or the use of powdered materials. Clean and dry your spreader thoroughly after each

use, as a preventative measure, coat all metal parts with a light oil or silicon spray.

Table of contents

Popular Spreader manuals by other brands

Western

Western ICE BREAKER Hopper Spreader installation instructions

Rauch

Rauch AXENT Series Operator's manual

REHOBOT

REHOBOT HS20-120 operating instructions

Tatu Marchesan

Tatu Marchesan DCA2 MC 2500 Operator's manual

Meyer

Meyer V-MAX 2636 Operators Operator's manual

JYDELAND

JYDELAND BOBMAN FL instructions

Rehau

Rehau HKV instruction sheet

Craftsman

Craftsman 24594 - Professional Universal Broadcast... Operator's manual

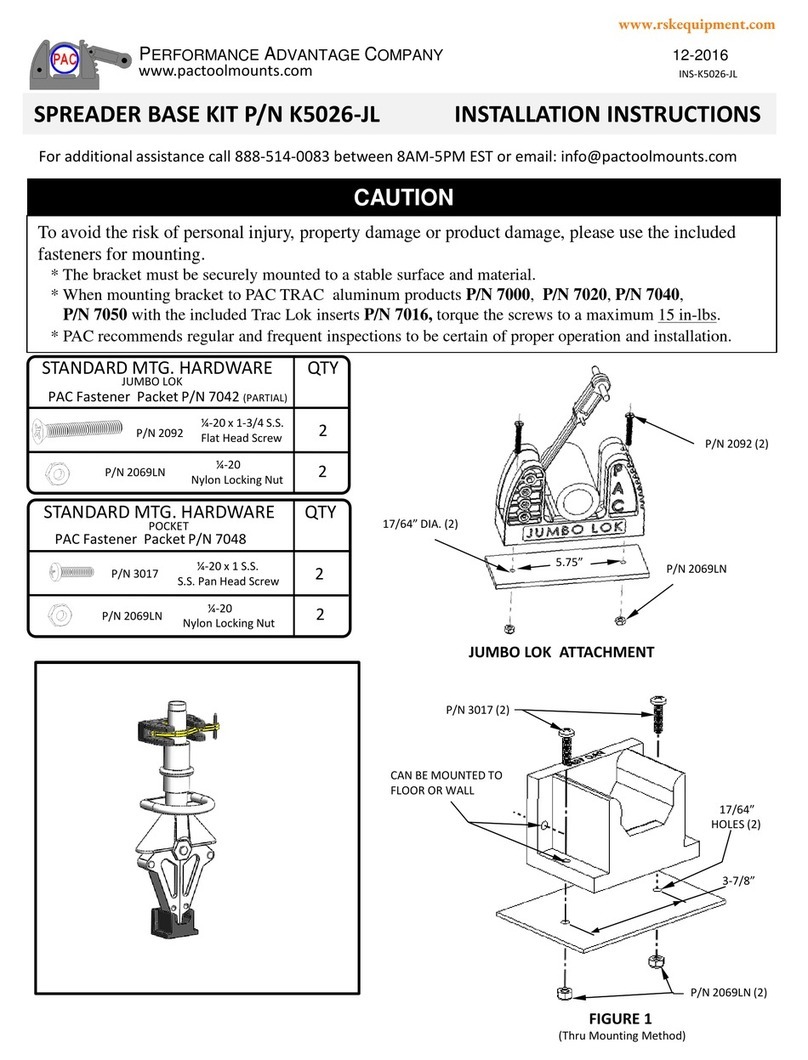

PERFORMANCE ADVANTAGE COMPANY

PERFORMANCE ADVANTAGE COMPANY K5026-JL installation instructions

Fisher

Fisher 110 owner's manual

Millcreek

Millcreek 27ss Operator's manual

IRIS Spreaders

IRIS Spreaders ILS-2200 Operator's manual