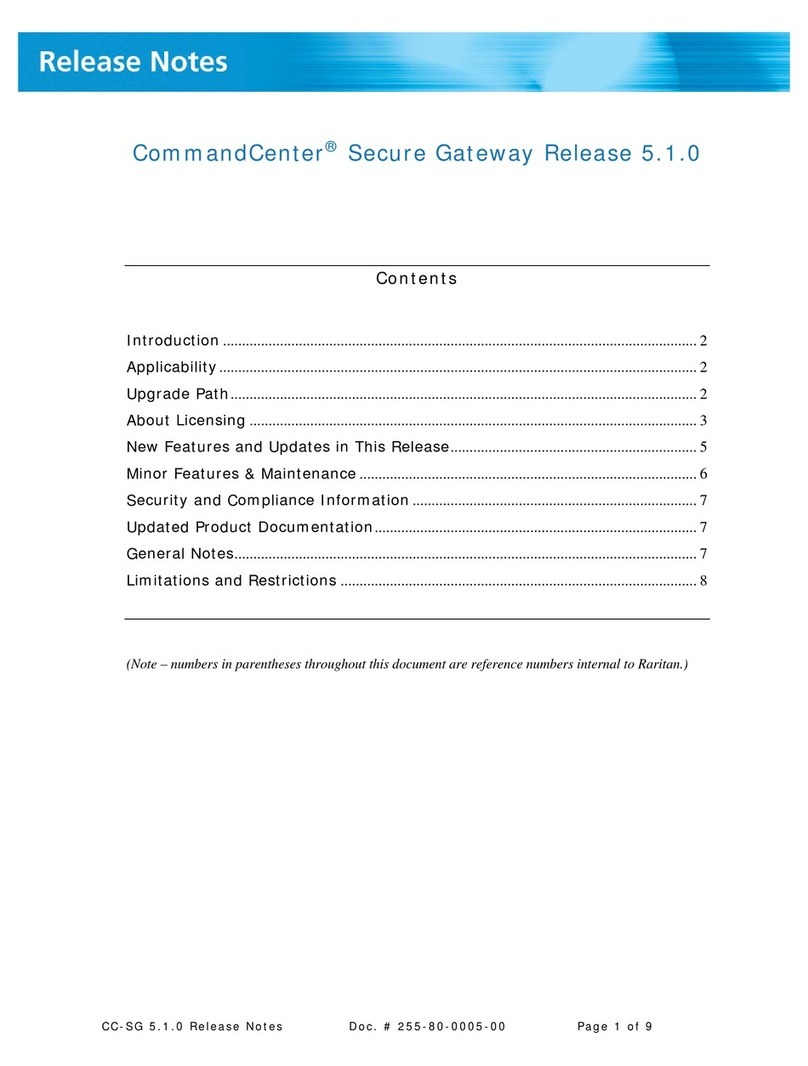

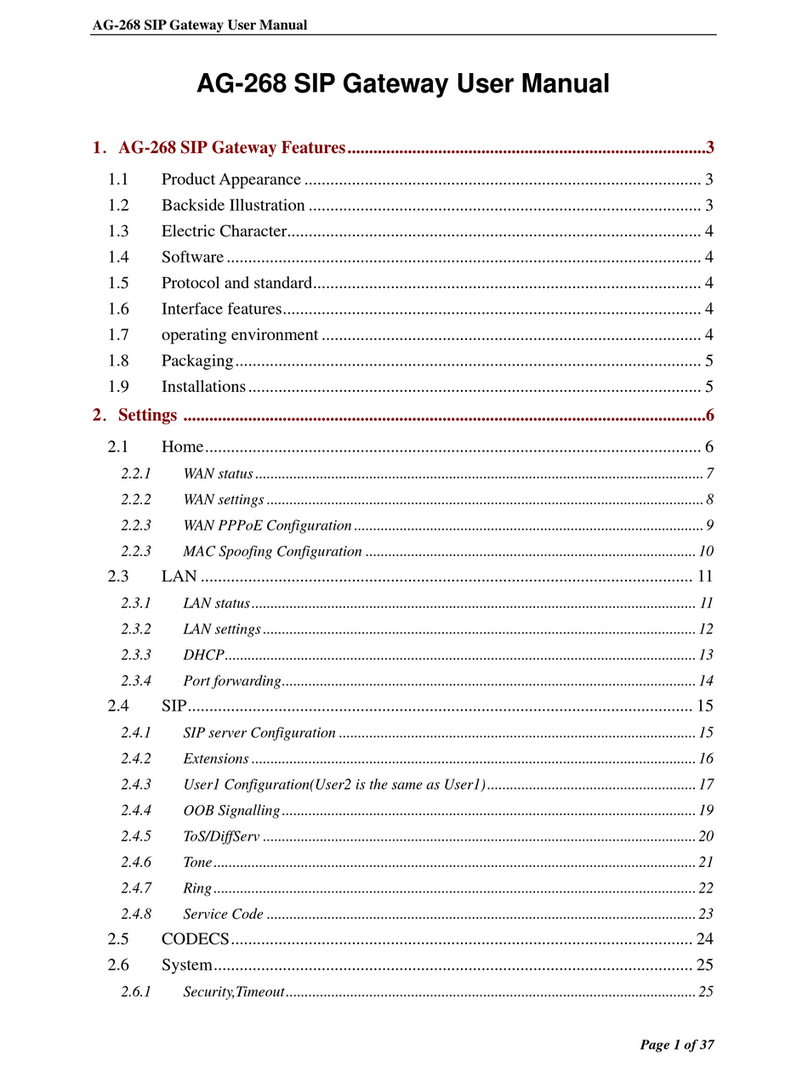

Contents

Preliminary .................................................................................................................................. ii

Manual Revisions...................................................................................................................... iii

INTRODUCTION...................................................................................................................... 6

1.1 Purpose of this Manual ......................................................................................................... 7

1.2 Introduction to Gateway........................................................................................................ 7

1.3 Gateway Applications: ........................................................................................................... 8

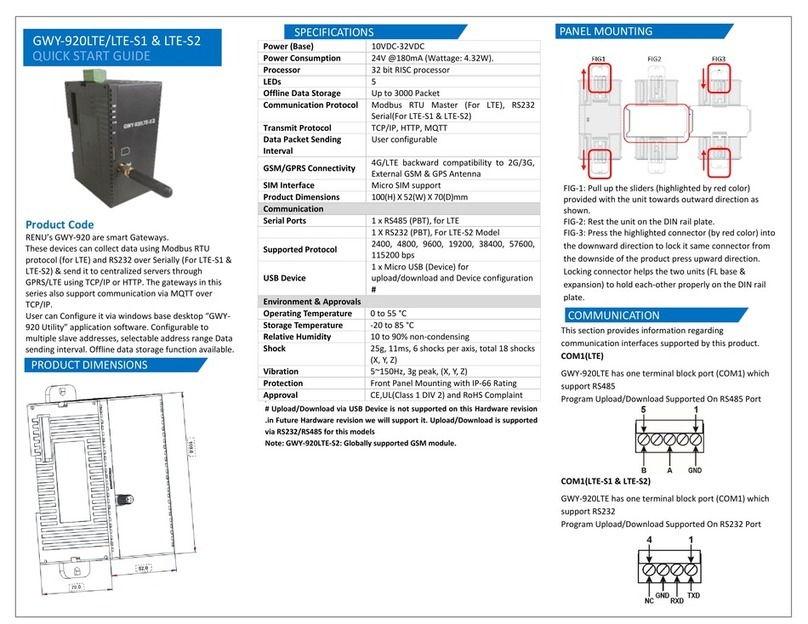

1.4 Gateway Specifications .......................................................................................................... 9

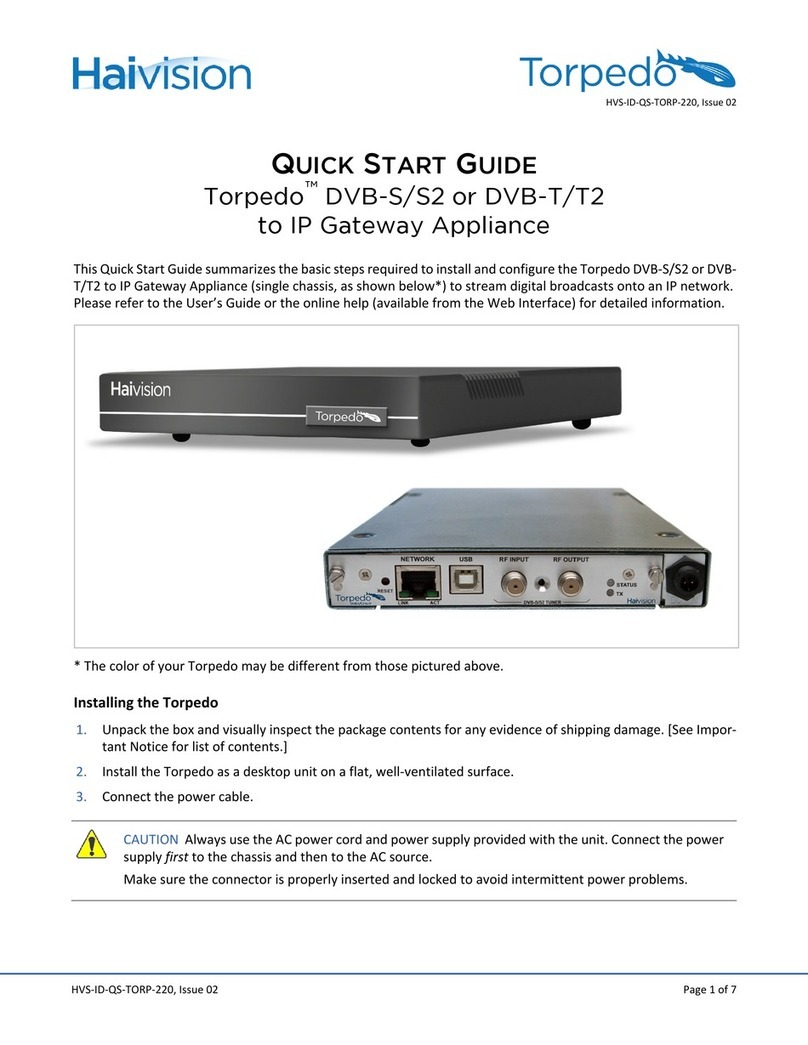

HARDWARE ............................................................................................................................ 10

2.1 Dimensional Details and Mounting Instructions ............................................................ 11

2.2 Power Requirements.......................................................................................................... 13

2.3 Communication Ports .........................................................................................................14

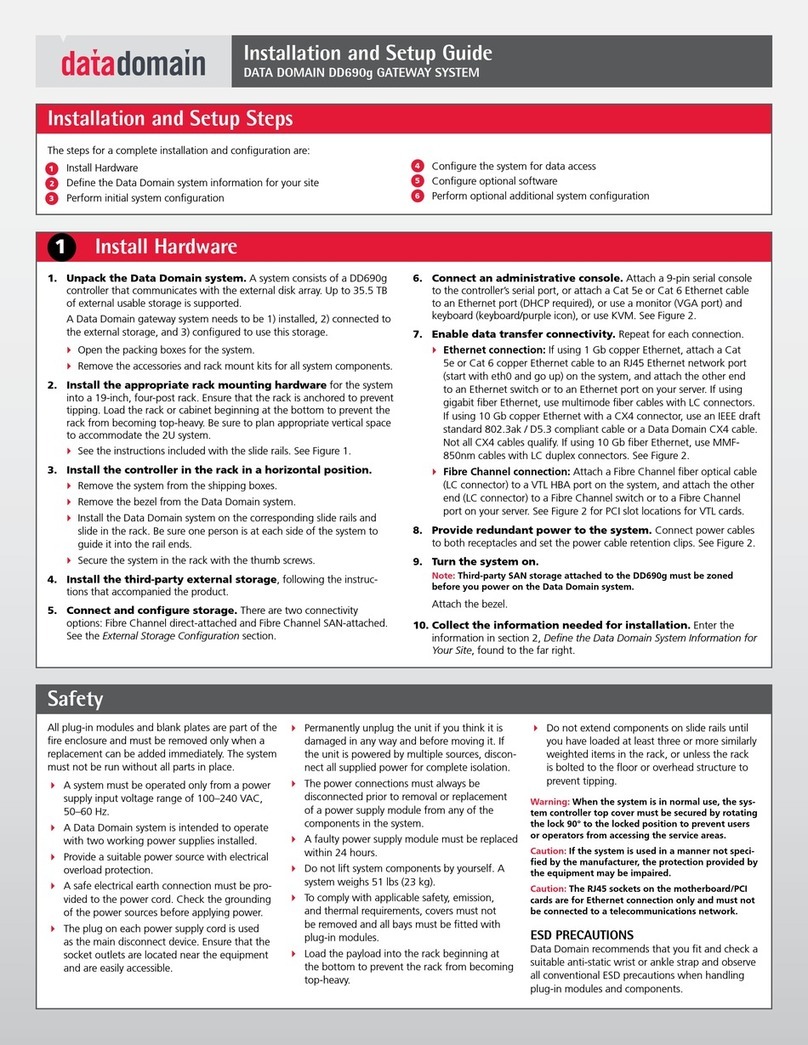

GETTINGSTARTED .............................................................................................................. 15

3.1 Introduction to Gateway......................................................................................................16

3.2 Gateway Operation - Configuration and Communication .............................................. 16

UNDERSTANDINGGATEWAYFEATURES........................................................................ 18

4.1 Gateway Modes.................................................................................................................... 19

4.1.1 Master-Masterconfiguration 19

4.1.2 Master-Slaveconfiguration 20

4.2 Multi-dropping of Devices using Gateway....................................................................... 22

4.3 Repeat Cycle ........................................................................................................................ 23

4.4 Control Word ........................................................................................................................ 23

4.5 Error Indication Bit ............................................................................................................. 24

4.6 Communication Parameters .............................................................................................. 24

4.6 Status LEDs .......................................................................................................................... 24

TYPICALPROJECTS ............................................................................................................. 25

5.1 Project Setup ........................................................................................................................ 26

5.2 Example 1: PLC to PLC Communication ....................................................................... 26

5.3 Example 2: Higher Level Controller (Modbus master) to PLC (Modbus slave).... 28

5.4 Example 3: PLC (Modbus master) to Other Device (Modbus slave). ...................... 29

CONFIGURATIONSOFTWARE ........................................................................................... 30

6.1 System Requirements:........................................................................................................ 31

6.2 Installation Instructions:..................................................................................................... 31

CABLEDIAGRAMS............................................................................................................... 32

7.1 Wiring Diagrams .................................................................................................................. 33

COMMUNICATIONCABLES FORGWY-00...................................................................... 34

8.1 AB SLC DH485 PORT TO GWY-00 (EC-P-007-00) ..................................................... 35

8.2 AB MICROLOGIX SERIES PLCs TO GWY-00 (EC-P-027A-00) ............................. 36

8.3 A B SLC DF1 PORT TO GWY-00 (EC-P-027B-00) ...................................................... 37

8.4 AROMAT FP0/FPM TO GWY-00 (EC-P-015A-00) ...................................................... 38

8.5 AROMAT FP1 TO GWY-00 (EC-P-015B-00) ................................................................ 39

8.6 AROMAT FP2 TO GWY-00 (EC-P-015D-00) ................................................................ 40

8.7 CALISTO PLC TO GWY-00 (EC-P-090-00) .................................................................. 41

8.8 GE 90 SERIES PLC TO GWY-00 (EC-P-002-00) .......................................................... 42

8.9 GE VERSAMAX PLC TO GWY-00 (EC-P-002B-00).................................................... 43

8.10 GE VERSAMAX PLC TO GWY-00 (EC-P-002A-00).................................................... 44

8.11 IDEC MICRO3 TO GWY-00 (EC-P-025A-00)............................................................... 45

8.12 KEYENCE KV PLC TO GWY-00 (EC-P-018-00).......................................................... 46

8.13 LG MASTER K SERIES PLC TO GWY-00 (EC-P-037-00).........................................47

8.14 MITSUBISHI FX SERIES PLC TO GWY-00 (EC-P-008B-00)................................... 48