M-Elec AL-2 Series User manual

AL-ⅡSeries Slave Controller Driver

2CD-7713v1/GDB5F40

Instructions Manual

(For designers' use)

MN0193

Please ensure to read and understand this

Instructions Manual before using the Product.

Please keep this Instructions Manual at hand

so that it is always available for reference.

-2-

Introduction

This instructions manual explains the handling of "AL- Series Slave Controller Driver 2CD-7713v1Ⅱ

/GDB5F40 for 5-phase stepping motor ", emphasizing the specifications to enable proper and safe use.

The manual is thus intended for designers of control systems using stepping motors.

Before using the product, read this manual carefully for better understanding.

Keep the manual handy so that you can read it whenever you want.

The 2CD-7713v1/GDB5F40 allows axes to be controlled independently and therefore referred to each

axis as follows:

1st axis 2nd axis

X-axis Y-axis

This manual basically explains only the X-axis.

Description of safety

This product must be handled correctly.

Handling the product incorrectly may cause unexpected accidents resulting in personal injuries or

damage to your properties.

Many of those accidents can be avoided if you have advance information on dangerous situations.

This manual provides precautions where dangerous situations are predicted. The manual provides the

following alert marking and messages for this purpose:

This indicates a hazardous situation that could result in death or serious

WARNING

personal injury if you do not perform the procedure correctly.

This indicates a potentially hazardous situation that could result in personal

CAUTION

injury or physical damage if you do not perform the procedure correctly.

Before use

This product is not designed for use in the equipment related to nuclear power, aerospace equipment,■vehicles, marine vessels, medical equipment directly in touch with human body, equipment

anticipated to give a serious impact to properties, and other equipment required to provide high

reliability.

Take failsafe measures so that the whole system operates safely even if the input power causes an■error, a signal line is disconnected, or the main unit fails.

This product is equipped with a LIMIT overtravel signal and an FSSTOP signal to prevent■()

mechanical damage.

The initial values of these signals are set to ACTIVE OFF B contact . Accordingly, even in a()

system configuration in which the FSSTOP and LIMIT signals are not used, pulses are not output

unless NORMAL ON GND connection is enabled.()

Be sure to use this product within the scope of the specifications described in this instruction manual■in accordance with the specification method described therein.

Set up the product before operating it.■Please refer to the Section 3, "Setting."

Please refer to separate manual "AL- series device driver manual for Windows" also when you■Ⅱ

handle this product.

2CD-7713v1/GDB5F40

Instructions Manual

-3-

Introduction

Description of safety

Before use

Contents PAGE

Overview1.1-1. Features 5

1-2. Product configuration 6

1-3. Example of system configuration 6

1-4. Function block diagram 7

1-5. Externals of product 9

Specifications2.2-1. General specifications 11

2-2. Communication specifications 11

2-3. Specifications 12

1 Controller part 12()

2 Driver part 14()

2-4. Input and output signal table 15

1 Serial communication connector J1, J2 15() ( )

2 Sensor connector J3: X-axis, J4: Y-axis 15() ( )

3 Controller power supply connector J5 16() ( )

4 Driver power supply connector J6: X-axis, J8: Y-axis 16() ( )

5 Motor connector J7: X-axis, J9: Y-axis 16() ( )

6 General-purpose I/O connector J10 17() ( )

7 Extend I/O communication connector J11 17() ( )

2-5. Input and output specifications 18

1 Output specifications 18()

2 Input specifications 18()

2-6. Outside dimensions 19

Setting3.3-1. Setting of the controller part 20

1 Installation of device driver for Windows 20()

2 Address setting of the AL- series S1 20() Ⅱ ( )

3 Baud rate setting of the AL- series S2 20() Ⅱ ( )

3-2. Setting of the driver part 21

1 Description of operating 21()

2 Setting of HOLD SWITCHING TIME SELECT DHT SEL switch 21() ( )

3 Setting of STEP TABLE S.T SEL switch and STEP ANGLE SELECT STEP SEL switch 22() ( ) ( )

4 Setting of DRIVE CURRENT SELECT DRIVE I. SEL switch 22() ( )

5 Setting of HOLD CURRENT SELECT HOLD I. SEL switch 23() ( )

Installation and connection4.4-1. Installation 24

1 Installation distance 24()

2 Installation method 24()

4-2. Connection of AL- communication system 25Ⅱ

1 Core connection of AL- communications cable 25() Ⅱ

2 Connection of terminator 25()

3 Wiring distance of AL- communication 25() Ⅱ

4 Power supply and slave power supply for communication 25()

4-3. Connection example 26

1 Examples of connection to power supply 26()

2 Examples of connection to motor 27()

3 Examples of connection to sensor at photosensor 28() ( )

4 Examples of connection to general-purpose I/O 30()

5 Examples of connection to Extend I/O unit 30()

2CD-7713v1/GDB5F40

Instructions Manual

-4-

2CD-7713v1/GDB5F40

Instructions Manual

Contents PAGE

Applicable motor5.5-1. List of applicable motor 31

5-2. Torque characteristics 31

Maintenance6.6-1. Maintenance and Inspection 36

1 Cleaning method 36()

2 Inspection method 36()

3 Replacement method 36()

6-2. Saving and disposal 36

1 Saving method 36()

2 Disposal method 36()

The main parts which revised by this manual

-5-

2CD-7713v1/GDB5F40

Instructions Manual

Overview1.

1-1. Features

The AL- series is a high speed serial communication system of original controlling the flexible stepping motor,●Ⅱ

servo motor which can cope easily as well and I/O in the decentralization of the device and supporting axial addition.

The AL- series is an insulation type high-speed serial communications of 20 Mbps/50 m or 10 Mbps/100 m.・Ⅱ

As a result, the saving wiring for the personal computer system can be attempted by the performance ratio of(

our company that equals a board controller so far.)

The shift of board controller C-VX870 series Device-function for PCI made of our company and the USB series・()

Device-function and Unit-function is easy depending on the device driver function for Windows.()

2CD-7713v1/GDB5F40 is a version up product with the 2CD-7713/GDB5F40 upward compatibility.●The status of two axis batch reading and the command of two axis batch execution by the Unit Function became

possible.

This Unit-function can perform a unit and AL- interface by one function execution from an application.Ⅱ

By this,

The time crunch can be done compared with accessed Device-function of each axis and I/O-port-function of each・I/O port.

The unit function writing suppresses the difference at time until it instructs time each axis and each I/O output・()

signal.

The Unit-function can reduce the load of the application.・It supports the Device-function, and can use the Device-function.・The Unit-function can be used together with the Device-function and the I/O-function.・

Access example in Device-function and I/O-function Access example in Unit-function

Time lag

Reading X-axis STATUS1 X-axis STATUS1

Reading Y-axis STATUS1 Y-axis STATUS1

Time lag Batch Reading

Reading X-axis Control I/O A Unit X-axis Control I/O()

Reading Y-axis Control I/O Y-axis Control I/O

General-purpose I/O General-purpose I/OReading

Reading Extend I/O 0 Extend I/O 0

n

n

Reading Extend I/O 1 Extend I/O 1

o

o

i

i

t

t

Time lag

Batch Writing X-axis DATA1 X-axis DATA1

a

a

Eachaxis X-axis DATA2 X-axis DATA2

c

c

()

X-axis COMMAND X-axis COMMAND

i

i

Batch Writing Y-axis DATA1 Y-axis DATA1

l

l

Each axis Y-axis DATA2 Y-axis DATA2

p

p

()

Y-axis COMMAND Y-axis COMMAND

p

p

Time lag Batch Writing

A

A

Writing X-axis Control I/O A Unit X-axis Control I/O()

Writing Y-axis Control I/O Y-axis Control I/O

General-purpose I/O General-purpose I/OWriting

Writing Extend I/O 0 Extend I/O 0

Writing Extend I/O 1 Extend I/O 1

2CD-7713v1/GDB5F40 is equipped with our chip controller MCC to enable motor control using simple commands.●It enables drive of two axes of 5-phase stepping motor of from 0.75 A/phase to 1.4 A/phase.・It enables two independent drive and two axes linear interpolation drive by an easy commands.・After the command being executed is finished, the commands stored in the reservation register are executed・()sequentially. Then this function can be allowed continuous drive. Applied function

The wiring working efficiency improves by an unnecessary driver all-in-one design to wire between the controller and・the motor driver.

2CD-7713v1/GDB5F40 is equipped with for each two points general-purpose I/O.●In addition, connect an Extend I/O unit 16/16 points or 32/32 points by the serial communication without minding()

address setting and add a general-purpose I/O and can control it.

This general-purpose I/O and Extend I/O unit can read and write at the same time accessing MCC according to the

Unit-Function.

-6-

2CD-7713v1/GDB5F40

Instructions Manual

1-2. Product configuration

Product name Rating Maker Quantity Remarks

()Controller 2CD-7713v1/GDB5F40 Melec Inc. 1 Main Unit

()Connector 51067-0200 Molex 2 For driver power supply connector Accessory

()Connector 51067-0500 Molex 2 For motor connector Accessory

()Connector 51103-0300 Molex 1 For controller power supply connector Accessory

()Connector 51103-0600 Molex 2 For sensor connector Accessory

()Connector 51103-0700 Molex 1 For general-purpose I/O connector Accessory

()Contact 50217-9101 Molex 16 For 51067 connector Accessory

()Contact 50351-8100 Molex 24 For 51103 connector Accessory

×− ()Screw M2.6 4 2 For shield cable fixation Accessory

1-3. Example of system configuration

PC

()OFF LINE Initial data edit/Kind operation

USB * 15 slave's unit can be connected by one master board.

AL- series slave unitAL- PCI master boardⅡⅡ

PC AL2-01v1/PCI

5-phase stepping motor

2CD-7713v1/GDB5F40

AL- communication cable SensorⅡ

Slot in 20 Mbps/50 m or 10 Mbps/100 m CWLM,CCWLM,ORG,NORG signal/ Each axis

X-axis

Extend I/O Terminator CB-54/R

Device driver Insert core CB-52/3232-MIL etc. Y-axis※

●()MPL-34-01vx.xx/AL2W32 *1 ZCAT2032-0930

Windows 2000 Extend I/O interface cable・

Windows XP 32 bit CE-66-01/IO-A03 etc.・()

Windows Vista 32 bit 32/32 points 5 Mbps/1 m or less・() ()

・()Windows 7 32 bit

MPL-35-01vx.xx/AL2W64 *1●

・()Windows XP 64 bit

・()Windows Vista 64 bit

・()Windows 7 64 bit

*1 Version No. Please confirm the latest version of vx.xx at the manual of the device driver.…

AL- series prepared connectable cables easily.・Ⅱ

Please refer to the "connection / others" instruction manual for details of connection of the AL- series.Ⅱ

Example of other AL- seriesⅡ

()Power supply relay board Controller for servo or stepping motor Controller with built-in driver General-purpose I/O Extend type and Slave type

CB-55-01/PS-T35 2C-771v1 2C-776Av1 CB-53/1616-MIL 2CB-01v1/3232-MIL 2CB-02v1/1616-MIL2CD-7710v1/ADB5F30

4-distribution 4-axes 4-axes 2-axes for 5-phase Extend type Slave type Slave type・・・・・・・

output of DC 24 V For stepping or For encoder input stepping motor In:16-points In:32-points In:16-points・・ ・・・

1 A/terminal simple servo 0.75 A/phase Out:16-points Out:32-points Out:16-points・・・・・

()3.5 A in total

J2

J1

10 201

AL2‑01/PCI1

MADEIN JAPAN

S1

4030 60300001

MADEIN JAPAN

PL1

PL2

PL3

PL4

J1 J2

J3 J4

J6J5

DC+24V

INOUT

INOUT

MADE IN JAPAN

MADEIN JAPAN

OUT IN

DC+24V

J4J3 J2

J1

GND

8

OUT +24V

KP1516‑0A

MADEIN JAPAN

1

4

1

IN

+24VGND

3.5A

MADE IN JAPAN

J7J15 J17J9J14 J16J8 J6

J5 J3DC+24V

J4

J2

J1

INJ6OUTJ5

J2J1

MADEIN JAPAN DC+24VJ3

J4

OUT INJ7 J8

J4 J3DC+24V

MADE IN JAPAN

J1 J2

J5 OUT J6 IN

J6 J7

J10 J11

J1

RDY

J8

J12

J14 J2

J3DC+24V

J5J4

J9

J13

MADE IN JAPAN

CTO 503

40

OS CTO 503

40

OS

MADEINJAPAN

RDY

CTO 503

40

OSCTO 503

40

OS

J9

S6 S5

MADEINJAPAN

J5

J4

J3

J1

J8

J2

J6

J7

S4 S3

J2J1

RDY

DC+24VJ5

SENSOR/YJ4SENSOR/X

J3

S3

S6 S4 S5

J7

MOTOR/X

J6

DC+24V/X S7

S10 S8 S9

J9

MOTOR/Y

J8

DC+24V/Y

J10

J11 MADEIN JAPAN

-7-

2CD-7713v1/GDB5F40

Instructions Manual

1-4. Function block diagram

2CD-7713v1/GDB5F40

Controller block Driver block

Isolation by photocouplerSerial interface

control block

J3

Sensor faction

e

e

J6

c

n

l

Pulse Driver 24 V

X-axis X-axis

a

i

o

MF,C.S

J7

f

L

r

E

Drive control block 5-phase stepping

DALM,PO Motor

r

t

N

motor driver

0.75 A or 1.4 A/phase

Ⅱ

J1

e

n

n

I

X-axis Counter block ・

J4

-

t

o

o

L

Sensor faction

L

n

i

C

A

I

t

N

J2

J8

a

O

Ⅱ

Pulse Driver 24 V

Y-axis Y-axis

Ⅱ

l

-

I

MF,C.S

J9

-

o

L

T

Drive control block 5-phase stepping

DALM,PO Motor

L

s

A

A

motor driver

0.75 A or 1.4 A/phase

A

I

L

Y-axis Counter block ・

O

J10

S

FSSTOP

I

()General-purpose I/O General-purpose inputs IN0, IN1

In :2-Points・

Serial interface Out:2-points・

()control block Contains Extend I/O()General-purpose outputs OUT0, OUT1

・()In :32-Points max.

・()

e

Out:32-points max.

()

O

c

l

Control I/O area

Out:C.S / Each axis

/

a

o

・

I

f

r

r

t

J11

d

e

n

n

t

o

e

n

C

t

I

x

d

E

d

n

n

e

e

t

t

x

x

E

()

E

Inside power supply

DC/DC

Forcontroller24VJ5

()Power supply for outside interface

-8-

2CD-7713v1/GDB5F40

Instructions Manual

Serial interface control block

This department is control block for AL- serial communication.Ⅱ

The AL- serial communications interface department is insulated with +24 V power supply and the internal logics.Ⅱ

Serial interface control block

This department is control block for serial communication of Extend unit.

This block performs an Extend I/O unit and serial communication and can extend the I/O of 32 points /32 points

input output at the maximum .()

The serial communication interface part is insulated from power supply +24 V.

Drive control block

The drive control block outputs serial pulses to the motor driver from pulse generator MCC.

()MCCismadebyMELECInc.

This department detects origin sensor and a limit sensor signal and motor is controlled.・Enables two axes independent drive or two axes linear interpolation drive.・Enables stop two axes at immediate stop by FSSTOP signal from the outside.・

To distinguish two axes, it is named X-axis and Y-axis.

Counter block

The counter block has two types of counters: ADDRESS COUNTER, and PULSE COUNTER.

ADDRESS COUNTER, PULSE COUNTER has 32-bit counter.

These counters count pulses output by the controller.

Each counter equipped with three compare registers. These registers count optional count.

* The counter function of 2CD-7713v1/GDB5F40 is specifications to count pulse of the pulse output.

When the application of the counter which used an outside pulse is necessary, please examine a controller

product corresponding to the outside pulse input.

General-purpose I/O block

This block is controlling the following input/output.

These input/output ports can control easily by I/O-function.

Control I/O area・Driver's resolution switch C.S signal can be operated.…()

General-purpose I/O area・The reading of the general-purpose Input IN0 signal and IN1 signal, the operation of the general-purpose…output OUT0 signal and OUT1 signal are possible.

Moreover, enables operation as Latch signal and Clear signal of X-axis SS0 signal by the IN0 signal input.

And, enables operation as Latch signal and Clear signal of Y-axis SS1 signal by the IN1 signal input.

Extend I/O area・When the area secure an extension input/output area for 32 points /32 points input/output and access it…from an application in this input/output area, the area can control input/output by an Extend I/O unit

and cyclic communication.

Stepping motor driver block

This block which installed two axes driver can drive 5-phase stepping motors until 1.4 A/ phase.

This block can drive a stepping motor from low speed smoothly, and the resolution is possible until maximum

2,000,000 pulse/revolution .()

Control part and the driver part are isolated by a photocoupler.

In addition, the power supply of a stepping motor driver part and the control part is independent.

This part can control the following signal from the drive control block.

M.F Enables interception of the stepping motor current by M.F on/off operation of MCC SIGNAL OUT・…

command DRST/M.F bit .()

O.H.A By MCC DRIVE STATUS2 PORT DALM bit , O.H.A can detect driver overheat warning.・… ( )

In addition, by an MCC SPEC INITIALIZE3 command, the stop of the motor drive is possible with the

detection of the driver's overheat warning.

P.O The machine origin detection that used the phase out P.O signal of the driver for by an ORIGIN・… ()

SPEC SET function is possible.

-9-

2CD-7713v1/GDB5F40

Instructions Manual

1-5. Externals of product

【】Controller block

J1, J2 These are shield connector of the RJ-45 type that connects the AL- communication.Ⅱ

J1 and J2 are connected with each unit and the communications cable can be connected in

the multidrop.

J3, J4 These are connectors to connect the sensor signals such as a limit signal or the ORG signal.

J3 is the one for the X-axis, and J4 is the one for the Y-axis.

J5 This is a connector to connect +24 V power supply for controllers.

J10 This is a connector that connects immediate stop FSSTOP signals and general-purpose I/O()

IN0, IN1, OUT0, and OUT1 signals .()

J11 This is a connector to connect an Extend I/O unit.

S1 This is a setting switch of the slave address of the AL- communication.Ⅱ

S2 This is a setting switch of the baud rate of the AL- communication.Ⅱ

Controller LED RDY LED Green color turns on at the time of RDY state the X-axis and Y-axis of each axis.()

()RDY

Terminal The terminal connect to the shield when the sensor cable of shield.

Use the screw of attached M2 .6 4.×

J1 J2

J11

S7

S10 S8 S9

J9

J10 J3 J4 J5

J8J6

J7

MADE IN JAPAN

S3

S6 S4 S5

-10-

2CD-7713v1/GDB5F40

Instructions Manual

【】Driver block

J6, J8 These are connectors to connect +24 V power supply for drivers.

The power shutdown can turn the power supply on and off independently of the power supply

in the controller's part.

J6 is the one for the X-axis, and J8 is the one for the Y-axis.

J7, J9 These are connectors to connect a motor.

J7 is the one for the X-axis, and J9 is the one for the Y-axis.

S3, S7 These are switches that sets for the motor driver each.

()Please refer to the setting at chapter 3. for the details.

S3 is the one for the X-axis, and S7 is the one for the Y-axis.

S4, S8 These are DRIVE I. SEL DRIVE current selection switch.()

S4 is the one for the X-axis, and S8 is the one for the Y-axis.

S5, S9 These are STEP SEL STEP ANGLE selection switch.()

S5 is the one for the X-axis, and S9 is the one for the Y-axis.

S6, S10 These are HOLD I. SEL HOLD current selection switch.()

S6 is the one for the X-axis, and S10 is the one for the Y-axis.

Driver LED POWER LED Green color turns on at the time of power on state the X-axis and Y-axis of()

POWER, O.H.A each axis.()

O.H.A LED Red color turns on when the driver part overheats and cooling is needed.()

The state of O.H.A can be read from the application by the DALM signal.

()

Base installation These are part that fixes the main unit to the installation base. two places

part Use the M3 or M4 screw.

Connector for This is a connector for adjustment of the main unit.

adjustment Do not connect anything.

This is surface of heat radiation in the driver part.

Set up so that this surface may stick to a metallic panel.

-11-

2CD-7713v1/GDB5F40

Instructions Manual

Specifications2.

2-1. General specifications

No. Item Specifications

●(±)1 Supply voltage Contoroller power supply :DC +24 V less than 10 % of the power supply voltage

●()Driver power supply :DC +24 V less than rippled voltage 2.0 V p-p

2 Power consumption Contoroller power supply :350 mA or less *1●Driver power supply *2 :●Current rating/axis at DRIVE DRIVE I. SEL No. F setting : 2.0 A/axis・〔⇒〕

Current rating/axis at HOLD HOLD I. SEL 40 % setting : 0.4 A/axis・〔⇒〕

*1 The value when the main body supplies the power supply for the sensor is indicated.

The main body current consumption is 110 mA.

Example: at the sensor of the current consumption 25 mA

4 25 mA 2 axes 110 mA 200 110 310 mA( × × )+ =+=pieces

The totaled current consumption must not exceed 350 mA.

*2 Use a power supply that provides sufficient driver consumption current.

・℃〜+ ℃3 Operating ambient 0 40

・% ( )temperature and 80 RH or less without dew condensation

humidity

・℃〜+ ℃4055Storage temperature ・% ( )and humidity 80 RH or less without dew condensation

5 Installation Inside a well-ventilated cabinet installed indoor, free from direct sunlight.・

environment Not exposed to corrosive and flammable gasses, and not affected by oil mist,・dust,salt, iron powder, water, and chemicals.

Not subject to constant vibration or excessive shock.・Not affected by electromagnetic noise caused by power equipment.・Free of radioactive materials and magnetic fields, and not in vacuum.・

()6 Dimensions W 45.7 × H 87.5 × D 170 mm

7 Weight Approx. 0.6 kg

2-2. Communication specifications

No. Item Specifications

Ⅱ・ ()1 AL- interface Conformity standard :RS485 insulation type

Transmission protocol :Protocol for AL- communication・Ⅱ

・〜( 〜)Slave connection number :1 15 slave slave address setting range: H' 1 H' F

()()・Wiring distance/baud rate :100 m 10 Mbps / 50 m 20 Mbps

・( )2 Extend interface Conformity standard :RS485 non-insulation: but there is insulation with +24 V.

Connection number :Up to one unit・Wiring distance/baud rate :1 m/5 Mbps・

-12-

2CD-7713v1/GDB5F40

Instructions Manual

2-3. Specifications

1 Controller part()

Basic Specifications●

No. Item Specifications

1 Pulse output Output frequency 0.1 Hz to 1 MHz

function ()Acceleration/deceleration 5000 ms/kHz to 0.0025 ms/kHz Trapezoid/S-curve

time constant

Acceleration/deceleration Trapezoid・

・( )shape S-curve This feature enables to set asymmetrical shape.

Triangular drive prevention During S-shaped acceleration/deceleration drive, INDEX drive may end

function before the maximum speed is reached.

In this event, triangular drive can be automatically avoided.

Number of output pulses JOG drive : -65,535 to +65,535 pulse・SCAN drive : Up to infinite pulses・INDEX drive : -2,147,483,647 to + 2,147,483,647 pulses・

2 Drive function JOG drive Pulses are constantly output until the specified pulses.

SCAN drive Pulses are continuously output until a stop command is detected.

INDEX drive Pulses are output until the specified relative or absolute address is

reached.

ORIGIN drive The specified drive processes are performed.

This drive is finished when the ORG signal specified edge is detected.

2-axis linear interpolation Linear interpolation is performed toward the specified coordinates from・

drive the current coordinates.

Driving type is selected from INDEX drive or SCAN drive.・Positional errors for the specified straight line are 0.5 LSB.・±

The absolute and relative addresses that can be specified for・coordinates range from -2,147,483,647 to +2,147,483,647 32 bits .()

Linear speed constant Control is performed to keep the synthesized speed of the two axes

control working for interpolation drive constant.

3 Stop function Slow stop function SLOW STOP command・Detection of a match of the comparator of each counter.・Deceleration stop by overheating warning of driver.・

Immediate stop function FAST STOP command・

・()FSSTOP signal two axes stop

Detection of a match of the comparator of each counter.・Immediatestopbyoverheatingwarningofdriver.・

LIMIT signal direction stop●+

Immediate stop by CWLM signal and slow stop can be selected.・Slow stop or immediate stop can be performed for each axis upon・detection of a match of the comparator COMP2 of each counter.()

direction stop●-

Immediate stop by CCWLM signal and slow stop can be selected.・Slow stop or immediate stop can be performed for each axis upon・detection of a match of the comparator COMP3 of each counter.()

4 Counter ADDRESS COUNTER 32-bit counter that manages absolute addresses by counting drive output

function pulses.

PULSE COUNTER 32-bit counter that counts the drive pulse output.

Comparator function Detection of a match of the three comparators of each counter.

Upon detection of a match by the comparator, pulse output can be・decelerated and then stopped, or stopped immediately.

Upon detection of a match by the comparator, status can be read.・

AUTO CLEAR function The counter can automatically be cleared upon detection of a match of

COMP1 of each counter.

AUTO ADD function If the counter value reaches the COMP1, a value that is set by the data

add to COMPARE REGISITER1 of each counter.

-13-

2CD-7713v1/GDB5F40

Instructions Manual

No. Item Specifications

5 Other Data reading function Current status information can be read in real time.

functions Current status information includes status data, count data of a counter

etc.

General-purpose I/O Two points of input/output are prepared as general purpose I/O.

Applied functions●

No. Item Specifications

1 Drive function PLS INDEX CHANGE function Upon detection of the PLS INDEX CHANGE command,

the system performs PLS INDEX drive by setting the specified

data at the stop position of the relative address for which the

start position is the origin.

INDEX drive control the start This function is allowed to set OFFSET of the start point at auto

point at auto deceleration deceleration.

This function can be used when INDEX drive, liner interpolation

and INDEX drive.

2 Counter function Count data latch/clearance This function latches count data of a counter at a specific latch

function timing and holds it till the next latch timing.

Each counter can latch counter value at arbitrary timing.

It is possible to clear a counter value at the latch timing.

IN0 signal: for X-axis

IN1 signal: for Y-axis

3 Other functions Command reservation function Each axis has a reservation register that can store data

commands for ten instructions.

General-purpose commands of drive commands can be・reserved in the reservation register.

After the command being executed is finished, the commands・stored in the reservation register are executed sequentially.

Then this function can be allowed continuous drive.

Input signal logical switch The logic of the following input signals can be changed:

function CWLM signal・CCWLM signal・FSSTOP signal・

Please refer to the chapter of the AL- series device driver manual application function for details※Ⅱ

of applied specification.

-14-

2 Driver part()

No. Item Specifications

1 Motor output DRIVE current: 0.3 A/phase 1.35 A/phase●〜

●()current HOLD current: Approx. 40 % of DRIVE current value factory-set

Can set the DRIVE current with a DRIVE I. SEL switch in conformity to an application motor.

In addition, user can set the HOLD current by the ratio approx. 10 % - 100 % with the DRIVE()

()current by an HOLD I. SEL switch. It is approx. 40 % at the time of factory-set

2 Resolution of step At S.T SEL1●

angle /STEP 0.72/ 0.36/ 0.18/ 0.072/ 0.036/ 0.018/ 0.0072/ 0.0036/ 0.0018/ 0.0009/(゜ ) 0.00072/ 0.00036/ 0.00018

At S.T SEL2●0.09/ 0.045/ 0.009/ 0.0045

The above-mentioned resolution can be selected by step table selection S.T SEL and step()

angle selection STEP SEL .()

Moreover, the resolution set with the switch by the C.S signal operation from the application

canbeswitchedto0.036 step.゜

The motor can be driven at high speed by switching the C.S signal from the application when・the setting of resolution is high.

3 Motor excitation The stepping motor output current can be intercepted by the M.F signal operation from the

current ON/OFF application. As a result,

The manual operation of the machine can be done.・Generation of heat of the motor can be lowered.・

At this time, the holding torque of the motor is lost.

CAUTION

Deterioration of the holding power with the motor may cause breakage of the machine or

injury. Check safety before inputting.

When this signal is input, motor torque may be lost, resulting in failure to retain the load

transported. In particular, this risk is high with the vertical drive such as the Z-axis .()

4 Hold switching time DRIVE/HOLD current automatic switchingtimeissetupwiththeDHTSELswitch.

select There is a possibility to become heat decrease of the motor when the stop time・of the drive is short.

5 Warning of When the temperature in the unit reaches at the temperature approx. 70 for which cooling(℃)

overheat is necessary, driver alarm signal DALM status is outputted.()

Moreover, LED of overheating warning O.H.A: Red color is lighted.()

Consecutive driving is possible in the range where this signal is not output.・The motor output current is not intercepted at the time of ON this signal.・When DALM is enabled by the setting of the controller's department, the motor can be・stopped automatically.

WARNING

May be fired by overheat.

When this signal output, please stop driving.

Confirm whether abnormality occurred at the motor and the product.

When this signal is turned on with abnormality not found, please enlarge the installation base

or give cooling of the forced air cooling etc.

6 P.O detection The P.O signal is generated only once in the pulse number hit that rotates by 7.2 by setting°

each resolution.

When this signal is set as a origin detection signal of the controller's department, a highly

accurate machine origin point can be detected.

2CD-7713v1/GDB5F40

Instructions Manual

-15-

2CD-7713v1/GDB5F40

Instructions Manual

2-4. Input and output signal table

() ( )1 Serial communication connector J1, J2

●()

12345678 12345678

Connector :RJ-45 Shield type

●□□□□(〜)Recommendation cable :KB-STP- L : length 30 m or less

()Made by Sanwa Supply: It is not an accessory.

Reference

For more information about a cable preparing in the

AL- series and a recommended cable, refer to theⅡ

instruction manual of "connection / others" .

No. Signal name DescriptionDirection

1 N.C Connection is prohibited.−

2 N.C Connection is prohibited.−

()3 I/O +AL Ⅱ+ side input/output signal of the serial data line driver positive logic

Ⅱ()4 I +V Power supply for AL- communication +6 V

Ⅱ()5 I -V GND for AL- communication 0 V

()6 I/O -AL Ⅱ- side input/output signal of the serial data line driver negative logic

7 N.C Connection is prohibited.−

8 N.C Connection is prohibited.−

J1 and J2 are the same terminal arrays. It is possible to connect with either.・When the multidrop is connected, the divergence connection is done to other slave equipment through・J1 or the J2 connector.

() ( )2 Sensor connector J3: X-axis, J4: Y-axis

●()Connector : 53426-0610 Molex

●()Conformity connector : 51103-0600 Molex: accessories

●()Conformity contact : 50351-8100 Molex: accessories

●()Conformity crimp tool : 57295-5000 Molex

Acceptable wire : AWG28 AWG22●〜

(φ〜φ)Coating 1.15 1.8

()Contact insertion side

()For shield connection M2.6 tap

No. Signal name DescriptionDirection

() ( )1 I CWLM + CW direction LIMIT signal B contact

() ( )2 I CCWLM - CCW direction LIMIT signal B contact

3 I NORG Machine origin proximity signal

4 I ORG Machine origin signal

5 GND Power supply GND for sensor−()

6 O EXTVCOM+ Power supply +24 V for sensor()

The sensor connector is the same terminal array in both X-axis and Y-axis.・The default values of the LIMIT signal of each axis are ACTIVE OFF input B contact .・()

()The pulse is not output if it doesn't connect into the status of NORMAL ON GND connection

when signal unused.

+24 V power supply GND and internal can be connected , and can use as power supply GND for return GND・of sensor.

GND and +24 V power supply GND is mutually connected internally.・These can be used as power supply GND for return GND and sensor.

It can supply EXTVCOM+ as a power supply for sensor to the +24 V Max 150 mA/axis.・()There is an overcurrent protection circuit.

When user drops the shield of a cable for sensor, user uses a terminal in the sensor connector side,・and please connect it.

1

1

J3SENSOR/X J4 SENSOR/Y

1123456

J2J1

-16-

2CD-7713v1/GDB5F40

Instructions Manual

() ( )3 Controller power supply connector J5

●()Connector : 53426-0310 Molex

●()

()Contact insertion side Conformity connector : 51103-0300 Molex: accessories

●()Conformity contact : 50351-8100 Molex: accessories

●()Conformity crimp tool : 57295-5000 Molex

Acceptable wire : AWG28 AWG22●〜

(φ〜φ)Coating 1.15 1.8

Conformity cable : CE-76/003C10-51103●()1 m: It is not an accessories.

No. Signal name DescriptionDirection

1 I +24 V DC +24 V power supply

2 GND GND of +24 V power supply−

3 F.G Frame GND is connected with case.−

() ( )4 Driver power supply connector J6: X-axis, J8: Y-axis

●()Connector : 53259-0229 Molex

●()Conformity connector : 51067-0200 Molex: accessories

●()Conformity contact : 50217-9101 Molex: accessories

●()Conformity crimp tool : 57189-5000 Molex

Acceptable wire : AWG24 AWG18●〜

(φ〜φ)Coating 1.4 3.0

Conformity cable : CE-48/002C10-51067●()

()Contact insertion side 1 m: It is not an accessories.

No. Signal name DescriptionDirection

1 I +24 V DC +24 V power supply

2 GND GND of +24 V power supply−

The driver power supply is independent with the controller power supply.・The driver power supply of X-axis and Y-axis is independent with each axis.・

() ( )5 Motor connector J7: X-axis, J9: Y-axis

●()Connector : 53259-0529 Molex

●()Conformity connector : 51067-0500 Molex: accessories

●()Conformity contact : 50217-9101 Molex: accessories

●()Conformity crimp tool : 57189-5000 Molex

Acceptable wire : AWG24 AWG18●〜

(φ〜φ)

()Contact insertion side Coating 1.4 3.0

Conformity cable : CE-50/005C10-51067●()1 m: It is not an accessories.

No. Signal name DescriptionDirection Example of motor lead color Example of motor lead color

1 O A-phase VIO/BLU BLK

2 O B-phase RED/GRY GRN

3 O C-phase BLK/YLW ORN

4 O D-phase WHT/ORN RED

5 O E-phase GRN/BRN BLU

The motor connector is the same terminal array in both X-axis and Y-axis.・The display according to the color is a lead wire color of motor.・

DC+24V

J5

1

1123

J6

DC+24V/X DC+24V/Y

J8

11

12

J7

MOTOR/X J9

MOTOR/Y

11

12345

-17-

2CD-7713v1/GDB5F40

Instructions Manual

() ( )6 General-purpose I/O connector J10

●()Connector : 53426-0710 Molex

●()Conformity connector : 51103-0700 Molex: accessories

●()Conformity contact: : 50351-8100 Molex: accessories

●()Conformity crimp tool : 57295-5000 Molex

Acceptable wire : AWG28 AWG22●〜

(φ〜φ)Coating 1.15 1.8

()Contact insertion side

No. Signal name DescriptionDirection

−()1 R.GND Return GND of each signal for +24 V interface

()2 I FSSTOP Immediate stop signal of both X-axis and Y-axis B contact

3 I IN0 General-purpose input 0

4 I IN1 General-purpose input 1

5 O OUT0 General-purpose output 0

6 O OUT1 General-purpose output 1

7 N.C Connection is prohibited.−

The default values of the FSSTOP signal is ACTIVE OFF input B contact .・()

()The pulse is not output if it doesn't connect into the status of NORMAL ON GND connection

when signal unused.

() ( )7 Extend I/O communication connector J11

●()Connector : 1565994-4 e-CON:Tyco Electronics

●()Conformity cable : CE-66-01/IO-A03 0.3 m, It is not an accessories.

(): CE-66-02/IO-A10 1 m, It is not an accessories.

No. Signal name DescriptionDirection

()1 I/O +RS485 EXT() + side signal of the Extend I/O serial data Line driver positive logic

()2 I/O -RS485 EXT() - side signal of the Extend I/O serial data Line driver negative logic

3 S.G Signal GND for Extend I/O−

4 F.G Frame GND is connected with case.−

Number of Extend I/O that can be connected from J11 is one unit.・

J10

1

112 3 4567

1

J11

-18-

2CD-7713v1/GDB5F40

Instructions Manual

2-5. Input and output specifications

1 Output specifications()

Circuit Description

Signal name OUT0, OUT1

Interface+24 V +24 V

voltage

Nch transistor

Output method

OUT0,OUT1 Open collector output←

Lamp ON/OFF

Max. 30 mA ()Photocoupler

etc. (= )

ON : 30 mA Vce 1 V or less

Output current

R.GND (= )50 mA Vce 2 V or less

OFF : 0.1 mA or less

Common for OUT0 and OUT1 Output 1 ms or less

(→、→)response time ON OFF OFF ON

Photocoupler isolation

Insulation ()Between internal circuits and external circuits.

2 Input specifications()

Circuit Description Sensor faction●

Signal name ORG, NORG, CWLM, CCWLM *1

+24 V ()EXTVCOM+ EXTVCOM+ can be supplied by 24V for the sensor: Up to 100mA

24 V 2 V or less〜

±General-purpose faction

()Polyswitch Max. 100 mA ●

IN0 , IN1

Sensor faction

●Other6.8 K Ω●

Photocoupler R.GND

FSSTOP *1

Interface+24 V +24 V

voltage

Input

●General-purpose Ω

faction 6.8 K

impedance

FSSTOP

●ON/OFF ON : 2.5 mA or more6.8 K Ω

Photocoupler R.GND

level OFF : 0.8 mA or less

Input 1 ms or less

The sensor system is each axis and a common specification. (→、→)response time ON OFF OFF ON

()The general purpose faction and additionally FSSTOP is excluded. Photocoupler isolation

Insulation ()Between internal circuits and external circuits.

1 The default value of each axis LIMIT signal and the FSSTOP signal is the ACTIVE OFF input B contact .*()

()The pulse is not output if it doesn't connect it in the state of NORMAL ON GND connection

when it is signal unused.

・()The logic of B contact input can be switched to A contact input. Applied function

-19-

2CD-7713v1/GDB5F40

Instructions Manual

2-6. Outside dimensions

General tolerance 0.5 mm or less±

Externals tolerance 1 mm or less±

J1 J2

J11

S7

S10 S8 S9

J9

J10 J3 J4 J5

J8J6

J7

MADE IN JAPAN

S3

S6 S4 S5

151.6

160

170

22.9

39.9

45.7

4.5

83.3

(16)

(35)

60600501

2CD‑7713v1/GDB5F40

Made in Japan

Model name seal

(Dimension of installation for user)

(Dimension of

installation for user )

(Dimension of installation for user )

2-M3

(Also M4 is possible)

87.5

-20-

2CD-7713v1/GDB5F40

Instructions Manual

Setting3.

3-1. Setting of the controller part

1 Installation of device driver for Windows()Device driver for Windows is necessary to operate this product.

Please refer to the installation manual attachment to a exclusive use device driver MPL-34-01vx.xx/AL2W32 or・ 「

MPL-35-01vx.xx/AL2W64 for details of the installation method.」

Please refer to the PCI master manual of the AL- series when it sets and operating by using application・Ⅱ

MAP-19-01vx.xx.

* Version No. Please confirm the latest version of vx.xx at the manual of the device driver,…and MAP-19 application.

() Ⅱ ( )2 Address setting of the AL- series S1

The slave address of the AL- communication is set with dip switch S1.Ⅱ

The master address is H' 0 fixation. And, please set not to overlap the address of each slave unit.

4321

ADDRESS SWITCH No.

OFF OFF OFF OFFSetting is prohibited.

H' 1 OFF OFF OFF ON Factory-set←

H' 2 OFF OFF ON OFF

H' 3 OFF OFF ON ON

H' C ON ON OFF OFF

H' D ON ON OFF ON

H'E ONONONOFF

H'F ONONONON

When turning on power, the setting of S1 becomes effective.・Set switch while turning off the power supply.

And, turn on the power supply after the setting change.

() Ⅱ ( )3 Baud rate setting of the AL- series S2

The baud rate of the slave units of AL- communication is set with dip switch S2.Ⅱ

Set to masters the baud rate by an Environment-function.

And, set the same transmission rate as master to all slave units connected with the AL- series by the dip switch S2.Ⅱ

4321

RATE SWITCH No.

OFFOFFOFFOFFSetting is prohibited. OFFOFFOFFONSetting is prohibited.

10 Mbps OFF OFF ON OFF

20 Mbps OFF OFF ON ON Factory-set←

Turn off the 3rd and 4th bit of S2. These are the set prohibition.・When turning on power, the setting of S2 becomes effective.・Set switch while turning off the power supply.

And, turn on the power supply after the setting change.

ADDRESS

N

O

1

2

3

4

RATE

N

O

1

2

3

4

This manual suits for next models

11

Table of contents

Other M-Elec Controllers manuals

M-Elec

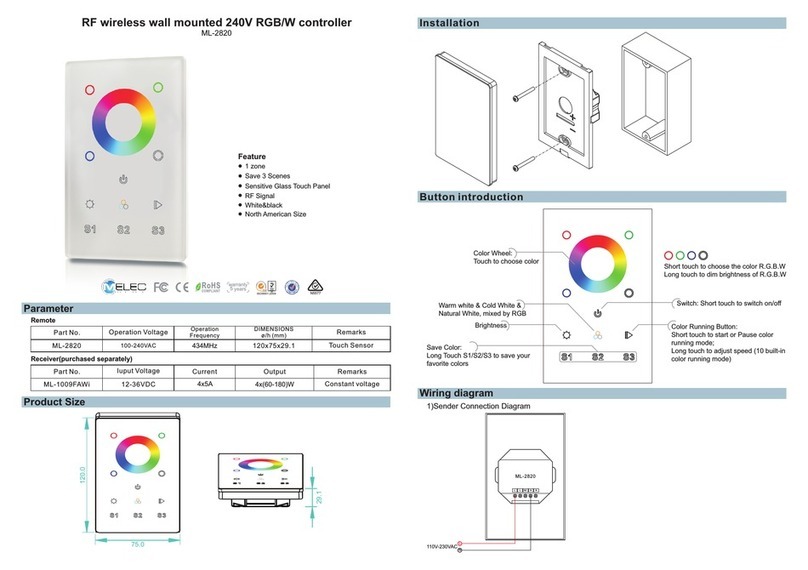

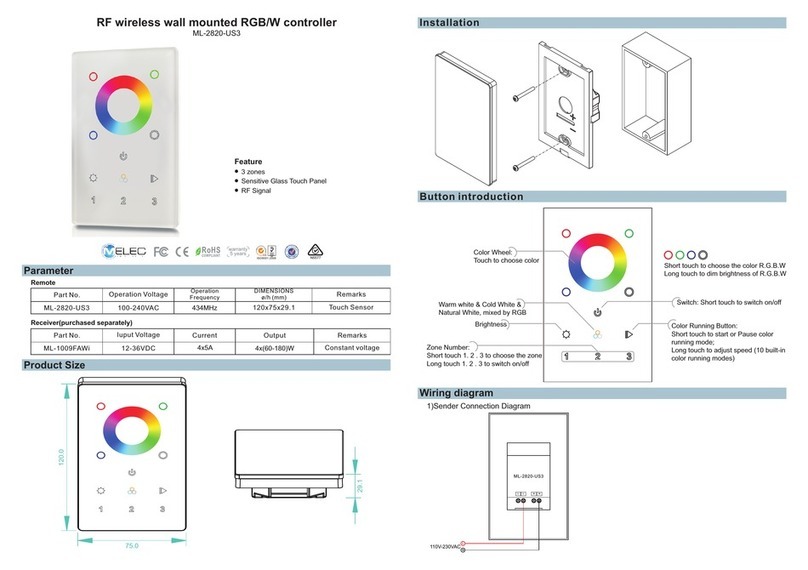

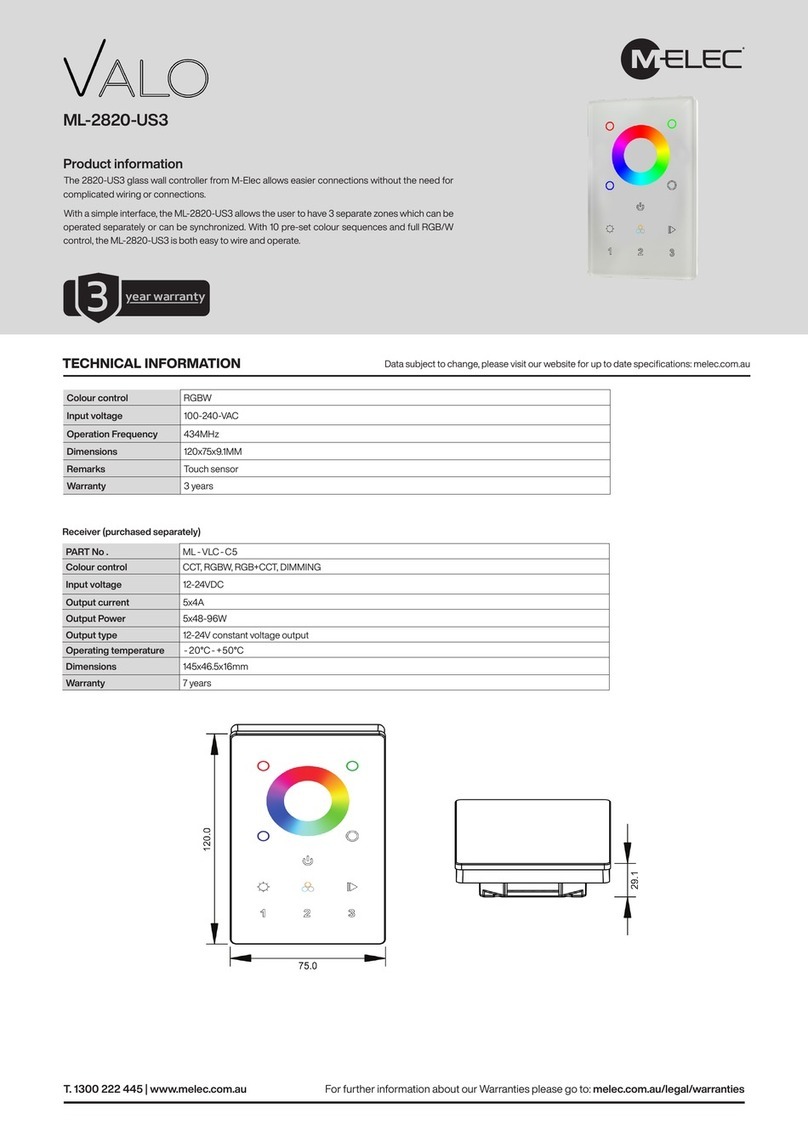

M-Elec ML-2820-US3 User manual

M-Elec

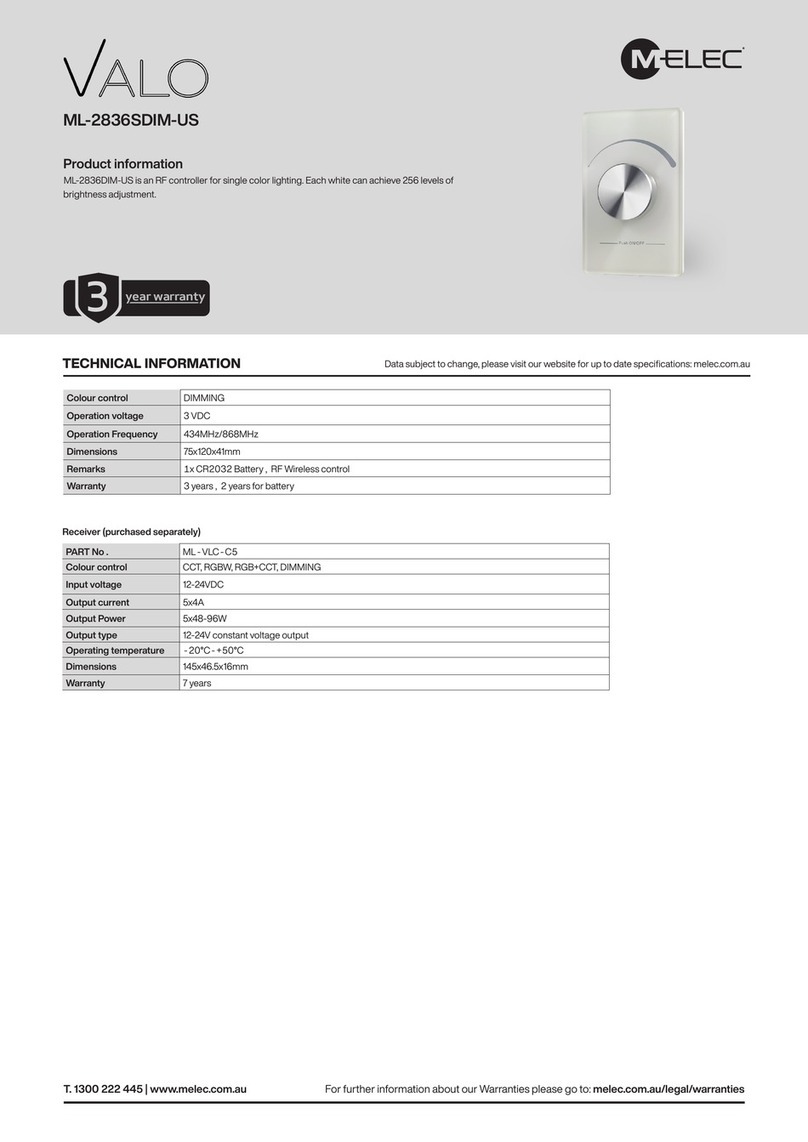

M-Elec VALO ML-2836SDIM-US User manual

M-Elec

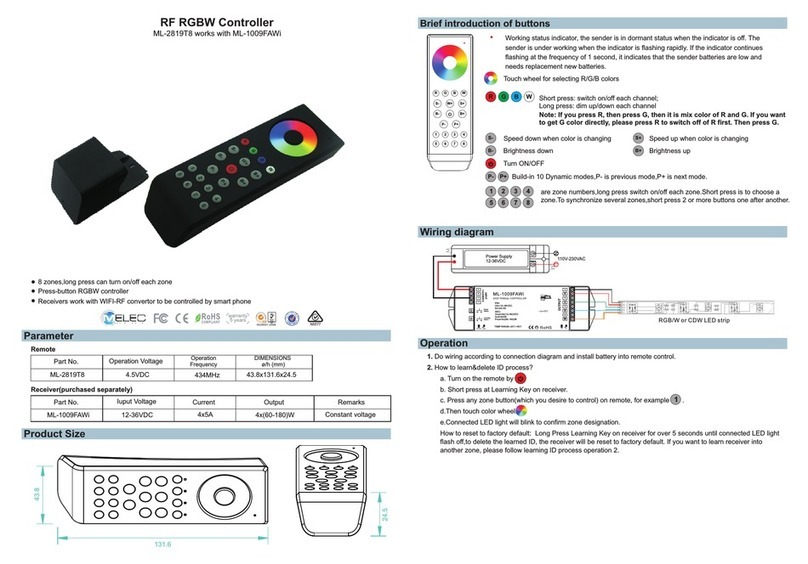

M-Elec ML-2819T8 User manual

M-Elec

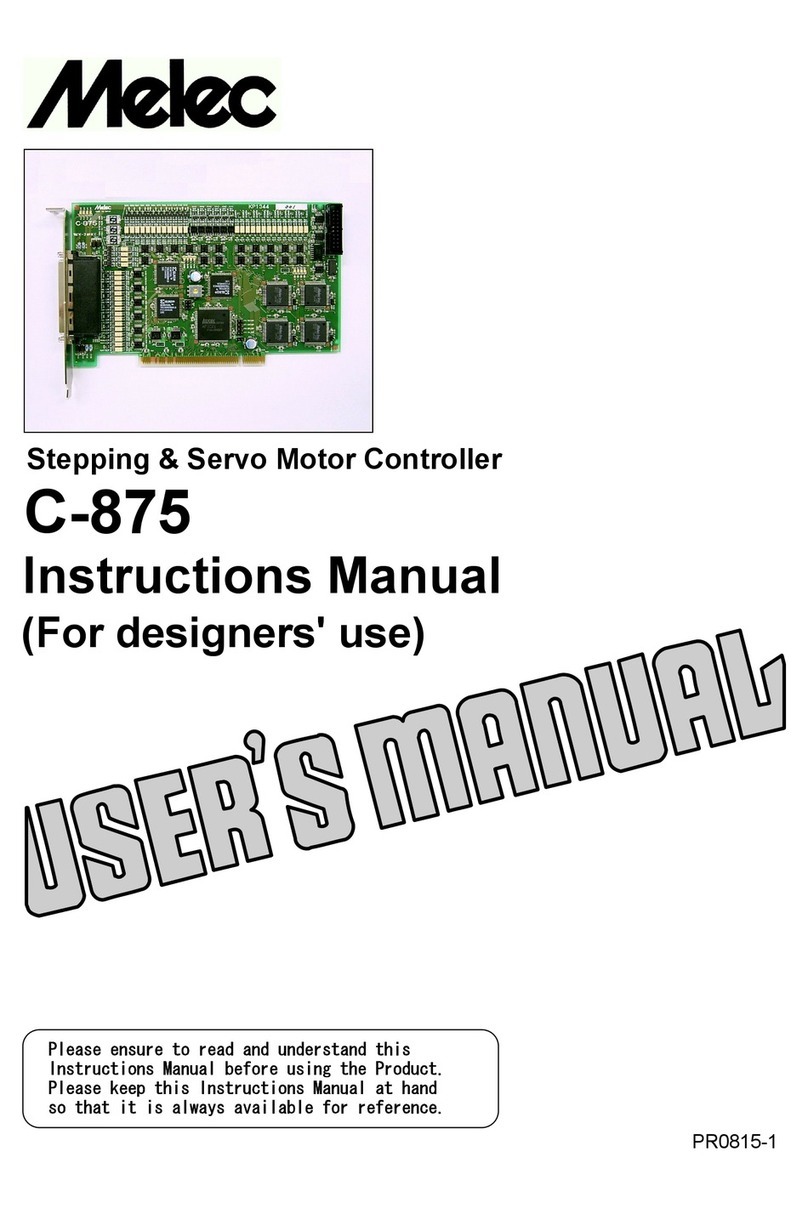

M-Elec C-875 User manual

M-Elec

M-Elec DB-2310/B32 User manual

M-Elec

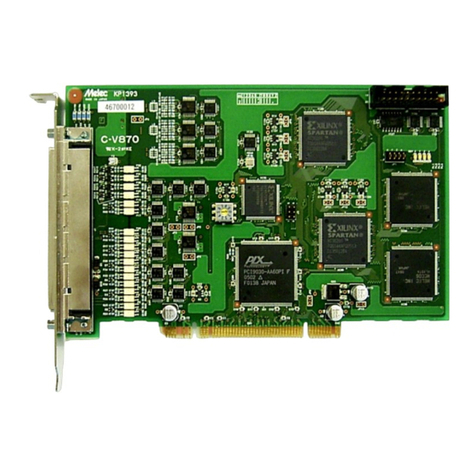

M-Elec C-V870 User manual

M-Elec

M-Elec Valo ML-2820-US3 User manual

M-Elec

M-Elec AL-II Series User manual

M-Elec

M-Elec ADB-2F60B User manual

M-Elec

M-Elec C-VX875 User manual

Popular Controllers manuals by other brands

Karl Suss

Karl Suss CIC 1200 manual

Pontec

Pontec PondoSolar 250 Control operating instructions

ESP Safety

ESP Safety UPES-50D operating manual

Bernard

Bernard LE Series Installation, start-up and maintenance instructions

AXIOMATIC

AXIOMATIC AX032200 user manual

Mitsubishi

Mitsubishi AL2 Series Programming manual