SSD Drives 690+ Series User manual

Copyright 2004 SSD Drives Limited (formerly Eurotherm Drives Limited)

All rights strictly reserved. No part of this document may be stored in a retrieval system, or transmitted in any form or by

any means to persons not employed by an SSD Drives company without written permission from SSD Drives Ltd.

Although every effort has been taken to ensure the accuracy of this document it may be necessary, without notice, to

make amendments or correct omissions. SSD Drives cannot accept responsibility for damage, injury, or expenses

resulting therefrom.

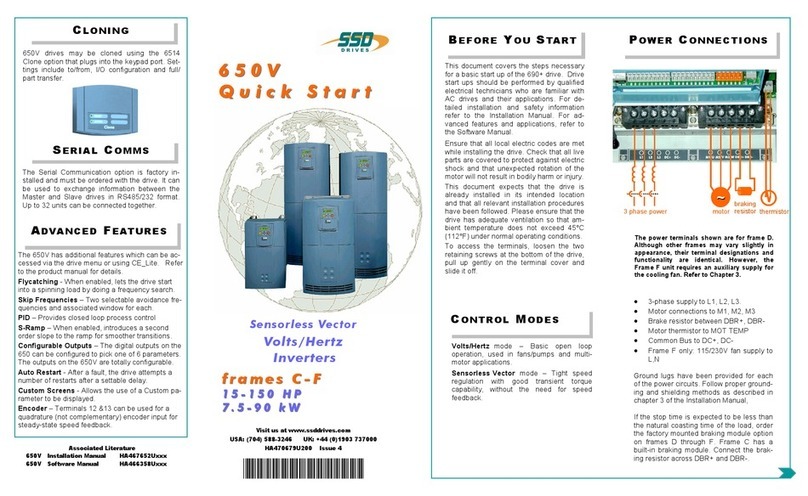

690+ Series

AC Drive

Frame B, C, D, E & F

Installation Product Manual

HA465492U005 Issue 3

Compatible with Version 5.x Software

Cont.2

WARRANTY

SSD Drives warrants the goods against defects in design, materials and workmanship

for the period of 12 months from the date of delivery on the terms

detailed in SSD Drives Standard Conditions of Sale IA058393C.

SSD Drives reserves the right to change the content and product specification without notice.

Cont.3

Requirements

IMPORTANT: Please read this information BEFORE installing the equipment.

Intended Users

This manual is to be made available to all persons who are required to install, configure or

service equipment described herein, or any other associated operation.

The information given is intended to highlight safety issues, and to enable the user to obtain

maximum benefit from the equipment.

Complete the following table for future reference detailing how the unit is to be installed and

used.

INSTALLATION DETAILS

Serial Number

(see product label)

Where installed

(for your own

information)

Unit used as a:

(refer to Certification

for the Drive)

RComponent RRelevant Apparatus

Unit fitted: RWall-mounted REnclosure

Application Area

The equipment described is intended for industrial motor speed control utilising AC induction or

AC synchronous machines.

Personnel

Installation, operation and maintenance of the equipment should be carried out by qualified

personnel. A qualified person is someone who is technically competent and familiar with all

safety information and established safety practices; with the installation process, operation and

maintenance of this equipment; and with all the hazards involved.

!

Safety Information

Cont.4

Hazards

WARNING!

This equipment can endanger life through rotating machinery and high voltages.

Failure to observe the following will constitute an ELECTRICAL SHOCK HAZARD.

This is a product of the restricted sales distribution class according to IEC 61800-3.

In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

This product is designated as “professional equipment” as defined in EN61000-3-2.

Permission of the supply authority shall be obtained before connection to the low

voltage supply.

xThe equipment must be permanently earthed due to the high earth leakage current.

xThe drive motor must be connected to an appropriate safety earth.

xThe equipment contains high value capacitors which take time to discharge after removal of

the mains supply.

xBefore working on the equipment, ensure isolation of the mains supply from terminals L1,

L2 and L3. Wait for at least 3 minutes for the dc link terminals (DC+ and DC-) to discharge

to safe voltage levels (<50V). Measure the DC+ and DC- terminal voltage with a meter to

confirm that the voltage is less than 50V.

xNever perform high voltage resistance checks on the wiring without first disconnecting the

drive from the circuit being tested.

xWhen replacing a drive in an application and before returning to use, it is essential that all

user defined parameters for the product’s operation are correctly installed.

xThis equipment contains electrostatic discharge (ESD) sensitive parts. Observe static

control precautions when handling, installing and servicing this product.

IMPORTANT: Metal parts may reach a temperature of 90 degrees centigrade in operation.

Application Risk

The specifications, processes and circuitry described herein are for guidance only and may need

to be adapted to the user’s specific application.

SSD Drives does not guarantee the suitability of the equipment described in this Manual for

individual applications.

Risk Assessment

Under fault conditions, power loss or other operating conditions not intended, the equipment

may not operate as specified. In particular:

xThe motor speed may not be controlled

xThe direction of rotation of the motor may not be controlled

xThe motor may be energised

Guards

The user must provide guarding and /or additional safety systems to prevent risk of injury and

electric shock.

Protective Insulation

xAll control and signal terminals are SELV, i.e. protected by double insulation. Ensure all

wiring is rated for the highest system voltage.

Note: Thermal sensors contained within the motor must be double insulated.

xAll exposed metalwork in the Drive is protected by basic insulation and bonding to a safety

earth.

RCDs

These are not recommended for use with this product but ,where their use is mandatory, only

Type B RCDs should be used.

!

Safety Information

Contents

Contents Page

Cont.5

Chapter 1 GETTING STARTED

Introduction ..................................................................................................1-1

Equipment Inspection ...................................................................................1-1

Packaging and Lifting Details ...................................................................... 1-1

About this Manual ........................................................................................ 1-2

Initial Steps .............................................................................................................1-2

How the Manual is Organised .................................................................................1-2

xInformation for Users without a Keypad .................................................1-3

Chapter 2 ANOVERVIEW OF THE DRIVE

Component Identification .............................................................................2-1

Control Features ...........................................................................................2-6

Functional Overview .....................................................................................2-7

Filter Board (Frame B only) ......................................................................................2-8

Power Board/Stack..................................................................................................2-8

Control Board.........................................................................................................2-8

xProcessor .............................................................................................2-8

xTechnology Options..............................................................................2-8

xKeypad Interface...................................................................................2-8

xSystem Board Interface..........................................................................2-8

Chapter 3 INSTALLING THE DRIVE

Mechanical Installation ................................................................................3-1

Mounting the Drive..................................................................................................3-1

Ventilation ..............................................................................................................3-1

xMinimum Air Clearance (Frame B).........................................................3-2

xMinimum Air Clearance (Frame C) ........................................................3-3

xMinimum Air Clearance (Frame D) ........................................................3-5

xMinimum Air Clearance (Frame E).........................................................3-7

xMinimum Air Clearance (Frame F).......................................................3-10

Electrical Installation ..................................................................................3-12

Gland Plate Details ...............................................................................................3-12

Cable Gland Requirements....................................................................................3-13

Protective Earth (PE) Connections .....................................................................3-13

Power Wiring Connections (Frame B) .....................................................................3-14

Power Wiring Connections (Frame C).....................................................................3-14

Power Wiring Connections (Frame D).....................................................................3-15

Power Wiring Connections (Frame E) .....................................................................3-15

Power Wiring Connections (Frame F) .....................................................................3-16

Motor Thermistor Connections ...............................................................................3-16

Control Wiring Connections...................................................................................3-17

Terminal Block Acceptance Sizes............................................................................3-18

Terminal Tightening Torques .................................................................................3-18

Contents

Contents Page

Cont.6

Optional Equipment ................................................................................... 3-19

xSystem Board .....................................................................................3-19

xEncoder Connections ..........................................................................3-20

xSSD Drives Approved Encoders............................................................3-20

xTechnology Options............................................................................3-21

xFitting the Remote 6901 Keypad..........................................................3-23

xTop Cover ..........................................................................................3-24

xExternal Brake Resistor ........................................................................3-24

xExternal AC Supply EMC Filter .............................................................3-26

xEMC Motor Output Filter .....................................................................3-30

xOutput Contactors ..............................................................................3-30

xEarth Fault Monitoring Systems............................................................3-30

xLine Chokes (input) .............................................................................3-30

xAC Motor Choke (output) ....................................................................3-30

x5703/1 Speed Repeater Support .........................................................3-30

Chapter 4 OPERATING THE DRIVE

Pre-Operation Checks ..................................................................................4-1

Control Philosophy........................................................................................ 4-2

Start/Stop and Speed Control....................................................................... 4-2

xSelecting Local or Remote Control .........................................................4-3

Initial Start-up Routines ...............................................................................4-4

Routine 1: Remote Control using Control Terminals ..................................................4-4

xReading the Status LEDs ........................................................................4-4

Routine 2: Local Control using the Keypad ...............................................................4-5

xSet-up as an Open-loop Drive (V/F Fluxing) ...........................................4-6

xSet-up using the Sensorless Vector Fluxing Mode ....................................4-6

xSet-up using the Closed-loop Vector Mode.............................................4-7

The Autotune Feature ..............................................................................................4-7

xStationary or Rotating Autotune?............................................................4-8

xNecessary Data ....................................................................................4-8

xPerforming a Rotating Autotune .............................................................4-8

xPerforming a Stationary Autotune ..........................................................4-9

xSetting the Encoder Sign........................................................................4-9

The Start/Stop Mode Explained ..................................................................4-10

Starting and Stopping Methods .................................................................4-11

Normal Stopping Methods.....................................................................................4-11

xRamp to Stop......................................................................................4-12

xCoast to Stop......................................................................................4-12

Advanced Stopping Methods .................................................................................4-13

xForced Fast Stop .................................................................................4-13

xForced Coast Stop ..............................................................................4-13

xThe Trip Condition..............................................................................4-13

xLogic Stopping....................................................................................4-14

Contents

Contents Page

Cont.7

Starting Methods ...................................................................................................4-14

xStarting Several Drives Simultaneously .................................................4-15

xSingle Wire Logic Starting....................................................................4-15

xTwo Wire Logic Starting.......................................................................4-15

xThree Wire Logic Starting ....................................................................4-15

Chapter 5 THE KEYPAD

Connecting the Keypad ................................................................................5-1

xThe Power-Up Condition.......................................................................5-1

Controlling the Drive using the Keypad....................................................... 5-2

Control Key Definitions............................................................................................5-2

xKeys for Programming the Drive ............................................................5-2

xKeys for Operating the Drive Locally ......................................................5-2

LED Indications .......................................................................................................5-3

The Menu System.......................................................................................... 5-4

Navigating the Menu System....................................................................................5-4

Menu Viewing Levels ...............................................................................................5-4

Changing a Parameter Value...................................................................................5-5

What do the Symbols mean next to some Parameters?..............................................5-5

xParameter Status Information ÆÅ=.................................................5-5

xExpanded Menu Information >>..........................................................5-5

Alert Message Displays............................................................................................5-5

The Menu System Map ............................................................................................5-6

The PROG Key ........................................................................................................5-8

The L/R Key ............................................................................................................5-8

The OPERATOR Menu.................................................................................... 5-9

Parameter Selection ................................................................................................5-9

String Entry ...........................................................................................................5-10

xCustomising the Parameter Name .......................................................5-10

The DIAGNOSTICS Menu ............................................................................ 5-11

The QUICK SETUP Menu .............................................................................5-15

The SYSTEM Menu....................................................................................... 5-16

Saving/Restoring/Deleting Your Application............................................................5-16

Selecting the Language .........................................................................................5-18

Special Menu Features ...............................................................................5-18

Quick Save Feature ...............................................................................................5-18

Quick Tag Information ..........................................................................................5-19

Quick Link Information..........................................................................................5-19

Password Protection ..............................................................................................5-20

xTo Activate Password Protection ...........................................................5-20

xTo De-activate Password Protection......................................................5-20

xTo Re-activate Password Protection ......................................................5-20

xTo Remove Password Protection (default status) ....................................5-20

Contents

Contents Page

Cont.8

Power-up Key Combinations ......................................................................5-21

Resetting to Factory Defaults (2-button reset)...........................................................5-21

Changing the Product Code (3-button reset)...........................................................5-21

Quick Enter Configuration Mode ...........................................................................5-22

Chapter 6 TRIPS AND FAULT FINDING

Trips ..............................................................................................................6-1

What Happens when a Trip Occurs..........................................................................6-1

xDrive Indications...................................................................................6-1

xKeypad Indications (when connected).....................................................6-1

Resetting a Trip Condition........................................................................................6-1

Using the Keypad to Manage Trips...........................................................................6-2

xTrip Messages ......................................................................................6-2

xAutomatic Trip Reset .............................................................................6-5

xSetting Trip Conditions ..........................................................................6-5

xViewing Trip Conditions ........................................................................6-5

Checksum Fail ........................................................................................................6-5

xDrive Indications...................................................................................6-5

xKeypad Indications (when connected).....................................................6-5

Fault Finding.................................................................................................6-6

Chapter 7 ROUTINE MAINTENANCE AND REPAIR

Routine Maintenance....................................................................................7-1

Repair ...........................................................................................................7-1

Saving Your Application Data ..................................................................................7-1

Returning the Unit to SSD Drives ..............................................................................7-1

Disposal .................................................................................................................7-1

Chapter 8 TECHNICAL SPECIFICATIONS

Understanding the Product Code .............................................................................8-1

xModel Number (Europe)........................................................................8-1

xCatalog Number (North America)..........................................................8-4

Environmental Details..............................................................................................8-5

Earthing/Safety Details ............................................................................................8-5

Cabling Requirements for EMC Compliance.............................................................8-6

Cooling Fans ..........................................................................................................8-6

Electrical Ratings (230V Build Variant) ......................................................................8-7

Electrical Ratings (400V Build Variant) ......................................................................8-9

Electrical Ratings (500V Build Variant) ....................................................................8-12

Input Fuse Ratings (Europe)....................................................................................8-14

External AC Supply (RFI) Filters...............................................................................8-16

EMC Compliance..................................................................................................8-16

Internal Dynamic Brake Switch (Frame B) ...............................................................8-18

Internal Dynamic Brake Switch (Frame C)...............................................................8-18

Internal Dynamic Brake Switch (Frame D)...............................................................8-19

Contents

Contents Page

Cont.9

Internal Dynamic Brake Switch (Frame E)................................................................8-19

Internal Dynamic Brake Switch (Frame F)................................................................8-20

Control Terminals .................................................................................................8-21

System Board Terminals (option) ............................................................................8-22

Analog Inputs/Outputs ..........................................................................................8-23

Digital Inputs ........................................................................................................8-23

Digital Outputs .....................................................................................................8-23

System Board Digital Inputs/Outputs (DIGIO11-15)................................................8-23

Supply Harmonic Analysis (Frame B Constant)........................................................8-24

Supply Harmonic Analysis (Frame C Constant) .......................................................8-25

Supply Harmonic Analysis (Frame C Quadratic)......................................................8-26

Supply Harmonic Analysis (Frame D Constant) .......................................................8-28

Supply Harmonic Analysis (Frame D Quadratic)......................................................8-29

Supply Harmonic Analysis (Frame E Constant) ........................................................8-31

Supply Harmonic Analysis (Frame E Quadratic) ......................................................8-32

Supply Harmonic Analysis (Frame F Constant) ........................................................8-34

Supply Harmonic Analysis (Frame F Quadratic) ......................................................8-35

Chapter 9 CERTIFICATION FOR THE DRIVE

Requirements for EMC Compliance ..............................................................9-1

Minimising Radiated Emissions ................................................................................9-1

Earthing Requirements.............................................................................................9-1

xProtective Earth (PE) Connections ...........................................................9-1

xEMC Earth Connections ........................................................................9-1

Cabling Requirements .............................................................................................9-2

xPlanning Cable Runs.............................................................................9-2

xIncreasing Motor Cable Length..............................................................9-2

EMC Installation Options.........................................................................................9-3

xScreening & Earthing (wall mounted, Class A) ........................................9-3

xScreening & Earthing (cubicle mounted, Class B) ....................................9-3

xStar Point Earthing ................................................................................9-4

xSensitive Equipment ..............................................................................9-5

Requirements for UL Compliance ................................................................. 9-6

xSolid-State Motor Overload Protection ...................................................9-6

xShort Circuit Rating ...............................................................................9-6

xSolid-State Short-Circuit Protection.........................................................9-6

xRecommended Branch Circuit Protection................................................9-6

xMotor Base Frequency...........................................................................9-6

xField Wiring Temperature Rating ...........................................................9-6

xField Wiring Terminal Markings.............................................................9-6

xTerminal Tightening Torques .................................................................9-6

xRecommended Wire Sizes .....................................................................9-7

xField Grounding Terminals....................................................................9-9

xOperating Ambient Temperature ...........................................................9-9

xDirect Wall-Mountable Models ..............................................................9-9

Contents

Contents Page

Cont.10

xInput Fuse Ratings (North America)......................................................9-10

European Directives and the CE Mark........................................................ 9-11

CE Marking for Low Voltage Directive ....................................................................9-11

CE Marking for EMC - Who is Responsible? ...........................................................9-11

xLegal Requirements for CE Marking.....................................................9-12

xApplying for CE Marking for EMC........................................................9-12

Which Standards Apply?........................................................................................9-12

xPower Drive Product Specific................................................................9-12

Certificates ...........................................................................................................9-14

Chapter 10 APPLICATION NOTES

Synchronous Motor Control ........................................................................10-1

Brake Motors ..............................................................................................10-1

Using Line Chokes ...................................................................................... 10-1

Using Output Contactors............................................................................. 10-2

Using Motor Chokes ...................................................................................10-2

Using Multiple Motors on a Single Drive....................................................10-3

Dynamic Braking ........................................................................................10-3

High Starting Torque .................................................................................. 10-4

Winder Applications ...................................................................................10-4

Roll Diameter Calculation Accuracy........................................................................10-4

Basic Set-up Instruction..........................................................................................10-6

xInformation Required ..........................................................................10-6

xSet-up with no Web connected to the Winder .......................................10-7

Equations .............................................................................................................10-7

xSimple Centre Winder Equations .........................................................10-7

4-Q Regen Control/Common DC Bus Applications ................................... 10-10

Single Motor System ............................................................................................10-10

Multi-Motor System .............................................................................................10-11

Brake Mode........................................................................................................10-12

Pre-Charge Sizing ...............................................................................................10-12

3-Phase Choke Sizing .........................................................................................10-14

PWM Carrier Frequency ......................................................................................10-14

Software Function Block.......................................................................................10-15

Macro 8 : 4Q Regen ...........................................................................................10-15

xConnection Diagram ........................................................................10-16

Contactor and Fusing..........................................................................................10-16

EMC Filtering ......................................................................................................10-17

2-Q Common DC Bus Applications ........................................................... 10-17

Chapter 11 THE DEFAULT APPLICATION

The Default Application ..............................................................................11-1

Macro Descriptions .....................................................................................11-1

xMacro 0 .............................................................................................11-1

xMacro 1: Basic Speed Control (default) ................................................11-3

Getting Started 1-1

690+ Series AC Drive

1GETTING STARTED

Introduction

The 690+ Series AC Drive is designed for speed control of standard 3-phase induction motors.

Larger models are available in a range of ratings for constant torque and quadratic torque

applications. This dual mode feature provides a cost effective solution to general industrial

applications, as well as the control of pumps and fans.

xThe unit can be controlled remotely using configurable analogue and digital inputs and

outputs, requiring no optional equipment.

xControlling the unit locally using the 6901 Keypad, or remotely using ConfigEd Lite (or

other suitable PC programming tool) gives access to parameters, diagnostic messages, trip

settings and full application programming. Other features also become available, such as the

advanced sensorless vector control scheme which gives high torque, low speed operation;

selectable switching frequencies; and a unique Quiet Pattern control system that minimises

audible noise from the motor.

xTechnology Options can be fitted to the drive to give serial communications, closed loop

speed control, and the factory-fitted dynamic braking functions.

xA factory-fitted System Board enables the drive for high end web processing or mini PLC

replacement applications.

The optional internal RFI filters offer enhanced EMC compliance without the need for

additional external components (where fitted).

IMPORTANT: Motors used must be suitable for drive duty.

Note: Do not attempt to control motors whose rated current is less than 25% of the drive rated

current. Poor motor control or Autotune problems may occur if you do.

Equipment Inspection

xCheck for signs of transit damage

xCheck the product code on the rating label conforms to your requirement.

If the unit is not being installed immediately, store the unit in a well-ventilated place away from

high temperatures, humidity, dust, or metal particles.

Refer to Chapter 2: “An Overview of the Drive” to check the rating label/product code.

Refer to Chapter 7: “Routine Maintenance and Repair” for information on returning damaged

goods.

Packaging and Lifting Details

Caution

The packaging is combustible and, if disposed of in this manner incorrectly, may lead to

the generation of lethal toxic fumes.

Save the packaging in case of return. Improper packaging can result in transit damage.

Use a safe and suitable lifting procedure when moving the drive. Never lift the drive by its

terminal connections.

Prepare a clear, flat surface to receive the drive before attempting to move it. Do not damage

any terminal connections when putting the drive down.

Refer to Chapter 3: “Installing the Drive” - Mechanical Installation for unit weights.

1-2 Getting Started

690+ Series AC Drive

About this Manual

This manual is intended for use by the installer, user and programmer of the 690+ drive. It

assumes a reasonable level of understanding in these three disciplines.

Note: Please read all Safety Information before proceeding with the installation and operation

of this unit.

Enter the “Model Number” from the rating label into the table at the front of this manual. There

is also a column for you to record your application’s parameter settings in the Parameter

Specification Table in the Software Product Manual. It is important that you pass these manuals

on to any new user of this unit.

Initial Steps

Use the manuals to help you plan the following:

Installation

Know your requirements:

xcertification requirements, CE/UL/CUL conformance

xwall-mount or enclosure?

xconformance with local installation requirements

xsupply and cabling requirements

Operation

Know your operator:

xhow is it to be operated, local and/or remote?

xwhat level of user is going to operate the unit?

xdecide on the best menu level for the Keypad (where supplied)

Programming (Keypad or suitable PC programming tool only)

Know your application:

xinstall the most appropriate macro

xplan your “block diagram programming”

xenter a password to guard against illicit or accidental changes

xcustomise the keypad to the application

How the Manual is Organised

The information is arranged in to separate “Installation” and “Software” Product Manuals.

The Installation Product Manual is considered to be Volume 1, the Software Product Manual is

Volume 2. Each manual is divided into chapters and paragraphs. Page numbering restarts with

every chapter, i.e. 5-3 is Chapter 5, page 3.

Application Block Diagrams

You will find the appropriate diagrams at the rear of each manual. The pages unfold to show a

complete block diagram, these will become your programming tool as you become more

familiar with the 690+ unit’s software.

Quick-Start Guide

Chapters 3 and 4

install and run

the product

details the

Operator Station

and menu system

Chapter 5

Chapter 8

technical details

holds many of the

Chapter 1

explains all the

function blocks

lists all the

parameters

Chapter 2

Chapter 5

macro details

has all the

Installation Product Manual Software Product Manual

Getting Started 1-3

690+ Series AC Drive

Information for Users without a Keypad

This symbol identifies important text for users operating the drive using the default (factory) set-

up. If the text is italic, such as this, then the information is especially for users without the

keypad or suitable PC programming tool.

DEFAULT

An Overview of the Drive 2-1

690+ Series AC Drive

2ANOVERVIEW OF THE DRIVE

Component Identification

8

2

4

5

3

13

10

14

12

Front View (with items removed)

11

15

7

16

1

9

17

6

Figure 2-1 690+ AC Drive, Frame B 0.75 - 4.0kW

1Main drive assembly 10 Control terminals

2Top cover (optional) 11 Power terminals

36053 technology box (optional) 12 Earth terminals

4Terminal cover retaining screw 13 Keypad port (P3)

5Terminal cover 14 Future communications option (P8)

6Gland plate 15 Thermistor connection

7Cooling fan 16 Speed feedback board (optional)

86901 Keypad 17 System Board (optional)

9Blank cover (Part Number: LA389836U001)

2-2 An Overview of the Drive

690+ Series AC Drive

2

8

15 14

4

13

12

9

16

10

11

Front View (with items removed)

1

6

3

16

5

17

7

Figure 2-2 690+ AC Drive, Frame C 5.5 - 11.0kW

1Main drive assembly 10 Power terminals

2Top cover (optional) 11 Earthing points

3Terminal cover retaining screw 12 Keypad port (P3)

4Terminal cover 13 Gland plate

5RS232 programming port (P3) 14 Comms technology box (optional)

6Power terminal shield 15 Speed feedback technology box (optional)

76901 Keypad 16 Future communications option (P8)

8Blank cover (Part Number: LA389836U001) 17 System Board (optional)

9Control terminals

Through-panel fixing plate and screws not illustrated

An Overview of the Drive 2-3

690+ Series AC Drive

16 15

19

18

2

3

8

14

10

21

11

12

Front View (with items removed)

13 13

1

17

4

9

5

20

6

22

7

Figure 2-3 690+ AC Drive, Frame D 15 - 22kW

1Main drive assembly 12 Earthing points

2Lower front cover retaining screw 13 Chassis fan

3Lower front cover 14 Power board fan

4Upper front cover retaining screw 15 Comms technology box (optional)

5Upper front cover 16 Speed feedback technology box (optional)

6RS232 programming port (P3) 17 Power terminal shield

76901 Keypad 18 Gland plate

8Blank cover (Part Number: LA389836U001) 19 Gland plate retaining screw

9Keypad port (P3) 20 Top cover (optional)

10 Control terminals 21 Future communications option (P8)

11 Power terminals 22 System Board (optional)

Through-panel fixing plate and screws not illustrated

2-4 An Overview of the Drive

690+ Series AC Drive

18

16

15

8

19

1

2

3

20

13

10

17

11

Front View (with items

removed)

14

13

12

14

6

4

5

4

921

22

7

Figure 2-4 690+ AC Drive, Frame E 30 - 45kW

1Main drive assembly 13 Chassis fan

2Lower front cover retaining screw 14 Power board fan

3Lower front cover 15 Comms technology box (optional)

4Upper front cover retaining screw 16 Speed feedback technology box (optional)

5Upper front cover 17 Future communications option (P8)

6RS232 programming port (P3) 18 Gland plate

76901 Keypad 19 Gland plate retaining screw

8Blank cover (Part Number: LA389836U001) 20 Top cover (optional)

9Keypad port (P3) 21 Motor thermistor terminals

10 Control terminals 2

22

System Board (optional)

11 Power terminals

12 Earthing points

Through-panel fixing plate and screws not illustrated

An Overview of the Drive 2-5

690+ Series AC Drive

1

4

5

10

16

11

Front View (with items removed)

6

18

19

12

9

4

2

3

17

15

8

7

14

20

13

21

Figure 2-5 690+ AC Drive, Frame F 55 - 90kW

1Main drive assembly 11 Power terminals

2Lower front cover retaining screw 12 Earthing points

3Lower front cover 13 Chassis fan

4Upper front cover retaining screw 14 Comms technology box (optional)

5Upper front cover 15 Speed feedback technology box (optional)

6RS232 programming port (P3) 16 Future communications option (P8)

76901 Keypad 17 Gland plate

8Blank cover (Part Number: LA389836U001) 18 Motor thermistor terminals

9Keypad port (P3) 19 System Board (optional)

10 Control terminals 2

20

Auxiliary supply terminals (fan)

21

Brake terminals

2-6 An Overview of the Drive

690+ Series AC Drive

Control Features

The drive is fully-featured when controlled using the optional Keypad (or a suitable PC

programming tool).

The `General’ control features below are not user-selectable when the unit is controlled using

the analog and digital inputs and outputs.

General

Output

Frequency Selectable 0-500Hz, or 0-1000Hz t6kHz (V/Hz mode)

Selectable 0-350Hz (closed loop vector mode)

Selectable 0-120Hz (sensorless vector mode)

Switching

Frequency

Constant Torque

: selectable 3kHz, 6kHz or 9kHz

depending on power rating

Quadratic Torque

: 3kHz for all units

Voltage Boost 0-25% (Fixed or Auto Boost)

Flux Control 1. V/F control with linear or fan law profile

2. Sensorless vector with automatic flux control and slip

compensation

3. Closed loop vector

(with speed feedback Technology Box)

Skip Frequencies 4 skip frequencies with adjustable skip band width

Preset Speeds 8 presets with programmable ramp rates

Stopping Modes Ramp, ramp with hold, coast, dc injection, fast stop

Ramps Symmetric or asymmetric ramp up and down rates

Raise/Lower Programmable MOP function

Jog Programmable jog speed

Logic Functions 10 programmable 3 input logic function blocks

performing NOT, AND, NAND, OR, NOR and XOR

functions

Value Functions 10 programmable 3 input value function blocks

performing IF, ABS, SWITCH, RATIO, ADD, SUB, RATIO,

TRACK/HOLD, and BINARY DECODE functions

Diagnostics Full diagnostic and monitoring facilities

Protection

Trip Conditions Output short line to line, and line to earth

Overcurrent > 220%

I*t overload 50-105% (adjustable)

Heatsink overtemperature

Motor Thermistor overtemperature

Overvoltage and undervoltage

Current Limit Adjustable 50%-150%

180% shock load limit

Voltage/

Frequency Profile Linear Law

Fan Law

User Defined (v5.1 onwards)

Inputs/

Outputs

Analog Inputs 4 configurable inputs - voltage or current

Analog Outputs 3 configurable outputs - voltage or current

Digital Inputs 7 configurable 24V dc inputs, 1 fixed 24V dc inputs

Relay Outputs 3 relay contacts (volt-free)

Table 2-1 Control Features

DEFAULT

An Overview of the Drive 2-7

690+ Series AC Drive

Functional Overview

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PROCESSOR

CONTROL

CONTROL

TERMINALS

18

17

16

15

20

19

RELAY

24

23

22

21

26

25

6901

PROGRAMMING

PORT

RS232

OPERATOR

INTERFACE

STATION INTERFACE

TECHNOLOGY OPTION

INTERFACE

TECHNOLOGY OPTION TECHNOLOGY OPTION 1

INTERFACE

CONNECTOR

TECHNOLOGY OPTION 2

INTERFACE

CONNECTOR

POWER

FILTER

M1 M2 M3

PE

DC+

DC-

DBR

L1 L2/N L3

UVW

Diode Bridge

INTERFACE

SYSTEM BOARD

SYSTEM BOARD

INTERFACE

CONNECTOR

Figure 2-6 Functional Block Diagram (Frame B)

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PROCESSOR

POWER

CONTROL

M1 M2 M3

CONTROL

TERMINALS

6901

18

17

16

15

PROGRAMMING

PORT

UVW

RS232

OPERATOR

INTERFACE

STATION

Diode Bridge

INTERFACE

TECHNOLOGY OPTION

INTERFACE

TECHNOLOGY OPTION TECHNOLOGY OPTION 1

INTERFACE

CONNECTOR

Charging

Circuit

DC+

DC-

DBR-

L1

L2

L3

DBR+

MOTOR

TERMINALS

THERMISTOR

20

19

RELAY

24

23

22

21

26

25

TECHNOLOGY OPTION 2

INTERFACE

CONNECTOR

(LOCATION VARIES

WITH FRAME SIZE)

INTERFACE

SYSTEM BOARD

SYSTEM BOARD

INTERFACE

CONNECTOR

DC Link

Choke

Frames

C & D

AC Line Choke

Frames E & F

Figure 2-7 Functional Block Diagram (Frames C, D, E, F)

Table of contents

Other SSD Drives Controllers manuals