SSZ SSZ-RZ4 User manual

MADE IN GERMANY

INSTALLATION AND SYSTEM DESCRIPTION

FOR SSZ CONTROL UNIT

TYPE SSZ-RZ4/SSZ-RZ4B

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten2

Thüringerstrasse 17, 46286 Dorsten

Tel: +49 236940 94

Fax: +49 23 69 - 2 15 97

Email: info@ssz-gmbh.de

Issue 2017, Version 1

This Operating Manual applies to control unit

• Type: SSZ- RZ4, Performance Level PL d (in system) Category

3, acc. to EN ISO 13849-1 to be connected to: SSZ-Safety

Mats and SSZ-Safety Rails. SSZ-Safety Bumpers in automatic

modus only.

• Type: SSZ-RZ4B, Performance Level PL d (in system) Category

3, acc. to EN ISO 13849-1, to be connected with SSZ Safety

Bumper in manual modus acc. to EN ISO 13856:3.

• Response time < 20 ms

• Reset function - automatic/manual

Control unit identication is provided with the number, printed

on a hologram (on the housing).

For proper device identication, the Installer

should write down the ID number from the

hologram in the device identifying form!

Prior to installation, it is recommended to

read with understanding all the contents

of this Operating Manual, together with

operating manuals of particular pressure-

sensitive safeguarding products.

- SSZ safety mat instructions of use

- SSZ safety bumper instructions of use

- SSZ safety edge instructions of use

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten3

TABLE OF CONTENT

TABLE OF CONTENT ........................3

ABOUT THIS OPERATING MANUAL ...........4

INTENDED USE ............................4

SAFETY RECOMMENDATIONS................5

CONTROL UNIT LABELLING .................6

MAINTAINED SAFETY LEVEL.................6

TECHNICAL PARAMETERS ...................7

SAFETY UNIT

FUNCTIONALITY TESTS . . . . . . . . . . . . . . . . . . . . . 9

CONNECTING OF SAFETY UNITS ............10

MOUNTING ..............................12

MAINTENANCE AND CONTROL OF PROPER

FUNCTIONALITY ..........................12

STORAGE AND TRANSPORT ................15

UTILISATION .............................15

NOTES ...................................15

These instructions form an essential part of the product.

These instructions contains basic information that must be noted when installing the system. It is important that the personnel famil-

iarize themselves with these instructions before installation and commissioning. The following documents from the purchaser also

apply in addition to these instructions:

• The drawing of the conguration (optional)

• The cable diagrams (optional)

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten4

Keep the operating manual at accessible location during the

entire service life of the product. This operating manual shall

be passed onto any subsequent owners / users of the product.

Any updates to the contents of the operating manual, received

from the product manufacturer, shall immediately be included

in this operating manual.

The technical personnel shall be familiar with assembly and

mounting techniques, as well as with the functions of devices

and systems.

This operating manual is valid only for the product specied on

the title page. In addition to this operating manual, the following

documents shall be followed:

• structure drawings of machine / device, remaining at the

customer’s disposal (optional),

• a schematic drawing of connection

• an assembly drawing of devices with SSZ sensor(s) - see

Annex No. 1 to this operating manual.

This operating manual is a part of the product

The control unit is a part of the system:

SSZ pressure sensitive safety products + a

control unit. The system shall be connected

to a machine by properly trained technical

personnel only.

In no event shall the SSZ GmbH Company be

liable for any damages arising from or being

a consequence of the product usage not in

compliance with the operating manual.

The target group of this operating manual

includes the product end-user and properly

trained personnel (operators), authorised to

use the product.

Before use of the product, read thoroughly

this operating manual.

ABOUT THIS OPERATING MANUAL

SSZ-RZ4/SSZ-RZ4B control units are intended to generate a

safety-related signal for emergency stop of machines and other

technical devices. The control units may also be used to generate

warning signals of persons. The control units are designed for

analysis and control of two-channel elements of in an electric

circuit, including SSZ safety edges, SSZ safety mats and SSZ

safety bumpers.

In wires, including the voltage supply wire, constant monitoring

covers: electric energy ow direction, short-circuits and crossed

wires, in compliance with the constant current principle.

SSZ-RZ4/SSZ-RZ4B control units can be supplied with direct

current: 10.6 VDC - 36 VDC or an alternating current 8 VAC - 24V

AC with frequency 50/60 Hz.

In either case, the polarity of connected wires is not important.

The RZ4B control unit is designed for exclusive

use with a safety bumper.

INTENDED USE

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten5

Supply voltage control shall be ensured. The supply voltage

must be equal to the voltage value on the rated plate.

REQUIRED SPACING

While performing assembly tasks in the electric cabinet, it is

necessary to maintain proper distance from heat sources.

PROTECTION FROM SUNLIGHT

The electric cabinet shall be protected from direct sunlight.

TERMINAL CURRENT LOAD

Terminal current load shall be observed.

PROTECTION OF RELAY CONTACTS

The risk of welding together: the relay contacts beyond the

connecting area shall be provided with an overcurrent protec-

tion with activation amperage equal to the maximal permitted

current of relay contact. Do not overload SSZ-RZ4 and SSZ-RZB

control units. The specied switching (load) current shall not

be exceeded.

IN CASE OF ANY FAILURE, SWITCH OFF THE UNIT!

SSZ-RZ4 or SSZ-RZ4B control unit shall be switched o in case

of any failure or defects.

DO NOT USE THE CONTROL UNITS IN POTENTIALLY EXPLO-

SIVE (ATEX) ZONES

SSZ-RZ4 nor SSZ-RZ4B control unit can mot be used in zones

with explosion hazards (ATEX zones).

THE RISK OF INJURY FROM ELECTRIC SHOCK!

Both before and during the mounting works of SSZ-RZ4 and

SSZ-RZ4B control units, all the electric machines/devices to be

connected must be switched o from voltage supply.

OPERATION FAILURE DUE TO OVERHEATING

A pressure-sensitive product (SSZ safety mat, SSZ safety edge

or SSZ safety bumper) functions may be disturbed in result of

control unit overheating. A safety unit shall be mounted in en-

closures with IP54 as minimal protection index (e.g. in control

cabinets).

TERMINAL ASSIGNMENT

Terminal assignment shall be observed when connecting the

supply voltage

PROTECTION OF RELAY CONTACTS

Any changes shall be forbidden in control unit

setting or structure.

The machine shall not be switched on in

case of any hazard! Failure to respect these

recommendations may be hazardous to health

or even life-threatening!

The CE declaration of conformity is not valid

when devices or control units, other than SSZ,

are connected.

SAFETY RECOMMENDATIONS

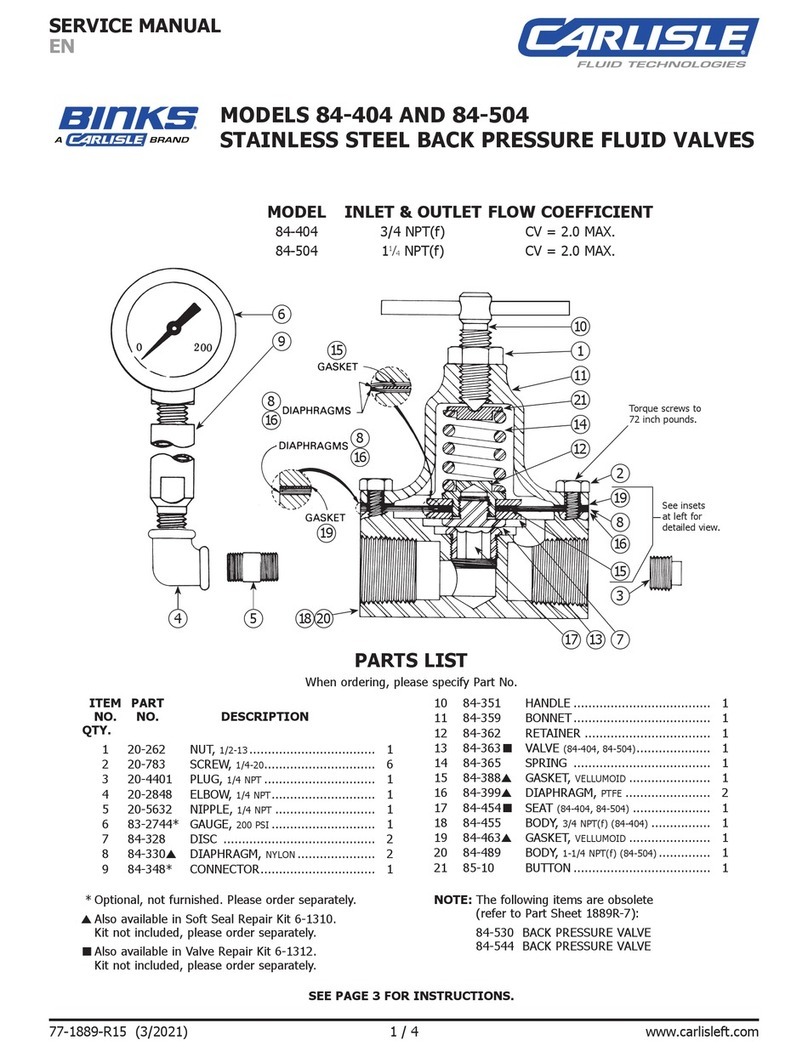

THE SCOPE OF DELIVERY

1 x safety unit

An enclosure with an electronic module and plug-in connec-

tions

1 x operating manual

Immediately after delivery is received, it shall be checked for

completeness and visual status.

Danger of contact welding Relay output shall additionally be

external protected

DO NOT OVERLOAD CONTROL UNITS

It shall be ensured that contact current is not exceeded.

MAINTAINED REDUNDANCY

It shall be ensured that all connections are made within the

circuit or that another control unit.

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten6

CONTROL UNIT LABELLING

MAINTAINED SAFETY LEVEL

SSZ-RZ4 /SSZ-RZ4B

The control units correspond to category 3, Performance Level

PLd - in compliance with EN ISO 13849-1.

NOTE: The control unit is a part of the system. SSZ a pressure-sen-

sitive device + a control unit, PLd is the highest safety level for

the entire system.

Any modications nor installation of any other devices in the sys-

tem is allowed. Only the SSZ control unit is an appropriate device

to control the SSZ pressure-sensitive product. Any replacements

of devices: of a control unit or of a pressure-sensitive product

by a solution of other manufacturer pose risks of failure or mal-

function of the entire system. Components may be replaced by

the end-user. Replacement tasks shall be undertaken by properly

trained technical personnel, with technical knowledge of machine/

device assembly and functions.

The end-user shall independently determine

the safety level of its application.

Safety category and level shall comply with

the category and level of safety assurance, as

determined by risk assessment.

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten7

TECHNICAL PARAMETERS

Nominal supply voltage SSZ-RZ4 / SSZ-RZ4B 24V AC 50 Hz or 24 VDC

Allowable voltage 10.6 VDC - 36 VDC or 8 VAC - 24 VAC

Max. current consumption 290mA@12VDC; 135mA@24VDC; 250mA@24VAC

Rated current 100mA@24VDC

Power consumption P1 2,4 W

Internal fuse 1500 mA

Power circut required fuse 2A

DIN Rail mount Yes

Max. resistance of the sensor element channel

1 and 2

250kOhm

Max. resistance dierence between the chan-

nels 1 und 2

20 %

Max. response time < 20ms

Performance Level acc. to EN ISO 13849-1 PL=d (Pl e)*

The service life 20 years

MTTFd in connection with SSZ-presure equip-

ment

74,1

CCF (common cause failure) 75

PFHd acc. to IEC/EN 62061 in connection with

SSZ-Pressure equipment

6.8E-8

The category acc. to IEC/EN 62061 SIL 2

Safety category acc. to EN ISO 13849-1:2016-02 3

Contact rating acc. to EN 60947-5-1 15 VAC (50/60Hz) - 3A 13 VDC - 3A

Min. switching current I1channel 9-10/11-12 5V/10 mA

Max. switching current I2channel 9-10/11-12 2 A

Mechanical endurance channel 9-10/11-12 >107

Electrical endurance channel 9-10/11-12 >3,6 x 105(DC24V/1A)

Rated operational power 800mW

Reset automatic/manual

Storage temperature [°C] -10 - +50

Grade of protection acc. to IEC 60529:2003 IP30

Dimensions 112 x23x 9 9

Weight 180g

SSZ-RZ4/SSZ-RZ4B/ TESTING BASICS EN ISO 13849-1/2, EN ISO 13856 1-3

Working temperature range 0°C - +50°C

DC (diagnostic coverage) 90%

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten8

*SSZ-RZ4 and SSZ-RZ4B control units are a

part of the system:

SSZ-pressure-sensitive device in connection

with SSZ-safety unit, therefore, despite PL e

category, obtained by SSZ-RZ4/RZ4B units,

the category has been decreased to PL d,

following the safety evaluation rules, and

this category shall be regarded valid because

whole system has to be considered.

Prior to the system connection, the installer is

obliged to read the operating manual of the

proper equipment in use:

- SSZ safety mat instructions of use

- SSZ safety edge instructions of use

- SSZ safety bumper instructions of use

SSZ-CONTROL UNITS, IN

COMBINATION WITH SSZ-PRESSURE-

SENSITIVE DEVICE (SAFETY MATS,

EDGES, BUMPERS) MAY OBTAIN THE

HIGHEST SAFETY LEVEL OF PLd.

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten9

SAFETY UNIT

FUNCTIONALITY TESTS

• Disconnect sensors on terminals 3, 4, 5 and 6. Short terminals

3 and 5 with one wire and terminals 4 and 6 with another.

• After supply voltage is on red and the two green control LEDs

shall be illuminated and the output relays shall become active.

• If terminals 3 and 4 or 5 and 6 are shorted, then both channels

shall be inactivated: the green LEDs shall be o, while the

red LED shall be illuminated.(Simulation of the SSZ pressure

sensitive equipment activation)

• If the connection of terminals 3/5 is broken, the K1 relay shall

be inactivated. (Simulation of the broken cable).

• If the connection of terminals 4/6 is broken, the K2 relay shall

be inactivated. (Simulation of the broken cable).

• In manual reset, when terminals 3 and 5 and 4 and 6 are

shorted, only the red LED shall be illuminated. In order to

activate the K1 and K2 relays, press the reset button on

connected the RR terminals..

SAFETY UNIT TERMINALS

Safety unit terminal SSZ-RZ4/

SSZ-RZ4B

24VAC/DC

3SSZ-Sensor, terminal 3

4SSZ-Sensor, terminal 4

5SSZ-Sensor, terminal 5

6SSZ-Sensor, terminal 6

9 Relay outputs - 2 circuit

10 Relay outputs - 2 circuit

11 Relay outputs - 1 circuit

12 Relay outputs - 1 circuit

13 External safety circuit*

14 External safety circuit *

RManual RESET button

RManual RESET button

31 Potential free output

32 Potential free output

VL +24V AC/DC

VL 0V

• * Opening of the circuit will cause switching to safety mode

The SSZ-RZ4 and SSZ-RZ4 B control units are

factory set to operate with automatic reset.

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten10

CONNECTING OF SAFETY UNITS

If the RESET switch is in position “I“, the safety unit works in the

automatic reset mode. If the Reset switch is in position `0`the

SSZ-Control unit works in manual reset mode. In this case the

Reset button connected on Terminals RR shall be pressed and

released. To avoid any manipulation of the system the acknowl-

edgment follows after release of the before pressed Reset button.

The SSZ-RZ4B will be released after pressing the Reset button.

SCHEMATIC PRESENTATION OF THE SAFETY FUNCTION BE-

TWEEN SSZ-CONTROL UNIT AND THE MACHINE CONTROL

SYSTEM.

The output contacts of the control unit, serially connected, shall

be integrated with the machine emergency switch circuit. Unless

the pressure-sensitive device is activated, the relay contacts, i.e.,

also the emergency switch circuit, are closed. When the pres-

sure-sensitive device is activated, the relay contacts of the control

unit are opening, what stops the risk posing run of the machine.

Fig. Example of connection to machine control system with the

use of an SSZ-RZ4 control unit

Additional examples for each control units shall be available in

the operating instructions of a given control unit.

Reset options: automatic or via an external

button, closing the R-R circuit

Sensor terminals 3, 5, 4 and 6

Colours of cables 3 = green

5 = yellow

4 = brown

6 = white

Colours in case of

safety mats with

connector

3 = blue

5 = black

4 = brown

6 = white

Safety circuit 9-10 and 11-12

The safety of machine and proper

functionality of the safety pressure devices

depends on the correct installation of mutual

connections.

SSZ-Sensor

K1

K2

Safe

release

A

Safe

release

B

9 10 11 12 31 32 R R 13 14

Reset Exit

SSZ-RZ4

SSZ-RZ4B

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten11

SSZ-RZ4/RZ4B CONTROL UNIT CONNECTION TO MACHINE

OPERATING SYSTEM

Safe stop by external devices in manual reset

Safe stop by intern contacts in manual reset Safe machine stop by external devices in automatic reset

Safe stop by intern contacts in automatic reset

911

10 12 32

K1

K2

13 14

31

SSZ-RZ4

SSZ-RZ4B

911

10 12 32

K1

K2

13 14

31

SSZ-RZ4

SSZ-RZ4B

911

10 12 32

K1

K2

13 14

31

SSZ-RZ4

SSZ-RZ4B

911

10 12 32

K1

K2

13 14

31

SSZ-RZ4

SSZ-RZ4B

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten12

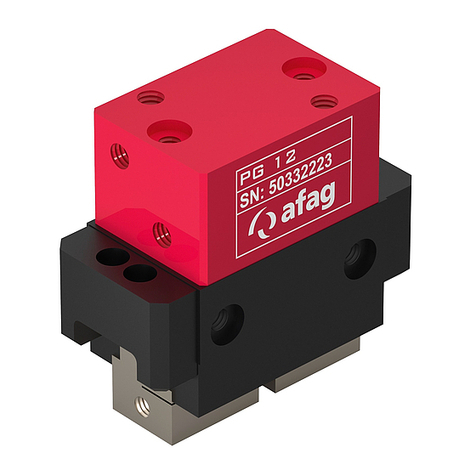

MOUNTING

MAINTENANCE AND CONTROL OF

PROPER FUNCTIONALITY

Safety units of SSZ-RZ4 and SSZ-RZ4B type are mounted on a

DIN 35 mm rail, see the drawing below.

The functional tests of control units shall be carried out daily.

• Prior to any maintenance works, disconnect the control unit

and the connected devices from the electric supply and

protect them against unintentional activation.

• Check if no voltage is present on any part or component.

• Clean the housing on the outside with a clean cloth.

AUTOMATIC RESET CONTROL FOR SSZ-RZ4 AND SSZ-RZ4B UNIT

The control unit is provided with an automatic reset function.

In a pressure-sensitive device is released, then K1 and K2 relays

will immediately return to their baseline position, switching the

control unit to standby mode.

Danger of electric shock!

Before re-start of the unit, check it for proper

functionality!

PROPER FUNCTIONALITY CONTROL FOR SSZ-RZ4 AND SSZ-

RZ4B UNIT: AUTOMATIC RESET CONTROL

1. Make sure that no SSZ pressure-sensitive device is activated.

• the “OK 3/5” and “4/6 OK” green LEDs are on

• The Relais contacts K1 & K2 are closed

2. Press the SSZ device

• the “OK 3/5” and “4/6 OK” green LEDs are o

• The Relais of K1 and K2 are open

• Release the pressure-sensitive device (do not press)

• the “OK 3/5” and “4/6 OK” green LEDs are on

• The relais contacts K1 and K2 are closed

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten13

Manual reset for SSZ-RZ4B control unit

The SSZ-RZ4B control unit is provided with automatic or manual

reset functions. Regarding the automatic reset function, the

functions are the same as in the SSS-RZ4 control unit. In case of

manual reset operation of reset button has no eect on output of

output signal switching device as long as forcepresent on sensor.

The output of output signal switching device remains in OFF state

. After removing the actuating force from sensor, signal switching

device remains in OFF state even though reset signal still present.

When releasing of reset button has no eect on output of output

signal switching device.

Reset is achieved after another operation of reset button without

actuating force on the sensor.

The SSZ-RZ4B is designed exclusively for use with safety bumper!

An SSZ-safety bumper is most often used to protect driverless

vehickles. The use of an SSZ-RZ4B control unit protects against

automatic movement, which may occur after incidental bridging

or failure of the reset function with a simultaneous release of

the bumper.

Manual reset control for SSZ-RZ4 and SSZ-RZ4B unit

1. Press the SSZ-pressure-sensitive device

2. Make sure that no one of the SSZ pressure sensitive devices

is pressed

• The green LED`s “OK 3/5” and “4/6 OK” are o

• The relais contacts of the channel K1 & K2 are opened

3. Press the reset button

• The “OK 3/5” and “4/6 OK” green LEDs are on

• The relais contacts of the channel K1 & K2 are closed

4. Press the SSZ pressure-sensitive device

• The “OK 3/5” and “4/6 OK” green LEDs are switch o

• The relais contact of the channel K1 & K 2 are opened

5. Unlock the pressure-sensitive device

• The “OK 3/5” and “4/6 OK” green LEDs are switched o

• The relais of the contacts channel K1 & K2 are opened

6. Press the reset button, while the pressure-sensitive device

should not be pressed

• The “OK 3/5” and “4/6 OK” green LEDs are switched on

• The relais contacts of the channel K1 & K2 are closed

• The SSZ-pressure-sensitive device is unlocked and ready

for operation

Do not switch on the machine as long as there

is any risk!

The SSZ-control unit check shall include:

• Visual check of the housing for possible damages.

• Exclusion of possible manipulations. The SSZ hologram shall

remain intact.

• Operation and functionality check executed acc. to this

Operation Manual.

• Checking the correctness of the installation in the electric box.

• Ensuring the correctness of connection to machine or device

After completing the assembly and function requirements the

system may be approved for use, according to the applicable

standards and regulations of the country of use.

The user may replace parts, using

exclusively their equivalents approved by

the manufacturer! Any modications or

installations of other components / devices in

the system shall be prohibited. The SSZ control

unit shall be the only device suitable for control

of SSZ sensitive devices. Replacing SSZ control

unit or pressure-sensitive devices by products

of other vendors poses a risk of functionality

failure or total collapse for the entire system!

No spare parts for the above-mentioned

system. In case of any failure, replacement

parts shall be sought from the manufacturer,

including the control unit, the cable, the

aluminium prole or the pressure-sensitive

device.

In order to ensure proper functionality

of a pressure-sensitive protective device,

as well as its installation, adhering to the

requirements of EN-ISO 13849-1-2 and EN ISO

13856-1-3 : 2013-1, the technical personnel

shall be familiar with assembly techniques,

as well as with gear and systems, supported

by training at the SSZ-GmbH Company or at

an agency, designated for the purpose by the

manufacturer.

In case of any technical problems, it is recommended to contact

the manufacturer or any responsible agency, representing the

manufacturer at a given country. See the manufacturer’s home-

page www.ssz-gmbh.de for the actual list of representatives.

Periodical inspections of the control unit should be carried out

at least twice a month, while the functionality of signalling lights

– LEDs – should be a subject of daily control. The frequency of

the inspections should be estimated appropriate to the safety

function activations

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten14

The applied prevention measures against systematic defects

(EN ISO 13849-1: 2015))

• The design of the devices ensures protection in case of sup-

ply voltage loss. The output relays become disconnected,

i.e., the electric circuit in open on the output relay contacts.

• In the supplying branches of measurement circuits, integrated,

voltage stabilisers are applied which, together with capacitive

lters, considerably protec t against input voltage variations.

• The input resistive measurement system has been designed

to eliminate as much as possible errors, resulting from un-

stable supply voltage.

• The applied output relays, designed for use in safety devices,

are subject of internal control.

• The design conguration of SSZ safety units has for years

been used in thousands of applications and is also used in

other, manufactured by us devices.

• Control units: SSZ-RZ4 and SSZ-RZ4B: have been designed

in line with the EU’s engineering pattern and checked and

approved with regards to electromagnetic compatibility,

ventilation, cooling and vibrations.

• The SSZ-GmbH Company has for more than 25 years been

carrying out internal quality control in its full scope, i.e.,

including particular elements and their documentation.

• The same team of qualied employees participates in the

production process.

• The parts and components in the devices originate from prov-

en, recognised manufacturers with appropriate certicates.

• The Company enjoys a more than 25-year tradition and

experience, represented all over the world, while in some

European countries, SSZ products are market leaders.

Acceptance procedure

1.Pressure-sensitive device assembly and functionality check

acc. to the requirements in the Operation Manual of the chosen

SSZ pressure sensitive device .

2.Checking for correct cabling from the control unit to the SSZ

pressure sensitive device; a particular attention shall be paid to

redundancy preservation in the system!

3.Checking of the safety function– acc. to the safety documen-

tation.

4.Measurement of the entire system’s response time and “full

time stop”, as well as functionality(lock or release) check, caused

by the activation of an SSZ pressure-sensitive device. The results

should be compared to the specication requirements. All results

should be written into the documentation of the machine.

5.A special attention shall be paid to the signalling system in the

SSZ control unit (one red and two green LEDs), indicating either

normal operation or failure of the system!

If none of the LEDs is active, the supply of the control unit should

be checked. If the supply connection to the control unit is cor-

rect, while its functionality still fails, it is necessary to contact

the manufacturer.

The same acceptance procedure shall be valid when particular,

individual components are replaced (either of SSZ pressure-sen-

sitive device or a replacement of the SSZ control unit)

The installer shall be obliged to ll in an identication form of

an installed device. In order to ensure a correct identication,

please enter in the form, the number from the hologram on the

pressure-sensitive device and on the SSZ control unit.

The system does not have an auto-check

function. According to the level of safety

assurance- PLd , the system in the standby

mode is controlled by the unit.

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten15

STORAGE AND TRANSPORT

UTILISATION

NOTES

SSZ-RZ4 and SSZ-RZ4B control units shall be stored and trans-

ported in their original, manufacturer’s packaging, protecting

them from damage. The units are individually packed in carton

boxes, together with operating manuals.

The devices, manufactured by the SSZ GmbH Company, are pro-

fessional electronic solutions, designed exclusively for industrial

applications (so called, B2B devices). Unlike the commonly used

household utilities (B2C), B2B devices must not be disposed to-

The units shall be stored at indoor, dry premises, the relative

humidity of which shall not exceed 80%. The ambient air temper-

ature shall not exceed the range from -10°C to 50°C. Protection

grade of control unit enclosure against external factors: IP 30

gether with municipal waste. When the service life of a B2B device

expires, it can be returned to the SSZ GmbH for proper utilisation.

Safety units are only a part of safety system

- design and construction of a safety system

shall be based on the rules and provisions,

contained in standards and in the machine

directive.

Before any unsafe machine task, the safety

system functionality shall be checked. The

functionality check involves ssz safety unit

activation and conrmation that a dangerous

machine run has been stopped.

Regardless of the circumstances, the

occupational safety rules, as well as other

appropriate regulations shall be adhered to.

Failure to do so may pose hazards for health

and life.

If a defect/failure occurs, such a unit shall be

returned to the manufacturer for repair.

All electric connections shall properly be

tightened and checked. Periodical checks of

electric terminals shall be scheduled.

SSZ-units shall be mounted exclusively in

electric cabinets. The required protection

degree shall be observed.

Opening the SSZ– control unit box may lead

to the loss of the system safety. Under no

circumstances shall the devices be opened.

Any hologram breach shall make the

guarantee void.

All external cable feeds shall be protected

against excessive loads and led in insulating

sleeves.

Rated load values on outer contacts shall not

be exceeded.

www.ssz-gmbh.de info@ssz-gmbh.de Thüringerstrasse 17, 46286 Dorsten16

Thüringerstrasse 17, 46286 Dorsten-Wulfen

+ 49 2369/4094

+ 49 2369/21597

info@ssz-gmbh.de

ssz-gmbh.de

ALL RIGHTS RESERVED

Version 2017

A:

T:

F:

E:

W:

This manual suits for next models

1

Table of contents

Other SSZ Control Unit manuals