Stübbe HFT C2 Compact Installation instructions

Hydrostatic filling

level sensor

Original operating manual Pump series

HFT C2 Compact,

HFT C2 Flex (hanging sensor)

Version BA-2017.06.01 EN

Print-No. 301 155

MA DE Rev001

ASV Stübbe GmbH & Co. KG

Hollwieser Straße 5

32602 Vlotho

Germany

Phone: +49 (0) 5733-799-0

Fax: +49 (0) 5733-799-5000

E-mail: [email protected]

Internet: www.asv-stuebbe.com

We reserve the right to make

technical changes.

Read carefully before use.

Save for future use.

Table of contents

Table of contents

1 About this document ............................... 3

1.1 Target groups ................................. 3

1.2 Other applicable documents ................ 3

1.3 Warnings and symbols ....................... 3

2 General safety instructions ....................... 4

2.1 Intended use .................................. 4

2.2 General safety instructions .................. 4

2.2.1 Obligations of the operating company . .... . 4

2.2.2 Obligations of personnel ..................... 4

2.3 Specific hazards .............................. 4

2.3.1 Hazardous media ............................ 4

3 Layout and Function ............................... 5

3.1 Type plate ..................................... 5

3.2 Description .................................... 5

3.3 Layout ......................................... 5

3.3.1 Layout ......................................... 5

4 Transport, Storage and Disposal ................. 6

4.1 Unpacking and inspection on delivery . . . . . . 6

4.2 Transportation ................................ 6

4.3 Storage ....................................... 6

4.4 Disposal ....................................... 6

5 Installation and connection ....................... 6

5.1 Check operating conditions ................. 6

5.2 Install device .................................. 6

5.2.1 Installing Compact version .................. 6

5.2.2 Installing Flex version ........................ 7

5.3 Perform the hydrostatic test (only

Compact) ..................................... 7

5.4 Electrical connection of device .............. 7

5.4.1 Electrical connection of Compact

version ........................................ 7

5.4.2 Electrical connection of Flex version .. . . . . . 7

6Operation ............................................ 8

6.1 Initial start-up ................................. 8

7 Maintenance ......................................... 8

7.1 Servicing ...................................... 8

7.2 Maintenance .................................. 8

7.2.1 Removing the device ........................ 8

7.2.2 Replacement parts and return .............. 8

8 Troubleshooting .................................... 8

9 Appendix ............................................. 9

9.1 Technical specifications ...................... 9

9.2 Dimensions ................................... 9

9.3 Accessories ................................... 9

9.4 Plug assignment ............................. 9

9.5 Sensor cable ................................. 9

List of figures

Fig. 1 Type plate ..................................... 5

Fig. 2 HFT-C2 Compact layout ..................... 5

Fig. 3 HFT-C2 Flex layout .......................... 5

Fig. 4 Connection diagram ......................... 9

Fig. 5 Sensor cable ................................. 9

List of tables

Tab. 1 Other application documents, purpose and

where found .................................. 3

Tab. 2 Warnings and symbols ....................... 3

Tab. 3 Explanation of the formulaic symbol .. . . . . . . 5

Tab. 4 Servicing activities ........................... 8

Tab. 5 Troubleshooting .............................. 8

Tab. 6 Accessories ................................... 9

2 HFT C2 BA-2017.06.01 EN 301 155

About this document

1 About this document

This manual

• is part of the equipment

• applies to all series referred to

• describes safe and proper operation during all operating

phases

1.1 Target groups

Operating company

• Responsibilities:

– Always keep this manual accessible where the device

is used on the system.

– Ensure that employees read and observe this docu-

ment, particularly the safety instructions and warnings,

and the documents which also apply.

– Observe any additional country-specific rules and reg-

ulations that relate to the system.

Qualified personnel, fitter

• Mechanics qualification:

– Qualified employees with additional training for fitting

the respective pipework.

• Electrical qualification:

– Qualified electrician

• Transport qualification:

– Qualified transport specialist

• Responsibility:

– Read, observe and follow this manual and the other

applicable documents, especially all safety instructions

and warnings.

1.2 Other applicable documents

To download:

Resistance lists

Resistance of materials used to

chemicals

www.asv-stuebbe.de/pdf_resistance/300051.pdf

To download:

Data sheet

Technical specifications, conditions of

operation

www.asv-stuebbe.de/pdf_datasheets/301149.pdf

To download:

CE declaration of conformity

Conformity with standards

www.asv-stuebbe.de/pdf_DOC/301192.pdf

Tab. 1 Other application documents, purpose

and where found

1.3 Warnings and symbols

Symbol Meaning

• Immediate acute risk

• Death, serious bodily harm

• Potentially acute risk

• Death, serious bodily harm

• Potentially hazardous situation

• Minor injury

• Potentially hazardous situation

• Material damage

Safety warning sign

Take note of all information

highlighted by the safety warning

sign and follow the instructions to

avoid injury or death.

Instruction

1., 2., ... Multiple-step instructions

Precondition

→Cross reference

Information, notes

Tab. 2 Warnings and symbols

301 155 BA-2017.06.01 EN HFT C2 3

General safety instructions

2 General safety instructions

The manufacturer accepts no liability for damages caused

by disregarding any of the documentation.

2.1 Intended use

The device measures the hydrostatic pressure of a liquid

medium.

• Device must only be used for measuring the filling level in

liquid media.

• Only use the device with suitable media (→resistance

lists).

• Adhere to the operating limits (→9.1 Technical specifica-

tions, Page 9).

2.2 General safety instructions

Observe the following regulations before carrying out any

work.

2.2.1 Obligations of the operating company

Safety-conscious operation

• Only operate the device if it is in perfect technical condition

and only use it as intended, staying aware of safety and

risks, and in adherence to the instructions in this manual.

• Ensure that the following safety aspects are observed and

monitored:

– Intended use

– Statutory or other safety and accident-prevention reg-

ulations

– Safety regulations governing the handling of haz-

ardous substances

– Applicable standards and guidelines in the country

where the pump is operated

• Make personal protective equipment available.

Qualified personnel

• Make sure all personnel tasked with work on the device

have read and understood this manual and all other appli-

cable documents, especially the safety, maintenance and

repair information, before they start any work.

• Organize responsibilities, areas of competence and the

supervision of personnel.

• The following work should be carried out by specialist tech-

nicians only:

– Installation, repair and maintenance work

– Work on the electrical system

• Make sure that trainee personnel only work on the device

under supervision of specialist technicians.

2.2.2 Obligations of personnel

Only complete work on the device if the following requirements

are met:

• System is empty

• System has been flushed

• System is depressurized

• System has cooled down

• System is secured against being switched back on again

• Do not make any modifications to the device.

2.3 Specific hazards

2.3.1 Hazardous media

• When handling hazardous media, observe the safety reg-

ulations for the handling of hazardous substances.

• Use personal protective equipment when carrying out any

work on the device.

• Collect leaking pumped liquid and residues in a safe man-

ner and dispose of in accordance with environmental reg-

ulations.

4 HFT C2 BA-2017.06.01 EN 301 155

Layout and Function

3 Layout and Function

3.1 Type plate

HFT–C2

Füllstandssensor

Messbereich 0-0,5 bar

4-20mA 2-Leiter Id.No.

140557

Anschluss DN25

M

Tankmontage

aterial PVC-U / PP/ PVDF

7m FEP-Kabel

1304-05371

1

2

3

4

6

5

7

9-35 V DC

Fig. 1 Type plate

1Devicetype

2 Filling level measurement range (hydrostatic pressure)

3Outlet

4 Connection

5 Gasket material

6 Installation cable

7 ID number

Device types

• HFT–C2 – Compact, current output

• HFT–C2 – Flex, current output

3.2 Description

The device measures the filling level of a liquid medium. It

transmits the measured value via a current output.

To calculate the filling height, use the following formula:

p(h) = ρ*g*h

Formu-

laic

symbol

Meaning

p(h) Hydrostatic pressure as a function of the liquid

column

ρDensity (for example of water: 998.2 kg/m³ at

20 °C); [ρ]=kg/m³

gLocation factor (gravitational acceleration,

gnorm = 9.80665 m/s²); [g] = m/s²

hHeight of liquid column; [h] = m

Tab. 3 Explanation of the formulaic symbol

3.3 Layout

3.3.1 Layout

1

2

3

Fig. 2 HFT-C2 Compact layout

1 4-pole plug M12

2 Sensor housing

3 Process connection

1

2

3

Fig. 3 HFT-C2 Flex layout

1 FEP cable

2 Sensor housing

3Protectioncap

301 155 BA-2017.06.01 EN HFT C2 5

Installation and connection

4 Transport, Storage and

Disposal

4.1 Unpacking and inspection on delivery

1. Unpack the device when received and inspect it for trans-

port damage and completeness.

2. Check that the information on the type plate agrees with

the order/design data.

3. Report any transport damage to the manufacturer immedi-

ately.

4. If fitted immediately: Dispose of packaging material

according to local regulations.

–Iffitted at a later point: leave device in its original pack-

aging.

4.2 Transportation

Device should preferably be transported in the original

packaging.

4.3 Storage

NOTE

Material damage due to inappropriate storage!

Store the device properly.

1. Make sure the storage room meets the following condi-

tions:

–Dry

– Frost-free

– Vibration-free

– Not in direct sunlight

– Storage temperature +10 °C to +60 °C

2. Device should preferably be stored in the original packag-

ing.

4.4 Disposal

Plastic parts can be contaminated by poisonous or radioac-

tive media to such an extent that cleaning will not be suffi-

cient.

WARNING

Risk of poisoning and environmental damage from

medium.

Use personal protective equipment when carrying out any

work on the device.

Prior to the disposal of the device: Neutralize residues of

medium in the device.

1. Remove battery and dispose of in accordance with local

regulations.

2. Remove electronic parts and dispose of in accordance with

local regulations.

3. Dispose of plastic parts in accordance with local regula-

tions.

5 Installation and connection

5.1 Check operating conditions

1. Ensure the required operating conditions are met:

– Resistance of body and seal material to the medium

(→resistance lists).

– Media temperature (→9.1 Technical specifications,

Page 9).

– Working pressure (→9.1 Technical specifications,

Page 9).

2. Consult with the manufacturer regarding any other use of

the device.

5.2 Install device

5.2.1 Installing Compact version

Process pipework has been properly prepared.

Process pipework has been secured against unintentional

opening with shut-off values.

Avoidance of medium buildup.

Select installation location so that no build-up or crystalliza-

tion is possible.

WARNING

Risk of injury and poisoning due to medium spraying out.

Use personal protective equipment when carrying out any

work on the fitting.

1. Unscrew union nut.

2. Insert union nut on to the spool piece of the process

pipework.

Check mounting direction.

3. Weld device insert to the process pipework spool piece.

4. Check O-ring fitting.

5. Connect device to the process pipework. Tighten union nut

by hand only.

6 HFT C2 BA-2017.06.01 EN 301 155

Installation and connection

5.2.2 Installing Flex version

Tank has been properly prepared.

Avoidance of medium buildup.

Select installation location so that no build-up or crystalliza-

tion is possible.

Lateral movements of sensors lead to measurement errors.

Fit protection tube or use additional weight if necessary

Select installation location so that no build-up or crystalliza-

tion is possible.

WARNING

Risk of injury and poisoning due to medium spraying out.

Use personal protective equipment when carrying out any

work on the fitting.

1. Insert the sensor into the tank at the top.

2. Lower the sensor to the bottom of the tank.

3. Screw the cable gland tight.

5.3 Perform the hydrostatic test

(only Compact)

Perform hydrostatic test using neutral medium, e.g. water.

1. Pressurize the device, ensuring

– Test pressure < 1.5 x PN(Nominal pressure)

– Test pressure < PN+5bar

– Test pressure < permissible system pressure

2. Check that the device is not leaking.

5.4 Electrical connection of device

5.4.1 Electrical connection of Compact version

Device is connected to the process pipework.

Power supply switched off and secured against being

switched back on again.

Cable without shielding can be used to connect the device.

If electromagnetic interference is anticipated, then shielded

cablemustbeused.

1. Cut sensor cable to length.

2. Fit plug (→9.4 Plug assignment, Page 9).

3. Connect sensor housing with sensor cable.

5.4.2 Electrical connection of Flex version

Device is installed in the tank.

Power supply switched off and secured against being

switched back on again.

Cable without shielding can be used to connect the device.

If electromagnetic interference is anticipated, then shielded

cablemustbeused.

1. Connect the sensor cable.

The sensor cable is prepared and can be connected to the

cable extension with the supplied crimp connectors.

2. Insert the wire ends into the single wire connectors. Ensure

that the wire ends are not stripped.

3. Close the single wire connectors.

4. Crimp the single wire connectors (→9.5 Sensor cable,

Page 9). Use combination pliers if necessary.

– The capillary tube must not be closed.

301 155 BA-2017.06.01 EN HFT C2 7

Troubleshooting

6Operation

6.1 Initial start-up

Device is connected properly to the process pipework.

Device is connected properly with the power supply and

ready for operation.

For this purpose, the current output for filling level must

be displayed in the higher-level controller as a measured

value.

After starting the higher-level controller, the device trans-

mits the filling level as current signal (4 … 20 mA).

7 Maintenance

WARNING

Risk of injury and poisoning due to hazardous or hot

media.

Use personal protective equipment when carrying out any

work on the device.

Allow device to cool.

Make sure the device is depressurized.

Block the media supply to the device.

Empty the process pipework, safely collect the media and

dispose of it in accordance with environmental regulations.

Switch off the power supply to the system.

Secure power supply against being switched back on

again.

Provide warning of maintenance and repair work and set

up warning signs.

7.1 Servicing

Interval Action

As necessary • Clean device with a damp cloth.

Six-monthly Visual and function check:

• Normal operating conditions

unchanged

• No leaks

• No unusual operating noises or

vibrations

Tab. 4 Servicing activities

Perform maintenance tasks according to the table.

7.2 Maintenance

7.2.1 Removing the device

System is empty.

System has been flushed.

System is depressurized.

System has cooled down.

System is secured against being switched back on again.

1. Unplug connection cable.

2. Disassemble device from the process pipework. For the

Flex version: Pull the sensor out of the tank.

3. Decontaminate device if required.

7.2.2 Replacement parts and return

1. Have the following information ready to hand when order-

ing spare parts (→3.1 Type plate, Page 5).

–Devicetype

– ID number

– Nominal pressure and diameter

– Connection and gasket material

2. Please complete and enclose the document of compliance

for returns (→www.asv-stuebbe.com/service/downloads).

3. Only use spare parts from ASV Stübbe.

8 Troubleshooting

WARNING

Risk of injury and poisoning due to hazardous media liq-

uids!

Use personal protective equipment when carrying out any

work on the device.

Error Possible cause Corrective action

Medium leaks

outatscrew

connection

Pre-tension of the

O-ring too small

Retighten

union nut by

hand.

Tab. 5 Troubleshooting

8 HFT C2 BA-2017.06.01 EN 301 155

Appendix

9 Appendix

9.1 Technical specifications

Technical data (→Data sheet).

9.2 Dimensions

Dimensions (→Data sheet).

9.3 Accessories

Description Ident. number

Tank lead-through 2" PP EPDM 148157

Tank lead-through 2" PP FPM 148158

Tank lead-through 2" PVDF EPDM 148149

Tank lead-through 2" PVDF FPM 148150

Tab. 6 Accessories

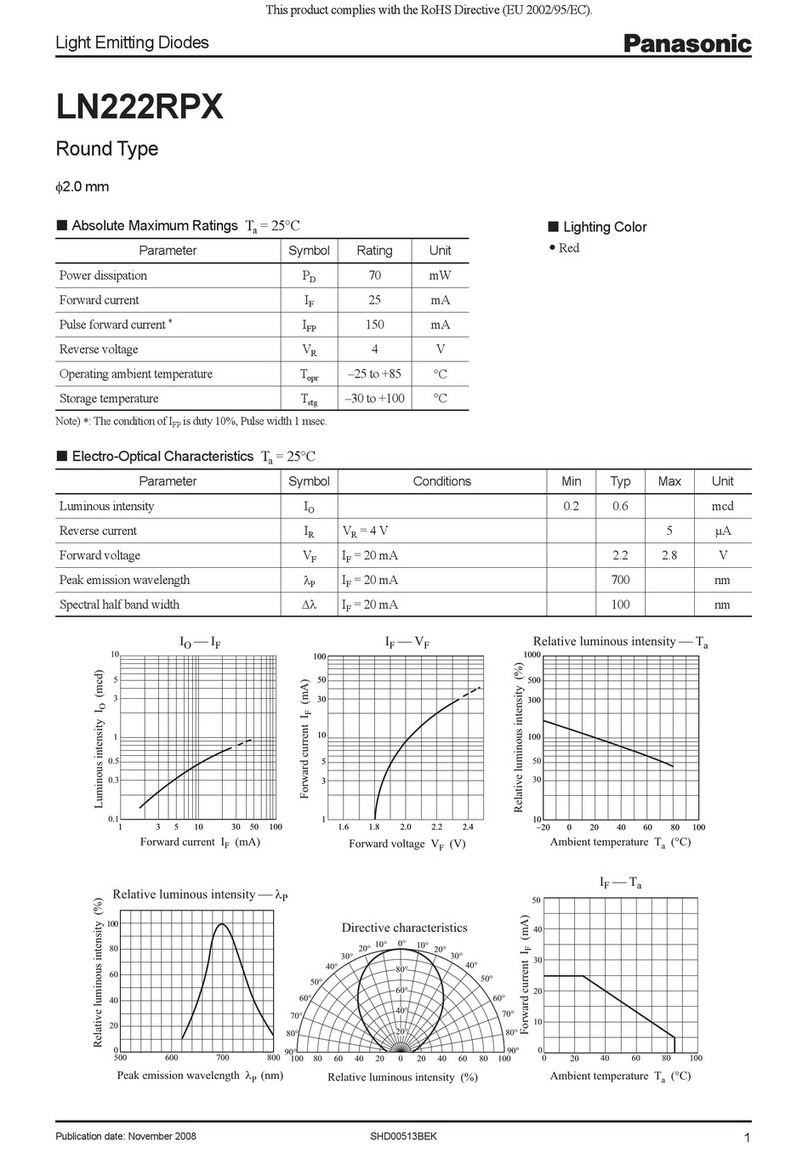

9.4 Plug assignment

2

34

1

Fig. 4 Connection diagram

1 Signal (+), 4...20 mA

2 Signal (-), 4...20 mA

3n.c.

4n.c.

9.5 Sensor cable

1

2

3

Fig. 5 Sensor cable

1 Capillary tube

2 Signal (+), brown wire

3 Signal (–), white wire

301 155 BA-2017.06.01 EN HFT C2 9

This manual suits for next models

1

Table of contents

Other Stübbe Accessories manuals