SSZ SSZ-CVS/N/2/230/24 User guide

1

®

Sicherheits-Systeme Zimmermann GmbH

system manual

2

About these operating instructions ............................................................................................. 3

System ......................................................................................................................................................... 5

Controllers .............................................................................................................................................. 10

Technical parameters ...................................................................................................................... 11

Terminals ............................................................................................................................................. 16

Function test ...................................................................................................................................... 20

Connections ....................................................................................................................................... 21

Fixation ................................................................................................................................................ 30

Storage and transport .................................................................................................................... 31

Acceptance procedure ................................................................................................................... 31

Maintenance ...................................................................................................................................... 33

Notes .................................................................................................................................................... 33

Safety mats ............................................................................................................................................. 36

Application ......................................................................................................................................... 37

Areas of application......................................................................................................................... 37

Types ..................................................................................................................................................... 38

Installation .......................................................................................................................................... 38

Function test ...................................................................................................................................... 39

Safety mat type SSZ-BAT .............................................................................................................. 40

Safety rails .............................................................................................................................................. 41

Application ......................................................................................................................................... 42

Areas of application ........................................................................................................................ 42

Types ..................................................................................................................................................... 42

Installation .......................................................................................................................................... 43

Function test ...................................................................................................................................... 44

Safety bumpers .................................................................................................................................... 45

Application ......................................................................................................................................... 46

Areas of application ........................................................................................................................ 46

Types ..................................................................................................................................................... 46

Installation .......................................................................................................................................... 47

Function test ...................................................................................................................................... 48

Annex ........................................................................................................................................................ 49

Content

3

About these operating instructions

1. Intended use

SSZ-Safety-Units are logic systems to assure safety functions (App. IV pos.21 MS Directive

2006/42/EC). Units of SSZ-Safety-Units type are used for stoppage of dangerous machines

and other equipment, which functioning can be dangerous for people present in their

hazardous zone. They can be also used for signaling and warning about danger for people

who will be present in such zone directly or indirectly and their life or health would be at risk.

Units are designed for cooperation with 2-channel sensors which are placed in- Pressure

Sensitive SSZ Safety Devices: SSZ-safety mat, SSZ-safety rail (SSZ-SSL 05 NBR, 06 NBR, 06

EPDM, 08 NBR, 08 EPDM, 10 NBR and 10 EPDM) and SSZ-safety bumper.

A short circuit, wire break or the actuated sensor is immediately recognized.

Units labeled 230/24 can be supplied by mains power 230V or (after switching position of an

internal switch VH (Voltage High) or VL (Voltage Low) by AC/DC 24V. In both cases, polarity

of plugged cables is not important.

These operating instructions are part of the product.

It consists important information which have to be taken into consideration during the

installation and use of the product. It is important to read the opearting instructions

before use, from operators and trained personnel who are familiar with installation and

commissioning.

In addition to the System manual, observe the following documents:

nDrawing of the sensor equipment (optional)

nWiring schematics (optional)

SSZ-GmbH is not responsible and accepts no warranty claims for damages due to failure to

observe the installation instructions.

4

About these operating instructions

2. Safety instructions

nDo not modify the control unit

nCheck supply voltage

Supply volatge must correspond with the connecting voltage on the label.

nProtect from sunlight

Protect from direct sunlight and from heat sources.

nObserve pin assignment

When connecting the supply voltage.

nFit spark absorbers

Whenconnectinginductiveloads,tsparkabsorbers(RCmodules)totheuser.

nDo not cross link control unit with other control units

nDo not overload control unit

Ensurethatthespeciedswitchingcurrentisnotexceeded.

nIn the event of fault put out of operation

In case of malfunctions and visible damage, put the control unit out of operation.

nDo not use in EX zones

Do not use the control units in potentially explosive environments (ATEX). The control unit

is not authorized for using in these zones

nInstallation: danger of injury due to electrocution!

Disconnect all devices and live parts in the immediate environment from the power supply

and protect them against being switched on again (see relevant operating instructions)

Check whether all devices and parts are disconnected from the power supply

nInstallation: impaired operation due to overheating

The operation of the protective device may be impaired due to overheating of the control

unit.

5

41

System

6

!

!

3

4

Sensor element 5

6

K1

K2

13

14

33

34

System

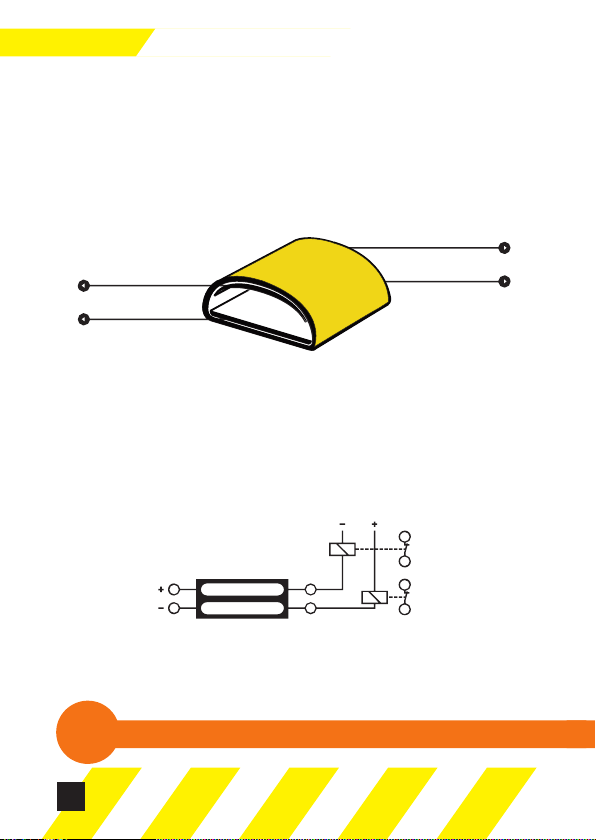

The sensor element is used for all transducers and is made out of a co-extruded, high elastic

plastic.

Duetothehoseshapedspecialproletheinternalconductivelayersareheldatadistance.

However,duetothematerialusedwiththesespecicadvantagestheconductivityislimited.

The result is that the transducer is operated in combination with a SSZ-controller.

The conductive layers of the sensor element which are depicted in a dark colour in picture 1

can be regarded as non-isolated resistor.

These resistors are provided with connecting wires at the beginning and at the end of the

sensor element. The connecting wires are lead to the controller by either 4-wire or 2-wire

cables.

The „inlet“ of the sensor element which has been depicted as two opposite resistors in

picture 2, is connected to the sensor output 3 and 4 of the controller.

3

4

5

6

Sensor element

Sensor element not in use

The „output“ is connected to the sensor inputs 5 and 6. Please ensure that the cables are

connected correctly as 3 and 5 or 4 and 6 respectively form a signal path.

Parallel connecting of the transducers is not permitted!

7

System

Ifthe sensorelementis notin usecurrency willow fromconnection 3to connection5

as well as from connection 4 to connection 6. This leads the relay K1 and K2 to close their

contact and therefore activate the output.

To obtain a secure output signal the contacts of relay K1 and K2 have to be switched in

sequence.

If the sensor element is activated the currency ratios at sensor inlets 5 and 6 of the controller

change.

This change causes the relays to switch off and the output contacts are opened. A short

circuit has the same effect on the transducer connection cable.

If a wire or a conductive stretch of the sensor element is cut, at least one relay is switched off.

Due to the sequence switching of the relay contacts a cut-off of the electric circuit is ensured.

The transducer connections are marked and colour coded.

The following table shows which colours are assigned to which connections.

Activated sensor element

3

4

5

6

K1

K2

13

14

33

34

4-wire cable

Label

Rails Bumpers

Mats

3 GREEN BLUE

4 BROWN BROWN

5 YELLOW BLACK

6 WHITE WHITE

two 2-wire cable

Label

Colour

3 BROWN

4 WHITE

5 BROWN

6 WHITE

8

!

!

Several transducers can be connected to a SSZ-controller. To function correctly all

transducers connected to one controller have to form a sequence.

If incorrect connections are made the device may not function correctly !

If the transducers are connected parallel a cable disconnection cannot be detected by the

controller.

The controllers are constructed for 50 m sensor element which corresponds to the same

length of safety edge or approx. 4.5 m² safety mat area.

For bumpers the number is according to the dimensions.

System

9

Note

nOnly sequence switched safety transducers are permitted, as parallel connections can

leadtosystemerrorsand theactivationofindividualtransducers cannotbeidentied

correctly.

nThe controllers must only be used in a room with a minimum protection of IP54.

nThe correct functioning of the systems must be checked at least once a day.

nThe user must follow the valid safety regulations and accident prevention regulations.

nThe controllers can only be used on currency circuits that have the same safety standards.

nTo protect against independent restart after a power cut or an emergency stop the

appropriate provisions have to be made.

nThe deformation distance of the safety edges and safety bumpers must be longer than

the stop path of the protected device.

nThe ventilation gaps on the back of the bumper must not be covered.

nWalking sticks, crutches or zimmer frames may not trigger a switching command.

nThe transducer should be kept clean to ensure a safe switching command.

System

10 41

Controllers

11

41

Controllers

SSZ-CVS/N/2/230/24 and Sensor SSZ-SG2, SSZ-SG3

Test principles EN ISO 13856, EN ISO 13849-1

Supply voltage 230V AC or 24V AC/DC

Load carrying capacity of safety circuits 2A

Operating temperature [°C] 0- +50

Can be used internally Yes

Maximum resistance of single sensor‘s channel 250 kΩ

Maximal difference between resistances of channels 20%

Maximum time of actuation <20 ms

Safetyclassications

MTTF 17,17

MTTFd 34 (medium)

DC (Diagnostic Coverage) 90%

CCF (Common Cause Failture) 80

PFHd (according to IEC/EN 62061) 4.477 x 10-6

Nop 60.000

Category compatible with IEC/EN 62061 SIL1

Class of safety category according to EN 954-1 2

Performance Level acc. to EN ISO 13849-1 PL c

Power consumption 1.8 VA

Storage temperature [°C] -10 - +70

Protection level IP30

1. Technical parameters

Controllers

12

Controllers

SSZ-CVS/N/3/230/24 and Sensor SSZ-SG2, SSZ-SG3

Test principles EN ISO 13856, EN ISO 13849-1

Supply voltage 230V AC or 24V AC/DC

Load carrying capacity of safety circuits 2A

Operating temperature [°C] 0- +50

Can be used internally Yes

Maximum resistance of single sensor‘s channel 250 kΩ

Maximal difference between resistances of channels 20%

Maximum time of actuation <20 ms

Safetyclassications

MTTF 203,3

MTTFd 406 (high)

DC (Diagnostic Coverage) 90%

CCF (Common Cause Failture) 80

PFHd (according to IEC/EN 62061) 0.375 x 10-6

Nop 60.000

Category compatible with IEC/EN 62061 SIL2

Class of safety category according to EN 954-1 3

Performance Level acc. to EN ISO 13849-1 PL d

Power consumption 1.9 VA

Storage temperature [°C] -10 - +70

Protection level IP30

Dimension (H/W/D) [mm] 112x23x99

13

Controllers

SSZ-RZ3 and Sensor SSZ-SG2, SSZ-SG3

Test principles EN ISO 13856, EN ISO 13849-1

Supply voltage 24V AC/DC and 230V AC

Load carrying capacity of safety circuits 2A

Operating temperature [°C] 0- +50

Can be used internally Yes

Maximum resistance of single sensor‘s channel 250 kΩ

Maximal difference between resistances of channels 20%

Maximum time of actuation <20 ms

Safetyclassications

Lifesycles 20 years

MTTFd 100 (high)

DC (Diagnostic Coverage) 90%

CCF (Common Cause Failture) 75

PFHd (according to IEC/EN 62061) 4.33E-8

Nop 95.040

Category compatible with IEC/EN 62061 SIL2

Class of safety category according to EN 954-1 3

Performance Level acc. to EN ISO 13849-1 PL d

Storage temperature [°C] -10 - +70

Protection level IP30

Dimension (H/W/D) [mm] 112x23x99

14

Testing basics EN ISO 13849-1/2; EN ISO 13856-1-3

Nominal supply voltage SSZ-RZ4 / SSZ-RZ4B 24V AC 50 Hz or 24 VDC

Allowable voltage

10.6 VDC - 36 VDC or 8 VAC - 24 VAC

Max. current consumption 290mA@12VDC; 135mA@24VDC;

250mA@24VAC

Rates current 100mA@24VDC

Power consumption P1 2,4 W

Internal fuse 1500 mA

Power circuit required fuse 2A

Working temperature range 0°C - +50° C

DIN Rail mount Yes

Max. resistance of the sensor element channel 1 and 2

250 kOhm

Max. resistance difference between the channels 1 and 2

20%

Max. response time <20ms

Performance Level acc. to EN ISO 13849-1 PL=d (Pl e)*

The service life 20 years

MTTFd in connection with SSZ-pressure

equipment 74,1

DC (diagnostic coverage) 90%

CCF (common cause failure) 75

PFHd acc. to IEC/EN 62061 in connection

with the SSZ-Pressure equipment 6.8E-8

The category acc. to IEC/EN 62061 SIL 2

Safety category acc. to

EN ISO 13849-1:2016-02 3

SSZ-RZ4/SSZ-RZ4B and Sensor SSZ-SG 2, SSZ-SG 3

Controllers

15

Contact rating acc. to EN 60947-5-1 15 VAC (50/60Hz) - 3A 13 VDC - 3A

Min. switching current I1, channel 9-10/11-12 5V/10 mA

Min. switching current I2, channel 9-10/11-12 2 A

Mechanical endurance channel 9-10/11-12 >107

Electrical endurance channel 9-10/11-12 9-10/11-12 >3,6 x 105 (DC24V/1A)

Rated operational power 800mW

Reset automatic/manual

Storage temperature [°C] -10 - +50

Grade of protection acc. to IEC 60529 IP30

Dimensions 112x23x99

Weight 180g

Controllers

SSZ-CVS/N/2

2

c

SSZ-CVS/N/3

3

d

SSZ-RZ3

3

d

SSZ-RZ4

3

d

Type of the control unit

Category

Performance Level

Power supply

24V AC/DC

230V AC (for 24/230

version only)

Reset

Automatic/Manual

Outputs

NC

NO

NO/NC

variable variable variable

variable

2

variable

1

1

variable

2

variable

1

2

Comparison of SSZ-control units

16

Controllers

Controllers

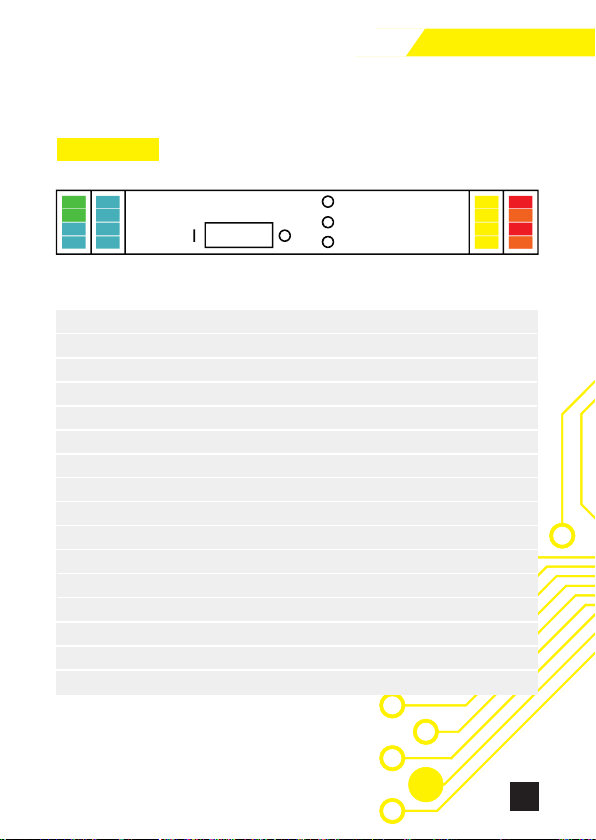

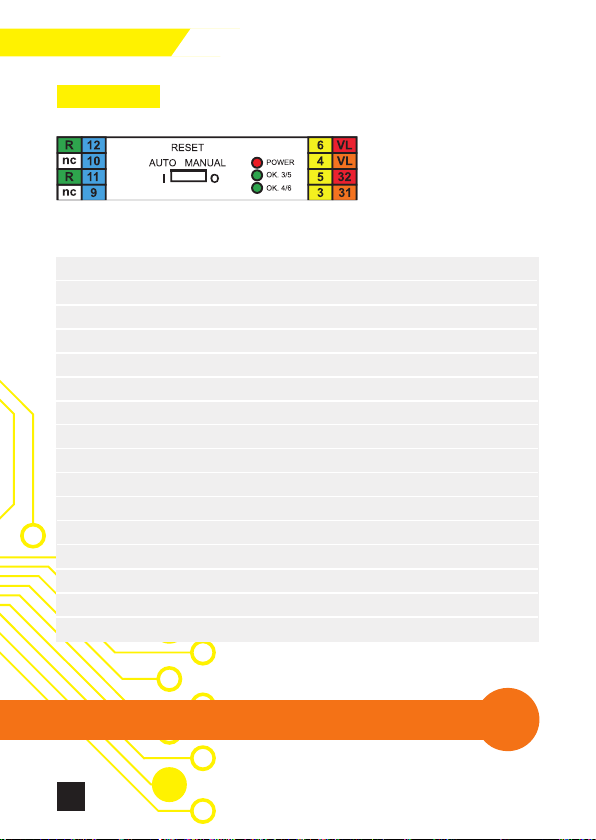

22

R

R

14

13

12

11

10

9

6

4

5

3

Vh

VL

Vh

VL

POWER

OK 3/5

OK 4/6

AUTO RESET

Terminal of

safety units

SSZ

CVS/N/2/230/24

SSZ

CVS/N/3/230/24

3

4

5

6

9

10

11

12

13

14

R

R

Vh

Vh

VL

VL

SSZ sensor, terminal 3

SSZ sensor, terminal 4

SSZ sensor, terminal 5

SSZ sensor, terminal 6

Relays output Relays output

Relays output Relays output

Relays output Relays output

Relays output Relays output

Relays output -

Relays output -

RESET Button

RESET Button

L (230V AC)

N (230V AC)

+24V AC/DC

0V

SSZ-CVS/N/24/230

SSZ-CVS/N/24/230

Terminal of SSZ SSZ

safety units CVS/N/2/230/24 CVS/N/3/230/24

3 SSZ sensor, terminal 3

4 SSZ sensor, terminal 4

5 SSZ sensor, terminal 5

6 SSZ sensor, terminal 6

9 Relays output Relays output

10 Relays output Relays output

11 Relays output Relays output

12 Relays output Relays output

13 Relays output -

14 Relays output -

R RESET Button

R RESET Button

Vh L (230V AC)

Vh N (230V AC)

VL +24V AC/DC

VL 0V

2. Terminals

17

Controllers

Controllers

23

R

R

14

13

12

11

10

9

6

4

5

3

Vh

VL

Vh

VL

POWER

OK 3/5

OK 4/6

AUTO RESET

Terminal of

safety units SSZ - RZ3 24V AC/DC

3

4

5

6

9

10

11

12

13

14

R

R

Vh

Vh

VL

VL

SSZ sensor, terminal

SSZ sensor, terminal 4

SSZ sensor, terminal 5

SSZ sensor, terminal 6

3

Relays output Relays output

Relays output Relays output

Relays output Relays output

Relays output Relays output

RESET Button

RESET Button

L (230V AC)

N (230V AC)

-

-

0V

-+24V AC/DC

SSZ - RZ3 230V AC

External relay monitoring or wire jumper

External relay monitoring or wire jumper

SSZ-RZ3

SSZ-RZ3

Terminal of SSZ SSZ

safety units SSZ - RZ3 230V AC SSZ - RZ3 24V AC/DC

3 SSZ sensor, terminal 3

4 SSZ sensor, terminal 4

5 SSZ sensor, terminal 5

6 SSZ sensor, terminal 6

9 Relays output Relays output

10 Relays output Relays output

11 Relays output Relays output

12 Relays output Relays output

13 External relay monitoring or wire jumper

14 External relay monitoring or wire jumper

R RESET Button

R RESET Button

Vh L (230V AC) -

Vh N (230V AC) -

VL -+24V AC/DC

VL OV

18

SSZ-RZ4

Safety unit SSZ - RZ4 / SSZ - RZ4B

terminal 24V AC/DC

3 SSZ sensor, terminal 3

4 SSZ sensor, terminal 4

5 SSZ sensor, terminal 5

6 SSZ sensor, terminal 6

9 Relay outputs - 2 circuit

10 Relay outputs - 2 circuit

11 Relay outputs - 1 circuit

12 Relay outputs - 1 circuit

13 External safety circuit*

14 External safety circuit*

R Manual RESET button

R Manual RESET button

31 Potential free output

32 Potential free output

VL +24V AC/DC

VL OV

* Opening of the circuit will cause switching to safety mode

Controllers

!

!

The SSZ-RZ4 and SSZ-RZ4B control units are factory set to operate

with automatic reset.

19

Controllers

Manual reset for SSZ-RZ4B control unit

The SSZ-RZ4B control unit is provided with automatic or manual reset functions. Regarding

the automatic reset function, the functions are the same as in the SSS-R24 control unit. In

case of manual reset operation of reset button has no effect on output of output signal

switching device as long as forcepresent on sensor. The output of output signal switching

device remains in OFF state. After removing the actuating force from sensor, signal switching

device remains in OFF state even though reset signal still present.

When releasing of reset button has no effect on output of output signal switching device.

Reset is achieved after another operation of reset button without actuating force on the

sensor.

The SSZ-RZ4B is designed exclusively for use with safety bumper!

An SSZ-safety bumper is most often used to protect driverless vehicles. The use of an SSZ-

RZ4B control unit protects against automatic movement, which may occur after incidental

bridging or failure of the reset function with a simultaneous release of the bumper.

Manual reset control for SSZ-RZ4 and SSZ-RZ4B unit

1. Press the SSZ-pressure-sensitive device

2. Make sure that no one of the SSZ pressure-sensitive devices is pressed

• The green LED‘s „OK 3/5“ and „4/6 OK“ are off

• The relais contacts ofthe channel K1 & K2 are opened

3. Press the reset button

• The „OK 3/5“ and „4/6 OK“ green LEDs are on

• The relais contacts of the channel K1 & K2 are closed

4. Press the SSZ pressure-sensitive device

• The „OK 3/5“ and „4/6 OK“ green LEDs are switch off

• The relais contact of the channel K1 & K 2 are opened

5. Unlock the pressure-sensitive device

• The „OK 3/5“ and „4/6 OK“ green LEDs are switched off

• The relais of the contacts channel K1 & K2 are opened

6. Press the reset button, while the pressure-sensitive device should not be pressed

• The „OK 3/5“ and „4/6 OK“ green LEDs are switched on

• The relais contacts of the channel K1 & K2 are closed

• The SSZ-pressure-sensitive device is unlocked and ready for operation

20

Controllers

3. Function test

nDisconnect sensors on terminals 3, 4, 5 and 6

nShort terminals by leads. Short terminals 3 and 5 by one lead, and 4 and 6 by the second

one. After switching on, two control lights will turn on green (OK 3/5 and OK 4/6) and

output-relays will be activated.

nIn case of safety units with manual blocking, only one light will turn on. Press RESET in

order to reset the safety unit.

nIf terminals 3 and 4 or 5 and 6 are short, then both channels (K1 and K2 releases) will be

deactivated.

nIf we break connection on 3/5 terminals, K1 relay will be deactivated.

nIf we break connection on 4/6 terminals, K2 relay will be deactivated.

This manual suits for next models

7

Table of contents