SSTOMM GT200-DP-MT User manual

PROFIBUS DP / Modbus TCP Gateway

GT200-DP-MT

User Manual

REV 2.2

SST Automation

E-mail: SUPPORT@SSTCOMM.COM

WWW.SSTCOMM.COM

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

2

Catalog

1 Product Overview...................................................................................................................................................... 4

1.1 General............................................................................................................................................................ 4

1.2 Important User Information............................................................................................................................4

2 About the Gateway.....................................................................................................................................................5

2.1 Function.......................................................................................................................................................... 5

2.2 Features........................................................................................................................................................... 5

2.3 Technical Specification...................................................................................................................................5

2.4 Attention..........................................................................................................................................................6

2.5 Related Products............................................................................................................................................. 6

3 Hardware Description................................................................................................................................................ 7

3.1 Product Appearance........................................................................................................................................ 7

3.2 Indicators.........................................................................................................................................................8

3.3 DIP Switch...................................................................................................................................................... 8

3.3.1 Status Configuration Switch................................................................................................................8

3.3.2 PROFIBUS DP Address Setting Switch..............................................................................................9

3.4 Connectors...................................................................................................................................................... 9

3.4.1 PROFIBUS DP Connector.................................................................................................................. 9

3.4.2 Ethernet Connector............................................................................................................................ 10

3.4.3 Power Connector............................................................................................................................... 10

4 Working Principle of Modbus TCP Master............................................................................................................. 11

5 Working Principle of Modbus TCP Slave............................................................................................................... 12

5.1 Network Status Monitoring......................................................................................................................... 12

6 Instructions of Configuration Software................................................................................................................... 13

6.1 Notes before Configuration......................................................................................................................... 13

6.2 User Interface................................................................................................................................................13

6.3 Equipment View Operation.......................................................................................................................... 15

6.3.1 Equipment View Interface................................................................................................................. 15

6.3.2 Equipment View Operation Mode.....................................................................................................15

6.3.3 Equipment View Operation Types.....................................................................................................16

6.4 The Operation of Configuration Interface....................................................................................................17

6.4.1 Fieldbus Configuration View Interface............................................................................................. 17

6.4.2 Ethernet Configuration View Interface............................................................................................. 18

6.4.3 Node Configuration View Interface.................................................................................................. 20

6.4.4 Command Configuration View Interface.......................................................................................... 21

6.4.5 Comment Interface............................................................................................................................ 23

6.5 Conflict Detect..............................................................................................................................................23

6.5.1 Command List Operation.................................................................................................................. 24

6.5.2 Memory Mapping Area Operation.................................................................................................... 24

6.6 Hardware Communication............................................................................................................................25

6.6.1 Ethernet Configuration...................................................................................................................... 26

6.6.2 Upload Configuration........................................................................................................................ 27

6.6.3 Download Configuration................................................................................................................... 28

6.7 Load and Save Configuration....................................................................................................................... 29

6.7.1 Save Configuration Project................................................................................................................29

6.7.2 Load Configuration Project............................................................................................................... 29

6.8 Export EXCEL..............................................................................................................................................30

6.9 Monitor I/O Data.......................................................................................................................................... 30

7 Typical Application.................................................................................................................................................. 32

8 Step7 Read and Write Gateway Data...................................................................................................................... 33

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

3

9 Installation................................................................................................................................................................35

9.1 Machine Dimension......................................................................................................................................35

9.2 Installation Method.......................................................................................................................................35

Appendix: Using STEP7 Set PROFIBUS DP............................................................................................................ 37

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

4

1 Product Overview

1.1 General

This document describes every parameters of the gateway GT200-DP-MT and provides using methods and

some announcements that help users use the gateway. Please read this document before using the gateway.

For further information, documentation etc., please visit the SSTCOMM website: http://www.sstcomm.com.

1.2 Important User Information

The data and examples in this document cannot be copied without authorization. SSTCOMM maybe

upgrades the product without notifying users.

is the registered trade mark of SST Automation.

The product has many applications. Users must make sure that all operations and results are in accordance

with the safety of relevant field, including laws, rules, codes and standards.

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

5

2 About the Gateway

2.1 Function

Connects Modbus TCP devices to PROFIBUS DP network, and establishes communication between them.

2.2 Features

With an Ethernet interface (Modbus TCP master / Modbus TCP slave) and a PROFIBUS DP slave interface

Ethernet 10/100M adaptive

IP address conflict detection

Support DHCP, BOOTP and static setting

Support standard Modbus TCP master and slave protocol

I/O data monitoring capabilities

Easy-to-use configuration software SST-EP-CFG

2.3 Technical Specification

[1] Support PROFIBUS DP V0 protocol;

[2] PROFIBUS DP slave, baud rate adaptive, maximum baud rate 12M;

[3] PROFIBUS DP max input data bytes is 244 bytes and output data bytes is 244 bytes, input + output data

bytes is 488 bytes;

[4] As a Modbus TCP master, it can support visiting Modbus TCP server of at most 36 different IPs or

different unit IDs;

[5] As a Modbus TCP master, it can support the function code: 01H, 02H, 03H, 04H, 05H, 06H, 0FH and

10H;

[6] As a Modbus TCP slave, it can support up to 36 TCP connections;

[7] As a Modbus TCP slave, it can support the function code: 03H, 04H, 06H and 10H;

[8] PROFIBUS DP interface: 1KV photoelectric isolation;

[9] Power supply 24VDC (11V to 30V), 160mA (24VDC);

[10] Operating temperature: -4 ° F to 140 ° F (-20℃~60℃), relative humidity 5% ~ 95% (no condensation);

[11] External Dimensions (W*H*D): 1.57in*4.92in*4.33in (40mm* 125mm * 110mm);

[12] Installation: 35mm rails;

[13] Protection class: IP20;

[14] Test standard: Complies with EMC test standards.

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

6

2.4 Attention

To prevent stress, prevent module panel damage;

To prevent bump, which may damage internal components;

Power supply voltage should be controlled within the scope of the requirements to prevent burning

module;

To prevent water, which will affect the normal work;

Please check the wiring, before any wrong or short circuit.

2.5 Related Products

Related products include:

GT200-DP-CA, GT200-CO-EI, GT200-EI-2RS485, GT200-DP-CO and so on

More information about these products, please visit: http://www.sstcomm.com, or dial technical support line:

+1-844-606-2886.

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

7

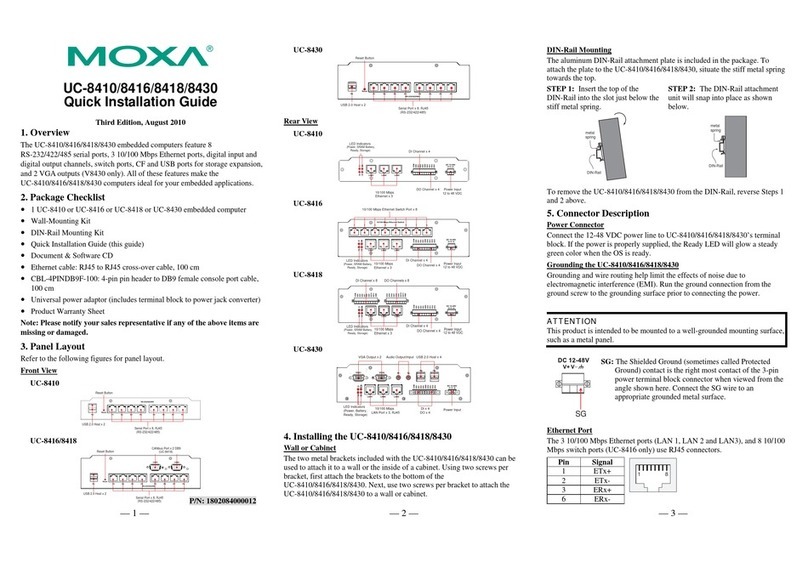

3 Hardware Description

3.1 Product Appearance

Note: This picture is for reference only. Product appearance should refer to the real object.

Ethernet

PROFIBUS

DP interface

DIP Switch

Power supply

LED

Rotary address Switch

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

8

3.2 Indicators

Indicators

Status

Description

STA(green)

blink

PROFIBUS DP bus data is communicating

Off

No data communicating

PBF (red)

On

PROFIBUS DP bus data communication fails

Off

Communication is ok

MS

Blink (red)

DHCP or BOOTP status

On (red)

IP confliction

OFF(red)

Normal communication

NS

On(green)

Modbus TCP connection has been established

Flash(green)

Modbus TCP connection is not established or

disconnected

OFF(green)

Modbus TCP is not started

MS, NS, and STA flashes once

Boot up

MS and NS ON

Configuration status

3.3 DIP Switch

3.3.1 Status Configuration Switch

The configuration switch is located on the button of the product. The function is listed below:

Off

On 1 2

Status(1)

Status(2)

Description

Off

Off

Run mode, allow reading and writing configuration data

Off

On

Run mode, forbid reading and writing configuration data

On

Off or On

Configuration mode, IP address is 192.168.0.10 (fixed), this

mode can read and write configuration data but cannot finish

communication between Modbus TCP and PROFIBUS DP

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

9

Notes:

Restart GT200-DP-MT (power off and power on) after resetting the configuration to make the

configuration take effect!

3.3.2 PROFIBUS DP Address Setting Switch

The 2-code rotary switch in the left-side is used for setting the PROFIBUS DP address of the device.

In this example, the calculation formula of PROFIBUS DP address will be: 42 ((4x10) + (2x1)).

3.4 Connectors

3.4.1 PROFIBUS DP Connector

DB9 pin

Function

3

PROFI_B, Data positive

5

GND

8

PROFI_A, Data negative

PROFI-B

PROFI-A

GND

PROFI-B

PROFI-A

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

10

3.4.2 Ethernet Connector

Ethernet interface uses RJ-45 connector, 10/100M self-adaptive; its pin (standard Ethernet signal) is defined

as below:

pin

Signal Descriptions

S1

TXD+, Tranceive Data+, output

S2

TXD-, Tranceive Data-,output

S3

RXD+, Receive Data+, input

S4

Bi-directional Data+

S5

Bi-directional Data-

S6

RXD-,Receive Data-, input

S7

Bi-directional Data+

S8

Bi-directional Data-

3.4.3 Power Connector

GND

NC

24V+

1

2

3

Pin

Function

1

GND, Power ground

2

NC, not connected

3

24V+, DC+24V

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

11

4 Working Principle of Modbus TCP Master

Ethernet supports Modbus TCP master function, described as below:

Data exchange of Modbus TCP and PROFIBUS DP of GT200-DP-MT is set up through “mapping”. There

are two data buffer areas, one is PROFIBUS DP network input buffer and the other is PROFIBUS DP network

output buffer. When the gateway acts as Modbus TCP master, Modbus read commands will write the read data to

the network input buffer for PROFIBUS DP accessing. Modbus write register commands get data from network

output buffer and export to the Modbus TCP slave equipment through write command.

Modbus TCP can support up to 36 nodes and 128 commands, each command reads a set of

consecutive Modbus registers.

Modbus

device 3

Modbus

device 4

Modbus

device 5

Modbus

device 6

Input Buffer

Output Buffer

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

12

5 Working Principle of Modbus TCP Slave

Data exchange of Modbus TCP and PROFIBUS DP of GT200-DP-MT is set up through “mapping”. There

are two data buffer areas, one is PROFIBUS DP network input buffer and the other is PROFIBUS DP network

output buffer. Network input and output buffer is all for PROFIBUS DP. When the gateway acts as Modbus TCP

slave, Modbus write register command will write the read data to the network input buffer for PROFIBUS DP

accessing. Modbus read command gets data from network output buffer and export to the Modbus TCP master

equipment through response message.

The gateway acts as Modbus TCP slave, support function: 03H, 04H, 06H and 10H. Users can select 03H

function code to read the data PROFIBUS DP master outputted or use 04H function code to read he data

PROFIBUS DP master outputted.

Network input buffer is Modbus TCP master output at the Modbus TCP side. It is mapped to the Modbus

holding register. Users can use No.3 command or No.4 command to read back. Users can select command No. in

the configuration software.

Network output buffer is Modbus TCP master input. It is mapped to Modbus input register. Users can use

No.4 or No.3 function code to read data. Users can select command No. in the configuration software.

5.1 Network Status Monitoring

When the gateway is a Modbus TCP slave, the gateway has the function of monitoring the network status.

When the monitoring is enabled, the first word of input buffer is used as counter which record the number of

TCP connections.

PROFIBUS

Input buffer

PROFIBUS

Output buffer

… …

0004H

0001H

0000H

0002H

0003H

0005H

0004H

0001H

0002H

0000H

0003H

0005H

… …

Modbus Write

command 06,10H

Modbus

Read command

03H or 04H

Modbus

Read command

03H or 04H

Modbus

Read command

03H or 04H

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

13

6 Instructions of Configuration Software

6.1 Notes before Configuration

SST-EP-CFG is a Windows-based platform, used to configure GT200-DP-MT and other products.

Here is to introduce the use of SST-EP-CFG. Double-click on the icon to enter the main interface:

6.2 User Interface

SST-EP-CFG user interface include: title bar, menu bar, toolbar, status bar, equipment plate, configuration

plate and comment plate.

Note: In this software, all gray parts cannot be modified.

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

14

Toolbar:

Toolbar is shown as below:

The function from left to right is: New, Open, Save, Add Nodes, Delete Nodes, Add Commands, Delete

Commands, Upload Config, Download Config, Conflict Detect, Auto Mapping, Export Xls and Monitor I/O data.

New: Create a new project

Open: Open a project

Save: Save the current project

Add a node: Add a Modbus TCP slave node

Delete a node: Delete a Modbus TCP slave node

Add command: Add a Modbus command

Delete command: Delete a Modbus command

Upload: Read the configuration information from the module and shown in the software

Download: Download the configuration into the gateway

Conflict detection: To check whether there are some conflicts with configured commands in the gateway

memory data buffer

Auto mapping: Used to automatically calculate the mapped memory address without confliction by each

Equipment plate:

Users can choose operation

object, includes Ethernet type,

adding node and command

Menu Bar

Title Bar

Configuration plate:

Input configuration parameters,

gray parts cannot be modified

Comment plate:

Explain the function of the

configuration options

Toolbar

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

15

command

Export Excel: Export current configuration to the local hard disk, saved as .xls file

Monitor I/O data: Monitor the gateway memory buffer data

6.3 Equipment View Operation

6.3.1 Equipment View Interface

6.3.2 Equipment View Operation Mode

For equipment interface, support three operation modes: edit menu, edit toolbar and right click edit menu.

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

16

6.3.3 Equipment View Operation Types

1) Add node operation: Left click on Ethernet or existing nodes, and then perform the operation of adding a

new node. Then there is a new node named "New node" under Ethernet.

2)Delete node: Left click on the node to be deleted, and then perform the operation of deleting the node.

The node and all commands will be deleted.

3)Add commands: Left click on the node, and then perform the operation of adding command to add a

command for the node. It will pop up the command selecting dialog box for users to choose. Shown as below:

Select the command: Double click command item

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

17

4)Delete commands: Left click on the command to be deleted, perform the operation of deleting the

command.

5)Edit node: Left click the node needs to be reset, and then set parameters of this node in configuration

interface.

6)Copy node: Left click the existing node, choose the node and execute the operation of copying nodes

(include all commands under the node)

7)Paste node: Left click and choose any existing node, execute operation of paste node. Then at the

Ethernet rear part you can see a new node (include all commands under the node); Node parameters of new node

is default setting, it needs to be reset.

6.4 The Operation of Configuration Interface

6.4.1 Fieldbus Configuration View Interface

Click the fieldbus in the equipment view interface, displaying configuration view interface as follows:

The configurable items include:

Bus Type: PROFIBUS DP

PROFIBUS DP input bytes: Set through the Hardware Configuration of PROFIBUS DP

PROFIBUS DP output byte: Set through the Hardware Configuration of PROFIBUS DP

Double-fault clear: open and close optional.

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

18

6.4.2 Ethernet Configuration View Interface

Click Ethernet in configuration view interface; when choosing a different type of protocol, the configuration

view interface and configurable items are different.

The protocol type selection: Modbus TCP master

Modbus TCP master configuration view is shown as follows:

The configurable items include: assign IP mode, IP address, subnet mask, gateway address, DNS1, DNS2,

response timeout, delay between polls, output mode. As shown below:

Assign IP mode: Manual Assign, BOOTP and DHCP optional.

Response wait time: After the Modbus TCP master sent out commands, it waited for response from the slave.

Delay between polls: A Receive the right response after one Modbus command has been sent or sending next

Modbus command after response timeout.

Output mode: Continuous output, disable output and change-of-value output can be selected.

The protocol type selection: Modbus TCP Slave

Modbus TCP slave configuration view is shown as follows:

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

19

Assign IP Mode: Manual Assign, BOOTP and DHCP optional, default value is manual assign;

Check unit ID: open and close optional.

Unit ID (1~255): valid when “Check unit ID” is opened, 1~255 optional.

Scan rate: the ratio of slow scan cycle and fast scan cycle.

Network status indication: mutual surveillance of both ends, PROFIBUS DP monitors the network state of

Modbus TCP, Modbus TCP monitor PROFIBUS DP network state and no indicating optional.

Modbus TCP master read data function code: "04H read the data DP sent to the Ethernet, 03H read back the

written data","03H read the data DP sent to the Ethernet, 04 read back the written data" is optional. Among them:

"04H read the data DP sent to the Ethernet, 03H read back the written data" means that Modbus TCP master is

using the 04H function code to read the output data from the PROFIBUS DP master to the Ethernet side, the use

of 03H read back the written data of the PROFIBUS DP master; "03H read the data DP sent to the Ethernet, 04

read back the written data" means that Modbus TCP master is using the 03H function code to read the output data

from the PROFIBUS DP master to the Ethernet side, the use of 04H read back the written data of the PROFIBUS

DP master.

The first address of read-only register (data direction: DP to Ethernet): range 0 to 65535, default value of 0;

The first address of the read/write registers (data direction: Ethernet to DP),: range 0 to 65535, default value

of 0.

User Manual

PROFIBUS DP Modbus TCP/ Gateway

GT200-DP-MT

WWW.SSTCOMM.COM

20

6.4.3 Node Configuration View Interface

In the equipment view, click on the Ethernet, the protocol type is Modbus master, right-click on the

"Ethernet", adding new nodes, the node configuration view interface displays the following:

Configurable parameters: Unit ID, IP address to access the server, device status, memory-mapped address,

and memory-mapped bit offsets.

Unit ID: Modbus TCP slave address, 1 to 255 optional.

IP address to access the server: IP address to access Modbus TCP slave.

Device status: open and close optional. When it is opened, memory-mapped address and memory-mapped

bits offset is available.

Memory-mapped address: Address range that equipment state is mapped in the module memory,

0x0000~0x00F3. Calculate by clicking “Auto mapping”.

Memory-mapped offset: Bit x where equipment state is in memory mapping byte, 0~7.

Table of contents