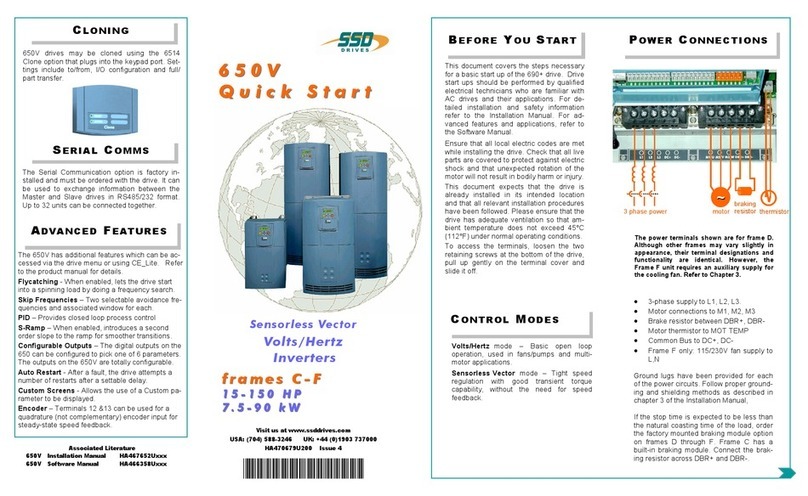

SSD Drives 650V User manual

Copyright 2005 SSD Drives Limited (formerly Eurotherm Drives Limited)

All rights strictly reserved. No part of this document may be stored in a retrieval system, or transmitted in any form or by

any means to persons not employed by an SSD Drives company without written permission from SSD Drives Ltd.

Although every effort has been taken to ensure the accuracy of this document it may be necessary, without notice, to

make amendments or correct omissions. SSD Drives cannot accept responsibility for damage, injury, or expenses

resulting therefrom.

650V AC Drive

Frames 1, 2, 3, C, D, E & F

Software Product Manual

HA466358U001 Issue 4

Compatible with Version 4.8 (onwards) Software

Cont.2

WARRANTY

SSD Drives warrants the goods against defects in design, materials and workmanship

for the period of 12 months from the date of delivery on the terms

detailed in SSD Drives Standard Conditions of Sale IA058393C.

SSD Drives reserves the right to change the content and product specification without notice.

Cont.3

Requirements

IMPORTANT: Please read this information BEFORE installing the equipment.

Intended Users

This manual is to be made available to all persons who are required to install, configure or

service equipment described herein, or any other associated operation.

The information given is intended to highlight safety issues, and to enable the user to obtain

maximum benefit from the equipment.

Complete the following table for future reference detailing how the unit is to be installed and

used.

INSTALLATION DETAILS

Serial Number

(see product label)

Where installed

(for your own

information)

Unit used as a:

(refer to Certification

for the drive)

RComponent RRelevant Apparatus

Unit fitted: RWall-mounted REnclosure

Application Area

The equipment described is intended for industrial motor speed control utilising AC induction or

AC synchronous machines.

Personnel

Installation, operation and maintenance of the equipment should be carried out by qualified

personnel. A qualified person is someone who is technically competent and familiar with all

safety information and established safety practices; with the installation process, operation and

maintenance of this equipment; and with all the hazards involved.

!

Safety Information

Cont.4

Hazards

WARNING!

This equipment can endanger life through rotating machinery and high voltages.

Failure to observe the following will constitute an ELECTRICAL SHOCK HAZARD.

This is a product of the restricted sales distribution class according to IEC 61800-3.

In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

This product is designated as “professional equipment” as defined in EN61000-3-2.

Permission of the supply authority shall be obtained before connection to the low

voltage supply.

•The equipment must be permanently earthed due to the high earth leakage current.

•The drive motor must be connected to an appropriate safety earth.

•The equipment contains high value capacitors which take time to discharge after removal of

the mains supply.

•Before working on the equipment, ensure isolation of the mains supply from terminals L1,

L2 and L3. Wait for at least 3 minutes for the dc link terminals (DC+ and DC-) to discharge

to safe voltage levels (<50V). Measure the DC+ and DC- terminal voltage with a meter to

confirm that the voltage is less than 50V.

•Never perform high voltage resistance checks on the wiring without first disconnecting the

drive from the circuit being tested.

•When replacing a drive in an application and before returning to use, it is essential that all

user defined parameters for the product’s operation are correctly installed.

•This equipment contains electrostatic discharge (ESD) sensitive parts. Observe static

control precautions when handling, installing and servicing this product.

IMPORTANT: Metal parts may reach a temperature of 90 degrees centigrade in operation.

Application Risk

The specifications, processes and circuitry described herein are for guidance only and may need

to be adapted to the user’s specific application.

SSD Drives does not guarantee the suitability of the equipment described in this Manual for

individual applications.

Risk Assessment

Under fault conditions, power loss or other operating conditions not intended, the equipment

may not operate as specified. In particular:

•The motor speed may not be controlled

•The direction of rotation of the motor may not be controlled

•The motor may be energised

Guards

The user must provide guarding and /or additional safety systems to prevent risk of injury and

electric shock.

Protective Insulation

•All control and signal terminals are SELV, i.e. protected by double insulation. Ensure all

wiring is rated for the highest system voltage.

Note: Thermal sensors contained within the motor must be double insulated.

•All exposed metalwork in the drive is protected by basic insulation and bonding to a safety

earth.

RCDs

These are not recommended for use with this product but ,where their use is mandatory, only

Type B RCDs should be used.

!

Safety Information

Contents

Contents Page

Cont.5

Chapter 1 PROGRAMMING YOUR APPLICATION

Programming with Block Diagrams .............................................................1-1

Modifying a Block Diagram Over Comms ................................................................1-1

•Configuration and Parameterisation Modes.........................................................1-1

•Execution Rules...................................................................................................1-2

•Saving Your Modifications...................................................................................1-2

Function Block Descriptions.......................................................................... 1-3

Understanding the Function Block Description ..........................................................1-3

Function Blocks by Category ....................................................................................1-4

Function Blocks in Alphabetical Order ......................................................................1-5

•ANALOG INPUT ................................................................................................1-5

•ANALOG OUTPUT.............................................................................................1-7

•APP CONFIG .....................................................................................................1-8

•AT LOAD ...........................................................................................................1-9

•AT SPEED.........................................................................................................1-10

•AUTO RESTART ................................................................................................1-11

•AUTOTUNE .....................................................................................................1-12

•BRAKE CONTROL ............................................................................................1-13

•COMMS CONTROL .........................................................................................1-14

•COMMS PORTS ...............................................................................................1-15

•CURRENT LIMIT ...............................................................................................1-17

•CUSTOM MENU ..............................................................................................1-18

•DEMULTIPLEXER...............................................................................................1-19

•DIGITAL INPUT ................................................................................................1-20

•DIGITAL OUTPUT.............................................................................................1-21

•DISPLAY/KEYPAD .............................................................................................1-22

•DYNAMIC BRAKING.........................................................................................1-23

•ENCODER .......................................................................................................1-24

•ENERGY METER ...............................................................................................1-25

•FEEDBACKS .....................................................................................................1-26

•FLUXING .........................................................................................................1-28

•FLYCATCHING ................................................................................................1-31

•INJ BRAKING ...................................................................................................1-33

•INVERSE TIME ..................................................................................................1-34

•I/O TRIPS.........................................................................................................1-35

•LOCAL CONTROL ...........................................................................................1-36

•LOGIC FUNCTION ..........................................................................................1-37

•MINIMUM SPEED .............................................................................................1-41

•MMI ACCESS ...................................................................................................1-42

•MOTOR DATA .................................................................................................1-43

•MULTIPLEXER ...................................................................................................1-45

•PATTERN GEN .................................................................................................1-46

•PID ..................................................................................................................1-47

•PRESET ............................................................................................................1-49

•RAISE/LOWER ..................................................................................................1-51

•REFERENCE......................................................................................................1-52

•REFERENCE JOG .............................................................................................1-54

Contents

Contents Page

Cont.6

•REFERENCE RAMP ............................................................................................1-55

•REFERENCE STOP ............................................................................................1-57

•SEQUENCING LOGIC .....................................................................................1-58

•SKIP FREQUENCIES..........................................................................................1-60

•SLEW RATE LIMIT..............................................................................................1-62

•SLIP COMP ......................................................................................................1-63

•SPEED LOOP ...................................................................................................1-64

•STABILISATION ................................................................................................1-66

•STALL TRIP .......................................................................................................1-67

•TORQUE LIMIT ................................................................................................1-68

•TRIPS HISTORY.................................................................................................1-69

•TRIPS STATUS...................................................................................................1-70

•VALUE FUNCTION...........................................................................................1-73

•VOLTAGE CONTROL .......................................................................................1-80

•ZERO SPEED ....................................................................................................1-81

Normal/Heavy Duty Selection ....................................................................1-82

Chapter 2 PARAMETER SPECIFICATION

Specification Table: Tag Number Order....................................................... 2-2

MMI Parameters ......................................................................................... 2-13

Pref Cross Reference Table ....................................................................................2-16

Product-Related Default Values .................................................................2-17

* Frequency Dependent Defaults ............................................................................2-17

** Power Dependent Defaults.................................................................................2-18

Chapter 3 SERIAL COMMUNICATIONS

Communications Technology Options...........................................................3-1

ConfigEd Lite ..........................................................................................................3-1

Connection to the P3 Port .............................................................................3-1

Contents

Contents Page

Cont.7

Chapter 4 SEQUENCING LOGIC

Principle State Machine ................................................................................ 4-1

Main Sequencing States...........................................................................................4-1

State Outputs of the SEQUENCING LOGIC Function Block .......................................4-1

Transition of States..................................................................................................4-2

State Diagram ........................................................................................................4-3

External Control of the Drive ........................................................................4-4

Communications Command....................................................................................4-4

•Example Commands.............................................................................4-5

Communications Status ...........................................................................................4-6

Chapter 5 APPLICATIONS

The Default Application ................................................................................ 5-1

How to Load an Application .........................................................................5-1

Application Description ................................................................................ 5-1

Application 1 : Basic Speed Control (default) ............................................................5-3

Application 2 : Auto/Manual Control ......................................................................5-5

Application 3 Preset Speeds ..................................................................................5-7

Application 4 : Raise/Lower Trim..............................................................................5-9

Application 5 : PID ................................................................................................5-11

Application Control Blocks.....................................................................................5-13

Contents

Contents Page

Cont.8

Programming Your Application 1-1

650V AC Drive

1PROGRAMMING YOUR APPLICATION

You can program the drive to your specific application. This programming simply involves

changing parameter values. Access the parameters using the keypad, or ConfigEd Lite (or other

suitable programming tool).

Each Application recalls a pre-programmed set of default parameters and links when it is

loaded.

Refer to Chapter 5: “Applications” for further information.

Programming with Block Diagrams

Block diagram programming provides a visual method of planning the software to suit your

application. There are block diagrams provided at the end of this chapter, each showing the

software connections for an Application. These pages replicate the ConfigEd Lite programming

screens. ConfigEd Lite is SSD Drive’s own programming tool.

The processes performed by an Application are represented as a block diagram, consisting of

function blocks and links:

•Each function block contains the parameters required for setting-up a particular processing

feature. Sometimes more than one instance of a function block is provided for a feature, i.e.

for multiple digital inputs.

•Software links are used to connect the function blocks. Each link transfers the value of an

output parameter to an input parameter of another (or the same) function block.

Each individual block is a processing feature, i.e. it takes the input parameter, processes the

information, and makes the result available as one or more output parameters.

Modifying a Block Diagram Over Comms

Configuration and Parameterisation Modes

There are two modes of operation used while modifying a block diagram:

Configuration and Parameterisation modes.

Configuration Mode

In the Configuration Mode you can modify the links in the function block diagram.

You can also change parameter values, as above. The drive cannot run in this mode.

When you attempt to change a parameter value requiring Configuration Mode to be

enabled, the drive automatically enters Configuration Mode.

Once in Configuration Mode, to return to Parameterisation Mode simply press the E

key repeatedly.

Parameterisation Mode

In parameterisation mode you can change parameter values. The drive can be running

or stopped. Note that some parameters can only be changed when the drive is stopped.

It is not possible to modify the internal links when the drive is in parameterisation

mode.

DEFAULT

1-2 Programming Your Application

650V AC Drive

Execution Rules

The complete block diagram is executed every 5ms. Just before a function block is executed, all

the links that have that block as their destination are executed, thereby copying new values in to

the block’s parameter inputs. The input parameters are then processed to produce a new set of

output parameters. The execution order of the blocks is automatically arranged for minimal

delay.

•The output value transferred by a link on execution is clamped to be between the maximum

and minimum value for its destination input parameter.

•Refer to the table below for the result of linking different parameter types.

Source Value

(the input)

Source Type Destination

Type

Destination Value

(the result)

TRUE Boolean Real 0.01

FALSE Boolean Real 0.00

≥0.005 Real Boolean TRUE

≤0.005 Real Boolean FALSE

LOCAL ONLY (1) Enumerated Real 1.00

2.00 Real Enumerated REMOTE ONLY (2) (Note that (2) will not

always return Remote Only)

Table 1-1 Execution Rules

Saving Your Modifications

Whenever a value/link is changed, the modification is stored automatically and will be saved on

power-down.

Programming Your Application 1-3

650V AC Drive

Function Block Descriptions

Note: To view all parameters available on the MMI, Full menu detail must be selected in the

DETAILED MENUS parameter ( ST99). Additional blocks/parameters are available over the

Comms.

Understanding the Function Block Description

The following function

blocks show the parameter

information necessary for

programming the drive.

Input parameters are shown

on the left hand side, and

output parameters are shown

on the right hand side of the

block.

The diagrams assume that the

UK country code is selected

and that a 400V 11kW Frame

C power board is fitted. This

is reflected in the values of

certain parameters, see “*”

and “**” in the table below.

Instance Name Names the function block and MMI menu

Default Value The default value of the unmodified macro, Macro 0

Input/Output

Parameter Name

The name shown on ConfigEd Lite

Tag Number Unique identification used for communications

*Parameters marked with “*” are set to a value depending upon the

“operating frequency” of the drive. Refer to Chapter 2: “Parameter

Specification” - Frequency Dependent Defaults; and the Installation

Product Manual, Chapter 5: “The Operator Station” - Changing the

Product Code (3-button reset).

** Parameters marked with “**” are set to a value depending on the overall

“power build “ of the drive indicated by the product code. Refer to

Chapter 2: “Parameter Specification” - Power Dependent Defaults; and the

Installation Product Manual: Chapter 2: “Understanding the Product

Code”.

Note: The “Range” for a parameter value is given in the Parameter Description Table on each

Function Block page. Ranges for outputs are given as “—.xx %”, for example, indicating

an indeterminate integer for the value, to two decimal places.

F

Parameters indicated with Fare visible with Full menus only. Refer to the DETAILED

MENUS parameter ( ST99) in the MMI ACCESS function block, page 1-42.

MParameters indicated with Mare Motor Parameters. They are not reset by changing

Application using parameter P1; all other parameters are reset to default values.

VF Parameters indicated with VF are only visible when the drive is in VF (Volts/Hz)

motor control mode, as selected by parameter SCL01.

SV Parameters indicated with SV are only visible when the drive is in SV (Sensorless

Vector) motor control mode, as selected by parameter SCL01.

Default Value

Output Parameter

Name

Default Value

Instance Name

Input Parameter

Name

Tag Number

Analog Input 1

–VALUE [ 16] –0.0 %

100.00 % –[ 14] SCALE –

0.00 % –[ 15] OFFSET –

0..+10 V –[ 13] TYPE –

Figure 1-1 Function Block Parameter Information

1-4 Programming Your Application

650V AC Drive

Function Blocks by Category

The function block descriptions in this chapter are arranged in alphabetical order, however, they

are listed below by Category.

Communications

COMMS PORTS 1-15

Configuration

APP CONFIG 1-8

Encoder Functions

ENCODER 1-24

Hoist/Lift

BRAKE CONTROL 1-13

Inputs/Outputs

ANALOG INPUT 1-5 DIGITAL INPUT 1-20

ANALOG OUTPUT 1-7 DIGITAL OUTPUT 1-21

Menus

CUSTOM MENU 1-18 MMI ACCESS 1-42

Miscellaneous

DEMULTIPLEXER 1-19 MULTIPLEXER 1-45

LOGIC FUNCTION 1-37 VALUE FUNCTION 1-73

Motor Control

AUTOTUNE 1-12 INVERSE TIME 1-34

CURRENT LIMIT 1-17 MOTOR DATA 1-42

DISPLAY/KEYPAD 1-22 PATTERN GEN 1-46

DYNAMIC BRAKING 1-23 SLEW RATE LIMIT 1-62

ENERGY METER 1-25 SLIP COMP 1-63

FEEDBACKS 1-26 SPEED LOOP 1-64

FLUXING 1-28 STABILISATION 1-66

FLYCATCHING 1-31 TORQUE LIMIT 1-68

INJ BRAKING 1-33 VOLTAGE CONTROL 1-80

Sequencing and Referencing

AUTO RESTART 1-11 REFERENCE JOG 1-54

COMMS CONTROL 1-14 REFERENCE RAMP 1-55

LOCAL CONTROL 1-36 REFERENCE STOP 1-57

REFERENCE 1-52 SEQUENCING LOGIC 1-58

Setpoint Functions

AT LOAD 1-9 PRESET 1-49

AT SPEED 1-10 RAISE/LOWER 1-51

MINIMUM SPEED 1-41 SKIP FREQUENCIES 1-60

PID 1-47 ZERO SPEED 1-81

Trips

I/O TRIPS 1-35 TRIPS HISTORY 1-69

STALL TRIP 1-67 TRIPS STATUS 1-70

Programming Your Application 1-5

650V AC Drive

Function Blocks in Alphabetical Order

ANALOG INPUT

The analog input block converts the input voltage or current into a value expressed as a

percentage of a configurable range.

Analog Input 1

–VALUE [ 16] –0.0 %

100.00 % –[ 14] SCALE –

0.00 % –[ 15] OFFSET –

0..+10 V –[ 13] TYPE –

Analog Input 2

–VALUE [ 25] –0.0 %

100.00 % –[ 23] SCALE –

0.00 % –[ 24] OFFSET –

4..20 mA –[ 22] TYPE –

0.0 % –[ 26] BREAK VALUE –

Parameter Descriptions

SCALE SET/IN IP11 & IP21 Range: -300.00 to 300.00 %

A scaling factor applied to the raw input. With a scaling factor of 100.00% and an offset of

0.00%, an input equal to the low input range will appear as a value of 0.00%. Similarly, an

input equal to the high input range will appear as a value of 100.00%.

OFFSET SET/IN IP12 & IP22 Range: -300.00 to 300.00 %

An offset added to the input after the scaling factor has been applied.

TYPE SET/IN IP13 & IP23 Range: Enumerated - see below

The input range and type.

ANALOG INPUT 1 supports Types 0 and 1 only. ANALOG INPUT 2 support all types.

Enumerated Value : Type

0 : 0..+10 V

1 : 0..+5 V

2 : 0..20 mA

3 : 4..20 mA

BREAK VALUE Range: -100.0 to 100.0 %

The value that will appear as the VALUE output when BREAK is TRUE

VALUE FSET/IN IPA1 & IPA2 Range: —.x %

The input reading with scaling and offset applied.

1-6 Programming Your Application

650V AC Drive

Functional Description

The drive has two analog inputs. There is an analog input function block for each:

ANALOG INPUT 1 is associated with the signal on terminal 2

ANALOG INPUT 2 is associated with the signal on terminal 3

The input voltage is pre-processed and converted into a numeric value by the analog input

electronics of the drive. The analog input function blocks further process this reading so that a

value of 0.00% represents an input equal to the low input range, while a value of 100.00%

represents an input equal to the high input range. The SCALE and OFFSET factors are then

applied as shown to produce a value suitable for use in the application.

The break detect facility is only used in conjunction with the "4 to 20mA" hardware range. An

input break is defined as an input reading less than either 0.1V or 0.45mA. When an input break

has been detected, the VALUE output is forced to be the BREAK VALUE.

If you don't want the break detect facility, select the "0 to 20mA". You can also apply OFFSET

to recreate the "4 to 20mA" hardware range.

+

VALUE

SCALING OFFSET

X

INPUT

BREAK VALUE

INPUT LOSS LEVEL

TYPE

UNPROCESSED

Programming Your Application 1-7

650V AC Drive

ANALOG OUTPUT

The analog output block converts the

demand percentage into a form suitable

for driving the analog output electronics

of the drive.

Functional Description

The drive has one analog outputs:

ANALOG OUTPUT 1 is associated with terminal 6

The scaling and offset parameters are applied to the demand value as shown.

If ABS is TRUE then the final output is the magnitude of value after being scaled and offset and

the output sign is ignored

If ABS is FALSE then as above, except that the output sign is valid.

XOUTPUT

SCALE

+

OFFSET

VALUE

ABS

Analog Output

0.0 % –[ 45] VALUE –

100.00 % –[ 46] SCALE –

0.00 % –[ 47] OFFSET –

TRUE –[ 48] ABSOLUTE –

Parameter Descriptions

VALUE SET/OUT OP05 Range: -300.0 to 300.0 %

The demanded value to output.

SCALE SET/OUT OP02 Range: -300.00 to 300.00 %

A scaling factor to apply to VALUE . A scaling factor of 100.00% has no effect.

OFFSET SET/OUT OP03 Range: -300.00 to 300.00 %

An offset added to VALUE after the scaling factor has been applied. An offset factor of 0.00%

has no effect.

ABS SET/OUT OP04 Range: FALSE / TRUE

When TRUE the output sign is ignored.

1-8 Programming Your Application

650V AC Drive

APP CONFIG

This block controls the selection of user

application and of the output wiring

App Config

STANDARD –[1091] APPLICATION –

DEMAND –[1092] ANOUT SOURCE –

HEALTH –[1093] RELAY SOURCE –

NONE –[1094] DIGIO2 SOURCE –

FALSE –[1064] APP LOCK –

Parameter Descriptions

APPLICATION PAR\ P1 Range: Enumerated - see below

This parameter selects and loads the Application to be used. APP 0 will not control a motor. APP

6, 7 & 8 are for future use. You can edit an Application in ConfigEd Lite and, then set this

parameter to CUSTOM to produce your own custom Application.

Refer to Chapter 5: "Applications" which gives detailed information about each Application.

0 : NULL

1 : STANDARD

2 : LOCAL/REM (AUTO/MANUAL)

3 : PRESETS

4 : RAISE/LOWER

5 : PID

6 : APP 6

7 : APP 7

8 : APP 8

9 : CUSTOM

ANOUT SOURCE SET/OUT OP01 Range: Enumerated - see below

The source of the analog output, terminal 5. An internal link is made to one of the following

parameters:

0 : NONE No link is made

1 : DEMAND SPEED DEMAND in the REFERENCE block

2 : CURRENT MOTOR CURRENT% in the FEEDBACKS block

3 : PID ERROR ERROR in the PID Block

4 : R/L OUTPUT OUTPUT in the RAISE/LOWER block

RELAY SOURCE SET/OUT OP31 Range: Enumerated - see below

The source of the relay output, terminals RL1A and RL1B. An internal link is made to one of the

following parameters:

0 : NONE No link is made

1 : HEALTH HEALTHY in the SEQ LOGIC block

2 : TRIPPED TRIPPED in the SEQ LOGIC block

3 : RUNNING RUNNING in the SEQ LOGIC block

4 : AT ZERO AT ZERO SPD in the ZERO SPEED block

5 : AT SPEED AT SPEED in the AT SPEED block

6 : AT LOAD AT OR ABOVE LOAD in the AT LOAD block

DIGIO2 SOURCE SET/OUT OP21 Range: Enumerated - see below

The source of the digital output 2, terminal 10. An internal link is made to one of the following

parameters:

0 : NONE No link is made

1 : HEALTH HEALTHY in the SEQ LOGIC block

2 : TRIPPED TRIPPED in the SEQ LOGIC block

3 : RUNNING RUNNING in the SEQ LOGIC block

4 : AT ZERO AT ZERO SPD in the ZERO SPEED block

5 : AT SPEED AT SPEED in the AT SPEED block

6 : AT LOAD AT OR ABOVE LOAD in the AT LOAD block

APP LOCK FSET\SETP ST98 Range: FALSE / TRUE

Set this parameter to TRUE to prevent the APPLICATION parameter from being edited.

Programming Your Application 1-9

650V AC Drive

AT LOAD

This function block is used to generate the

AT OR ABOVE LOAD signal that may be

used as a digital output (refer to the APP

CONFIG block).

If operating as an open-loop drive (V/F fluxing) it is important to enter the no-load current at

rated speed in to the MAG CURRENT parameter (SCL14 - MOTOR DATA function block),

otherwise the LEVEL from this block could be inaccurate.

At Load

–AT OR ABOVE LOAD [622] –FALSE

100.0 % –[621] LEVEL –

FALSE –[1259] ABSOLUTE –

Parameter Descriptions

LEVEL SET\SETP ST42 Range: -300.0 to 300.0 %

This parameter sets the value of load at which the AT OR ABOVE LOAD parameter becomes

TRUE. 100% = rated torque for the motor.

ABSOLUTE SET\SETP ST43 Range: FALSE / TRUE

When TRUE, the direction of rotation is ignored. In this case, the comparison level should

always be positive.

When FALSE, the direction of rotation is not ignored. Driving a load in the reverse direction

gives a negative value for torque. In this case, the comparison level may be positive or

negative.

AT OR ABOVE LOAD Range: FALSE / TRUE

This parameter is TRUE if the load is equal to or above the value set by the LEVEL parameter.

1-10 Programming Your Application

650V AC Drive

AT SPEED

This function block is used to generate

the AT SPEED signal that may be used

as a digital output (refer to the APP

CONFIG block).

At Speed

AT SPEED [1096] –FALSE

1.0 % –[1095] HYSTERISIS –

Parameter Descriptions

HYSTERISIS Range: 0.0 to 300.0 %

Provides a hysteresis band about the Speed Setpoint in which the AT SPEED output is stable.

The Speed Setpoint is shown by the Speed Setpoint (%) diagnostic in the Diagnostics menu,

which is shown as a percentage of the MAX SPEED parameter (Hz).

true zero

SPEED SETPOINT

speed demand

AT SPEED

0.5%

0.3%

0.7%

HYSTERESIS

Example where HYSTERISIS = 0.2%

Off level

On level

true

false

AT SPEED Range: FALSE / TRUE

This parameter is TRUE when the speed demand is within the hysterisis band, as shown

above, otherwise it is FALSE.

Programming Your Application 1-11

650V AC Drive

AUTO RESTART

Auto Restart (or Auto Reset) provides the

facility to automatically reset a choice of trip

events and restart the drive with a

programmed number of attempts, after

which, a manual or remote trip reset is

required if the drive is not successfully

restarted. The number of attempted restarts

are recorded. This count is cleared after a

trip-free period of operation

(5 minutes or 4 x ATTEMPT DELAY 1,

whichever is the longer), or after a successful manual or remote trip reset, or by removing the

Run signal.

In addition, if the POWER UP START parameter in the SEQUENCING LOGIC function block

is True, then the Auto Restart feature will also operate even if the trip initially occurs when the

drive is not running (as long as the Run signal remains True).

Auto Restart

–PENDING [608] –FALSE

–RESTARTING [616] –FALSE

–ATTEMPTS LEFT [614] –0

–TIME LEFT [615] –0.0 s

0–[612] ATTEMPTS –

10.0 s –[613] ATTEMPT DELAY 1 –

0x0000 –[609] TRIGGERS 1 –

0x0000 –[744] TRIGGERS 1+ –

Parameter Descriptions

ATTEMPTS SET\SETP ST21 Range: 1 to 10

Determines the number of restarts that will be permitted before requiring an external fault

reset.

ATTEMPT DELAY 1 SET\SETP ST22 Range: 0.0 to 600.0 s

Determines the delay between restart attempts for a trip included in TRIGGERS 1 . The delay

is measured from all error conditions clearing.

TRIGGERS 1 and

TRIGGERS+ 1

SET\SETP ST23 and

SET\SETP ST24

Range: 0000 to FFFF

Allows Auto Restart to be enabled for a selection of trip conditions.

Refer to TRIPS STATUS, page 1-70 for an explanation of the four-digit codes.

PENDING Range: FALSE / TRUE

Indicates that an auto restart will occur after the programmed delay.

RESTARTING Range: FALSE / TRUE

Indicates that an auto restart is occurring. TRUE for a single block diagram execution cycle.

ATTEMPTS LEFT Range: —.

Indicates the number of attempts left before an external fault reset is required.

TIME LEFT Range: —.x s

When in the Restarting state, this parameter indicates the time left before an auto restart

attempt will be permitted. When non-zero, this value is unaffected by changes to ATTEMPT

DELAY 1.

1-12 Programming Your Application

650V AC Drive

AUTOTUNE

Designed for SENSORLESS VEC Motor

Control Mode.

The Autotune is an automatic test sequence

performed by the drive to identify motor

model parameters. The motor model is used

by the Sensorless Vector control mode. You MUST perform an Autotune before operating the

drive in the Sensorless Vector control mode.

Refer to the Installation Product Manual, Chapter 4: “Operating the Drive” - Set-up using the

Sensorless Vector Fluxing Mode.

Functional Description

The Autotune sequence identifies the following motor parameters:-

•Per-phase stator resistance (STATOR RES)

•Per-phase leakage inductance (LEAKAGE INDUC)

•Per-phase mutual inductance (MUTUAL INDUC)

•Rotor time constant (ROTOR TIME CONST)

•No-load magnetising line current (MAG CURRENT)

The Rotating Autotune sequence rotates the motor up to the user-programmed MAX SPEED

(REFERENCE function block) in order to identify these parameters.

The Stationary Autotune sequence does not rotate the motor and requires the correct value of

Magnetising Current to be entered.

The values of the above are stored in the MOTOR DATA function block. Autotune will

overwrite any previous entry made for these parameters. Autotune can only be initiated from the

“stopped” condition. When the test is complete, the stack is disabled and ENABLE is set to

FALSE.

Autotune

–ACTIVE [604] –FALSE

FALSE –[603] ENABLE –

STATIONARY –[689] MODE –

0x0000 –[1025] TEST DISABLE

Parameter Descriptions

ENABLE SV SET\CTRL CL21 Range: FALSE / TRUE

Determines whether the Autotune sequence is operational or not. The Autotune sequence is

operational when set to TRUE and the drive is run. Refer to the Installation Product Manual,

Chapter 4: “Operating the Drive” - The Autotune Feature.

MODE SV SET\CTRL CL20 Range: Enumerated - see below

Selects the Autotune operating mode. Refer to the Installation Product Manual, Chapter 4:

“Operating the Drive” – The Autotune Feature.

Enumerated Value : Mode

0 : STATIONARY

1 : ROTATING

ACTIVE Range: FALSE / TRUE

This indicates the current state of the Autotune sequence. The Autotune sequence is

operational when displaying TRUE.

TEST DISABLE Range: 0000 to FFFF

This allows individual Autotune tests to be disabled. The values corresponding to disabled

tests are shown below.

Value Disabled Tests

0000 None

0001 Stator Resistance

0002 Leakage Inductance

0003 Stator Resistance and Leakage Inductance

0004 Magnetising Current

0005 Stator Resistance and Magnetising Current

0006 Leakage Inductance and Magnetising Current

0007 All tests

Other manuals for 650V

2

Table of contents

Other SSD Drives Controllers manuals

Popular Controllers manuals by other brands

Kitz

Kitz EXCN Operation manual

CiA

CiA TVMX2406 How to install

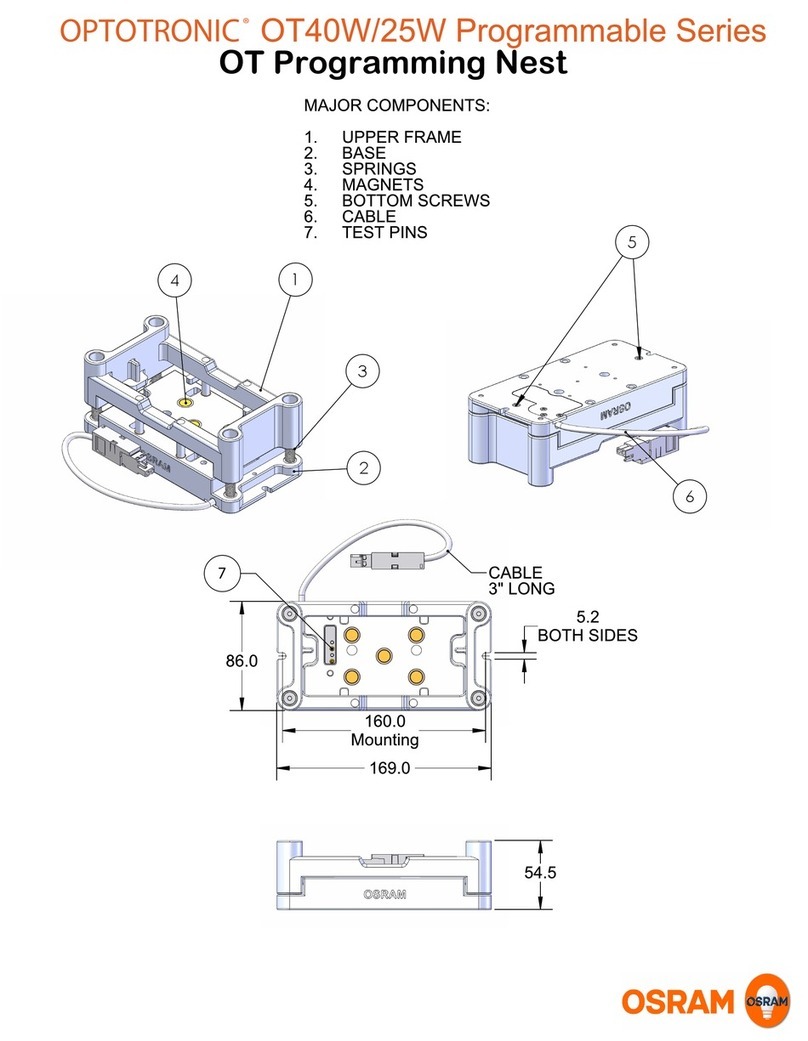

Osram

Osram OPTOTRONIC OT40W/25W Programmable Series Operational Procedures Guide

Signcomplex

Signcomplex LC-0RGB-WiFi-01 manual

salmson

salmson ACSON VARIO Installation and starting instructions

Pleion

Pleion EOLIPSE Installation and operating manual