SSP HOLDX L1 User manual

Table of Contents

Version 1.0

Februar 2017

HOLDX L1

Magnetic process guard locking

EN Operating Manual

SSP Safety System Products GmbH & Co. KG

Max-Planck-Str. 21

D-78549 Spaichingen

www.safety-products.de

4 Electrical connection ........................................4

4.1 General notes for electrical connection ................................4

5 Diagnostic functions ........................................4

5.1 Diagnostic function of the process guard locking.........................4

5.2 Pulse diagram...................................................4

6 Commissioning and Maintenance ..............................6

6.1 Function check ..................................................6

6.2 Maintenance ...................................................6

7 Disassembly and Disposal ....................................6

7.1 Removal.......................................................6

7.2 Disposal .......................................................6

8 Appendix .................................................6

8.1 Electrical connection..............................................6

8.2 Pin assignment..................................................7

9 Equipment ................................................7

9.1 Equipment for HOLDX L1 ..........................................7

10 Declaration of Conformity....................................8

10.1 EC conformity regulations..........................................8

1 About This Document .......................................2

1.1 Function.......................................................2

1.2 Safety instruction for the authorized skilled personnel......................2

1.3 Symbols .......................................................2

1.4 Scope of application ..............................................2

1.5 Attention: Safety instructions .......................................2

1.6 Attention: Incorrect use............................................2

1.7 Liability Disclaimer ...............................................2

2 Product Description.........................................2

2.1 Intended use ...................................................2

2.2 Design types....................................................2

2.3 Special design types ..............................................2

2.4 Intended use ...................................................2

2.5 Mode of operation ...............................................2

2.6 Technical data ..................................................3

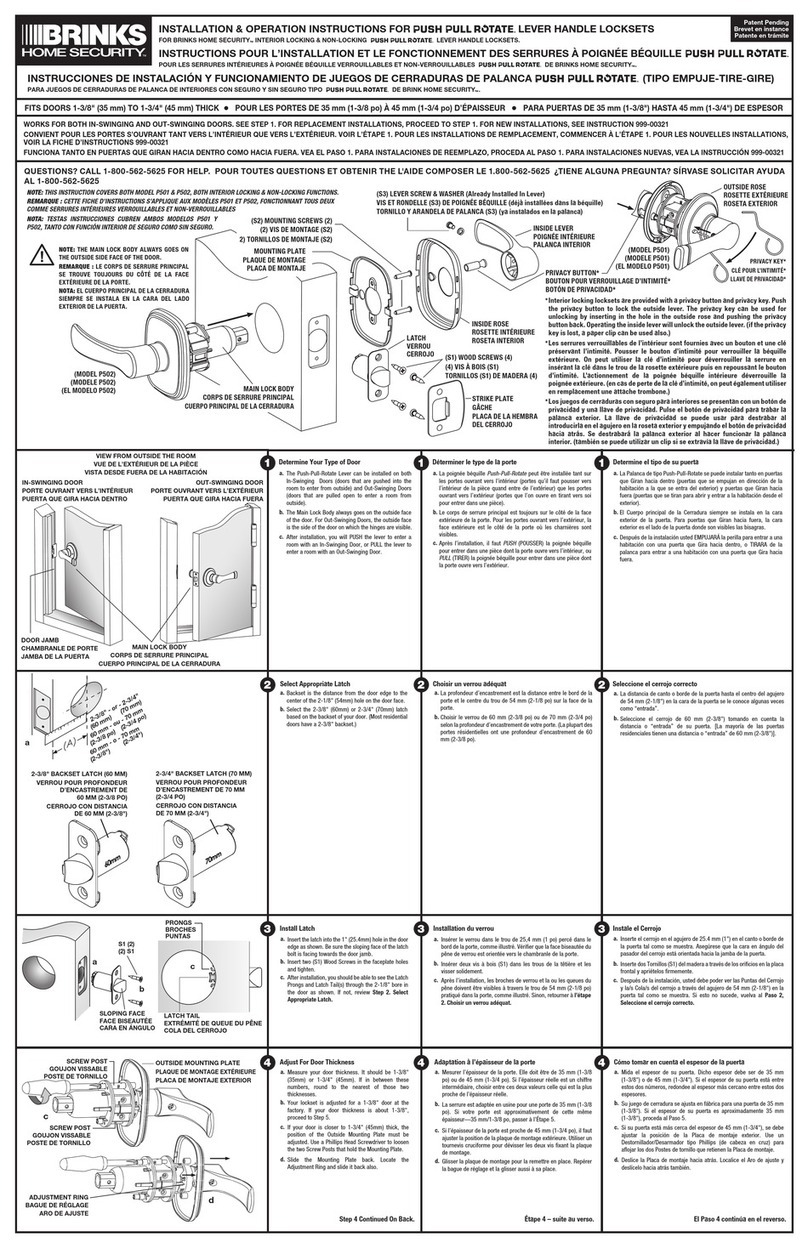

3 Installation ...............................................3

3.1 General installations notes .........................................3

3.2 Dimensions.....................................................3

This operating manual is a translation of the original

operating manual.All rights, errors and changes reserved.

Depending on features of your device, description of

optional functions in the form of additional sheets will

be provided as a complement to this operating manual.

2

1. About This Document

1.1 Function

This operating manual provides all necessary information for the assembly, installation, safe

operation and disassembly of the magnetic process guard locking HOLDX L1.The operating

manual must always be readable and available during the operating life of the device.

Read the operating manual carefully before using the device. Always hand this operating

manual over to future owners and users of the device. Add any supplement received from

the manufacturer to the operating manual.

1.2 Safety instruction for the authorized skilled personnel.

The tasks described in this operating manual may only be carried out by trained skilled

personnel authorized by the plant owner. You must read and understand the operating

manual before starting the HOLDX L1. Familiarize yourself with the applicable rules and

regulations relating to industrial safety and accident prevention. National and international

legislation apply to assembly, installation and regular technical inspections.

1.3 Symbols

Caution

If the warnings are not observed, faults or malfunctions as well as injury to

persons and/or damage of the machines can occur.

Information

Helpful additional information

1.4 Scope of application

The described products have been developed to be a part of an overall system or machine

for non-safety related applications in process and automation technology.The manufacturer

of the plant or machine is responsible for ensuring the correct overall function of the system.

If a safety sensor, e.g. SAFIX, is installed and used for a safety function,observe the operating

manual of the respective safety sensor.

1.5 Attention: Safety instructions

Observe the safety instructions in the operating manual, which are identified by an above

symbol for caution or warning. Follow national installation, safety and accident prevention

regulations. For additional technical information refer to SSP data sheets or visit our website

at www.safety-products.de.

All information is supplied without liability. We reserve the right to make technical mod-

ifications for reasons of improvement. No remaining risks are known, if the safety notes

and instructions regarding assembly, installation, operation and maintenance are followed.

1.6 Attention: Incorrect use

Danger to persons or damages to parts of machines or installations can arise as a result of

inappropriate or incorrect use or manipulation of the process guard locking.The process guard

locking HOLDX L1 without additional safety sensor does not comply with the requirements

of EN ISO 13849-1 or ISO 14119 for safety locking devices. Please observe the related

information in the standard ISO 14119.

It is prohibited to use with HOLDX L1 spare parts or accessories, which have not been

expressly approved by the manufacturer.

1.7 Liability Disclaimer

We accept no liability for damages or operational malfunctions resulting from improper

installation or failure to comply with this operating manual. No other liability is accepted

by the manufacturer for damages resulting from use of spare parts or accessories, which

have not been approved by the manufacturer.Any unauthorized repairs,reconstructions and

modifications are not permitted for safety reasons and rule out liability of the manufacturer

for resulting damages.

2. Product Description

2.1 Intended use

The device can only be used in industrial applications

2.2 Design types

This operating manual is valid for the following design types:

HOLDX L1 connector via M12 5-pin male contact

HOLDX L1 HOLDX L1 anchor plate

2.3 Special design types

For special design types, that are not listed under 2.2 type code, the above and following

information is accordingly applicable if they correspond to the standard design.

2.4 Intended use

HOLDX L1 is a magnetic process guard locking. It is an electro-technical component and

cannot be operated without the corresponding anchor plate. The electrical process guard

locking can be completed with an appropriate safety sensor. RFID safety sensor “SAFIX”is an

example of a suitable sensor.The process guard locking does not assume the safety function.

Information

Observe the installation regulations of the applied sensors. HOLDX L1 can lock

a door or a flap with a locking force of up to 1200 N.

2.5 Mode of operation

The magnetic process guard locking with locking force monitoring (e.g. if the solenoid

surface is soiled, it is detected and reported that the locking force is too low, see Table 2).

3

2.6 Technical data

Environmental conditions

Storage temperature max. −25°C … +70°C

Operating temperature max. -20°C … +50°C

Protection class IP67

Air and creeping distances acc. to IEC/EN 606641

- Overvoltage category 3

- Degree of contamination 3

Mechanical data

Design of the electrical connection

X1.1 - supply line plug connector M12, 5-pin

Locking force Fmax

- typical 1500 N

- guaranteed 1200 N

Fixing force 30 N

Vertical offset ± 2.5 mm

Lateral offset ± 2.5 mm

Housing aluminum, hard-anodized

Solenoid aluminum, hard-anodized

Anchor plate steel, nickel-plated

Mechanical lifetime >107 switching operations

Shock resistance 30 g/11 ms

Vibration resistance 10-55 MHz

Dimensions

- Width 24.4 mm

- Length 257.0 mm

- Height 22.2 mm

Anchor plate dimensions

- Width 34.0 mm

- Length 130.0 mm

- Height 9.1 mm

Electrical data

Power supply UB Ue: 24 V DC − 15%/+ 10% (PELV acc. to 60204-1)

Power consumption at UB 7.2 W (300 mA at 24 V DC)

Switching frequency 1 kHz

Rated insulation voltage Ui ± 4 kV

Rated operating current Ie max. 40 mA

Utilization category DC-13

Idle current I0 max. 300 mA

Electrical data inputs

Input

- Safety sensor IN 1, Pin 4

- Solenoid control IN 2, Pin 5

Rated operating voltage Ue −3 V … +5 V (low)

+15 V … +30 V (high)

Rated operating current Ie < 2 mA / 24 V

Electrical data diagnosis output

Diagnosis output OUT 1, pin 2

Function type sourcing, short circuit proof

Rated operating voltage UE −3 V … +5 V (low)

+15 V … +30 V (high)

Rated operating current IE < 2 mA / 24 V

Diagnosis function, OUT1

- Continuous signal input safety sensor OK and solenoid locked

- 1x flashing safety sensor switched on, solenoid not locked

- 2x flashing safety sensor not switched on, solenoid locked

- 3x flashing locking force of 900N not reached

- 4x flashing magnetic flux interrupted when throw open the door

- 5x flashing error magnetic flux measurement

Note The diagnosis output is not a safety-related output

Note: the power supply unit has to comply with rules and regulations for protective

extra-low voltages (SELV, PELV).The inputs and outputs of the safety switch have

to be equipped with a protective separation of voltage higher than 60 V AC.

3. Installation

3.1 General installations notes

Always use support elements that are suitable for the expected ambient conditions. The

installation may only be carried out by authorized skilled personnel.

The process guard locking can be installed on left- or right-hinged swing doors or sliding

doors. Install the guard locking and the anchor plate parallel and opposite to each other.

If a safety sensor, e.g.SAFIX, is installed and used for a safety function, observe the operating

manual of the respective safety sensor.

Precautions during installation

Observe the following instructions to prevent injuries or damages to the device.

• Check after the installation of the solenoid and the anchor plate if the surfaces are

smooth and parallel to each other, in order to provide full contact when closing the door.

• HOLDX L1 has to be installed as close as possible to the door handle. If there is a

distance between the lock and the door handle, the door frame acts as a lever and the

operating power necessary to open the lock is reduced. Furthermore, this can cause a

rotation of the anchor plate towards the solenoid, which reduces the locking force of

the lock significantly.

• The locking force can be significantly reduced if the anchor plate and the foam cannot

move, for this reason a full contact always has to be reached.

• Connect the cable to the M12 plug only after the HOLDX L1 was installed on the safety door.

• Make sure that all safety functions were checked before commissioning of the system.

Caution

The anchor plate must not be used as the only form of door hinge. In order

to prevent damage to HOLDX L1, at least one additional door hinge has to

be installed.

The surface of the magnet coil can get hot in continuous operation.

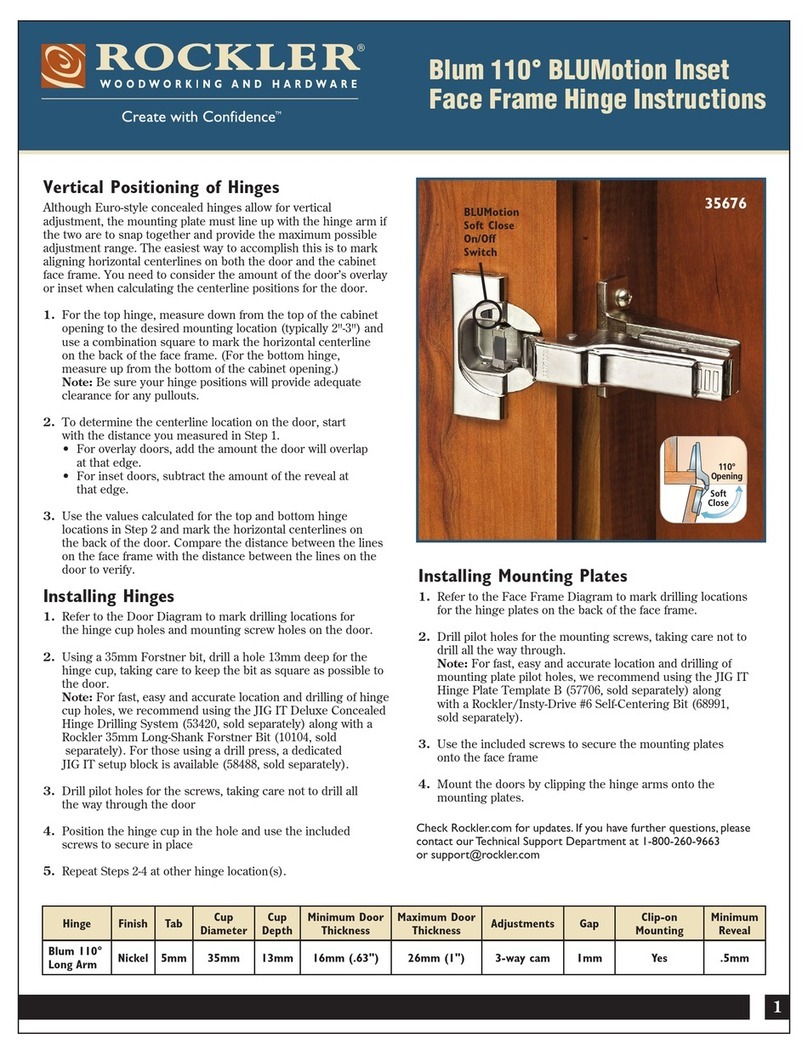

Installation of HOLDX L1 on a door

1. 2. 3.

1. Place the HOLDX L1 in the required position and tighten the bolts. Close the door.

2. Attach the anchor plate together with the foam to the mounting bracket with the

delivered bolts and washers.

3. Align the mounting bracket with the anchor plate to the same height as the HOLDX

L1 and screw the mounting bracket on the door.

Mounting brackets are available as additional equipment.

Influence

Be aware that magnetic fields can delete data carriers and impact or destroy

electronic or mechanic components, such as cardiac pacemakers. We are un-

aware of any negative influences for humans that originate from the magnetic

fields of permanent magnets.

During direct contact to magnetic materials and systems, allergic reactions

can arise (e.g. against ceramic and metallic materials as well as zinc, nickel

and plastics).

4

3.1 Dimensions

Dimensions in mm

HOLDX L1

12,5 162,5

245

256,5

17,2

34,4 22,2

M12 Stift-Stecker

5Pin A-codiert

passend für M6

Zylinderkopfschrauben

ISO 4762

HOLDX L anchor plate

M

8

(6

M

8

(6

10015

130

17

34

9.1

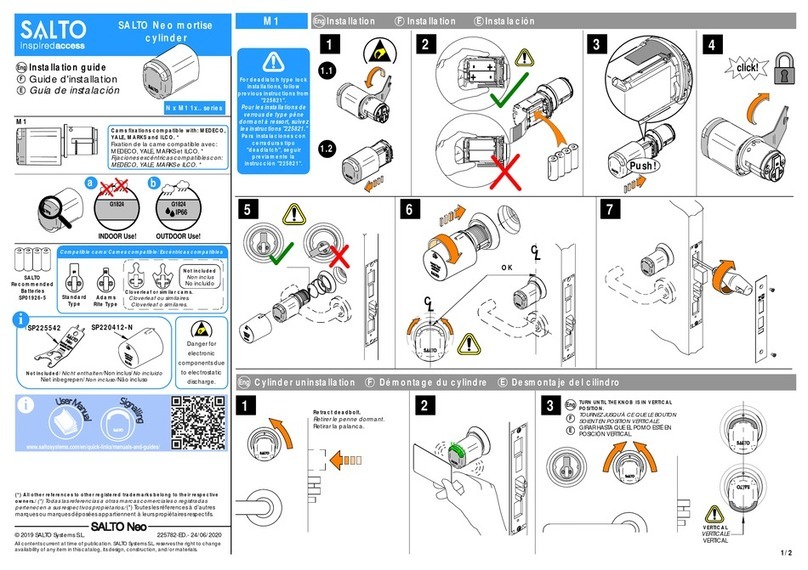

4. Electrical connection

4.1 General notes for electrical connection

The electrical connection should only be performed in a de-energized state by authorized

skilled personnel.

PELV power supply devices acc. to IEC 60204-1 have to be used in order to impede permanent

overvoltage and damage of the inputs A1, IN1 and IN2. The information output OUT1 is

not fail proof and must never be used to control a safety application.

5. Diagnostic functions

5.1 Diagnostic function of the process guard locking

The process guard locking HOLDX L1 indicates the operating condition as well as faults via

three LEDs in different colors on the front of the device.

LED diagnosis color code

green Power supply / input circuit IN1

red Error

blue Operating conditions

Diagnostic output

The short-circuit-proof diagnosis output OUT 1 can be used for control and

diagnosis tasks. It is not a safety-related output! Functional modules for various

PLC systems are available under www.safety-products.de.

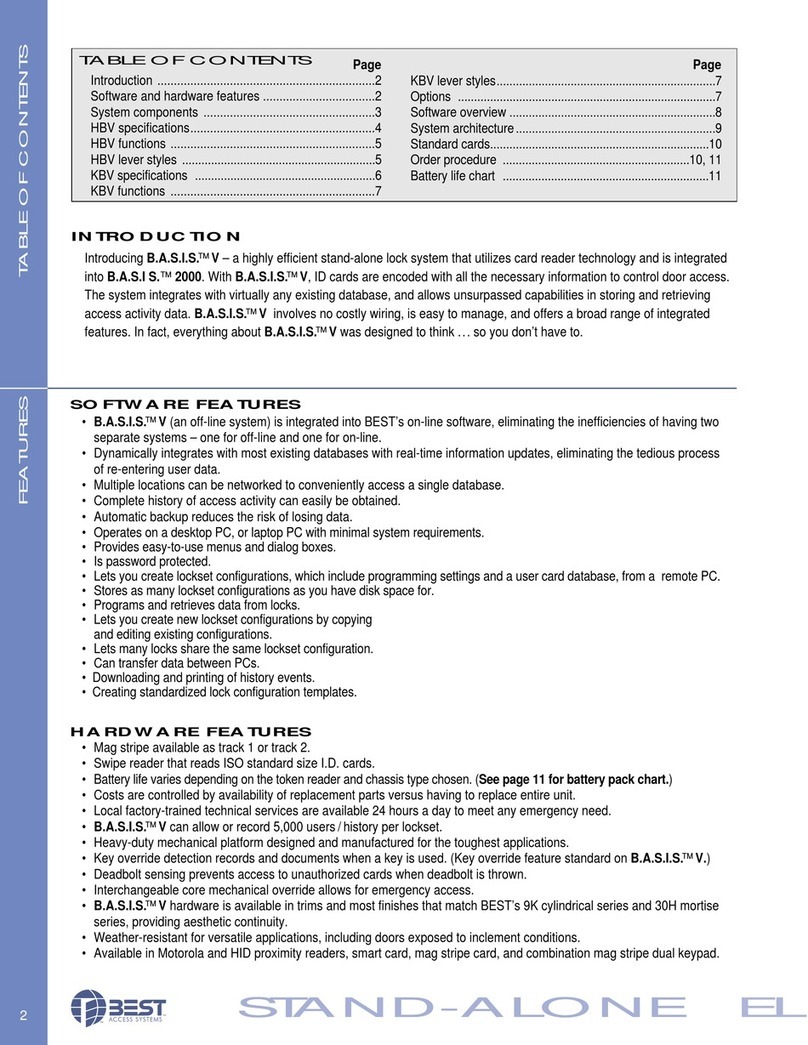

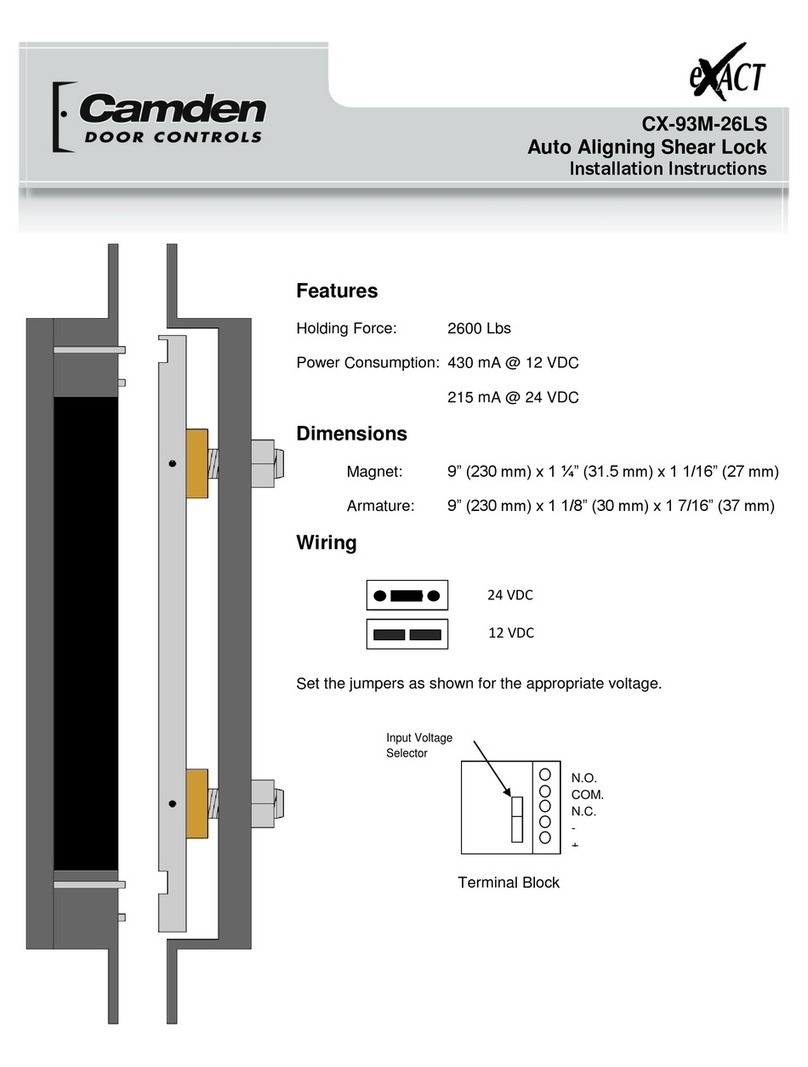

5.2 Pulse diagram

Table 1: Pulse diagram of the information output OUT 1

200ms

50ms 50ms50ms 50ms

Pulse diagram example

1 pulse

2 pulses

3 pulses

4 pulses

5 pulses

6 pulses

5

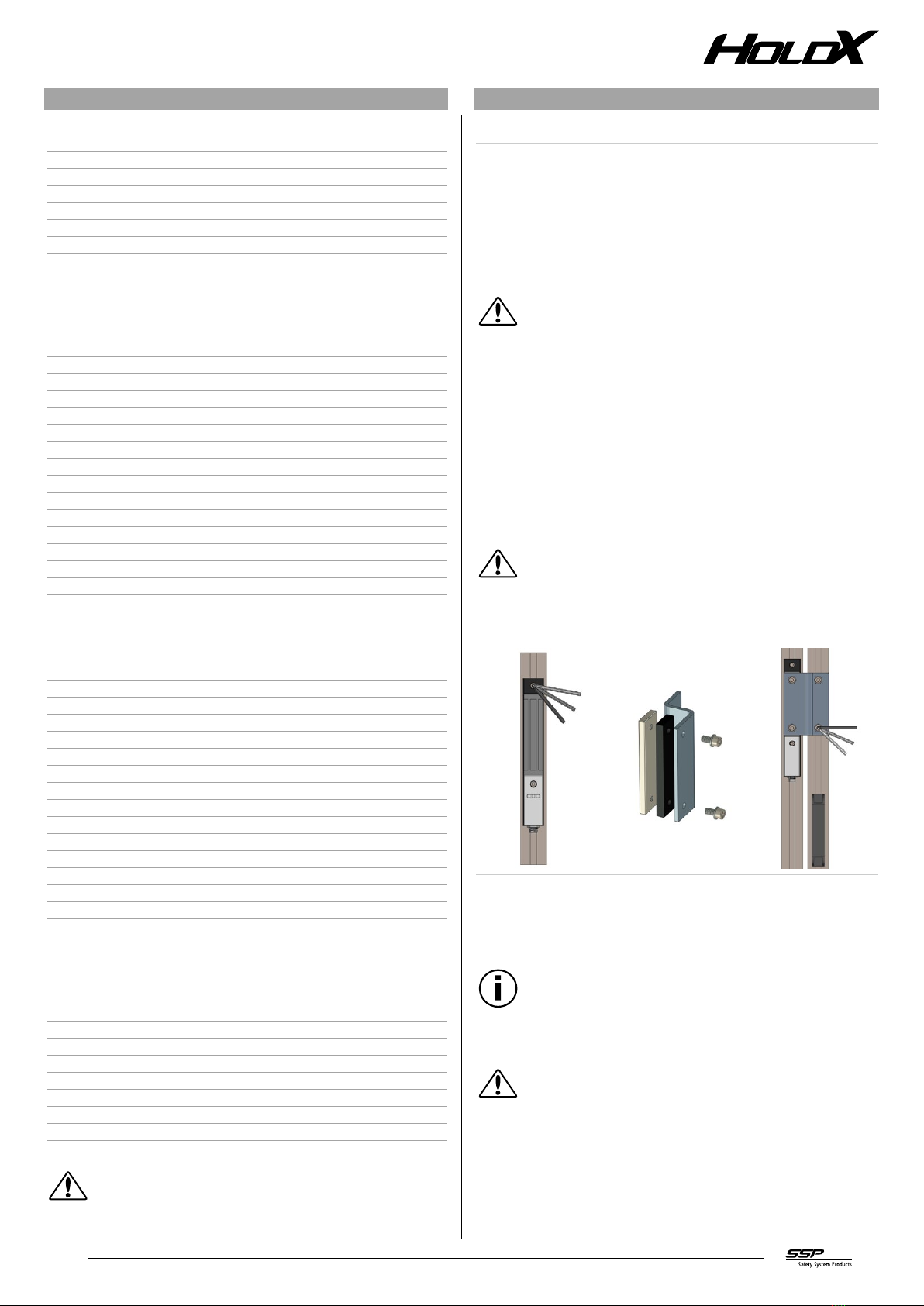

Table 2: Diagnostic function of the process guard locking

Function Input

Safety sensor

Input

Solenoid control

Feedback

Magnetic flux

measurement

LEDs Diagnos-

tic output Note

IN 1 IN 2 Green Red Blue OUT 1

1 Voltage supply OK 0 V 0 V not activated flashes

1x off off 0 V Input circuit IN 1 not available

2 Ready for operation 24 V 0 V not activated on off off 1X

pulsing Ready for activation of the guard locking

3Guard locking with typical

locking force 24 V 24 V activated off off on 24 V Min. 1200 N locking force existing

4Guard locking with typical

locking force 0 V 24 V activated off off flashes

1x 2x pulsing Min. 1200 N locking force existing

5Locking force not reached 24 V 24 V activated off off flashes

2x 3x pulsing Locking force of 900 N not reached *2)

6Locking force not reached 24 V 24 V not activated off on off 4x pulsing Magnetic flux interrupted when throw

open the door *1)

7 Error force measurement 24 V 24 V activated off flashes

1x off 5x pulsing Error in the magnetic flux measure-

ment *1)

8 Error reed contact 24 V 24 V x off flashes

2x off 6x pulsing Error in the magnetic flux measure-

ment *1)

*1) If this error is detected, the device will lock electronically and a standard error ac-

knowledgment is not possible any more. In order to acknowledge this error, the device

has to be disconnected from the power supply after removal of the cause of the error.

*2) If this error is detected, the device will lock electronically. In order to acknowledge

this error, the input IN 2 has to be switched off.

Note:

If several errors are detected, the first error remains in a pending state until

the errors have been eliminated.

6

6. Commissioning and Maintenance

6.1 Function check

The function of the HOLDX process guard locking has to be checked. Ensure the following

before you start:

• The process guard locking and the corresponding anchor plate are firmly seated.

• The supply line is firmly seated and not damaged.

• The system is free of all contamination.

Note

Damaged or defective devices must not be put into operation!

6.2 Maintenance

The magnet coils are maintenance-free. If during the operation faults or failures of unknown

origin occur, replace the magnetic guard lockings.Damaged or defective magnet coils or plug

connectors must not be repaired and have to be replaced. If the magnet coils are exposed

to excessive loads, additional safety measures may be necessary.

7. Disassembly and Disposal

7.1 Removal

Disassembly of the process guard locking HOLDX L1 should only be performed in a de-en-

ergized state.

7.2 Disposal

The process guard locking HOLDX L1 must be disposed of properly in accordance with

national and local regulations.

8. Appendix

8.1 Electrical connection

Note:

The illustrated examples are only suggestions.The user has the responsibility to

design the overall system in compliance with applicable rules and regulations.

Connection example 1: (individual wiring)

HOLDX L1 SAFIX S1

Connection example 2: Y-plug XCONN M12-Y

HOLDX L1 SAFIX S1

XCONN M12-Y

7

8.2 Pin assignment

Electrical data pin assignment

X1.1 Supply line

A1 Ue 1 BN brown

OUT 1 diagnosis output 2 WH white

A2 GND 3 BU blue

IN 1 input safety sensor 4 BK black

IN 2 input solenoid switch on 5 GY gray

9. Equipment

9.1 Equipment for HOLDX L1

Item Denomination Item no.

Passive junction XCONN

XCONN connection box

6 slots M12-8 pin

5 m connection cable

XCONN P6-M12-5m SP-X-71-000-00

XCONN connection box

6 slots M12-8 pin

10 m connection cable

XCONN P6-M12-10m SP-X-71-000-04

XCONN connection box

6 slots M12-8 pin

M23 connector plug for

connection cable

XCONN P6-M12-M23 SP-X-71-000-01

Y distributor XCONN Y1-M12 SP-X-71-000-02

Jumper plug M12-8 pin

Connector plug for unused slots

XCONN A1 SP-X-71-000-03

Safety sensors

RFID sensor SAFIX standard coding SAFIX S1 SP-K-70-000-00

RFID sensor SAFIX custom coding SAFIX I1 SP-K-70-000-01

RFID sensor SAFIX SAFIX W1 SP-K-70-000-02

SAFIX standard actuator SAFIX T3 SP-K-70-000-03

SAFIX flat actuator SAFIX T4 SP-K-70-000-04

Safe Control Technology

Basic device for emergency off

and safety door applications

S Series SP-S-00-001-02

Basic device for emergency off

and safety door applications

T series SP-S-00-002-02

Safety PLC MOSAIC M1 SP-R-11-000-00

8

Note

Signed EC Declaration of Conformity is available at the SSP website: www.

safety-products.de

10. Declaration of Conformity

10.1 EC conformity regulations

SSP Safety System Products GmbH & Co. KG

Max-Planck-Straße 21

78549 Spaichingen

+49 7424 98 049-0

info@ssp.de.com

www.safety-products.de

Table of contents