St George 5567800 Manual

Gas Cooktops

Installation Leaflet

Safety Precautions

Before connecting to gas, ensure the cooktop is suited to the gas type required.

This cooktop shall not be installed on a boat or marine environment. This appliance shall not be

used as a space heater.

This appliance must be installed by a qualified and competent person in accordance with the

gas installation code AS 5601, SAA Wiring Rules, as well as the requirements of all local statutory

and building authorities and regulations. The manufacturer does not accept any liability for any

damage or injury caused by improper installation.

Instruct The Customer

When satisfied that the cooktop has been installed and is operating correctly, instruct the

customer in its safe operation. Ensure the customer understands fully by having them operate the

cooktop.

This booklet must be left with the consumer.

Model No’s

5567800 5 burner gas cooktop

5566800 4 burner gas cooktop

5567100 5 burner gas cooktop with flame failure

5566010 4 burner gas cooktop with flame failure

2

Ensure Suitability Of Location

Before making any alterations to kitchen cabinetry, you should ensure that the proposed

location for the cooktop is suitable:

Electrical supply: there must be an earthed 240V 50 Hz 10Amp power socket within reach of the

supplied electrical cable (approximately 850mm from the rear right of the cooktop). The power

socket must be readily accessible without having to remove the appliance. If a power socket

needs to be installed or relocated, the work must be done by a licensed electrician.

Cabinetry: We recommend that the adjacent kitchen surfaces be capable of withstanding

temperatures of 100ºC, and that the cabinetry can support the weight of the cooktop plus filled

cooking utensils. If necessary, check with the bench top supplier that the material is suitable. St

George Appliances will not be liable for heat damage to incorrectly specified materials.

Clearances: Ensure there is sufficient room to install the cooktop with all required clearances as

specified on the next page.

Gas Supply: Ensure that it is possible to run gas lines to the gas connection point of the

appliance. The gas connection point must be accessible without having to remove the

cooktop. If a flexible hose is used, the connection point must also be accessible without having

to remove the cooktop.

Check Gas Type

Check that the gas type (ULPG or Natural Gas) available in the building matches the gas type

of the cooktop, as shown on the gas type sticker.

If the cooktop is suited to the incorrect gas type, it is possible to perform a gas conversion. This is

explained later in this manual.

Before Installation

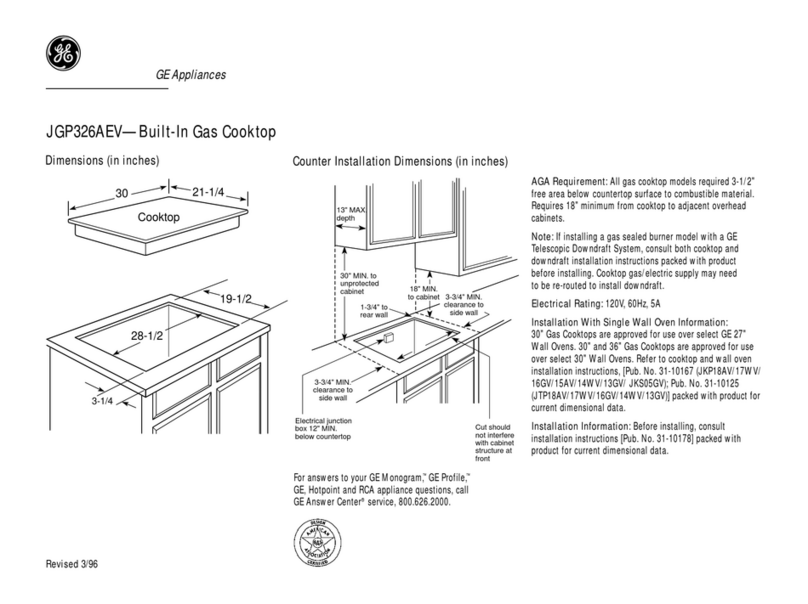

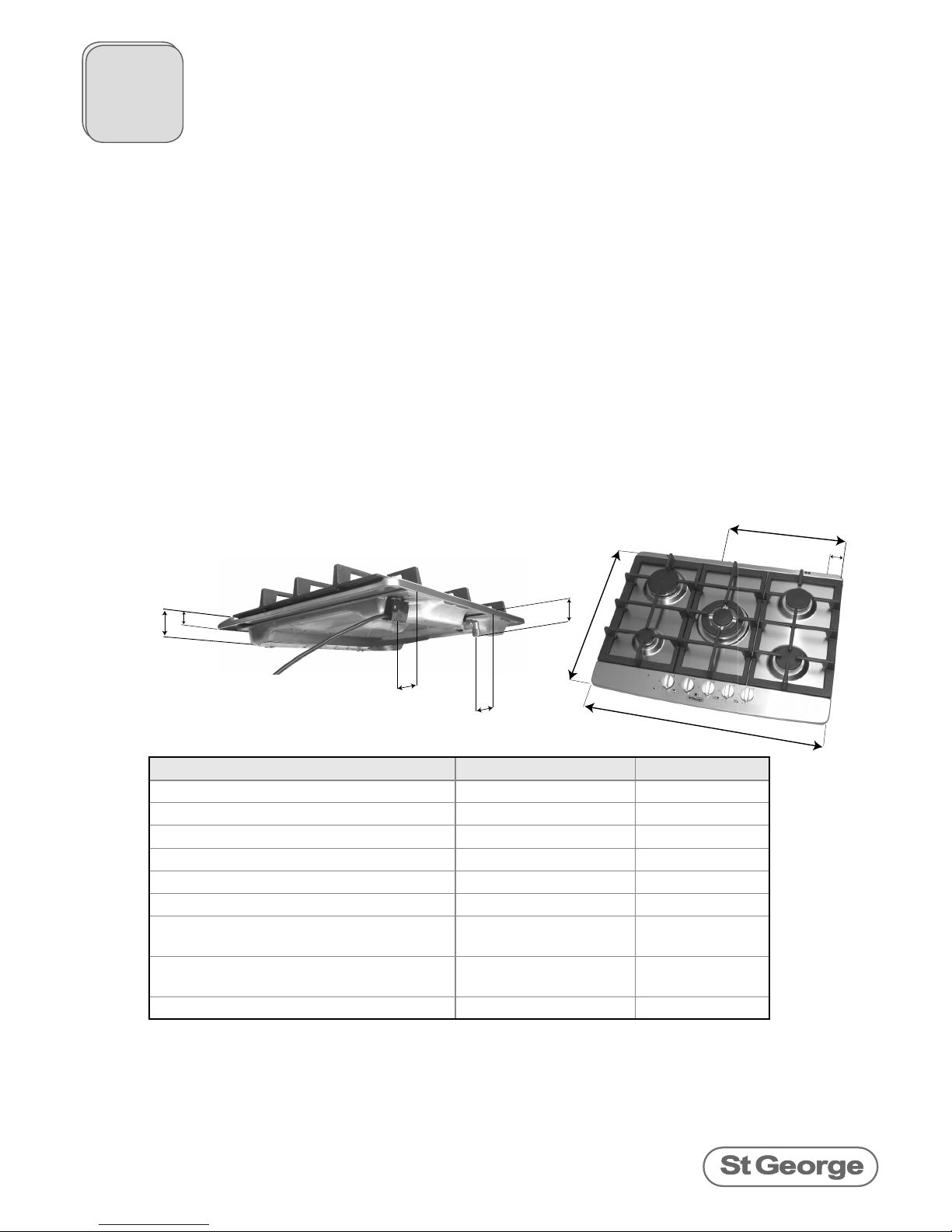

Dimensions 4 burner models 5 burner models

A - Depth 512 mm 512 mm

B - Width 595 mm 685 mm

C - Overall Height 45 mm 45 mm

D - Height above benchtop 19 mm 19 mm

E - Gas connection point to right edge 362 mm 395 mm

F - Gas connection point to back edge 41 mm 41 mm

G - Gas connection point to top surface

of hob

62 mm 62 mm

H - electrical junction (start of 1.4 metre

power cable) to right edge

28 mm 71 mm

J - electrical junction to back edge 62 mm 62 mm

F

J

G

CD

A

B

E

H

3

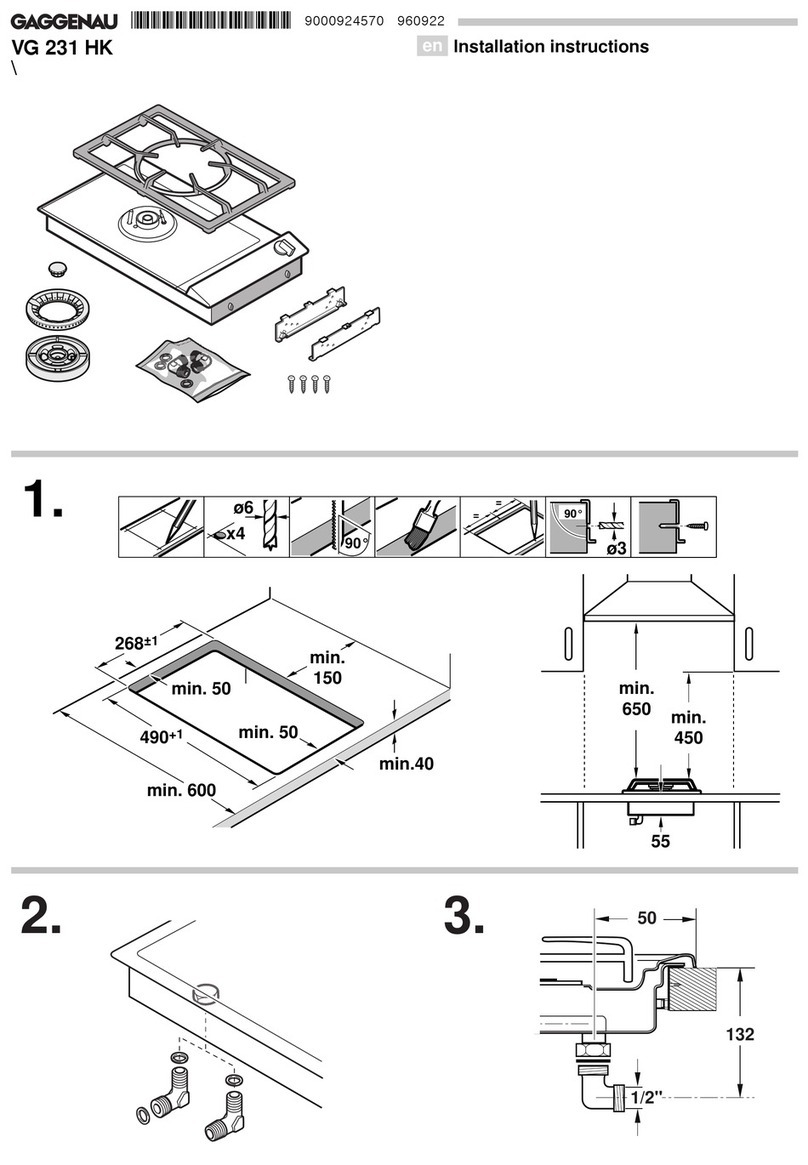

Clearances

Overhead Clearances

Rangehoods and overhead exhaust fans must be installed with at least the clearances

recommended by the manufacturer’s instructions, but in all cases the clearance from the

top of the highest burner to a rangehood must be at least 650mm, and to an exhaust fan

must be at least 750mm.

Allow at least 650m clearance between the top of the highest burner and any overhead

cabinetry that is made of combustible material.

If the overhead cabinetry is made of non-combustible material such as tiles, the overhead

clearance must be at least 450mm.

•

•

•

Before Installation

Side And Back Clearances From NON-Combustibles

If the wall is made of non-combustible material, the required

clearance is only 10mm all around the perimeter of the

cooktop. For each model, this equates to the following

measurements from the edge of the cutout:

Clearance from cutout

to NON-combustible

wall

600mm models 700mm models

A - back edge to

back wall

20 mm 20 mm

B - left side edge to

left side wall

30 mm 75 mm

C - right side edge to

right side wall

30 mm 75 mm

A combustible wall can be protected with non-combustible

material such as 5mm thick ceramic tiles, as long as this

protection is at least 150mm high, and extends for the full width

and depth of the cooktop.

Side And Back Clearances From Combustibles

The clearance from combustible materials (including walls,

cupboards and curtains) must be at least 200mm as measured

from the far edge of the burners. For each model, this equates

to the following measurements from the edge of the cutout:

Clearance from cutout

to combustible wall

600mm models 700mm models

A - back edge to

back wall

120 mm 130 mm

B - left side edge to

left side wall

165 mm 185 mm

C - right side edge to

right side wall

125 mm 170 mm

!"

#

4

Installation Details

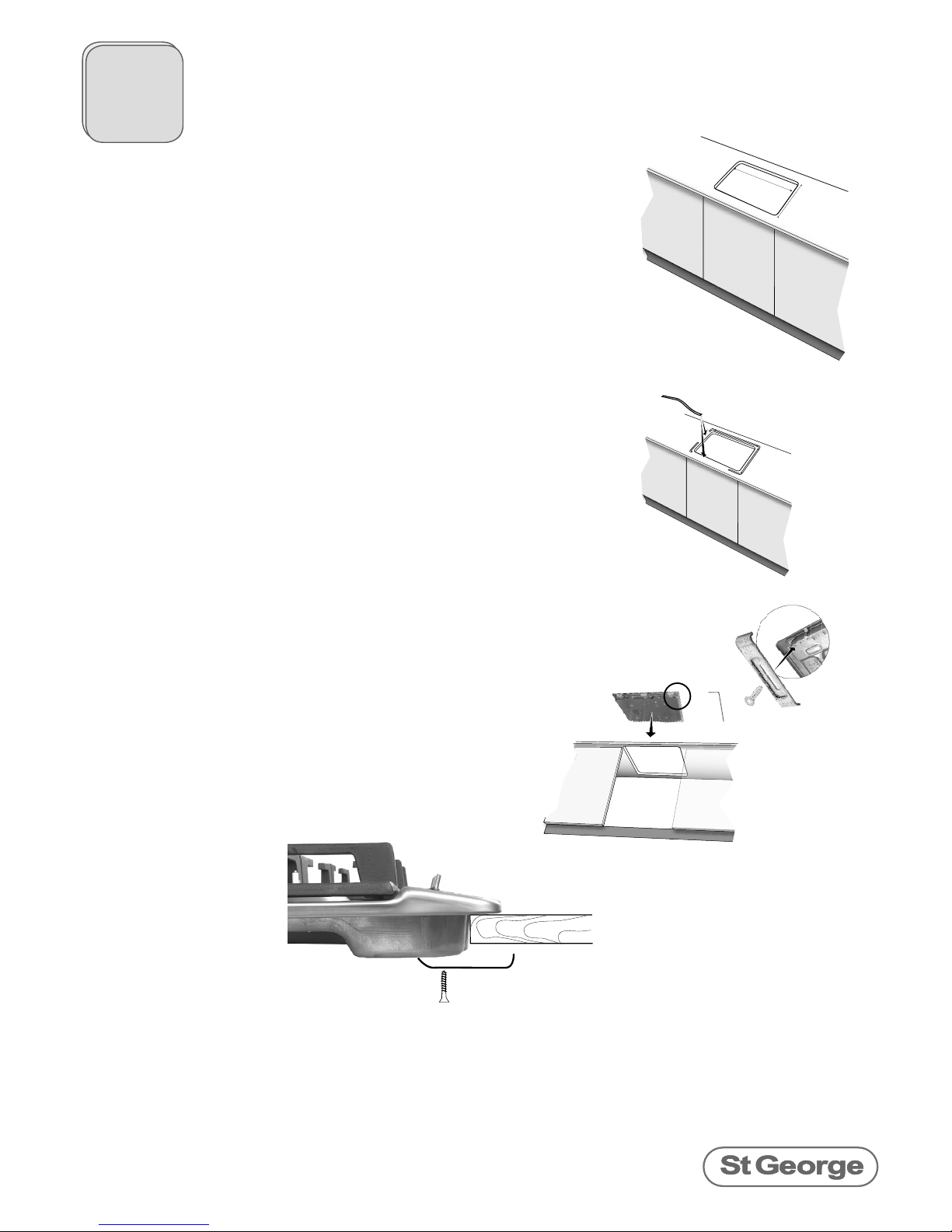

Lay The Rubber Seal

Rubber sealing material has been provided to help seat the

edges of the cooktop neatly onto the benchwork.

The cooktop must not be bonded to the benchwork with

any adhesive or permanent sealant, as this will prevent

future servicing and maintenance work to be carried out.

Instal The Cooktop and Secure With Brackets

Remove all packing material and literature from the

cooktop.

Lower the cooktop into the cutout. Use the 4

brackets and screws supplied to secure the cooktop

into the cabinetry.

The brackets are designed to clamp the cooktop to

a bench with thickness between 20mm and 50mm.

If the benchtop is thicker than 50mm, cut a recess

into the underside of the benchtop to a thickness of

50mm or less.

Create Cutout In The Benchtop

The required cutout dimensions are as shown in the

diagramme, Ensure all cutouts are neat and square,

and as close to the nominal dimensions as possible. A

tolerance of around +/- 2mm is allowed for.

We recommend sealing the cut edges of the benchwork

with a moisture proof paint to prevent future deterioration

to the benchtop material.

MM

MM

Attach The Duplicate Data Label

Once the cooktop is in position, attach the duplicate data label to a

visible surface adjacent to the cooktop, so that appliance details can

readily be seen for future maintenance.

5

Connect The Gas

For gas appliances, the final gas connection must be made using a flexible hose or annealed copper

tubing of sufficient length to permit the insertion and removal of the appliance. The gas Inlet fitting is

½ “ BSP (male) thread.

If a flexible hose is used.

Install with a hose assembly that complies with AS/NZ1869(AGA approved). 10mm ID class B or D.

and in accordance with AS5601. This hose must not exceed 1.2m in length. Ensure that the hose

does not contact the hot surfaces of the hotplate, oven, dishwasher or any other appliance that

may be installed underneath or next to the cook top. The hose should be positioned so that it does

not interfere with drawers or other moving parts, and so that it is not subjected to abrasion, kinking,

or permanent deformation. The hose should be able to be inspected along its entire length. Unions

compatible with the fittings must be used and all connections must be tested.

A restraining wire or chain of adequate strength is to be fixed to the appliance and the wall within

50mm of each connection point. The length of the chain or wire is not to exceed 80% of the length of

the hose assembly.

Connecting The Regulator or Test Point Adaptor

For natural gas installations, use only the regulator supplied with the cooktop. ULPG installations

that have pressure control regulators at the supply cylinder do not require

a separate appliance regulator. However, a test point adaptor must

be connected to the gas inlet of the cooktop to enable gas pressure

measurement at the appliance.

It is essential that the regulator on the appliance be held firmly with a

spanner when connecting the supply. Do not overtighten. The regulator

must not be connected to the appliance or the gas supply without thread

sealant/ lubrication as a dry connection may permanently bind the threads.

It is recommended that an isolating valve and union be fitted in an

accessible location, to enable simple disconnection for servicing, without

having to remove the appliance.

Pressure Testing

First turn the gas off to the appliance. Remove the sealing screw from the

test point and attach the hose of a manometer to it. Turn the gas on to

the appliance and light the wok burner and medium burners at their maximum setting. Check the

pressure and adjust at the regulator if necessary to the following settings:

NG Pressure 1 kPa / 4” WC

ULPG Pressure 2.75 kPa / 11” WC

Attach The Burner Head And Burner Cap

Place the correct burner head on each burner, ensuring that each head is

seated securely, and rotation is not possible.

When seating the small, medium and large burner heads ensure the hole

near the outer edge of the burner head goes over the igniter electrode.

When seating the wok burner head, position the burner head so that the

raised tracks underneath the head locate into the four channels on the hob

(situated in the 12 o’clock, 3 o’clock, 6 o’clock and 9 o’clock positions.)

Place a burner cap on each burner head, as well as the outer ring on the wok

burner. The caps are positioned correctly when they can rotate, but cannot

move from side to side.

•

•

Installation Details

6

Check For Leaks

Once the appliance is installed, conduct a full gas soundness check according to the

requirements of AS5601. Whenever any change to the installation is made that may affect gas

soundness (eg adjustments involving any disconnection and reconnection), then follow the

following leak test procedure. Never use a naked flame to check for gas leaks.

In a small container, mix up a solution of water and detergent or soap. Mix the solution well.

Make sure that the gas supply is turned on. Turn off all gas control valves on the appliance.

Using a brush or spray bottle, apply the solution to the gas line and each joint in the gas line,

including any flexible hosing and regulator.

Bubbling of the solution will indicate that there is a leak present. Re-tighten or re-seal any joints

that are leaking. If a leak persists contact the manufacturer for assistance.

•

•

•

Check Burner Operation

Light each burner and check for a clear blue flame. Occasional yellow tipping is acceptable.

Sometimes burners may not ignite immediately and may seem to “blow” slightly when they do

ignite. This is usually due to air in the gas line, which needs to be purged.

Excessive lift off, usually

due to pressure too high

Excessive yellowing, usually

due to insufficient oxygen

Good crisp blue flame.

Make Electrical Connection

When routing the flexible cord of the cooktop, no part of the cord may be subject to direct

heat. After installation of the cooktop, the cord must be positioned so that its temperature does

not exceed 75ºC, and so that it does not come into contact with any metal objects.

This appliance must be adequately earthed. If the cooktop does not have a plug, it must be

connected by means of a special power cord, which must be suitably earthed. In particular:

The cooktop must be connected to the mains via a bipolar switch which has at least 3mm

clearance between contacts.

All electrical work must be done by a licensed electrician.

Installation Details

The ignitor for each burner is activated by pressing down on the control knob. The ignition

system must be checked for all burners individually and in combination. Some models have

flame failure safeguards for each burner. The visible thermocouple probes need to be within the

flame to allow the thermocouple to heat up and allow the gas valve to remain open.

Check that the igniter for each burner successfully ignites the gas and that the burner remains

alight. If an igniter fails to work or a burner fails to remain alight, first remove the plug from

the electrical power outlet, and then check that all the electrical connections are in place.

Ensure the burner head is sitting correctly with the electrode neatly within the hole near its

circumference.

If the cooktop fails to operate correctly, call St George Appliances or their appointed agent for

service. Do not attempt to repair this situation yourself.

Check Igniter Operation

Attach Duplicate Data La-

bel

7

Connect The Appropriate Regulator

For natural gas installations, use only the regulator supplied with the cooktop. ULPG installations

that have pressure control regulators at the supply cylinder do not require a separate appliance

regulator. However, a test point adaptor must be connected to the gas inlet of the cooktop to

enable gas pressure measurement at the appliance.

Change The Gas Type Sticker

Replace the gas type sticker on the cooktop to indicate the correct gas type:

For Natural Gas Black text on white background "ONLY FOR USE WITH NATURAL GAS"

For ULPG Black text on white background "ONLY FOR USE WITH U-LPG"

Check Turn Down Settings And Adjust If Necessary

Turn each burner control knob to the minimum setting. The flame should still be visible above

the burner cap. In particular, it is most important that the minimum flame is not able to be

extinguished by air draughts.

If the flame is too small or too large, remove the burner control

knob. Insert a small flat blade screwdriver into the hole in

the middle of the valve spindle. If the screwdriver is not long

enough, it may be necessary to expose the valve (see “Basic

Servicing” next page). To increase the flame, turn the adjusting

screw anticlockwise. To decrease the flame, turn the adjusting

screw clockwise. Adjust for a minimum, stable and clear flame.

Reassemble the cooktop, ensuring that burner heads are

seated correctly.

Gas Conversion

injector

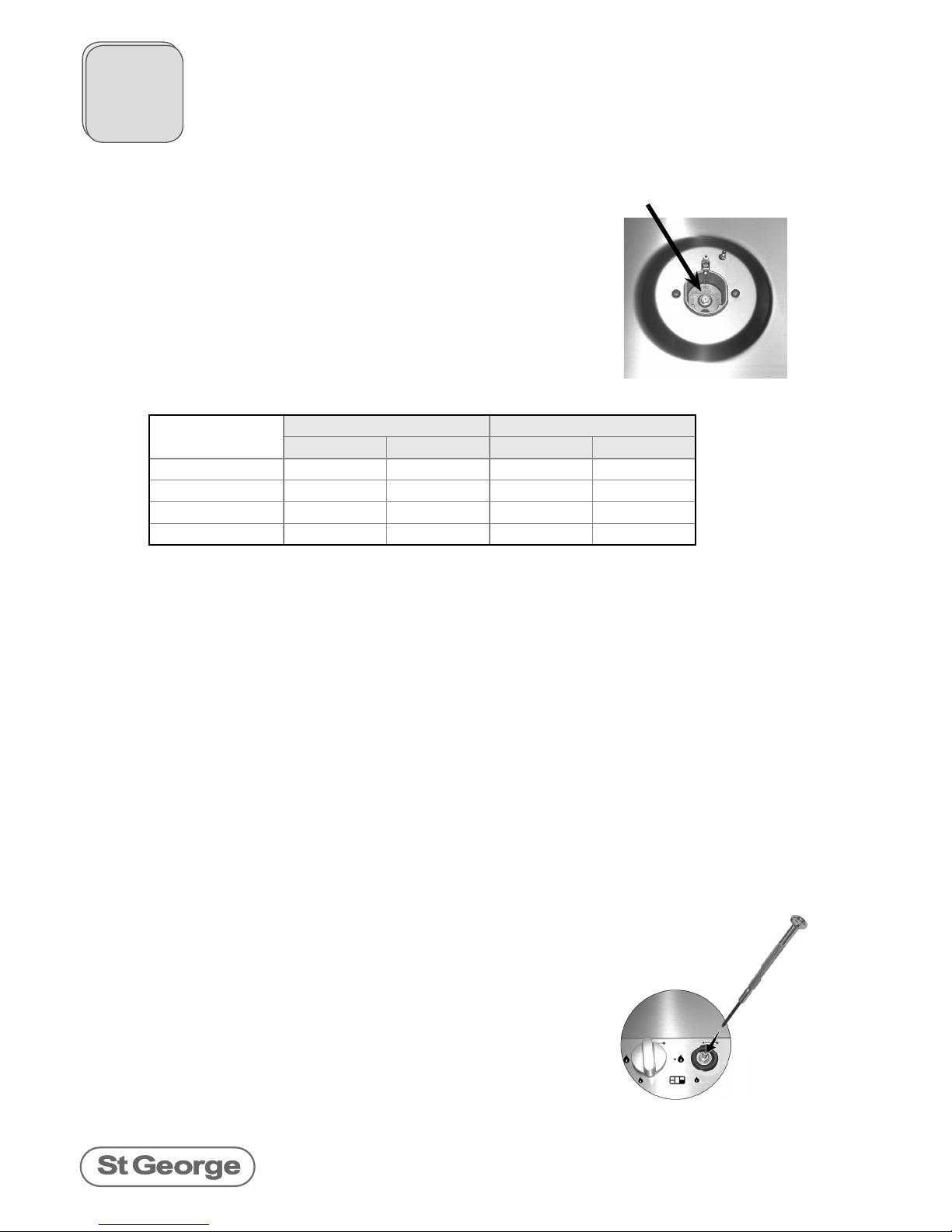

Change The Injectors

Ensure all gas is switched off and preferably disconnected from

the appliance. Ensure electrical power has been disconnected.

Remove the burner head and cap from each burner. Using a

7mm socket, undo the injector from each burner and replace

the correctly rated injector as shown in the following table:

Natural Gas ULPG

Injector Gas Rating Injector Gas Rating

Wok burner 1.7 mm 14.0 MJ/hr .97 mm 13.0 MJ/hr

Large burner 1.4 mm 10.0 MJ/hr .90 mm 12.0 MJ/hr

Medium burner 1.1 mm 6.4 MJ/hr .69 mm 6.3 MJ/hr

Small burner .90 mm 4.0 MJ/hr .53 mm 3.6 MJ/hr

8

St George Appliances

3-5 Birmingham Ave Chester Hill NSW 2162

ph 1300-305-366

www.sga.com.au

556xx00_instal_0106

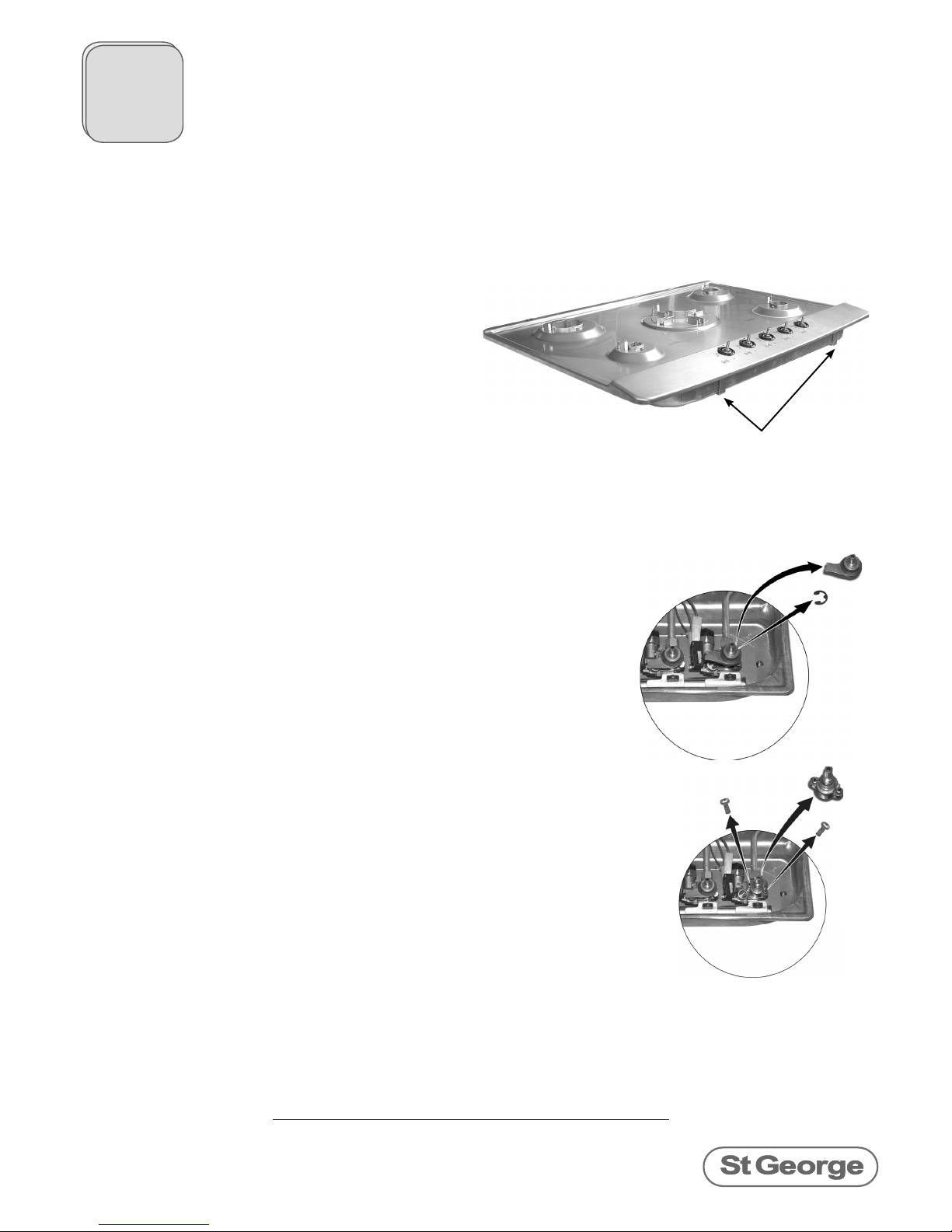

Basic Servicing

Ensure all gas and electricity is completely disconnected from the appliance, and all

components have cooled down from any previous use.

Remove the trivets, burner caps and burner heads.

Remove the burner control knobs, the brass

rings and the plastic surrounds.

Undo the screws adjacent to each burner.

There should be two screws associated with

each of the small, medium and large burners,

and four screws with the wok burner.

Undo the two screws under the front of the

cooktop, which hold two securing tabs.

Carefully lift the hob from the main cooktop chassis,

being careful not to damage the ignitor probe or

thermocouple (some models only).

Reverse the process to reassemble.

Removing The Hob

First, remove the hob as explained above.

Remove the e-clip from the valve spindle, and then lift the

ignition lever off the spindle.

Undo the two screws which secure the valve spindle from the

valve body. Ensure the spring does not get lost or misplaced in

this process.

Servicing such as lubricating the valves or adjusting the turn

down setting should only be carried out by an authorised

service agent.

Replace the valve spindle, ensuring the spring is properly

seated inside the spindle, and the two screws are secured but

not overtightened.

Replace the ignition lever, ensuring it sits directly above the

stainless steel tab on the electronic igniter box.

Secure with the e-clip.

Before replacing the hob, perform a leak test on all valves

which have been disassembled.

Replace the hob as described above.

Exposing The Valve

All parts including valves, manifolds, burners and electronic components are fully

accessible once the hob is removed.

All service work including parts replacement should only be carried out by authorised

service agents. Only genuine St George Appliance parts should be used.

Replacing Parts

Remove screws from under the

front of the cooktop, as well as

those around each burner.

This manual suits for next models

3

Table of contents

Other St George Cooktop manuals