1

Table of Contents

Thank You2

Warranty Statement 3

Safety Information 4

Specifications 5

Installation 6-7

Assembly Floor Track 8-15

Operating Instructions 16-17

Maintenance Schedule 18

Mechanical Components

Rigid Belt Base Unit, 460V 20-21

Rigid Belt Base Unit, 230V 22-23

Rigid Belt Frame Assembly 24-25

Assembly Rear/Front Suspension 26-27

Rigid Belt Gravity Discharge, 13,8 and 5 ft. Extensions 28-30

Power Steering Assembly 31

Decal Location 32

Rigid Belt Manual Steering Option, 13,8 and 5 ft. Extensions 33-35

Electrical Components

Electrical Assembly, Main Frame 37

Component Layout Main Electrical Enclosure 38

Main Electrical Panel Enclosure and Layout, 460 V Std. Speed 39-40

Main Electrical Panel Enclosure and Layout, 230 V Std. Speed 41-42

Main Electrical Panel Enclosure and Layout, 460 V Speed Opt. 43-44

Main Electrical Panel Enclosure and Layout, 230 V Speed Opt. 45-46

Electrical Assembly 13, 8 and 5 ft. Extensions 47-49

Schematics and Diagrams

Rigid Belt Schematic, Std. 480 V 51

Rigid Belt Schematic, Std. 240 V 52

Rigid Belt Schematic, Opt. Speed, 480 V 53

Rigid Belt Schematic, Opt. Speed, 240 V 54

12 x 12 Enclosure Wire Connection 55-58

Wiring Diagram, Limit Switch 59

Wiring Diagram and Parts List Operator Panel 60-63

AC Tech Frequency Drives 64

Frequency Drive for Optional Belt Speed 65

Troubleshooting the Electrical System 66-67

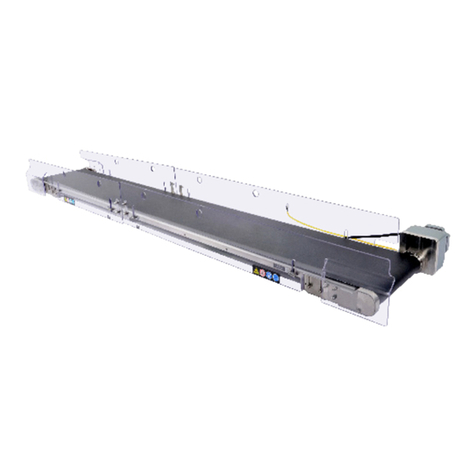

FMH Conveyors Operator’s Manual

BestReach Rigid Belt Conveyor