EKO INSTRUEMTNS CO., LTD. Heat Flow Sensors Instruction Manual Ver.7 Pg. 5

4. Introduction

Due to a strong drive for energy saving nowadays, obtaining accurate information on the thermal insulation of

facilities such as buildings, offices, factories, and houses has increased. The MF and HF-Series Heat Flow

Sensors are designed to directly measure the heat radiation or heat transmission from walls, floor/ground, stock

storage walls, and freezer walls, as well as to measure the heat flow rate underground, by embedding or attaching

the Heat Flow Sensor to the measuring part.

The MF-180 and MF-180M are compact type heat flow sensors with high sensitivity. MF-180M is designed for

outdoor use. HF-Series are thin types of heat flow sensors. Both HF-30S and HF-10S can be attached on a curved

surface. By combining several heat flow sensors with an insulated box, a calorimeter device can be created.

4-1. Main Functions

EKO heat flow sensors provide highly accurate measurements compared to heat flow measurements by a

common thermometer.

Due to their high sensitivity, EKO heat flow sensors perform well even with low heat flow measurements.

The heat flow sensors are calibrated using the improved GHP method (JIS A 1412, ASTM C1777).

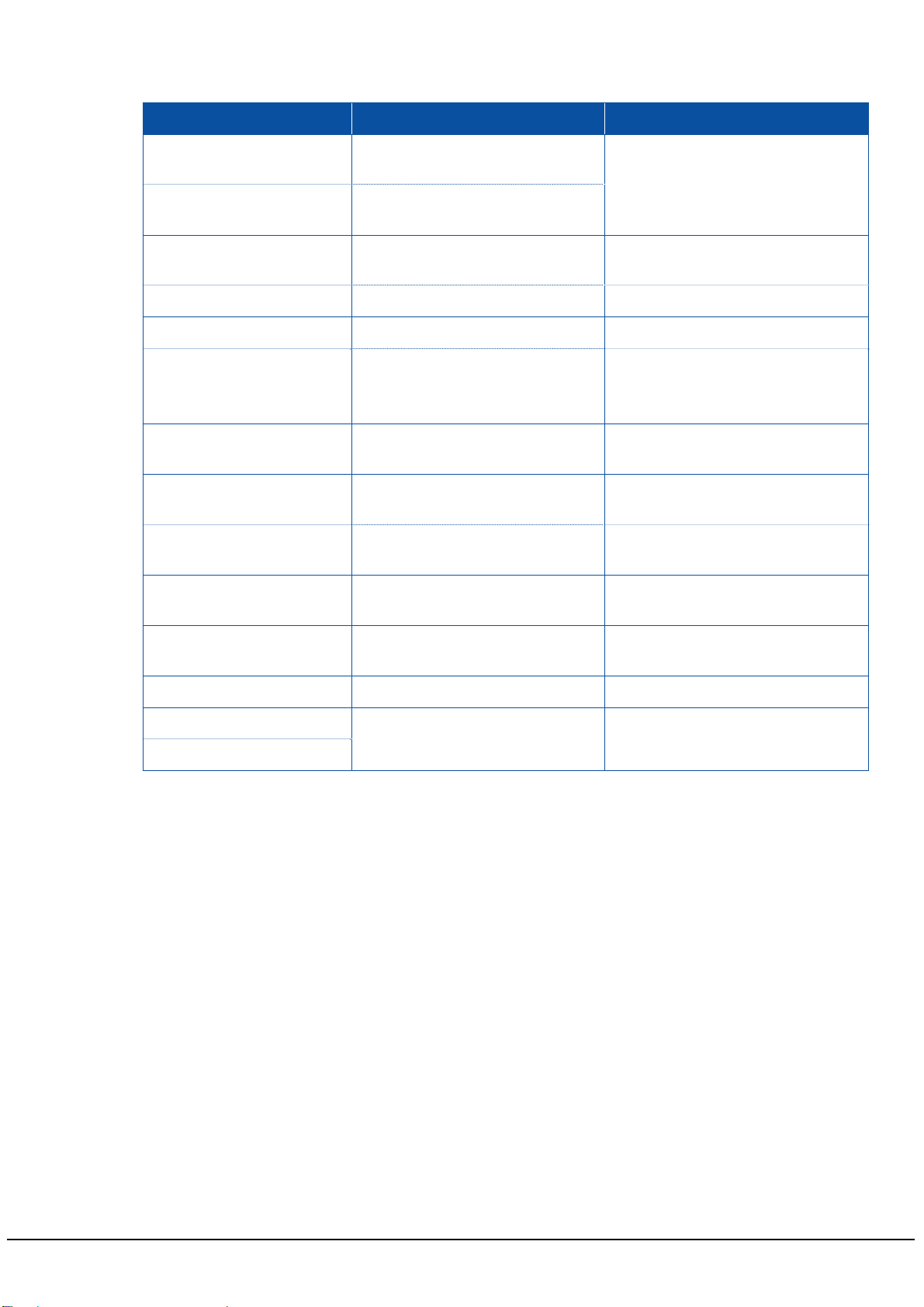

1. MF-180

The heat flow sensor is enclosed with a black polyester sheet.

For general use, compact, high sensitivity

2. MF-180M

The heat flow sensor is molded with epoxy resin which is highly waterproof for burying underground and

outdoor use for a long period of time.

Compact design with high sensitivity

For burying underground and high durability

3. HF-30S

300mm×300mm size heat flow sensor, both sides are coated with epoxy.

Thin type with low heat resistance, Large area(300mm x 300mm)

4. HF-10S

100mm×100mm size heat flow sensor, both sides are coated with epoxy.

Suitable for measuring heat radiation and transmission from boiler/combustion room, heat radiation from

lighting and heat source, and heating devices