SSP TurnPro User manual

Indexing Tube Bender

Pocket Guide

NOTICE: This publication is an uncontrolled copy of a controlled docu-

ment. SSP has made every reasonable effort to ensure the accuracy

of the information contained in this publication, and is not to be held

liable in any manner for any mistakes, omissions, typographical and/

or printing errors.

IMPROPER SELECTION OR IMPROPER USE OF THE

PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS

CAN CAUSE PERSONAL INJURY AND PROPERTY

DAMAGE.

It is the sole responsibility of the system designers and users to properly select

and use products for their specific applications. This document has been print-

ed for users with technical expertise as a reference for further investigation to

determine specific product needs relative to design requirements.

WARNING

1

Table of Contents

Table of Contents

Tube Bender Features ............................2

Selecng Tubing .....................................2

Tube Fing Installaon ..........................3

Sequenal Bend Method........................4

Oset Bends ...........................................6

Calculang Gain......................................7

Adjustment Gain Method.......................7

Using the Tube Bender ...........................9

Le Reference Bends..............................9

Right Reference Bends.........................12

Bends greater than 90°.........................10

Change in Plane and Direcon .............12

Troubleshoong ...................................14

2

TurnPro indexing tube benders are available in sizes to bend

1/4, 3/8, and 1/2 in. and 6, 8, 10, and 12 mm OD tubing. The

size of the tube bender is indicated on the face of the tube

bender near the alignment marks.

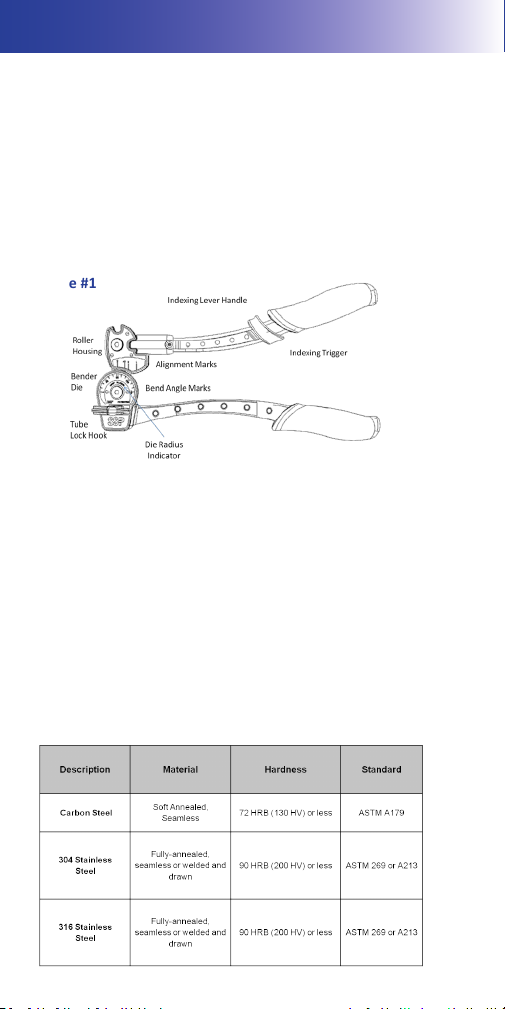

Selecng Tubing

Leak-ght connecons require high-quality tubing which

meets requirements for material hardness, roundness/

ovality, and wall thickness. The tables #1, 2, and 3 contain

suggested specicaons for fraconal and metric tubing.

Tubing Hardness

Read this manual before using the

TurnPro Tube Bender.

Tube Bender Components

TurnPro Indexing Handle Tube Benders provide consistent,

high-quality bends in stainless steel, carbon steel, nickel al-

loys, and other tubing materials used with SSP tube ngs.

The components of the tube bender are named in Figure #1.

Figure #1

Table #1

3

Metric Tubing Wall Thickness

Tubing Installaon

When bending tubing, it is important to allow a sucient

length of straight tubing between the shoulder of the tube

ng and the bend. ( See Figure 2)

Tables #4 and #5 specify the minimum required lengths for

straight tubing leading into a tube ng for each tubing OD

and bend radius.

Figure #2

Table #2

Fraconal Tubing Wall Thickness

Table #3

4

Bend Allowance Tables

Bend Layouts

In this secon, you will learn methods to plan, measure, and

mark tubing.

Sequenal Bending Method

In this method, users measure, mark, then bend each leg of

the fabricaon in a sequence unl the project is completed.

The steps are:

1. Add the lengths or all secon together to calculate the

overall length of tubing required for the job.

2. Mark the starng point (reference mark) for your project.

Hint: Remember to make all marks completely around the

tube.

3. Measure from the reference mark to the vertex of the

rst bend. The vertex is the point where the center lines

of the two legs of the angle meet. (See Figure 3)

4. Bend the tube using the direcons on page 9.

Table #4

Table #5

5

5. Using the vertex of this bend as the reference market for

the next bend, repeat steps 3 and 4 to complete the next

bend.

6. For addional bends, use the vertex of the previous bend

as the reference mark, repeat steps 3 and 4 for the next

bend.

Example

A 90° bend 4 inches from the reference mark followed by a

45° bend with 4 inches between bends .

Example Steps (see Figure #3 above)

1. Place a reference mark at the start of the tube.

2. Make the bend mark 4 inches from the reference mark.

3. Bend the tube 90° (See the instrucons on page 9).

4. Make a second bend mark 4 in . from the center line of

the rst leg.

5. Mark a point on the reference mark indicang the outside

of the bend. (See Figure #4)

6. Using the direcons on page 11, bend the tubing 45°.

Figure #3

6

Tip

Mark the outside of the

bend to make the next bend

easier to align.

Figure #4

Figure #5

Table #6

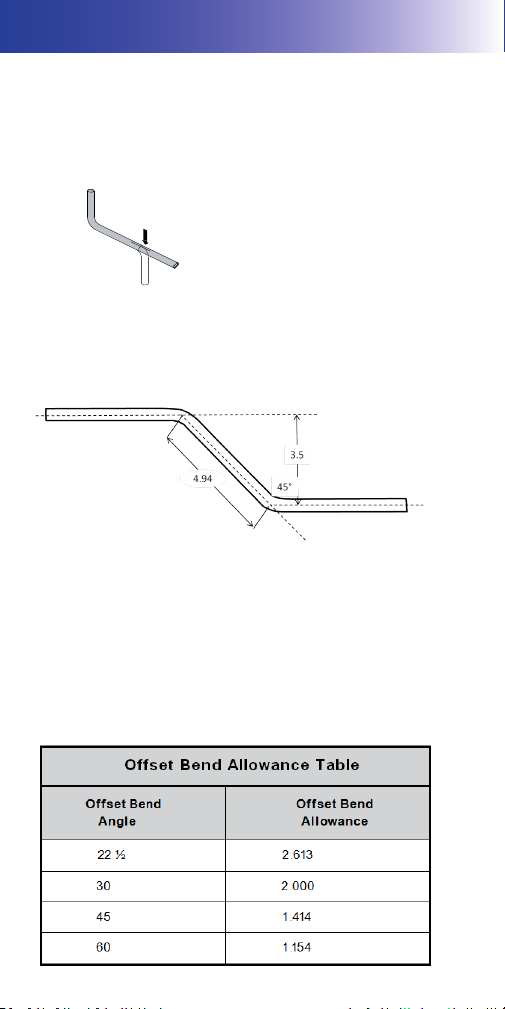

Laying Out Oset Bends

Oset bends change the centerline of the tubing run to

avoid an obstrucon.

To determine the distand between bend marks in an oset:

1. Determine the oset angle and locate it in table #6.

2. Mulply the oset bend allowance from table #6 by the

oset amount.

3. Use the oset calculaon as the distance between the

marks.

7

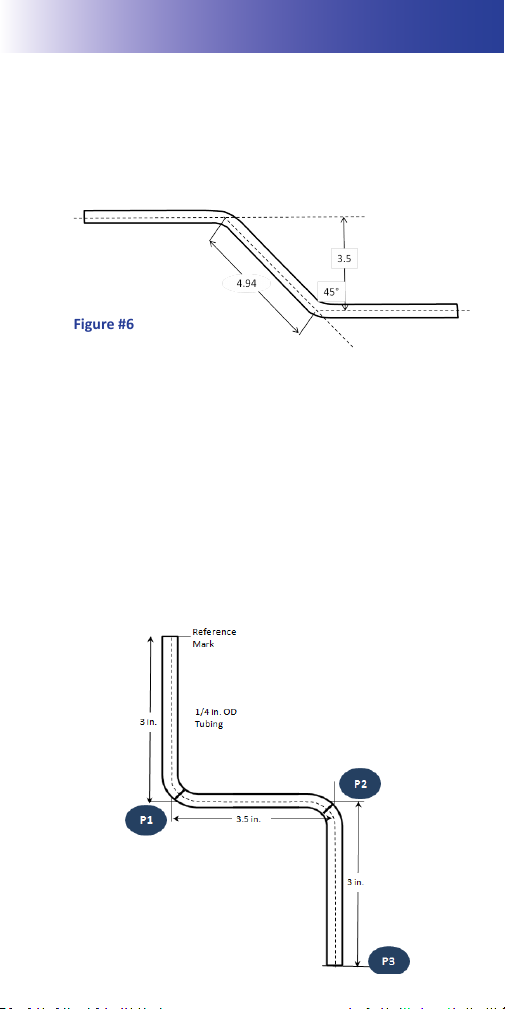

Example

Calucate the vertexes for the diagram below for 1/4 in. tube

bender with a 9/16 in. bend radius.

Figure #7

Figure #6

Example

Oset bend angle (E) 45°

Oset Dimension (O) 3.50 in .

3.5 x1 .414 = 4.94 in. or approximately 5 in.

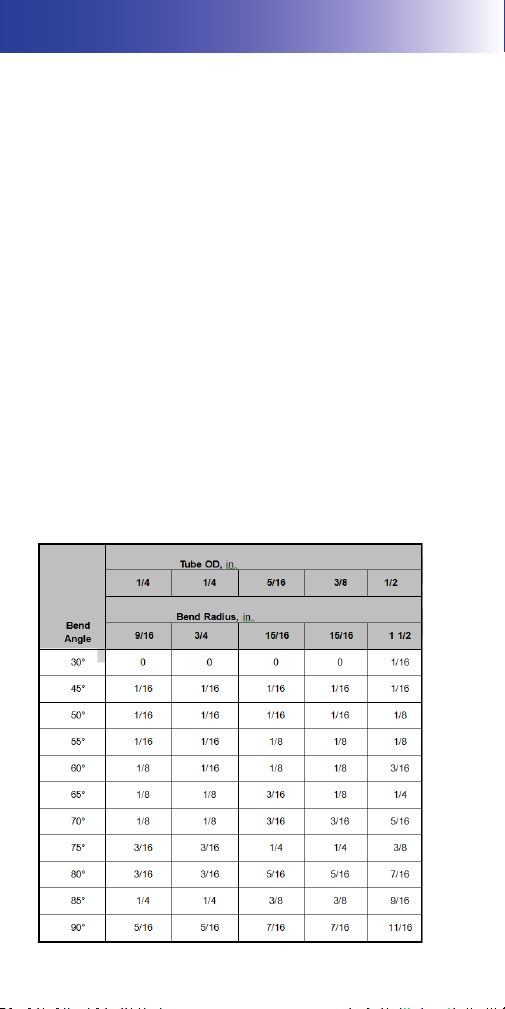

Adjustment (Gain) Method

The Adjustment or Gain Method measures and marks the

enre layout for a project prior to bending using adjustment

or gain factors. Gain is the amount that tubing stretches as it

bends. See the adjustment tables to determine the amount

of gain for each tube OD, bend radius and bend angle.

8

Adjust Method Example Steps (refer to Figure #7)

1. Mark the tubing for the rst vertex

P1= 3 in.

2. Calculate the second vertex mark by adding the second

leg to the rst then subtracng gain factor for the rst

bend. Use Table #7 and 8 to nd the gain factor. At the

top of the table locate the tube OD and bend radius, then

read down to the bend angle to nd the gain factor.

P2 = P1 + 3.5 in. – 5/16 in. adjustment = 6 3/16 in.

3. Follow the same procedure to caluclate and mark the

second bend.

P3 = P2 + 3 in. – 5/16 in. adjustment = 8 7/8 in.

8 7/8 in. is the total length of tube needed.

Fraconal Gain Adjustments

Table #7

9

Metric Adjustment Calculaons

Using the Tube Bender

Le Reference Bends

90° Bends

1. Swing the indexing handle up so it is above the die.

2. Open the tube lock hook.

3. Place the tube in the groove of the bender die with the

reference mark to the le of the tube lock hook.

4. Close the tube lock hook over the tube just enough to

hold the tube in place. This restricts movement of the

tube during inial posioning, but allows for addional

alignment

5. Carefully lower the indexing handle unl the rollers rest

gently on the tube.

6. Align the zero alignment mark with the zero angle

mark.

Table #8

10

Bend Angles Greater Than 90°

1. Follow the procedure above to create a 90° bend.

2. Pull the red indexing trigger toward the grip unl the

handle releases then swing the handle up unl it locks

into the new posion. (See Figure# 11)

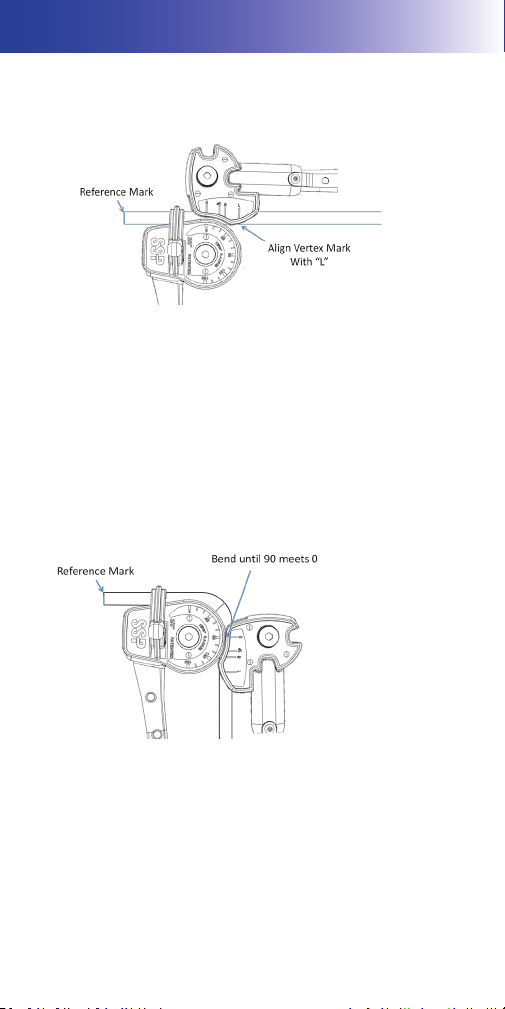

7. Align the vertex mark with the alignment mark that

corresponds to the bend angle. For 90° bends align the

vertex mark under the "L" as shown in Figure #8.

8. Push the tube latch rmly over the tube to secure the

tube in the bender die. Note: Excessive pressure on the

tube latch may damage so tubing.

9. Pull the indexing handle down unl the 0 reaches the

desired bend angle. Relax the pressure on the handle and

check the angle. In many cases, the tubing will spring

back 2-3 degrees. It might be necessary to bend the tube

slightly past the planned angle to compensate for spring

back.

Figure #8

Figure #9

11

3. Pull the handle down unl the 0 alignment mark meets

the desired angle mark. Note: You might have to press 2

or 3 degrees past your target angle to compensate for

spring back. (See Figure# 12)

Bend Angles Less than 90°

Making bends less than 90° is smililar to making 90° bends

except for the setup. For example, when making a 45° bend,

the vertex is aligned under the 45° alignment mark.

Figure #10

Figure #11

Figure #12

12

Right Reference Bends

Right reference bend are made with the reference mark to

the right of the bender die. The process is similar to making

left reference bends, except that the "R" alignment mark is

used instead of the "L" for 90° bends. (Figure #14)

Figure #14

For other angles less than 90° estimate where the alignment

mark should be then align the vertex mark on the tubing

under that alignment mark. For example, an arrow in Figure

13 indicate where the vertex is aligned for a 30° bend.

Figure #13

13

To make the bend on a new plane, rotate the tubing to angle

for the new plane. (Figure #16)

Once it is aligned, bend the tube to the desired angle. (Figure

#17)

Figure #16

Figure #17

Changes In Plane and Direcon

When making a bend on a new plane or a new direcon, it is

helpful to think of a protractor mounted on the tube bender

with the 0° at the straight up posion as shown. To make

our bend, set the tube in the bender such that the previous

leg is at the 0° posion. (Figure #15)

Figure #15

14

Troubleshooting

AUTHORIZED DISTRIBUTOR:

SSPTBPG-001-13A

©2013, SSP Fittings Corp.

8250 Boyle Pkwy

Twinsburg, OH 44087-2200

P: +1 330.425.4250

F: +1 330.425.8116

8

Table of contents

Other SSP Construction Equipment manuals