SSI Single Gas Analyzer for H2 User manual

Single Gas Analyzer for H2

OPERATIONS MANUAL

Super Systems Inc.

7205 Edington Drive

Cincinnati, OH 45249

513-772-0060

Fax: 513-772-9466

www.supersystems.com

Super Systems Inc.

Page 2 of 44

Super Systems Inc.

USA Office

Corporate Headquarters:

7205 Edington Drive

Shipping Address:

7245 Edington Drive

Cincinnati, OH 45249

Phone: (513) 772-0060

http://www.supersystems.com

Super Systems Europe

Unit E, Tyburn Trading Estate,

Ashold Farm Road, Birmingham

B24 9QG

UNITED KINGDOM

Phone: +44 (0) 121 306 5180

http://www.supersystemseurope.com

Super Systems México

Sistemas Superiores Integrales S de RL de CV

Acceso IV No. 31 Int. H Parque Industrial

Benito Juarez

C.P. 76120 Queretaro, Qro.

Phone: +52 442 210 2459

http://www.supersystems.com.mx

Super Systems China

No. 369 XianXia Road

Room 703

Shanghai, CHINA

200336

Phone: +86 21 5206 5701/2

http://www.supersystems.cn

Super Systems India Pvt. Ltd.

A-26 Mezzanine Floor, FIEE Complex,

Okhla Indl. Area, Phase –2

New Delhi, India 110 020

Phone: +91 11 41050097

http://www.supersystemsindia.com

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 3 of 44

Page 3 of 51

Table of Contents

Introduction..................................................................................................................................... 5

Oxygen Measurement Option (with Additional Sensor) .............................................................. 5

Specifications.................................................................................................................................. 5

Single Gas Analyzer (SGA)........................................................................................................... 5

Mechanical Diagrams ..................................................................................................................... 6

Initial Network Configuration ......................................................................................................... 7

nLocateIP Method ....................................................................................................................... 7

Touch Screen Interface................................................................................................................... 8

Main Screen................................................................................................................................. 8

Menu Screen ............................................................................................................................... 8

Trend Chart ................................................................................................................................. 9

Chart Sub Menu..........................................................................................................................11

Instrument Information (Menu Option) ......................................................................................11

Pump Control (Menu Option)......................................................................................................12

Instrument Configuration (Menu Option) ...................................................................................12

Output Configuration..................................................................................................................13

Communications (Menu Option).................................................................................................14

Alarms Setup..............................................................................................................................15

Output Calibration (Menu Option)...............................................................................................16

Overview..................................................................................................................................16

Zero Calibration......................................................................................................................16

Span Calibration .....................................................................................................................17

Sensor Calibration (Menu Option)..............................................................................................17

Zero Calibration Procedure....................................................................................................18

Span Calibration Procedure ...................................................................................................18

Digital IO Card (Menu Option).....................................................................................................19

Oxygen Units (Menu Option) .......................................................................................................19

Passcodes (Menu Option)...........................................................................................................19

H2 Gas Display Settings .............................................................................................................20

Exit Program (Menu Option).......................................................................................................20

Control Interface via a Web Browser.............................................................................................21

Main............................................................................................................................................21

Instrument Information..............................................................................................................22

Sensor Information ....................................................................................................................23

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 4 of 44

Page 4 of 51

Instrument Configuration...........................................................................................................24

Output Configuration..................................................................................................................25

Output Calibration ......................................................................................................................26

Sensor Calibration......................................................................................................................27

Alarms........................................................................................................................................28

SSI Configuration .......................................................................................................................29

Read/Write Registers.................................................................................................................30

Network Configuration...............................................................................................................31

Modbus Registers ..........................................................................................................................32

Replacement Parts ........................................................................................................................39

Warranty.........................................................................................................................................40

Revision History .............................................................................................................................41

Appendix A –Electrical Diagrams .................................................................................................42

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 5 of 44

Page 5 of 51

Introduction

SSi provides single gas analysis technology for use in heat treating and other production

environments. This manual covers the following product line used for the analysis of single gas

composition:

Single Gas Analyzer (SGA). The SGA includes a color touch screen and detection cell with

intelligent electronics contained in a metal enclosure designed for rugged industrial

environments. The SGA is preconfigured for detection of H2, CO, CO2, or CH4, depending

on customer needs. Trend charting is available via the touch screen. Control and

monitoring are possible with the touch screen interface and Ethernet-based web

interface. The SGA also includes onboard datalogging and communications via serial

connection, USB, or Ethernet.

Oxygen Measurement Option (with Additional Sensor)

The SGA provides the option of O2detection and monitoring with the addition of an external O2

sensor wired into the unit.

Specifications

Gas Measurement Specifications

H2Sensor

Range

0 –100%

Accuracy

±0.1%

Resolution

±0.1%

Measurement Method

Thermal Conductivity

O2Sensor (Add-On Sensor, Mounted Externally)

Range

0 - 21%

Accuracy

±0.1%

Measurement Method

Lambda Zirconia

Single Gas Analyzer (SGA)

Response Time

0 –6 seconds

Power Supply Input Voltage

110VAC or 230VAC

Maximum Operating Temperature

122 °F (50 °C)

Analog Outputs

2 (4-20mA or 0-5 V)

Serial Communications

2 RS485 ports using Modbus RTU,

configurable baud rate

Ethernet

1 port

USB

1 Type A port, 1 Type B port

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 6 of 44

Page 6 of 51

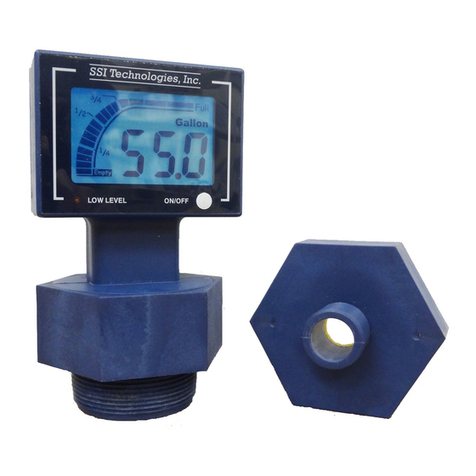

Mechanical Diagrams

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 7 of 44

Page 7 of 51

Initial Network Configuration

This section is intended for use by persons familiar with Ethernet network setup.

In order to work correctly, the unit must be properly configured for the network to which it is

connected. To locate the unit’s IP address, first connect the unit to an Ethernet network using

the appropriate cable.

If you already know the IP address of the web interface, skip to the

The Read/Write Registers page gives access to the underlying Modbus registers of the SGA.

This page is primarily intended for testing and troubleshooting purposes.

Please contact SSi before attempting to make any changes to the settings on this page.

Network Configuration section on page 30. The network configuration is described in this

section.

The IP address of the unit can be found by using SSi’s

nLocateIP

software. This method is

described in the following subsection.

nLocateIP Method

Once the unit is connected to the network, you should be able to locate it on the network using

SSi’s

nLocateIP

software. This program is available from SSi. To use it in locating the unit on

the network, follow these steps on a Windows-based PC:

1. Ensure that the unit is connected to the

network.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 8 of 44

Page 8 of 51

2. Open the

nLocateIP

program.

Figure 1 - Opening nLocateIP program

3. Once the program opens, click the Search

button. The program will begin searching

for SSi devices connected to the network.

Figure 2 - Search button in nLocateIP

4. Look for identifying text in the list of

instruments. The corresponding IP address

is the IP address that you will want to use.

Once you have found the IP address, you should be able to complete any additional network

configuration using the web interface. See the

The Read/Write Registers page gives access to the underlying Modbus registers of the SGA.

This page is primarily intended for testing and troubleshooting purposes.

Please contact SSi before attempting to make any changes to the settings on this page.

Network Configuration section on page 30.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 9 of 44

Page 9 of 51

If you are unable to find the unit in the list of devices, it is possible that a network setting (such

as subnet mask) may be different, the unit may be connected to a different network, or the unit

may not be powered on. SSi recommends consulting an IT engineer or network administrator.

If needed, call SSi at (513) 772-0060.

Touch Screen Interface

Main Screen

The Main screen shows the current percentage of H2. From here the user can enter the Menu

screen or the Chart screen.

Menu Screen

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 10 of 44

Page 10 of 51

The Menu screen also allows the user to log in to gain access to additional functions. Pressing

the Login key at the bottom of the screen will allow the user to enter a login user and password.

User names and passwords are case sensitive. There are three levels of security for the menu

system: Operator, Supervisor, and Administrator. Pressing the Login button will allow the user

to enter a user name and numeric password to log in. When the menu screen is first displayed,

the operator-level menu options are visible. The supervisor menu options will be displayed with

the login number 1. The Administrator menu options will be displayed with the login number 2.

The Menu options are described beginning on p.11.

Trend Chart

The Trend Chart Display shows between 1 hour and 24 hours of process variable data on the

screen and can be scrolled back to view all of the data stored on the hard drive. The vertical

timelines change as the time changes on the screen.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 11 of 44

Page 11 of 51

The function buttons run along the bottom of the screen.

The folder button - - stores saved templates. A different chart template can be selected here.

The Trend Lines button - - will allow the user to select or de-

select the trend lines on the trend chart to display. If the checkbox

next to each trend line is checked, then that trend line will be

displayed.

The Datagrid View button - - will display a screen with the

trend data in a grid format instead of with trend lines. The trend data is shown in 1-minute intervals.

Clicking on the OK button on this screen will close the screen down and return to the Chart Display screen.

The Refresh button - - will refresh the screen’s trend data if the screen is not in real-time mode.

The left-pointing green arrow button - - will move the chart’s view backward in time by the specified

chart interval.

The chart interval button - - will determine the number of hours displayed on the trend chart. The

options are: 1 Hour, 2 Hours, 4 Hours, 8 Hours, 12 Hours, or 24 Hours.

The right-pointing green arrow button - - will move the chart’s view forward in time by the specified

chart interval.

The Play/Pause button - - will put the chart into real-time mode if it is not in real-time mode, or

take the chart out of real-time mode if it is. When in real-time mode, the chart will automatically be updated

once a minute.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 12 of 44

Page 12 of 51

Chart Sub Menu

There is a sub-menu available by putting a finger or a stylus anywhere on the chart and holding it there for

two seconds.

The sub-menu will have the following options available: Zoom, Restore, Add Note, Data,

and Exit.

The Zoom option will allow the user to zoom in on a particular part of the screen. Once

this has been selected, the user can take a stylus or a finger and create a box around the

desired data. Once the user releases the stylus or finger, a zoom is no longer possible,

and the user will need to re-select the option from the sub-menu to zoom in again.

The Restore option will back out of any zoom options that have been performed and display the chart screen

as it initially was.

The Add Note option allows the operator to enter a note on the chart, similar to writing on a paper chart.

The note shows up when the chart is printed out using the utility software included with the SGA

instrumentation. Pressing the Add Note option displays a screen where the operator can enter the operator

ID or initials and a note. The user has the option to enter a note using the operator interface keyboard,

where he or she will be able to type in the note; or the user can use the Signature mode, which will allow

them to write a note using a stylus.

The Data option will show the trend data as a data grid instead of the trend lines on a chart. This

functionality is exactly the same as if the user pressed the Datagrid View button - - from the chart

screen.

Exit will close out the sub-menu without selecting an item.

Pressing the red ‘X’ in the top right-hand corner of the screen will take the user back to the status screen.

Instrument Information (Menu Option)

The Instrument Information screen provides basic information about the unit, including

Desciption, Part #, Serial #, Sub Serial #, Main Version #, and Sensor Version #. This

information can be useful for troubleshooting purposes.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 13 of 44

Page 13 of 51

Pump Control (Menu Option)

The Pump Control screen allows the user to turn the pump on or off. The current pump status

will be displayed on the screen. To change the status, tap the “Set Pump” button, select “On” or

“Off,” and tap “Select.” To exit the screen without changing the pump status, tap “Cancel.”

Instrument Configuration (Menu Option)

The Instrument Configuration menu allows the user to set values for various SGA paramaters.

Min. H2 This reading indicates the point at which anything below will be read as zero for

internal calculations.

N2 Flow: The value entered here will be used in nitriding calculations. Enter the

applicable N2 flow in your system.

NH3 Flow: The value entered here will be used in nitriding calculations. Enter the

applicable NH3 flow in your system.

DA Flow: The value entered here will be used in nitriding calculations. Enter the

applicable DA flow in your system.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 14 of 44

Page 14 of 51

H2 Flow: The value entered here will be used in nitriding calculations. Enter the

applicable H2 flow in your system.

CO2 Pres: (0-10) –Any value entered here will be used in place of the actual CO2 reading

for internal calculations. (Zero is the default setting)

Suppress Negative –When activated, any negative readings will be treated as zero.

To change an item, tap the desired row, then tap “Set Value.” Enter the desired value in the

“Input” box and click the “Set Val” button. Your new value will be displayed in the “Current”

column.

Output Configuration

The SGA has two outputs. These can be configured for Source, Zero Value, Span Value, Range,

and Manual.

The Source is the gas that applies to that output.

The Zero Value is the value that corresponds to 4mA on a 4-20mA scale. (4-20mA is the default

Range setting. If Range is set to 0-20mA, then the Zero Value refers to 0mA.)

The Span Value is the value that corresponds to 20mA on a 4-20mA scale. (4-20mA is the

default Range setting. If Range is set to 0-20mA, then the Span Value still refers to 20mA.)

Range allows the user to choose between an output signal of 4-20mA (default) and 0-20mA.

Manual allows the user to enter an output value to test the analog output. In order for this

option to function, Source must be set to External.

To change an item, tap the desired row, then tap “Edit.” Enter the desired value in the “Input”

box (or make a selection from the dropdown menu) and click the corresponding button. Your

new value will be displayed in the “Current” column.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 15 of 44

Page 15 of 51

Communications (Menu Option)

The Communications option allows you to view and change the current IP Address, Mask, and

Gateway for the SGA. To change this information, tap to highlight an item, then tap “Edit” and

use the keyboard screen to enter desired information.

Do not change these values without consulting your IT professional. Doing so could cause IP

conflicts and other network issues.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 16 of 44

Page 16 of 51

Alarms Setup

The Alarms option allows you to set lower and upper limits and assign actions to readings for

the SGA.

Tap to highligh the desired gas type. Then tap the appropriate buttons to enter a Lower Limit

and an Upper Limit. To select an Action, tap “Set Action” to cycle through the available options.

There are four possible actions for the alarms:

“None” will not energize any relays.

“AL1” will energize Relay 3;

“AL2” will energize Relay 4;

“Both” will energize Relays 3 and 4.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 17 of 44

Page 17 of 51

Output Calibration (Menu Option)

Overview

The Output Calibration screen allows the user to perform a zero/span calibration. The SGA is

equipped with two analog outputs. These outputs require calibration to ensure that the mA

signal corresponds to a given output value (zero value for the lowest value and span value for

the highest value). SSi recommends output calibration be performed on each output at least

once per year, or as needed.

To calibrate each output, first make sure that you have a multimeter (or other appropriate

testing instrument) available. Then follow these steps.

Zero Calibration

To calibrate the zero/span range for an output:

1. Attach a measuring device to the selected output.

2. Connect the gas to the “Cal Gas Inlet” on the side of the SGA enclosure. It is recommended

to let everything (gas and SGA) sit for approximately thirty minutes to allow the temperature

to achieve equilibrium.

3. Select “Output Calibration” form the Main Menu.

4. Once this is done, tap to highlight “Zero/Span,” then tap the “Toggle Zero/Span” button to

select “Zero.” “Zero” will now be displayed in the Zero/Span row.

5. To select the desired output, tap to highlight “Output#,” then tap the “Toggle Output

Number” button to select the appropriate setting. The current value will be displayed in the

“Output#” row.

6. Tap to highlight “Prep for Cal” and tap the “Prep for Cal” button.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 18 of 44

Page 18 of 51

7. Let the unit output what it has set for the zero measurement, and note the reading on your

attached measuring device.

8. Tap “Measured value (mA)” and tap the “Edit mA” button.

9. Enter the measured value and tap “OK.”

10. Then, tap “Run Cal” and tap the “Run Cal” button.

Span Calibration

To calibrate the span:

1. Use the “Toggle Zero/Span” button to select “Span.”

2. Tap to highlight “Prep for Cal” and tap the “Prep for Cal” button.

3. Let the unit output what it has set for the span measurement, and note the reading on

your attached measuring device.

4. Tap “Measured value (mA)” and tap the “Edit mA” button.

5. Enter the measured value and tap “OK.”

6. Then, tap “Run Cal” and tap the “Run Cal” button.

Sensor Calibration (Menu Option)

BEFORE YOU BEGIN:

Never perform a span calibration without first performing a zero calibration.

The Zero calibration should be performed with a gas that is not measured by the SGA. Ideally

this would be pure Nitrogen or Argon.

The concentration of the Span calibration gas should closely resemble the gas that is being

measured.

NOTE: Since the accuracy of the calibration gas directly influences the resulting accuracy of the

instrument, the highest possible accuracy grade should be obtained. Some gas suppliers refer

to this as a “Certified Primary Standard”. The high degree of accuracy is not required to obtain

nominal values that exactly match the values shown above. The accuracy is required to know

the exact composition of the gas in the cylinder. The actual composition will be shown on the

bottle when it is delivered.

When flowing calibration gas into the analyzer, turn the pump off. The amount of flow from the

gas cylinder should be approximately 1.5 SCFH at no pressure. The gas cylinders will be under

high pressure, so it is recommended that a two stage regulator with a low pressure secondary

stage be used. It is good practice to begin the flow of gas before attaching the calibration gas to

the instrument. This will prevent any high pressure bursts from entering the instrument.

Calibration gases can be obtained from Super Systems, however they can also be obtained from

any supplier of custom gases.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 19 of 44

Page 19 of 51

Zero Calibration Procedure

1. Connect the gas to the “Cal Gas Inlet” on the side of the SGA enclosure. It is

recommended to let everything (gas and SGA) sit for approximately thirty minutes to

allow the temperature to achieve equilibrium.

2. Select “Sensor Calibration” from the Main Menu.

3. Tap “Zero/Span” and use the “Toggle Zero/Span” button to select Zero.

4. Tap to highlight “Enter Gas Concentration” and tap the “Enter Gas %” button.

5. Enter the appropriate concentration of the calibration gas (in this case 0% since it is a

zero calibration).

6. Begin the flow of gas and allow the readings to come to equilibrium. This occurs when

the actual values are not moving in a specific direction, and they display only slight

movements up and down. This should take approximately 45 seconds.

7. At this point, tap to highlight “Run Calibration” and tap the “Run Calibration” button.

8. The Calibration Timer on the screen will count down, and when it reaches zero the

Current gas value will adjust to match the Gas concentration.

Span Calibration Procedure

1. First tap “Zero/Span” and use the “Toggle Zero/Span” button to select Span.

2. Tap to highlight “Enter Gas Concentration” and tap the “Enter Gas %” button.

3. Enter the appropriate concentration of the calibration gas (see note on p.15).

4. Begin the flow of gas and allow the readings to come to equilibrium. This occurs when

the actual values are not moving in a specific direction, and they display only slight

movements up and down. This should take approximately 45 seconds.

5. At this point, tap to highlight “Run Calibration” and tap the “Run Calibration” button.

6. The Calibration Timer on the screen will count down, and when it reaches zero the

Current gas value will adjust to match the Gas concentration.

Single Gas Analyzer (SGA)

Operations Manual

Super Systems Inc.

Page 20 of 44

Page 20 of 51

Digital IO Card (Menu Option)

The Digital IO Card menu displays Communication Status, Outputs, and Event Inputs. It also

allows the user to set and reset outputs. Tap the Set Output button to turn on an output, or tap

the Reset Output button to turn off an output. Then enter the desired information on the

ensuing screen.

Oxygen Units (Menu Option)

Allows the user to choose the display units for O2.(This is only available on H2O2models.)

Passcodes (Menu Option)

The Passcodes menu allows the user to set Supervisor and Administrator Passcodes. To

change the passcodes, tap to highlight the desired access level, then tap “Set Passcode.” Enter

the new passcode on the ensuing screen and tap “OK.”

Table of contents

Other SSI Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Sierra

Sierra QuadraTherm 640i Series instruction manual

Supelco

Supelco TURBIQUANT 1100 IR operating manual

Emerson

Emerson Rosemount 370XA quick start guide

Dwyer Instruments

Dwyer Instruments RPME Series Specifications-installation and operating instructions

Interacoustics

Interacoustics PA5 Instructions for use

Xylem

Xylem ebro SSX 210 manual

Endress+Hauser

Endress+Hauser Proline Promass 80 Brief operating instructions

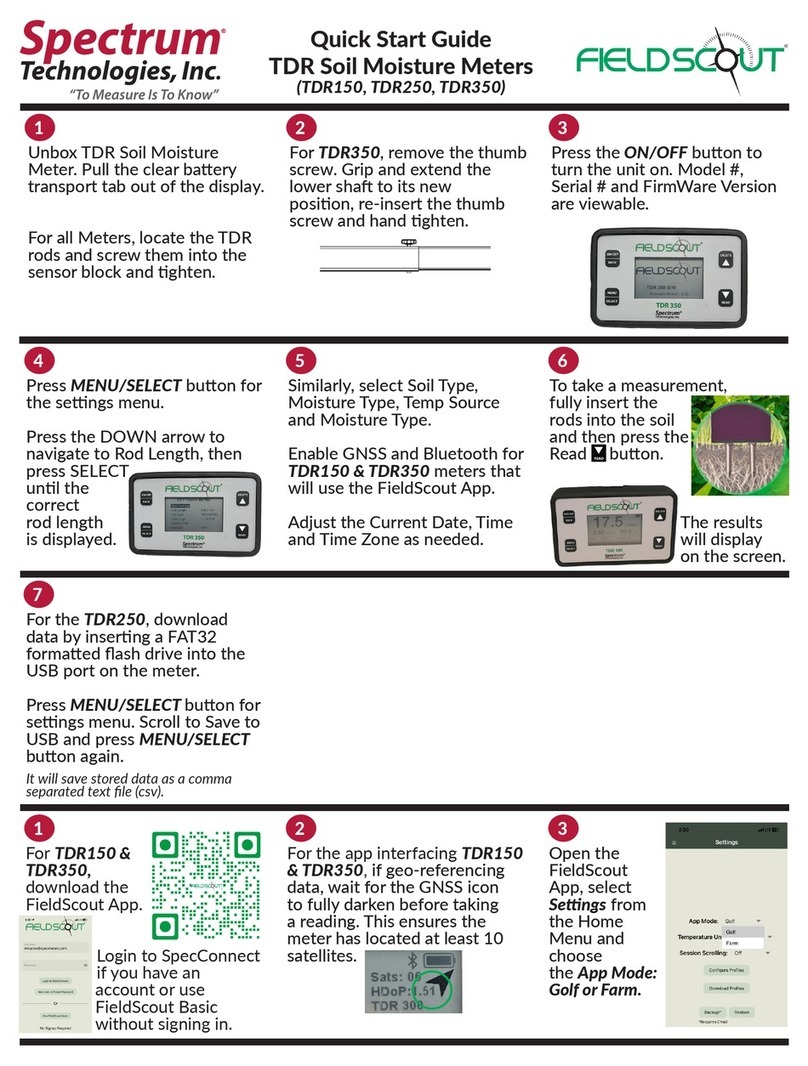

Spectrum Technologies

Spectrum Technologies FIELDSCOUT TDR Series quick start guide

Larson Davis

Larson Davis SoundAdvisor 831C Reference manual

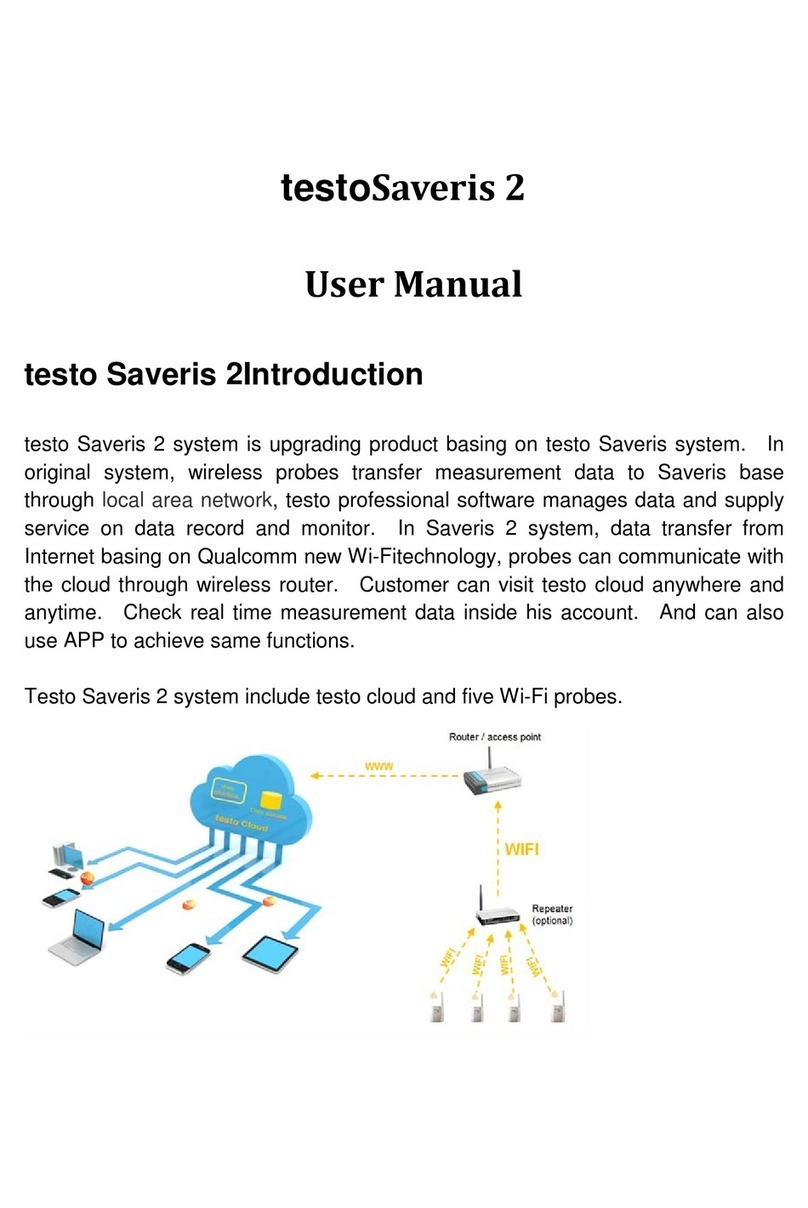

TESTO

TESTO Saveris T1 user manual

Nivetec

Nivetec PCM F instruction manual

YATO

YATO YT-7307 quick start guide