BEST ACCESS SYSTEMS B.A.S.I.S. V User manual

KBV lever styles....................................................................7

Options ................................................................................7

Software overview ................................................................8

System architecture..............................................................9

Standard cards....................................................................10

Order procedure ..........................................................10, 11

Battery life chart ................................................................11

TABLE OF CONTENTS

Introduction ..................................................................2

Software and hardware features ..................................2

System components ....................................................3

HBV specifications........................................................4

HBV functions ..............................................................5

HBV lever styles ............................................................5

KBV specifications ........................................................6

KBV functions ..............................................................7

PagePage

2

STAND-ALONE EL

TABLE OF CONTENTS

FEATURES

INTRODUCTION

STAND-ALONE EL

Introducing B.A.S.I.S.™V– a highly efficient stand-alone lock system that utilizes card reader technology and is integrated

into B.A.S.I S.™2000. With B.A.S.I.S.™V, ID cards are encoded with all the necessary information to control door access.

The system integrates with virtually any existing database, and allows unsurpassed capabilities in storing and retrieving

access activity data. B.A.S.I.S.™Vinvolves no costly wiring, is easy to manage, and offers a broad range of integrated

features. In fact, everything about B.A.S.I.S.™Vwas designed to think ... so you don’t have to.

SOFTWARE FEATURES

•B.A.S.I.S.™V(an off-line system) is integrated into BEST’s on-line software, eliminating the inefficiencies of having two

separate systems – one for off-line and one for on-line.

• Dynamically integrates with most existing databases with real-time information updates, eliminating the tedious process

of re-entering user data.

• Multiple locations can be networked to conveniently access a single database.

• Complete history of access activity can easily be obtained.

• Automatic backup reduces the risk of losing data.

• Operates on a desktop PC, or laptop PC with minimal system requirements.

• Provides easy-to-use menus and dialog boxes.

• Is password protected.

• Lets you create lockset configurations, which include programming settings and a user card database, from a remote PC.

• Stores as many lockset configurations as you have disk space for.

• Programs and retrieves data from locks.

• Lets you create new lockset configurations by copying

and editing existing configurations.

• Lets many locks share the same lockset configuration.

• Can transfer data between PCs.

• Downloading and printing of history events.

• Creating standardized lock configuration templates.

HARDWARE FEATURES

• Mag stripe available as track 1 or track 2.

• Swipe reader that reads ISO standard size I.D. cards.

• Battery life varies depending on the token reader and chassis type chosen. (See page 11 for battery pack chart.)

• Costs are controlled by availability of replacement parts versus having to replace entire unit.

• Local factory-trained technical services are available 24 hours a day to meet any emergency need.

•B.A.S.I.S.™Vcan allow or record 5,000 users/history per lockset.

• Heavy-duty mechanical platform designed and manufactured for the toughest applications.

• Key override detection records and documents when a key is used. (Key override feature standard on B.A.S.I.S.™V.)

• Deadbolt sensing prevents access to unauthorized cards when deadbolt is thrown.

• Interchangeable core mechanical override allows for emergency access.

•B.A.S.I.S.™Vhardware is available in trims and most finishes that match BEST’s 9K cylindrical series and 30H mortise

series, providing aesthetic continuity.

• Weather-resistant for versatile applications, including doors exposed to inclement conditions.

• Available in Motorola and HID proximity readers, smart card, mag stripe card, and combination mag stripe dual keypad.

SYSTEM COMPONENTS DESCRIPTION

B.A.S.I.S. Software– Software that lets you define programming settings and the user database for groups of locks, as

well as individual locks. The software lets you view and print information about locks at any time.

(To order, contact your local Best Access Systems office.)

Programming Cable – Programming cable allows you to connect to individual locks.

(To order, contact your local Best Access Systems office.)

Smart Card Cards – A credit-card-size card with a smart card chip containing information. These cards can be encoded

and sent to the user or encoded by the user at their facility. (To order, see page 10.)

Mag Stripe Cards – A credit-card-size card with a magnetic stripe containing information. These cards can be

encoded and sent to the user or encoded by the user at their facility. (To order, see page 10.)

Proximity Cards – A credit-card-size card with a proximity chip containing information. These cards can be

encoded and sent to the user or encoded by the user at their facility. (To order, see page 10.)

Smart Card Encoder – The device that “reads”, “writes” and “erases” information on the smart card. This also

includes the software that controls the card encoder. Requires a PC B.A.S.I.S. software. (To order, see page 11.)

Mag Stripe Card Encoder – The device that “reads”, “writes” and “erases” information on the magnetic-stripe card.

This also includes the software that controls the card encoder. Requires a PC & B.A.S.I.S. software. (To order, see page 11.)

Mag Stripe Electronic Lock – A battery-powered, self-contained swipe reader electronic lock that uses standard

mag stripe cards. Controls access to door and can be programmed with B.A.S.I.S. software. (To order, see page 10.)

Smart Card Electronic Lock – A battery-powered, self-contained insertion reader electronic lock that uses smart cards.

Controls access to door and can be programmed with B.A.S.I.S. software. (To order, see page 10.)

Dual Validation Reader – A battery-powered, self-contained dual validation reader electronic lock that combines standard

mag stripe and keypad validation. Controls access to door and can be programmed with B.A.S.I.S. software.

(To order, see page 10.)

Proximity Reader – A battery-powered, self-contained proximity card reader electronic lock that uses standard proximity

cards. Controls access to door and can be programmed with B.A.S.I.S. software. (To order, see page 10.)

PDA (palm top not shown) – A PDA (Personal Digital Assistant) is a palm top device that connects to a PC to transport

programming data from a B.A.S.I.S. system to the lockset or retrieve history data. The PDA can also provide diagnostic

data from the lockset. Software for the palm device is included in the B.A.S.I.S. software.

(Contact your local Best Access Systems office or visit our web site for a recommended BEST–supported device.)

3

ECTRONIC LOCKS

ECTRONIC LOCKS

SYSTEM COMPONENTS

SYSTEM COMPONENTS

The B.A.S.I.S.™VSystem is an electronic access control system that can be programmed to meet your facilities access

control needs. The system is designed to secure your facility by granting specific access rights to authorized people, based

on a defined time schedule for each lock in the system. By tracking events at the locks, the system provides information to

help you maintain the security of your facility.

Mag Stripe

Encoder

B.A.S.I.S.

Software

Mag Stripe

Electronic Lock Smart Card

Electronic Lock

Smart Card Encoder

Mag Stripe Cards/

Proximity Cards/

Smart Card Cards

COMPONENTS DESCRIPTION

1

Programming

Cable

2

67

Dual Validation

Reader Proximity

Reader

89

5

4

3

1

2

3

3

3

4

5

6

7

8

9

10

MECHANICAL

Case: Heavy wrought steel, 5 7⁄8"H x 4 1⁄4"D x 1"W steel parts are

zinc dichromate plated for corrosion protection.

Faceplate: Brass or bronze, 11⁄4"x 8"x 7⁄32". Armored. Adjustable

from flat to beveled 1⁄8"– 2".

Strike: Brass or bronze, 4 7⁄8"x 11⁄4"x 3⁄32". Fits standard door frame

cut out as specified in ANSI A115.1. Correct strike automatically

supplied with unit. Strike box supplied standard.

Door thickness: For doors 13⁄4"- 3"thick.

Installation: Lock requires modified door prep to mount the trim.

Faceplate dimensions fit standard door preparation as specified in

ANSI A115.1. Lockset is reversible for hand of door.

Latchbolt: Stainless steel, 3⁄4"throw with anti-friction latch.

Deadbolt: Solid stainless steel, 1"throw.

Auxiliary bolt: Stainless steel.

Die cast trim housing: Dimensions: 10 3⁄8"H x 3 1⁄4"W x 1"D

sloping down to 3⁄4".

Lever handle: Brass, bronze or stainless steel. (Lever #3, #14 and #15 conform to California Titles 19 and 24.)

Mounting: Lever attached with hardened set screw on inside knob or inside lever.

Finish: 605-bright brass, clear coated; 606-satin brass, clear coated; 611-bright bronze, clear coated; 612-satin bronze,

clear coated; 613-oxidized satin bronze, oil rubbed; 625-bright chromium plated; 626-satin chromium plated; 629-bright

stainless steel; 630-satin stainless steel.

4

STAND-ALONE EL

HBV SPECIFICATIONS

ELECTRONIC

SPECIFICATIONS FOR ALL READERS:

Primary power: Alkaline standard 4 cell or extended life cell battery pack.

Memory backup: Maintains programming and history data for up to 3 months after loss of power.

User feedback indicators: Visual and audible.

Serial communications port: Can be used to program locks individually.

Operating temperature: -35°C to +66°C (-31°F to +151°F).

Relative humidity: 10% to 90% non-condensing.

Sealing: Weatherproof lens and gasket provides protection for outdoor use.

(Usable in all environmental/exterior applications.)

Battery Life: See page 11 for battery life chart.

Dual Validation – Combination Keypad & Magstripe Reader:

Bezel size: 2 5⁄8"x 3

1⁄4".

Material: Bezel– High impact ABS. Keypad– Encapsulated elastomer.

ESD Protection: 15KV.

Button operating life: 1 million cycles.

Operating temperature: -35°C to +66°C (-31°F to +151°F).

Compliant to FCC and Canadian EMC requirements; ISO 7816, MP-COS EMV compliant; T0 & T1 protocol standard.

Magnetic Stripe Card Reader:

Read Rate: 5 inches per second to 50 inches per second.

Card thickness: ISO standard .030"±.003 thick.

Compliance to FCC, Canadian, and European EMC requirements; for interference FCC Class A digital apparatus.

Proximity Reader:

Bezel size: 2 5⁄8"x 3 1⁄4"

Material: Bezel–High impact ABS.

ESD Protection: 15KV.

Reader range: Card reader range 0"– 3".

Compliance to FCC, Canadian, and European EMC requirements; for interference FCC Class A digital apparatus.

Smart Card Reader – Contacted Insertion Reader:

Operating temperature (exterior side of door): -35°C to +66°C (-31°F to +151°F).

Smart card adaptation: Trim option that can accept other manufacturers’ cylinder.

Compliant to FCC and Canadian EMC requirements; ISO 7816, MP-COS EMV compliant; T0 & T1 protocol standard.

HBV SPECIFICATIONS

STAND-ALONE EL

Proximity Reader Dual Validation Reader

5

ECTRONIC LOCKS

HBV FUNCTIONS

ECTRONIC LOCKS

Latch w/o

key override

Deadbolt w/o

key override

Deadbolt w/

key override

Latch w/key

override Internal motor drive mechanism operated

by electronic signal, when presenting valid

card. Green light indicates valid access.

Red light and sounder indicate invalid

access attempt. Lock records card

number, time, date and type of event.

HBV FUNCTIONS

Latchbolt operated by lever either side,except

when outside lever is locked by internal motor

drive mechanism; latchbolt is retracted by key

outside. Deadbolt operated by key outside and

turn lever inside. When deadbolt is extended,

turning inside lever or electronically unlocked

outside lever retracts both deadbolt and

latchbolt simultaneously. Auxiliary latch

deadlocks latchbolt.

Internal motor drive mechanism

operated by electronic signal when

presenting valid card. Green light

indicates valid access. Red light and

sounder indicate invalid access attempt.

Lock records card number, time, date

and type of event. Electronic sensor

recognizes whether deadbolt is

retracted or thrown. Lock grants access

only to deadbolt-authorized personnel

when deadbolt is thrown.

Latchbolt operated by lever either side, except

when outside lever is locked by internal motor

drive mechanism. Deadbolt operated by turn

knob inside. When deadbolt is extended,

turning inside lever or electronically unlocked

outside lever retracts both deadbolt and

latchbolt simultaneously. Auxiliary latch

deadlocks latchbolt.

FV

LV

Latchbolt operated by lever either side, except

when outside lever is locked by internal motor

drivemechanism. Auxiliary latch deadlocks the

latchbolt.

NV

EV

Latchbolt operated by lever either side,except

when outside lever is locked by internal motor

drive mechanism; latchbolt is retracted by key

outside. Auxiliary latch deadlocks the latchbolt.

Diagram Function Mechanical Electronic

Code

HBV LEVER STYLES

#15 lever #16 lever #17 lever

#3 lever #12 lever #14 lever

HBV LEVER STYLES

6

STAND-ALONE EL

MECHANICAL

Materials: Internal parts are brass, zinc or corrosion-treated steel.

Chassis: 2 1⁄16"diameter to fit 2 1⁄8"diameter hole in door.

Strike: Brass or bronze, 4 7⁄8"x 1 1⁄4"x 3⁄32". Fits standard door

frame cut out as specified in ANSI A115.1. Correct strike

automatically supplied with unit. Strike box supplied standard.

Backset: 2 3⁄4"standard. 3 3⁄4"and 5"available.

Door thickness: For doors 1 3⁄4"- 2 1⁄4"thick.

Installation: Lock dimensions requires modified door prep,

ANSI A156.2 Series 4000, Grade 1 to mount housing.

Latchbolt: 9⁄16"throw.

Die cast trim housing: Dimensions: 10 3⁄8"H x 3 1⁄4"W x 1"D sloping

down to 3⁄4".

Lever handle: Made from high-quality zinc alloy. Body is

approximately 1 5⁄8"in diameter. Handle is approximately 4 3⁄4"in length (from center-line of chassis).

(Lever #3, #14 and #15 conform to California Titles 19 and 24.)

Finish: 605-bright brass, clear coated; 606-satin brass, clear coated; 611-bright bronze, clear coated; 612-satin bronze,

clear coated; 613-oxidized satin bronze, oil rubbed; 625-bright chromium plated; 626-satin chromium plated.

ELECTRONIC

SPECIFICATIONS FOR ALL READERS:

Primary power: Alkaline standard 4 cell or extended life cell battery pack.

Memory backup: Maintains programming and history data for up to 3 months after loss of power.

User feedback indicators: Visual and audible.

Serial communications port: Can be used to program locks individually.

Operating temperature: -35°C to +66°C (-31°F to +151°F).

Relative humidity: 10% to 90% non-condensing.

Sealing: Weatherproof lens and gasket provides protection for outdoor use.

(Usable in all environmental/exterior applications.)

Battery Life: See page 11 for battery life chart.

Dual Validation – Combination Keypad & Magstripe Reader:

Bezel size: 2 5⁄8"x 3

1⁄4".

Material: Bezel– High impact ABS. Keypad– Encapsulated elastomer.

ESD Protection: 15KV.

Button operating life: 1 million cycles.

Compliant to FCC and Canadian EMC requirements; ISO 7816, MP-COS EMV compliant; T0 & T1 protocol standard.

Magnetic Stripe Card Reader:

Read Rate: 5 inches per second to 50 inches per second.

Card thickness: ISO standard .030"±.003 thick.

Compliance to FCC, Canadian, and European EMC requirements; for interference FCC Class A digital apparatus.

Proximity Reader:

Bezel size: 2 5⁄8"x 3 1⁄4"

Material: Bezel–High impact ABS.

ESD Protection: 15KV.

Reader range: Card reader range 0"– 3".

Compliance to FCC, Canadian, and European EMC requirements; for interference FCC Class A digital apparatus.

Smart Card Reader – Contacted Insertion Reader:

Operating temperature (Exterior side of door): -35°C to +66°C (-31°F to +151°F).

Smart card adaptation: Trim option that can accept other manufacturers’ cylinder.

Compliant to FCC and Canadian EMC requirements; ISO 7816, MP-COS EMV compliant; T0 & T1 protocol standard.

Magnetic Stripe Reader

KBV SPECIFICATIONS

KBV SPECIFICATIONS

Dual Validation Reader

Diagram Function Mechanical Electronic

Code

7

ECTRONIC LOCKS

KBV FUNCTIONS

KBV FUNCTIONS

OPTIONS

AL– Abrasive levers from Best Access Systems are available with a special abrasive feature. Abrasive strip on the lever

immediately identifies warnings on doors to hazardous areas for the blind.

FM– The Free Motion feature allows the lever handle to move 45 degrees from parallel to the horizontal plane without

engaging the latchbolt assembly. When the lockset is in the locked mode, this feature makes over-torque or

over-leverage abuse more difficult to achieve. (Lower cost option.)

SH– Security head screws provided for all exposed screws.

Thick door– Specify thickness if other than 13⁄4".

TL– Tactile levers may be used in areas where improved grip is required or as a warning in hazardous or Safety First

areas. Grooves are machined into the back of the hand grasp portion of the lever to improve grip and/or provide a

sensory warning. This option can be used for blind, safety, or accessibility applications.

OPTIONS

#14 lever #15 lever #16 lever

KBV LEVER STYLES

KBV LEVER STYLES

Cylindrical Latch

w/key override DV Dead locking latchbolt operated by lever Internal motor drive mechanism operated by

either side, except when outside lever is time-activated electronic signal, or presenting

locked by internal motor drive mechanism; valid card/PIN. Green light indicates valid

latchbolt is deadlocked. access. Red light and sounder indicate invalid

access attempt. Lock records card/PIN number,

time, date and type of event.

The next generation of security & facility management systems

Best Access Systems Integrated Solutions (B.A.S.I.S.) system for Microsoft Windows®2000, NT 4.0 and Windows®98

combines the power of access control, alarm monitoring, ID card production, and personnel management into a single

seamlessly integrated software solution! One powerful and easy-to-use system allows you to create and encode

identification cards, assign cardholders access to restricted areas, and monitor security zones. This comes complete with

context-sensitive help.

Seamless integration means single system efficiency

A single seamlessly integrated solution for badge creation, ID management, access control, and alarm monitoring. Every

step is simplified, easy to perform, and tightly integrated to provide optimum efficiency and maximum security. This uses

a single database server to ensure data integrity, allow for real time security operations, and simplify system administration

tasks.

Truly distributed network architecture

Wiring from access control panels does not have to run to a central host computer, unlike traditional systems that must

have all panels wired to a single PC. This allows you to control access to any secured area and monitor any alarm from any

PC on the network.

Open architecture design means optimum flexibility

Supports an unlimited number of workstations, card readers, and cardholders. Its modularity allows you to easily upgrade or

add equipment at any time, without replacing the software. It works with any industry standard network protocol and

supports all industry standard ID card and reader technologies, including Wiegand, Proximity, bar code, and magnetic

stripe. It also supports industry standard databases including Microsoft SQL Server, Oracle Server, and Microsoft Access.

Easiest-to-use graphical user interface in the Industry

Using the keyboard or mouse, every important task can be accomplished in one or two steps! There are no overlapping

windows, confusing nested screens, or excessive menu options found in other systems.

Multimedia integration

Real-time, dynamic graphical maps mean that the graphical map screen will not have to repaint or refresh each time a new

alarm or event condition occurs. It supports customized voice alarm annunciation and flashing colored system icons for

each alarm that occurs. It also supports text instructions and pre-recorded audio voice instructions. It integrates real-time

live video user verification into alarm monitoring to allow guards to monitor cardholder activity in secure areas.

Seamless migration path

Upgrading is fast, efficient, and easy. All systems are 100% upwardly compatible. Even the graphical user interface is

identical for all systems, meaning the upgrades are virtually transparent to the user.

Hot standby, fault tolerant server architecture

Supports a fault tolerant server and redundant database architecture to allow for normal operations to occur in the event

that the database server fails. In the event of a server failure, it will automatically switch over to a backup server.

A complete solution

• Windows®2000, NT 4.0 and Windows®98 based • Configuration Wizards • Complete Reporting Capabilities

• Simple Operation, Maximum Security • Multi-Technology Cards • Data Import/Export Capabilities

• Supports Standard ID Card Technologies • Magnetic Stripe • Proximity

• Wiegand • Bar-code

E-Visitor

E-Visitor is an Internet-based solution that allows enterprise visitors to be enrolled and managed through standard Web

browsers. E-Visitor uses a customer’s existing desktop infrastructure, which means no additional software or hardware

installation is required for existing client workstations. Other advanced features of E-Visitor include visitor pre-enrollment,

visitor tracing, complete reporting capabilities and automatic e-mail notification of impending visits. E-Visitor provides the

ability to customize the system’s visitor screens and badge layouts according to the individual needs of the installation.

Asset Management

Asset Management is the only seamlessly integrated solution that is fully IBM Asset ID® enabled, utilizing HID RS-485

RFID technology. Asset tracking allows both an asset and the employee to which it is assigned, to be traced throughout an

enterprise. Asset Management delivers a truly distributed system architecture with which all asset decision-making

occurs in the Intelligent Asset Controller devices. Asset Management supports multiple asset control technologies and

has complete reporting capabilities.

8

STAND-ALONE EL

Laptop Computer

SOFTWARE OVERVIEW

SOFTWARE OVERVIEW

Programming Cable B.A.S.I.S Software PDA Photo ID Cards

Digital Video Management

Video Management is a Windows®NT-based Digital Video Management system that

seemlessly integrates with the Access Control & Alarm Monitoring and Asset

Management applications, which collectively uses a single database and one graphical

user interface. Video Management is the only solution in the industry that can link

digital video with access control alarms and events in real time. In addition, Video

Management can display live and pre-recorded video directly on alarm monitoring

workstations.

Open Architecture

B.A.S.I.S. was developed to be a true open architecture system and supports industry

standards for databases, networks, ID card printers, and video cameras. There is no

customized or proprietary PC or ID badge creation software or hardware required to

make the SYSTEM operate. The software was written to operate on a Windows®NT

multi-tasking, multi-threading 32-bit operating system as a true, native 32-bit, application.

B.A.S.I.S. is both scalable and portable to give the Customer the ability to increase performance based on customer

requirements. This gives the customer maximum flexibility and room for unlimited growth.

Open Database Connectivity Compliance

B.A.S.I.S. is Open Database Connectivity (ODBC) compliant and supports any relational database management system

with the proper 32-bit ODBC drivers. Examples of these databases include, but are not limited to, Microsoft SQL Server

and Oracle Server. These databases, through ODBC, are true client/server, high performance databases capable of

handling high transaction rates and multiple users concurrently accessing and modifying the database. The SYSTEM also

employs advanced database segmentation functionality. Each segment is allowed to have its own unique set of hardware

and system parameters, regardless of the ISC that generated the event.

Graphical User Interface

B.A.S.I.S. has an easy to use Windows Graphical User Interface. It is intuitive and all messages and commands are in

English prose. All functions are both keyboard and mouse driven. Within the alarm monitoring module of the SYSTEM, all

major functions can be accomplished in one or two mouse clicks. Help icons are available in all modules of the software

giving System Operators the ability to obtain on-line help with a single click of the mouse. Upgrading B.A.S.I.S. from

system level to system level is efficient, easy, and requires only a change in the software /hardware license key code for

the application portion of the SYSTEM.

Advanced Network Architecture

B.A.S.I.S. has been designed to allow it to work with any industry standard network protocol and topology such as TCP/IP,

Novell NetWare (IPX/SPX), and Digital (Pathworks). The SYSTEM supports an advanced distributed network architecture,

whereas Intelligent System Controllers (ISC) do not need to be home-run wired back to the database server. ISCs can be

wired to any Windows NT based PC that is licensed to run the software. The SYSTEM supports Remote Dial Up operations

to and from the ISC. The dial up connection can be either a constant connection or a scheduled connection. Also,

Intelligent System Controllers (ISC) can be connected to a Local Area Network/Wide Area Network via industry standard

TCP/IP communication protocol. Network based ISCs are able to communicate back with the database server through

industry standard network switches and routers and do not have to be on the same subnet, which means that any alarm in

the SYSTEM can be routed to any workstation(s) on the network.

Bi-Directional Data Interface

B.A.S.I.S. supports a bi-directional data interface to external databases such as Human Resources, Time & Attendance,

and Food Service Systems. The interface can be placed on a schedule to automatically import data into or export data out

of the SYSTEM database as needed.

Seamless Integration

All B.A.S.I.S. application modules, features, and functions are generated from a single source code set. The access

control, alarm monitoring, and ID management modules of the software are created from this single source code set. All

SYSTEM data reside in a single database on the network and are instantly accessible to every/any workstation connected

to the network which is licensed to do so. This provides automatic change propagation to all workstations on the SYSTEM

as well as a common database to consolidate all information and allow for better disaster recovery. This means that any

modifications made to either cardholders, time zones, or access levels are downloaded in real-time to all Intelligent Field

Panels.

9

ECTRONIC LOCKS

SYSTEM ARCHITECTURE

SYSTEM ARCHITECTURE

Access Control

10

STAND-ALONE EL

BV SERIES CARDS AND CARD OPTIONS

BV SERIES SYSTEM

BV SERIES ACCESSORIES

(not shown)

ORDER PROCEDURE

ORDER PROCEDURE

Custom Graphics Card Best Serialized Cards

Magnetic Strip / Proximity /

Smart Card

Card Specifications:

• Standard credit card size

• ISO standard .030" ±.003 thickness (PVC or Polyester)

• High coercivity ABA 3 tracks

STANDARD CARDS

STANDARD CARDS

Photo I.D. Card

Part Description Catalog Number

PVC - (Box of 500) VPA – PVC

Polyester - (Box of 500) VPA – POLY

Photo Identification/Custom Graphics*VPA – CUST

HID ProxCard® II Proximity Card 1326*VPA – HID – 1326

HID DuoProx® II Proximity Card 1336*VPA – HID – 1336

Motorola Image 30™Proximity Card ISO-30+*VPA – MOT – ISO30

Motorola LifeTime™Proximity Card ASC-121T+*VPA – MOT – ASC121T

Smart Card®* VPA – SC

*Special quote; contact local Best Access Systems office

Part Description Catalog Number

McGard™ Battery Door Screw (Specify Finish) VPD – HS – SCRW

McGard™ Driver Bit VPD – HS – DRVR

Standard Driver Bit VPD – T15

Cleaning Cards (Box of 50) VPD – CLN

Electrostatic Discharge (ESD) Kit VPD – ESD

Replacement Battery Pack VPD – BB

Extended Battery Pack VPD – EXBB

Part Description Catalog Number

Programming Cable BASD – CAB

Mag Stripe Encoder BASD – MSE

Smart Card Encoder BASD – SCE

B.A.S.I.S. Software BAS – SWS – V

11

ECTRONIC LOCKS

ORDER PROCEDURE

BATTERY LIFE CHART

ORDER PROCEDURE

Magstripe

Smart Card

Proximity

Dual Val

65,000 / 2–5 yrs.

62,000 / 2–5 yrs.

50,000 / 2–3.5 yrs.

65,000 / 2–5 yrs.

130,000 / 3–5 yrs.

110,000 / 3–5 yrs.

75,000 / 2–3.5 yrs.

130,000 / 3–5 yrs.

130,000 / 3–5 yrs.

120,000 / 3–5 yrs.

95,000 / 2–5 yrs.

130,000 / 3–5 yrs.

250,000 / 4–5 yrs.

225,000 / 4–5 yrs.

145,000 / 3–5 yrs.

250,000 / 4–5 yrs.

Reader Cylinder Mortise Cylinder Mortise

Cycles, Years Cycles, Years Cycles, Years Cycles, Years

BATTERY LIFE CHART

Standard Battery Pack Extended Battery Pack

(Page 7) (Page 7) (Page 7)

(Page 5) (Page 5) (Page 4) (Page 4) (Page 7)

HBV

35HBV 7 FV 14 MS 626 RH **

Series Core Function Lever Trim Finishes*** Hand Options

Housing Code Style Style

35HBV– lever 0– keyless EV– latch 3– solid tube MS– magnetic * 605 * 606 RH AL– abrasive lever (N/A 613)

7– 7 pin w/key w/ return stripe * 611 * 612 RHRB EXBB– extended battery pack

housing FV– deadbolt 12–solid tube PM– proximity, * 613 * 625 LH SH– security head screws*

w/key NV– latch 14– curved Motorola 626 629 LHRB Thick door– specify if other

w/o key w/return PH– proximity, 630 690 than 13/4" *

LV– deadbolt 15– contour w/ HID TL– tactile lever*(#14,#16)

w/o key angle return DV– dual Proximity Reader Only

16– curved validation ABA, 26 bit Weigand, 37 bit

no return Weigand

17– gullwing no

return

* Extra cost option.

** Must specify key mark and number of patented/standard keys.

*** Escutcheons are made from a zinc alloy and have been plated to be equivalent in appearance to the finishes listed.

KBV

93KBV 7 DV 14 MS STK 626 **

Series Core Function Lever Trim Strike Finishes*** Options

Housing Code Style Style Package

93KBV–2

3/4"7– 7 pin DV–14– curved MS– magnetic STK–standard *605 *606 AL– abrasive lever (N/A 613)

94KBV–3

3/4" * housing cylindrical return stripe S3–ANSI *611 *612 EXBB– extended battery pack

95KBV–5" * latch w/key 15– contour PM– proximity *613 *625 FM– free motion †

override angle Motorola 626 690 SH– security head screws*

return PH– proximity TL– tactile lever*(#14,#16)

16– curved HID Thick door-specify if other

no return DV– dual than 1 3/4" *

validation 3/4–3/4"throw *

Proximity Reader Only

ABA, 26 bit Weigand, 37 bit

Weigand

* Extra cost option.

** Must specify key mark and number of patented/standard keys.

*** Escutcheons and levers are made from a zinc alloy and have been plated to be equivalent in appearance to the finishes listed.

† Lower cost option.

(Page 6) (Page 6 )(Page 6)

BEST ACCESS SYSTEMS

Indianapolis, Indiana

1

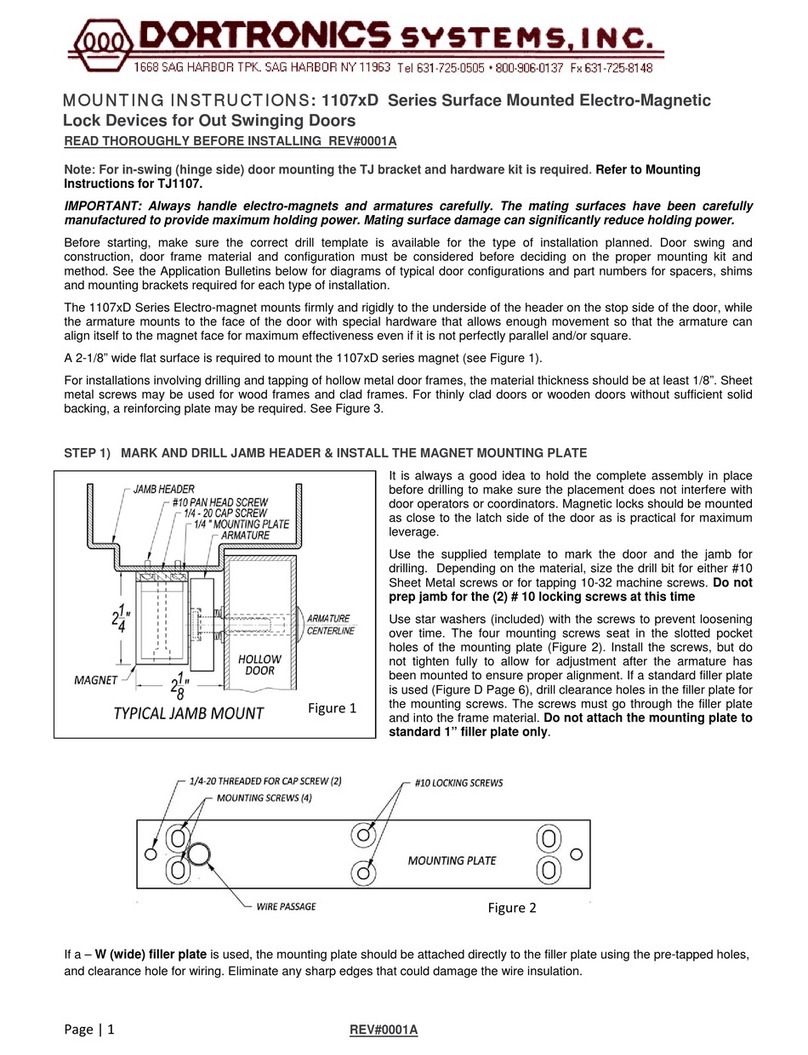

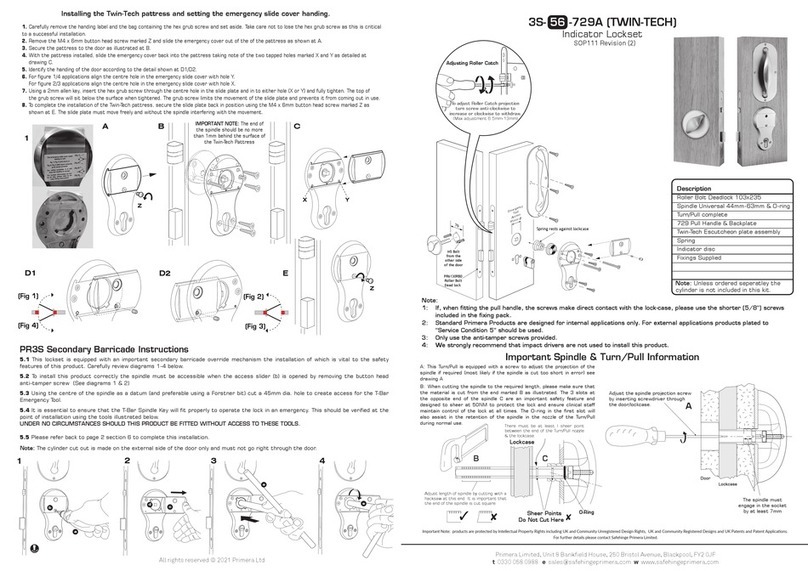

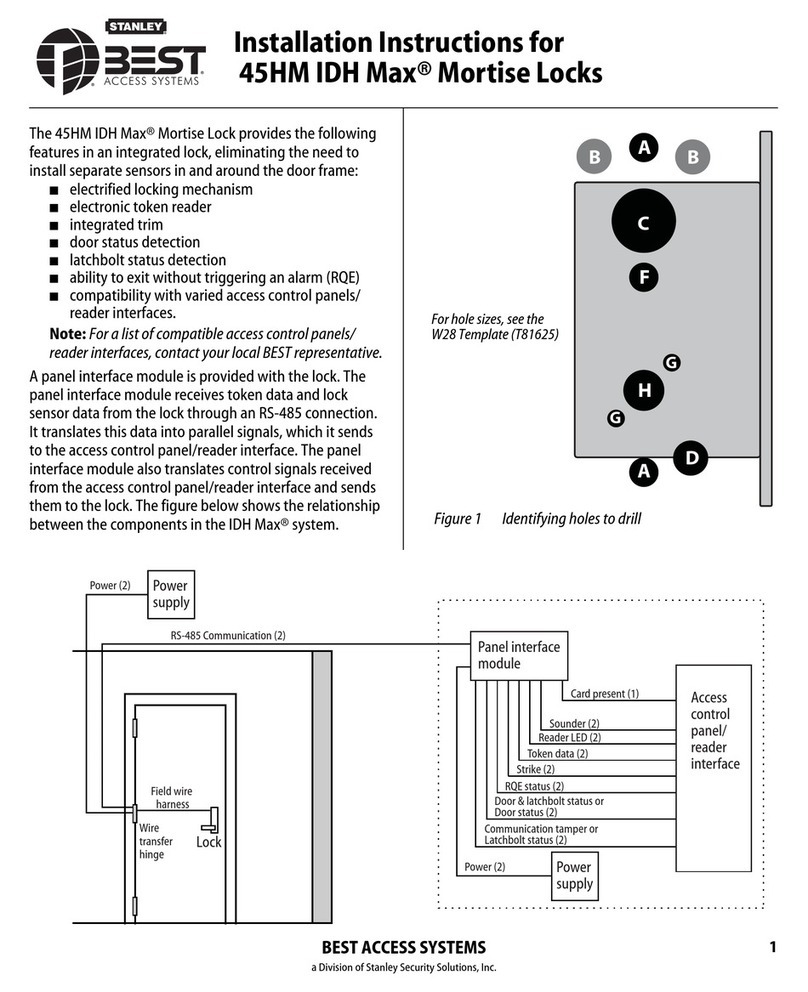

Planning the installation

Contents

These installation instructions describe how to install your

B.A.S.I.S. G (93KG–95KG) or B.A.S.I.S. V (93KBV–95KBV)

Cylindrical Lock. The following topics are covered.

Planning the installation................................................ 1

Preparing the door and door jamb ................................ 2

Installing the lock ............................................................ 6

Completing the installation............................................9

Site survey

Use the following survey to record information about the

installation site. You need this information to determine

how to prepare the door for the lock.

Door information

Door handing and bevel:

❑Left hand (LH)

❑Left hand, reverse bevel (LHRB)

❑Right hand (RH)

❑Right hand, reverse bevel (RHRB)

Door thickness: inches (1 3/4″to 2 1/4″)

Environment information

Ambient temperature:

❑Is within specifications. See the tables below.

This product meets the following Locked Door Outdoor

test requirements for ANSI/BHMA 156.25:

This product meets the following Full Indoor test

requirements for ANSI/BHMA 156.25:

Side of door Range

Inside +66°F to +74°F (+19°C to +23°C)

Outside –31°F to +151°F (–35°C to +66°C)

Side of door Range

Inside and outside +32°F to +120°F (0°C to +42°C)

Components checklist

Use the following checklist to make sure that you have the

items necessary to install your B.A.S.I.S. Cylindrical Lock.

Components provided in the box:

❑Chassis with outside lever and outside rose liner

assembly

❑Inside escutcheon assembly

❑Battery compartment door

❑Battery pack

❑Inside rose liner

❑Outside escutcheon assembly

❑Inside lever

❑Throw member package

❑Latch

❑Plastic bushing package

❑Escutcheon screw package

❑Strike package

❑Bar code ID sticker (for your records)

❑Temporary operator card

❑Installation template and instructions

Other components:

❑Core

❑Control key

Special tools checklist

Use the following checklist to make sure that you have the

special tools necessary to install your B.A.S.I.S. Cylindrical

Lock.

❑KD303 Drill jig

❑T15 TORX® bit driver†

❑KD325 Strike plate locating pin

❑KD315 Faceplate marking chisel

† TORX is a registered trademark of the Camcar

Division of Textron.

Installation Instructions for

B.A.S.I.S. Cylindrical Locks

Installation Instructions for B.A.S.I.S. Cylindrical Locks

BEST ACCESS SYSTEMS

Indianapolis, Indiana

Preparing the door and door jamb

2

1Position template and mark drill points

Note: If the door is a fabricated hollow metal door,

determine whether it is properly reinforced to support

the lock. If door reinforcement is not adequate, consult

the door manufacturer for information on proper

reinforcement. For dimensions for preparing metal

doors, see the G01 and G02 Templates—Installation

Specifications for 93KG and 93KBV Cylindrical Locks.

Note: If the door is a LH or RH door, mark the inside of

the door. If the door is a LHRB or RHRB door, mark the

outside of the door.

For uncut doors and frames

1 Measure and mark the horizontal centerline of the

lever (the centerline for the chassis hole) on the door

and door jamb. Mark the vertical centerline of the door

edge.

Note: The recommended height from the floor to the

centerline of the lock is 38″.

2 Fold the G05 Template—Installation Template for 93KG

and 93KBV Cylindrical Locks on the dashed line and

carefully place it in position on the high side of the

door bevel.

Note: For steel frame applications, align the template’s

horizontal centerline for the latch with the horizontal

centerline of the frame’s strike preparation.

3 Tape the template to the door.

4 Center punch the necessary drill points. Refer to the

instructions on the template.

For doors with standard cylindrical preparation

1 Fold the G05 Template—Installation Template for 93KG

and 93KBV Cylindrical Locks on the dashed line.

Looking through the hole from the opposite side of

the door, align the template so that you see the

template outline of the 2 1/8″diameter chassis hole.

2 Tape the template to the door.

3 Center punch the necessary drill points. Refer to the

instructions on the template.

Figure 1 Positioning the template

Horizontal centerline

of lever

Installation template

Installation Instructions for B.A.S.I.S. Cylindrical Locks

BEST ACCESS SYSTEMS

Indianapolis, Indiana

3

Installation Instructions for B.A.S.I.S. Cylindrical Locks

Preparing the door and door jamb Components checklist

2Drill holes and mortise for latch face.

1 Drill the holes listed below:

■upper and lower trim holes

—5/8″diameter

— through door

■harness hole

—3/4″diameter

— through door

— location based on handing

■motor wire hole

—7/16″diameter

— through door

— before drilling chassis hole

■chassis hole

—21/8″diameter

— through door

— after drilling motor wire hole

■latch hole

—1″diameter

— meets chassis hole

Note 1: To locate the center of a hole on the opposite

side of the door, drill a pilot hole completely through the

door.

Note 2: For holes through the door, it is best to drill

halfway from each side of the door to prevent the door

from splintering.

2 Mortise the edge of the door to fit the latch face.

3 Drill the holes for the screws used to install the latch.

Figure 2 Drilling holes and mortising for the latch face

Latch hole

Upper trim hole

Harness

hole

Motor wire hole

Chassis hole

Lower trim hole

Latch face

mortise

Inside of door

Installation Instructions for B.A.S.I.S. Cylindrical Locks

BEST ACCESS SYSTEMS

Indianapolis, Indiana

Preparing the door and door jamb

4

3Install latch

1 Install the latch in the door.

Note: The latch tube prongs should be centered and

should project into the chassis hole.

2 Check that the door swings freely.

4Use drill jig to drill through-bolt holes

1 Press the drill jig (KD303) onto the door, engaging it

with the latch tube prongs (see the close-up in

Figure 4). Make sure the front edge of the jig is parallel

with the door edge.

2 Drill the through-bolt holes (5/16″diameter) halfway

into the door.

3 Turn over the drill jig and repeat steps 1 and 2 from the

opposite side of the door.

Note: Replace the drill jig after 10 door preparations.

Figure 3 Installing the latch in the door

Latch

Location of latch

tube prongs

Chassis hole

Inside of door

Figure 4 Installing the drill jig and drilling the

through-bolt holes

Latch

tube

prongs

Drill upper through-bolt hole.

Drill lower through-bolt hole.

Inside of door

Installation Instructions for B.A.S.I.S. Cylindrical Locks

BEST ACCESS SYSTEMS

Indianapolis, Indiana

5

Installation Instructions for B.A.S.I.S. Cylindrical Locks

Preparing the door and door jamb

5Install strike box and strike plate

1 In alignment with the center of the latchbolt, mortise

the door jamb to fit the strike box and strike plate.

2 Drill the holes for the screws used to install the strike

box and strike plate.

3 Insert the strike box and secure the strike with the two

screws provided.

4 Check the position of the deadlocking plunger against

the strike plate.

Caution: The deadlocking plunger of the latchbolt

must make contact with the strike plate, as shown

in Figure 5b. The plunger deadlocks the latchbolt

and prevents someone from forcing the latch

open when the door is closed.

Figure 5a Installing the strike box and strike plate

Strike box

Strike plate

Door jamb

Figure 5b Aligning the deadlocking plunger with the

strike plate

Strike plate

Deadlocking

plunger

Door jamb

Installation Instructions for B.A.S.I.S. Cylindrical Locks

BEST ACCESS SYSTEMS

Indianapolis, Indiana

Installing the lock

6

6Remove outside lever

1 Insert the control key into the core and rotate the key

15 degrees to the right.

2 Insert a flat blade screwdriver into the figure-8 core

hole and into the lever.

3 Press the screwdriver blade in the direction of the

arrow in Figure 6.

Note: You cannot remove the lever if the screwdriver

blade is inserted too far past the keeper.

4 Slide the lever off of the sleeve.

7Adjust for door thickness

1 Determine the door’s thickness.

2 Pull the rose locking pin and rotate the outside rose

liner until the proper groove on the through-bolt stud

lines up with the hub face.

Note 1: Make sure that the locking pin fully locks into

the rose liner.

Note 2: The lockset fits doors 1 3/4″to 2 1/4″thick.

Figure-8

core hole

Figure 6 Removing the outside lever

Insert screwdriver

blade here.

Lever keeper

Figure 7 Adjusting the rose liner for the door thickness

1 3/4″

2″

2 1/4″ groove Through-

bolt stud

Hub face

Outside

rose liner

Rose locking

pin

Installation Instructions for B.A.S.I.S. Cylindrical Locks

BEST ACCESS SYSTEMS

Indianapolis, Indiana

7

Installation Instructions for B.A.S.I.S. Cylindrical Locks

Installing the lock

8Install lock chassis and engage

retractor in latch

From the outside of the door, insert the lock chassis

into the 2 1/8″chassis hole, routing the motor wire

through the notch.

Caution: Make sure that the latch tube prongs

engage the chassis frame and that the latch

tailpiece engages the retractor.

9Install through-bolts and inside rose

liner

1 Place the inside rose liner on the chassis, aligning the

holes in the rose liner with the holes prepared in the

door.

Caution: Make sure that there is clearance for the

motor wire between the rose liner and the door.

2 Install the through-bolts through the rose liner and

door in the top and bottom holes.

3 Tighten the rose liner on the door with the

through-bolts.

Figure 8 Installing the lock chassis and engaging the

retractor in the latch

Latch tube

prong

Retractor

Latch

tailpiece

Chassis

Chassis frame

Latch tube

prong

Notch

Inside of door

Figure 9 Installing the through-bolts and rose liner

Through-bolt

Motor wire

Inside of door

Rose liner

Installation Instructions for B.A.S.I.S. Cylindrical Locks

BEST ACCESS SYSTEMS

Indianapolis, Indiana

Installing the lock

8

10 Remove backup battery tab

Caution: For the lock to operate properly, you

must remove the backup battery tab.

1 Locate the backup battery tab on the inside of the

outside escutcheon.

2 Pull down on the tab and remove it from the outside

escutcheon to turn on the backup battery.

11 Route wire harness and position

outside escutcheon

1 Insert the two bushings into the harness hole on each

side of the door, as shown in Figure 11 and Figure 12.

2 From the outside of the door, feed the upgrade

connector, and then the motor connector and battery

connector, through the harness hole.

Caution: When routing the connectors, make sure

the wire harness is not routed across any sharp

edges or over any surface that could damage its

sleeving or wire insulation.

3 Temporarily rest the outside escutcheon on the door

by inserting the trim studs into the trim holes.

Note: You can temporarily install the outside lever to

hold the outside escutcheon in place. See task 15 on

page 10.

12 Make motor connection

From the inside of the door, connect the motor

connector from the chassis to its mating connector on

the wire harness.

Note: The upgrade cable is used for reprogramming the

lock’s firmware without removing the lock from the door.

This cable does not connect to a mating lock connector.

Caution: When making the motor connection,

make sure:

■there are no loose wire connections where the

wires are inserted into the connectors

■the connectors are firmly mated.

Wire connection Colors No. of

wires

No. of

pins

Motor Yellow

Gray

22

Figure 11 Feeding the wire harness connectors through

the harness hole

Motor connector

Outside escutcheon

Outside of door

Harnesshole

Battery connector

Bushing

Upgrade

connector

Figure 12 Making the motor connection

Inside of door

Motor connection

Bushing

Upgrade cable

Installation Instructions for B.A.S.I.S. Cylindrical Locks

BEST ACCESS SYSTEMS

Indianapolis, Indiana

9

Installation Instructions for B.A.S.I.S. Cylindrical Locks

Installing the lock

13 Secure escutcheons

1 Position the inside and outside escutcheons on the

door.

2 Making sure that the escutcheons do not pinch

the wires, secure the escutcheons to the door—but

do not tighten. Use the combination mounting screw

at the upper trim hole and the standard mounting

screw at the lower trim hole.

14 Install battery pack

1 Connect the battery pack to the battery connector on

the wire harness inside the battery compartment.

Caution 1: When routing the battery wires, make

sure the wires are not routed across any sharp

edges or over any surface that could damage their

sleeving or wire insulation.

Caution 2: When connecting the battery pack,

make sure:

■there are no loose wire connections where the

wires are inserted into the connectors

■the connectors are firmly mated.

2 Place the battery pack inside the battery compartment

so that the foam will face the battery compartment

door.

Wire

connection Color No. of

wires

No. of

pins

Battery Red w/white stripe

White

Black w/white stripe

33

Figure 13 Securing the escutcheons

Combination

mounting screw

Standard

mounting screw

Inside of door

Inside escutcheon

Figure 14 Connecting the battery pack

Battery pack

Inside escutcheon

Installation Instructions for B.A.S.I.S. Cylindrical Locks

BEST ACCESS SYSTEMS

Indianapolis, Indiana

Completing the installation

10

15 Install inside and outside levers

Note: To use a core and throw member from a

manufacturer other than BEST with a B.A.S.I.S. Lock, see

the Installation Instructions for 9K Non-

interchangeable Cores & Throw Members (T56093).

Skip task 15 and task 16.

For the inside and outside levers

1 With the handle pointing toward the door hinges,

position a lever on the outside sleeve and push firmly

on the lever until it is seated. Repeat, placing the other

lever on the inside sleeve.

2 Tighten the escutcheon mounting screws.

3 Turn the levers to check that they operate smoothly.

16 Install core and throw member

1 Install the blocking plate onto the throw member.

Caution: You must use the blocking plate to

prevent unauthorized access.

2 Insert the control key into the core and rotate the key

15 degrees to the right.

3 Insert the throw member into the core.

4 Insert the core and throw member into the lever with

the control key.

5 Rotate the control key 15 degrees to the left and

withdraw the key.

Caution: The control key can be used to remove

cores and to access doors. Provide adequate

security for the control key.

Figure 15 Installing the levers

Outside of door

Figure 16a Installing the blocking plate and throw

member

Core

Blocking

plate

Throw

member

Figure 16b Installing the core

Core

Control

key

Throw

member

Other manuals for B.A.S.I.S. V

1

This manual suits for next models

2

Table of contents

Other BEST ACCESS SYSTEMS Door Lock manuals

BEST ACCESS SYSTEMS

BEST ACCESS SYSTEMS B.A.S.I.S. V User manual

BEST ACCESS SYSTEMS

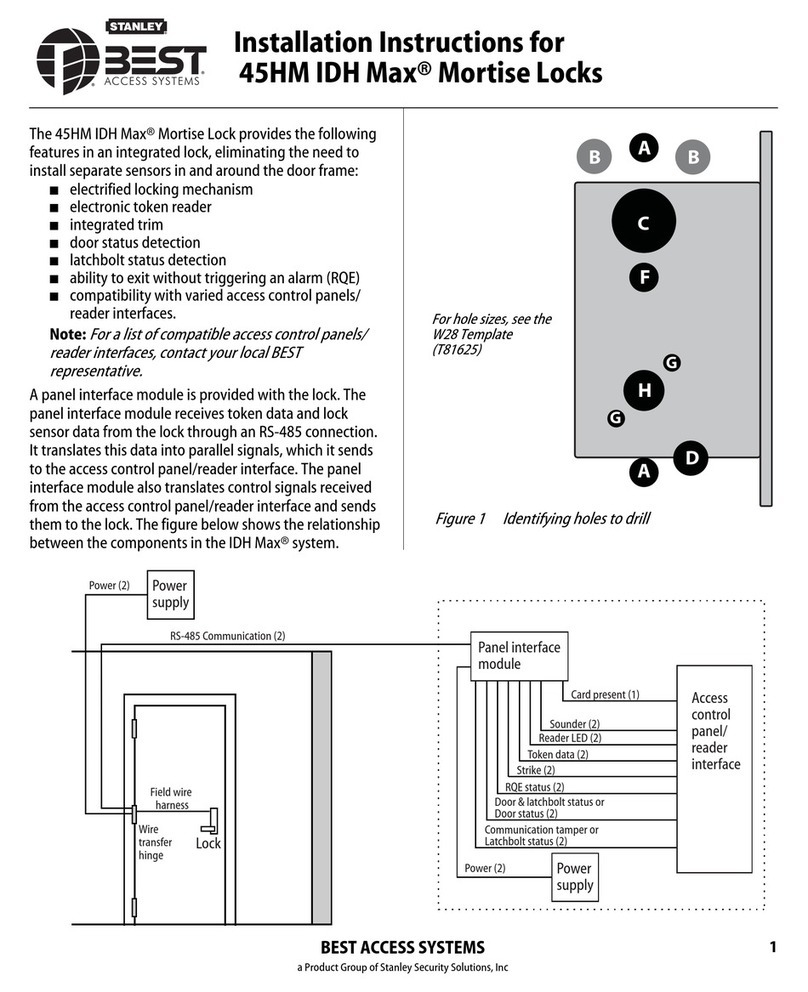

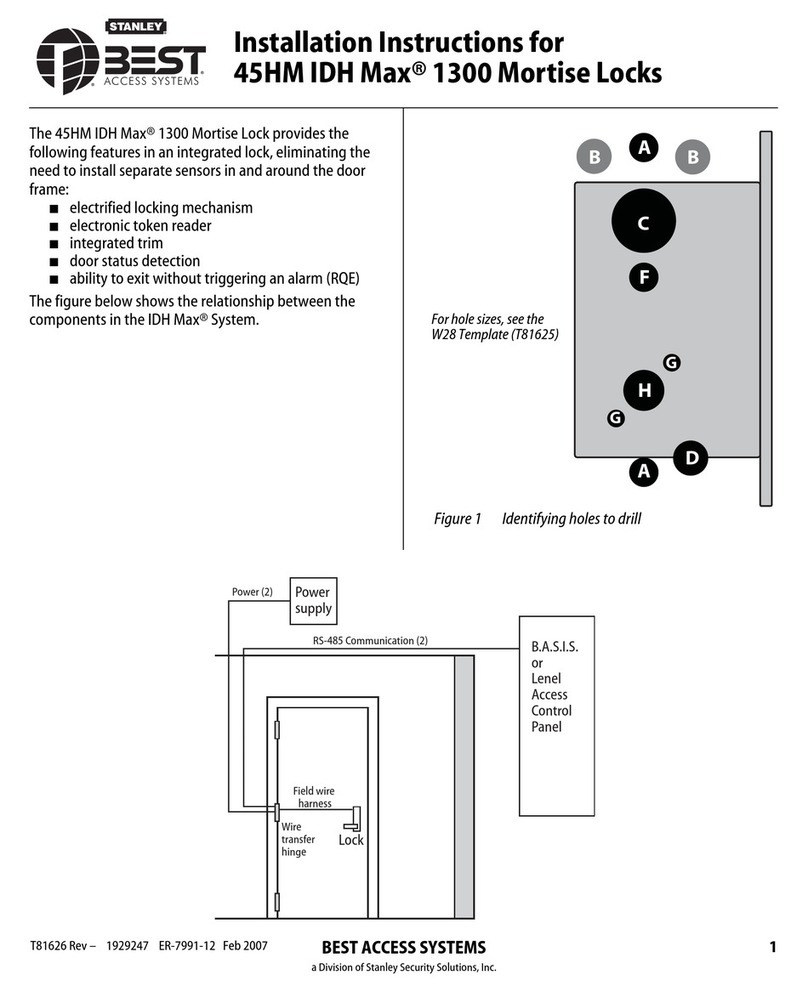

BEST ACCESS SYSTEMS 45HM IDH Max Mortise Lock User manual

BEST ACCESS SYSTEMS

BEST ACCESS SYSTEMS 45HM IDH Max Mortise Lock User manual

BEST ACCESS SYSTEMS

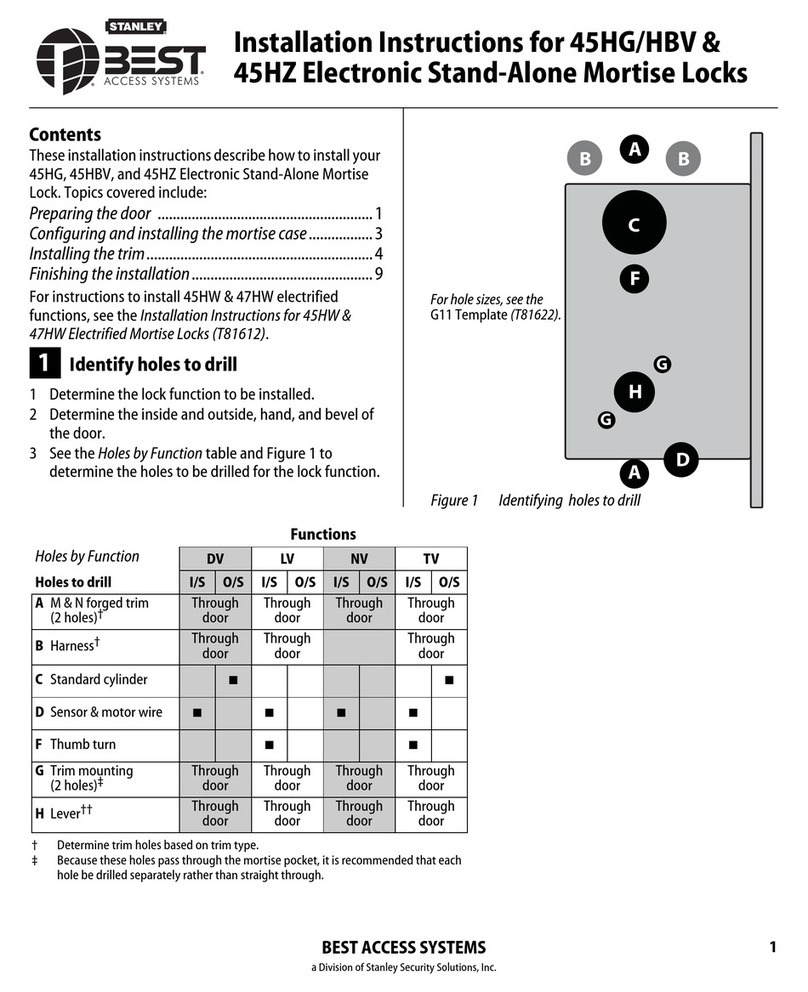

BEST ACCESS SYSTEMS 45HG User manual

BEST ACCESS SYSTEMS

BEST ACCESS SYSTEMS W Series User manual

BEST ACCESS SYSTEMS

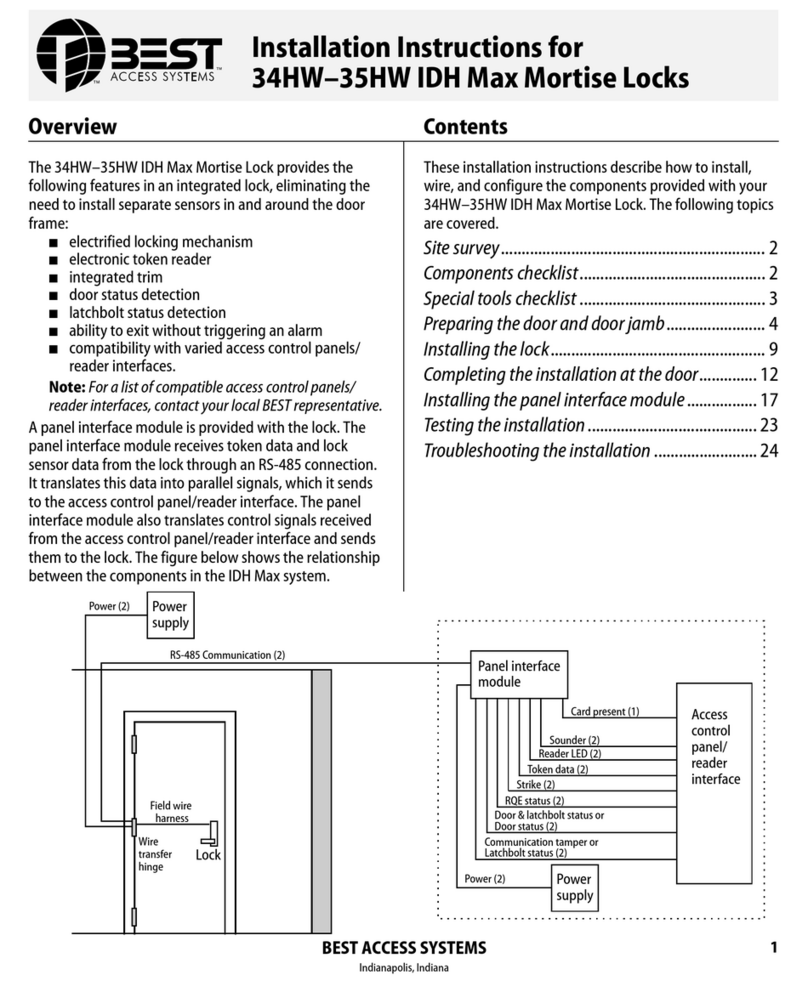

BEST ACCESS SYSTEMS 34HW User manual

BEST ACCESS SYSTEMS

BEST ACCESS SYSTEMS 45HM IDH Max 1300 User manual

BEST ACCESS SYSTEMS

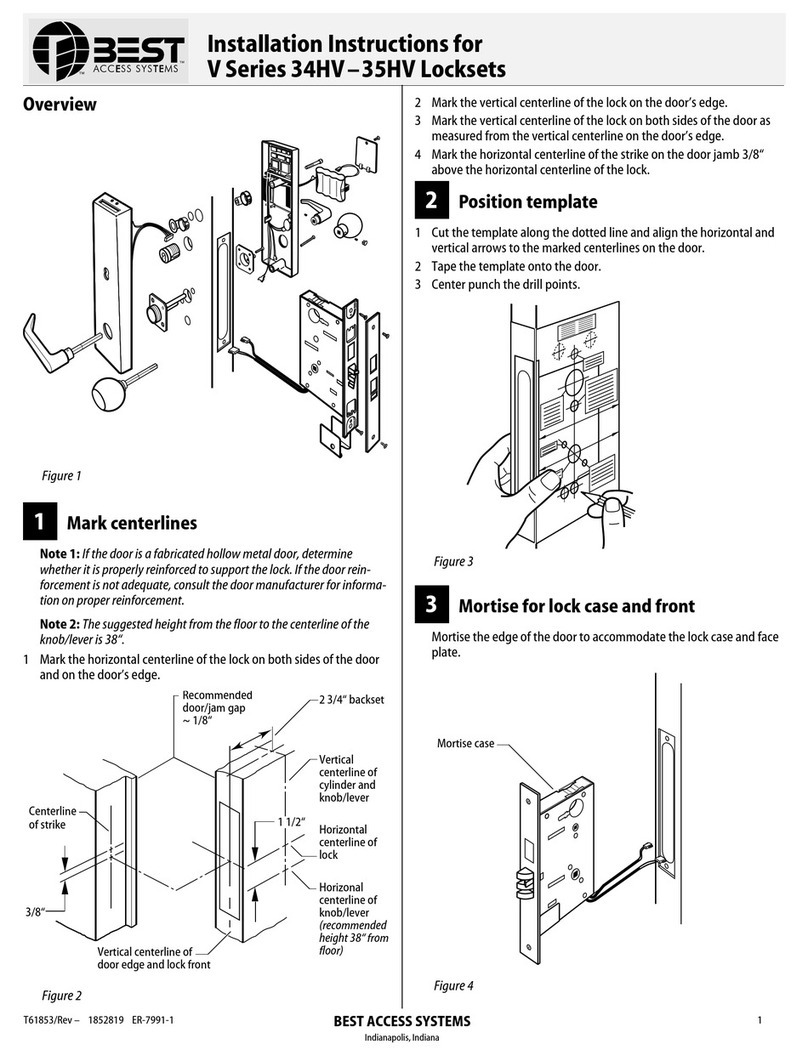

BEST ACCESS SYSTEMS V Series User manual