STABILUS ACE MC33-V4A Service manual

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

Table of contents Page

General instructions................................. 2

Safety information ................................... 2

Intended use........................................... 2

Description and function........................... 2

Calculation and design ............................. 2

Delivery and storage ................................ 2

Maintenance and care.............................. 2

Disassembly and disposal......................... 2

Mounting instructions........................... 3 - 8

Warranty ................................................. 9

Expected service life ................................. 9

Technical data.......................................... 9

MC33EUM-V4A

MC45EUM-V4A

MC64EUM-V4A

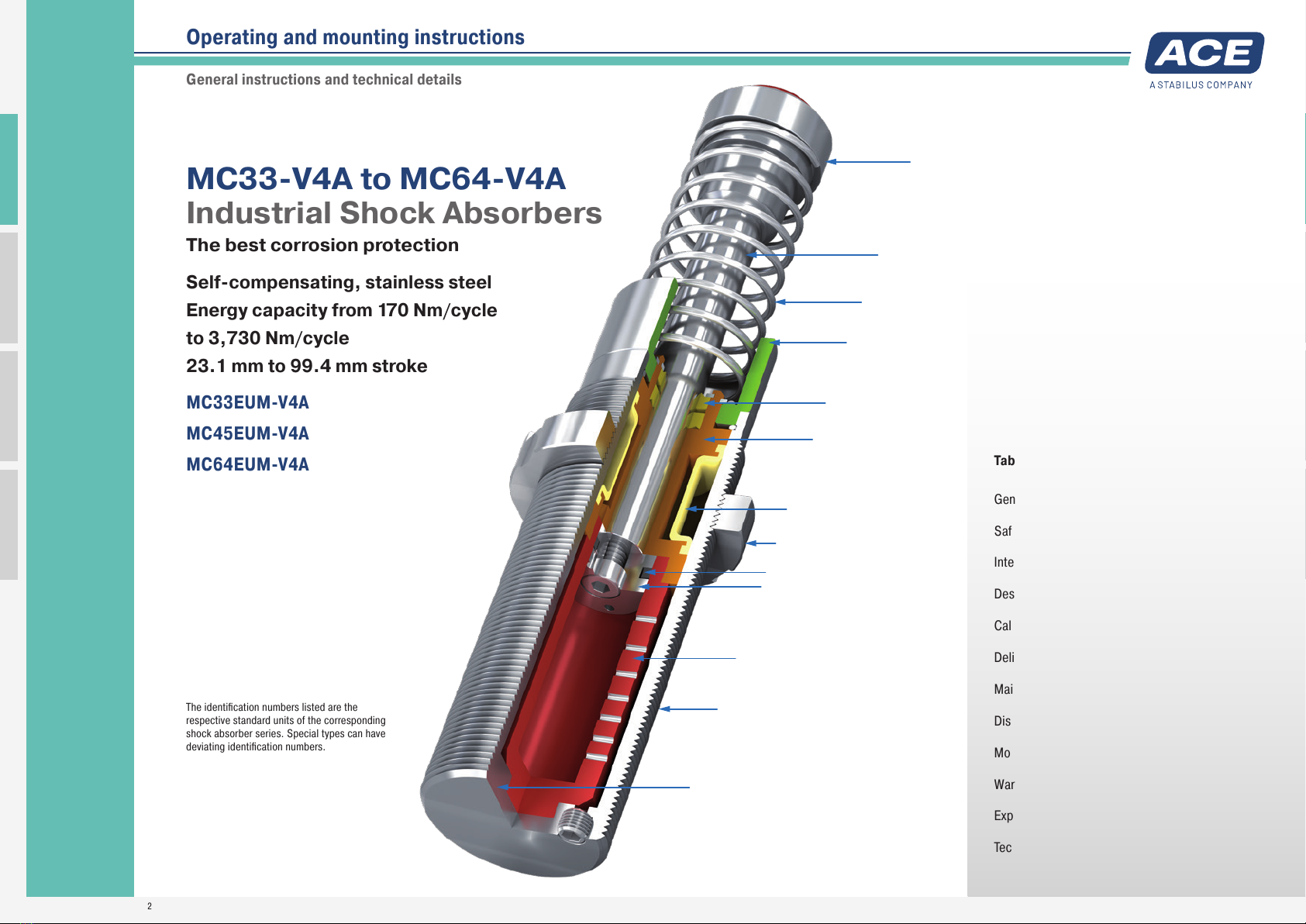

MC33-V4A to MC64-V4A

Industrial Shock Absorbers

The best corrosion protection

Self-compensating, stainless steel

Energy capacity from 170 Nm/cycle

to 3,730 Nm/cycle

23.1 mm to 99.4 mm stroke

The identification numbers listed are the

respective standard units of the corresponding

shock absorber series. Special types can have

deviating identification numbers.

Operating and mounting instructions

General instructions and technical details

Piston Rod

Membrane Accumulator

Return Spring

One-Piece Outer Body without Retaining Ring

Piston Ring

Pressure Chamber with Metering Orifices

Rod Button

Seals

Piston

Positive Stop

Main Bearing

Stainless Steel Outer Body

Stainless Steel Locking Ring

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

2

General instructions

This manual is for the disruption-free use of the product

types listed on page 1; its compliance is a prerequisite

for the fulfilment of any warranty claims.

Therefore, make sure to read this manual before use.

Please always maintain the specified limits from the per-

formance table (technical data). Take into account the

predominant environmental conditions and restrictions.

Note the regulations of the trade association, TÜV or

corresponding national, international and European reg-

ulations. Installation and commissioning only according

to mounting instructions.

Intended use

ACE industrial shock absorbers are used wherever moving masses

are to be slowed down in a defined end position. The industrial

shock absorbers are designed for force capacity in an axial

direction. Within the permissible load limits the industrial shock

absorber also acts as a stop.

Description and function

The ACE industrial shock absorbers MC33-V4A to MC64-V4A are

maintenance-free, ready-to-install hydraulic components with

numerous metering openings.

During the slowing down process the moving mass moves with

kinetic energy and, if necessary, an additional drive energy in

the axial direction of the piston rod with a defined impact velocity

against the rod end button of the shock absorber. Alternatively,

numerous shock absorbers can also be used in parallel. During the

initiated slowing down process the piston rod is pushed into the

shock absorber. The hydraulic oil located before the piston is dis-

placed through all metering orifices at the same time. The number

of effective metering openings reduces in proportion to the driven

stroke. The retraction speed reduces. The dynamic pressure ap-

plied in front of the piston corresponds to the counterforce applied

by the shock absorber and remains approximately constant over

WARNING

The dampers must be dimensioned in such a way that the

calculated values do not exceed the maximum values of the

respective performance table (technical data):

W3[Nm/cycle]

W4[Nm/h]

Effective weight me

Max. side load angle [°]

For a correct damping design the shock absorber must

represent the only braking system. Additional braking

systems, such as a pneumatic end position damping

length, must not overlap with the end position damping

length by the shock absorber and must be disabled.

Delivery and storage

- After delivery please check the shock absorber for any damage.

- The shock absorber can become damaged if it falls. Carefully

remove shock absorber from the packaging.

- Shock absorbers can generally be stored in any position.

- Storage in the original packaging is preferred.

- Always store shock absorbers in a dry place in order to avoid

oxidation.

- The recommended maximum storage time is three years.

Maintenance and care

Regularly check the shock absorbers for oil loss, return of the

piston rod and external damage.

Shock absorbers are machine elements that are subject to con-

tinuous wear. Increased service life results in reduced damping

effect. If this is no longer sufficient, the shock absorbers must be

replaced or exchanged as appropriate.

Disassembly and disposal

Take account of environmental protection (recovery of problematic

substances) during disposal of the shock absorber. The MC

industrial shock absorbers are filled with NSF-H1 approval special

oil. The corresponding data sheet is available on request.

Faulty dampers can be sent to our service department for

determination of the cause of failure.

WARNING

If ACE industrial shock absorbers are used where a

failure of the product could lead to personal injuries and/

or material damage, additional safety elements must be

implemented.

Free-moving masses can lead to injuries by crushing

during installation of the shock absorber. Secure moving

masses against inadvertent starting with suitable safety

precautions before installing the shock absorbers.

Safety information

Calculation and design

In order to ensure an optimum, fault-free and durable function of

the industrial shock absorbers they must be correctly dimen-

sioned and designed. The following parameters must be known

and used in the calculation:

- Moving mass [kg]

- Impact velocity of the mass into the shock absorber(s) [m/s]

- Additionally acting propelling force, propelling power or propel-

ling torque [N, kW, Nm]

- Number of shock absorbers acting in parallel [n]

- Number of strokes or cycles per hour [1/h]

The correct size of the shock absorbers can be determined

with the ACE online calculation programme at www.ace-ace.de.

You can also send us the completed online form via e-mail for

checking.

Or make use of our free calculation service by phoning: +49

(0)2173 - 9226-20.

General Function

F = Force (N) p = Internal pressure (bar) s = Stroke (m)

t = Deceleration time (s) v = Velocity (m/s)

* The load velocity reduces continuously as you travel through the stroke due to the

reduction in the number of metering orifices (*) in action. The internal pressure remains

essentially constant and thus the Force vs. stroke curve remains linear.

*4 *3

p = 400 bar

v = 2 m/s

*2 *1 *0

p = 400 bar

v = 1,5 m/s

p = 400 bar

v = 1 m/s

p = 400 bar

v = 0,5 m/s

p = 0 bar

v = 0 m/s

F/p

s/t

v

t

the entire stroke. A requirement for a constant rate of deceleration

is the correct calculation of the industrial shock absorber and

therefore the correct selection of the right metering orifice pattern

or the right hardness level of the shock absorber. The hardnesses

are graded from -0 to -4 (hard).

Industrial Shock Absorbers MC33-V4A to MC64-V4A (self-compensating, stainless steel)

Manual

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

3

Installation instructions

Before installation and use check whether the identification

number on the damper or on the packaging matches the respective

designation on the delivery note. Industrial shock absorbers are

maintenance-free and ready to install.

Operating temperature range: -12 °C to 66 °C

Mounting: As required but always in such a way that the entire

damper stroke is used. The dampers must always be mounted in

such a way that the forces are introduced centrally over the piston

rod. The maximum permissible side load angle (see table) must

not be exceeded. If there is a side load angle, it generally leads

to a reduction in service life. In the case of maximum permissible

values being exceeded a side load adapter must be used.

Self-compensating: The MC range of shock absorbers is

self-compensating. In a selectable range according to a table, the

different effects of power, weight, temperature and speed balance

out independently. The shock absorbers are divided into five

hardness ranges (me min. to me max.) as standard. The grading

ranges from -0 (very soft) to -4 (very hard).

WARNING

Temperature effect: The W4and me values given in the

performance table (see manual or catalogue) are valid

for room temperature. Deviating values apply to higher

temperatures.

During installation of the dampers moving masses can

lead to injuries due to inadvertent starting. Secure moving

masses against inadvertent moving.

The dampers may be unsuitable for use and have an

insufficient damping effect. Check the specific suitability

of the dampers before installation.

If operated outside of the operating temperature range,

the damper can lose its function. Operating temperature

range must be maintained. Do not paint dampers due to

heat emission.

Fluids, gases and dirt particles in the surrounding area can

attack or destroy the seal system of the damper and cause

it to fail. Protect or encapsulate piston rod and seal system

from external materials in the surrounding area.

Damage to the piston rod surface can destroy the seal

system. Do not grease, oil piston rod etc. and protect

against dirt particles.

The piston rod can be torn from the damper. Do not load

the piston rod with tensile stress.

Damper can tear off upon impact. Always lay out the

connection structure in such a way that the maximum

occurring forces can be absorbed with sufficient safety.

The maximum reacting forces listed in the calculation range

may deviate from the actually occurring reacting forces, as

these are based on theoretical values.

Commissioning

- After installation, start a test run of the moving mass at reduced

operating speed to begin with.

During the test run

- Gradually accelerate the load capacity up to the subsequent

operating speed. You can find this in the calculation for your

application. In the correct final setting, the piston rod of the

shock absorber reaches the end position (positive stop) without

a hard stop.

Mounting accessories

Information on the corresponding mounting accessories can be

found on the following pages.

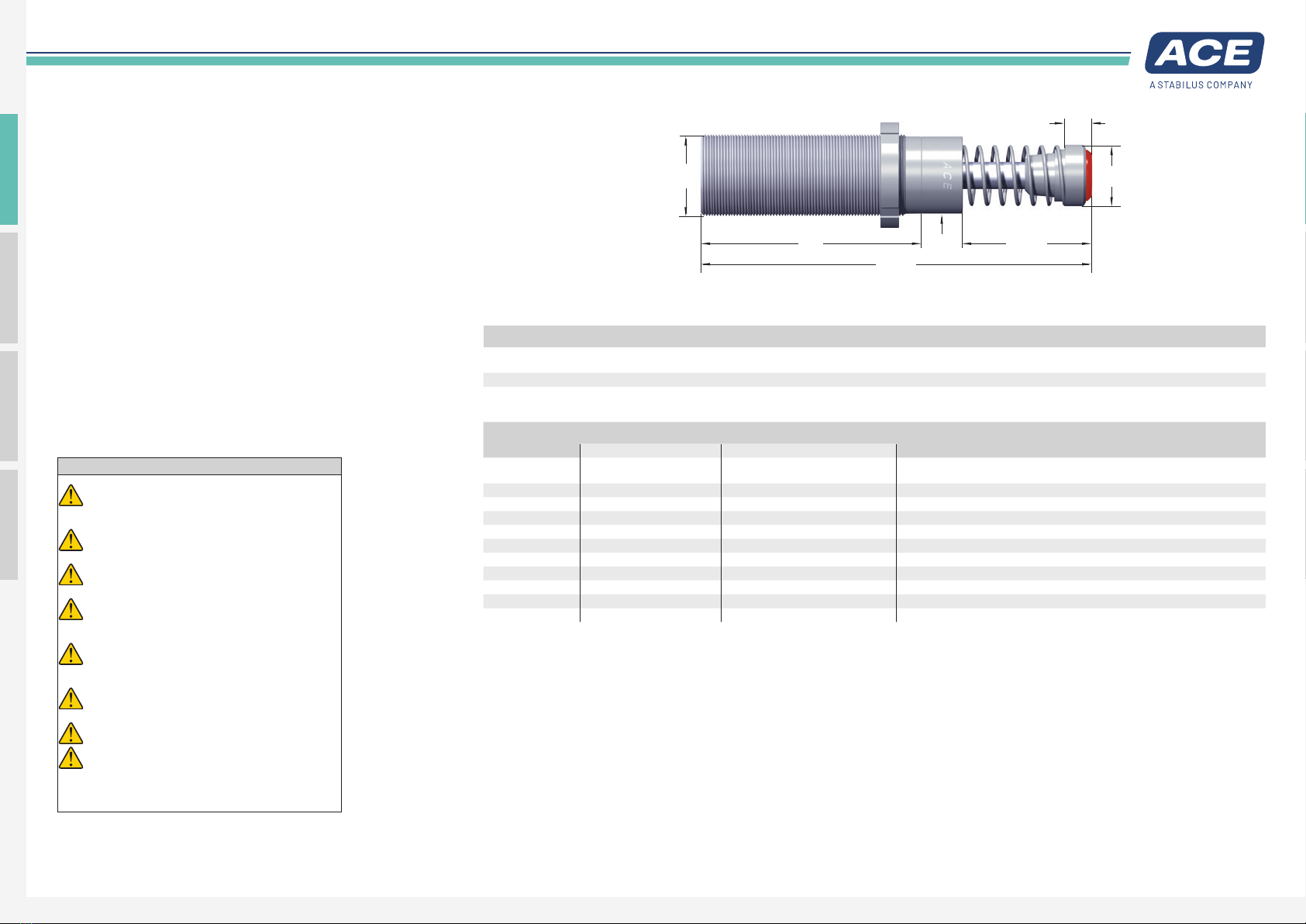

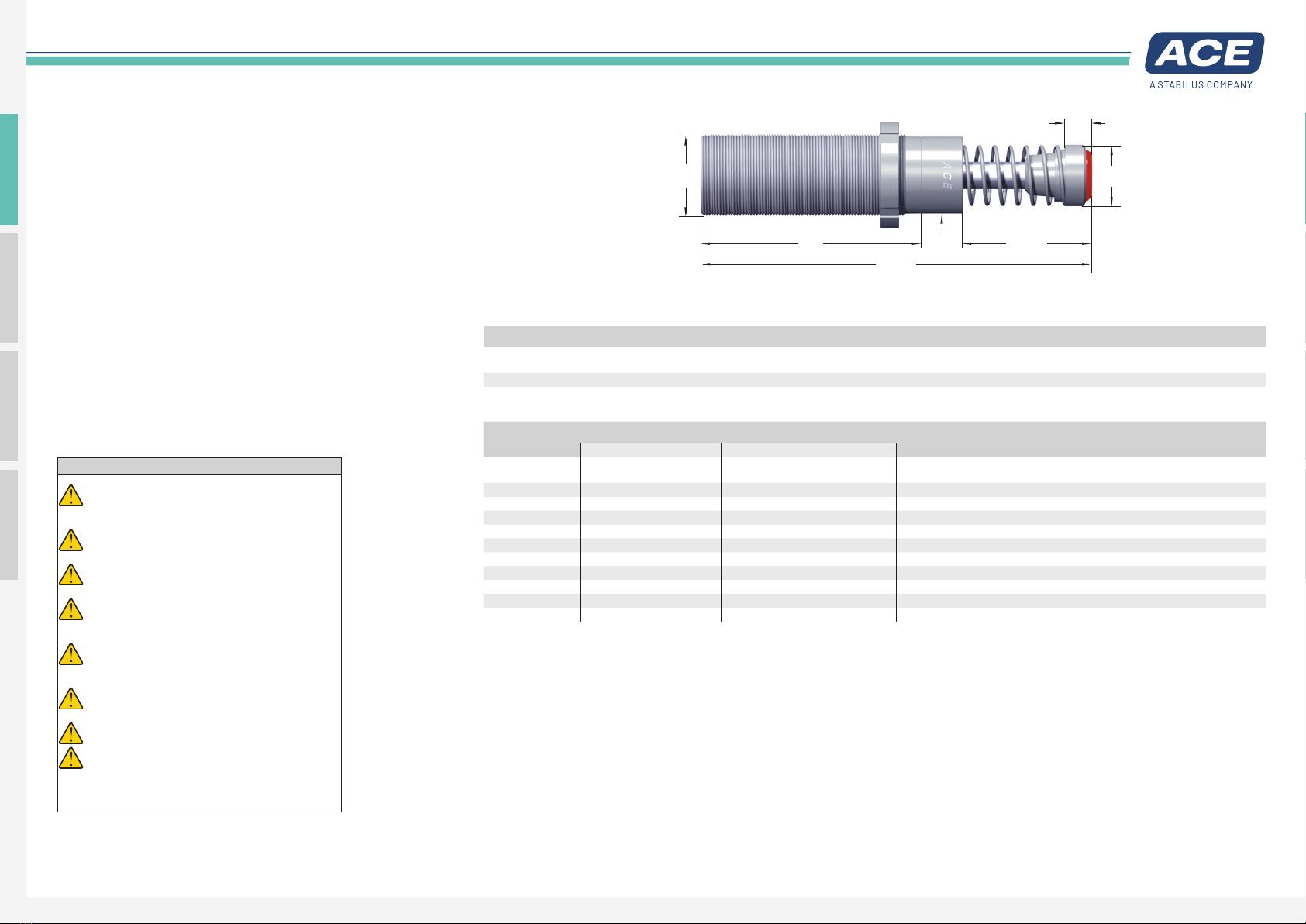

M

L2 Stroke

Ø

d1

Ø

d2

A max.

L1

Dimensions

TYPES

Stroke

mm

A max.

mm

d1

mm

d2

mm

L1

mm

L2

mm

M

MC3325EUM-V4A 23.2 151.2 30 29.2 13.2 83 M33x1.5

MC3350EUM-V4A 48.6 202.2 30 29.2 13.2 108 M33x1.5

Performance data

Max. Energy Capacity Effective Weight

TYPES

W3

Nm/cycle

W4

Nm/h

1me min.

kg

1me max.

kg

Hardness Return Force min.

N

Return Force max.

N

Return Time

s

2Side Load Angle max.

°

Weight

kg

MC3325EUM-0-V4A 170 75,000 3 11 -0 45 90 0.03 4 1.57

MC3325EUM-1-V4A 170 75,000 9 40 -1 45 90 0.03 4 0.51

MC3325EUM-2-V4A 170 75,000 30 120 -2 45 90 0.03 4 1.57

MC3325EUM-3-V4A 170 75,000 100 420 -3 45 90 0.03 4 1.55

MC3325EUM-4-V4A 170 75,000 350 1,420 -4 45 90 0.03 4 1.57

MC3350EUM-0-V4A 330 85,000 5 22 -0 45 135 0.06 3 1.64

MC3350EUM-1-V4A 330 85,000 18 70 -1 45 135 0.06 3 1.63

MC3350EUM-2-V4A 330 85,000 60 250 -2 45 135 0.06 3 1.63

MC3350EUM-3-V4A 330 85,000 210 840 -3 45 135 0.06 3 1.61

MC3350EUM-4-V4A 330 85,000 710 2,830 -4 45 135 0.06 3 1.63

1It is permissible to exceed the stated energy in emergency stop situations. In the event of such a case, please contact ACE.

2If side load angle is higher contact ACE.

Packaging disposal

Please dispose of the transportation packaging in an environ-

mentally-friendly manner. Recycling packaging materials saves

raw materials and reduces waste. The packaging materials do not

contain any prohibited materials.

Model type prefix

Standard types

MC: self-contained with return spring, self-compensating

Special types

MCA: not self-contained, without spring. Use only with external air/oil tank.

MCS: not self-contained, with spring. Use only with external air/oil tank.

MCN: self-contained, without spring

Mounting instructions and mounting accessories

Industrial Shock Absorbers MC33-V4A (self-compensating, stainless steel)

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

4

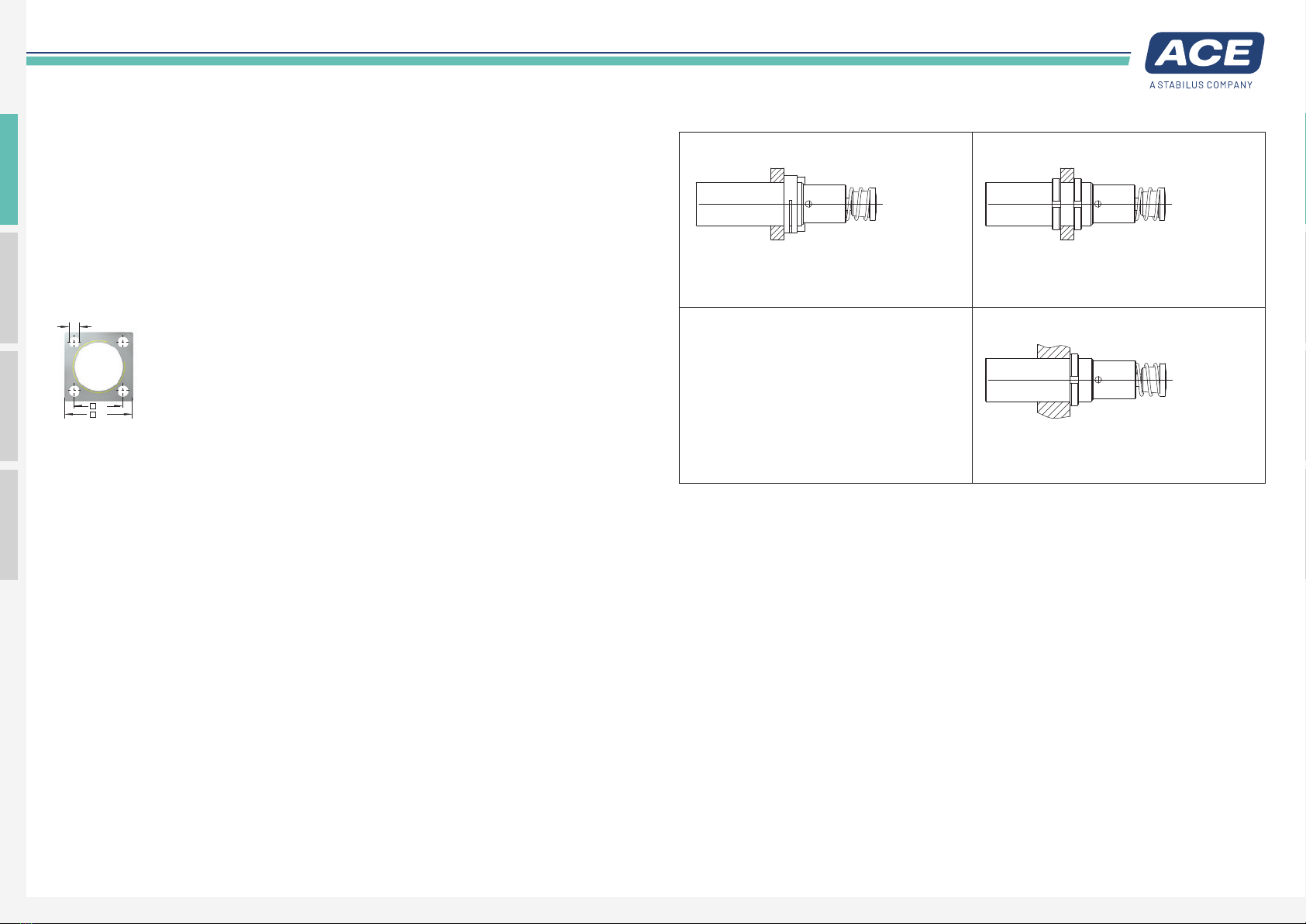

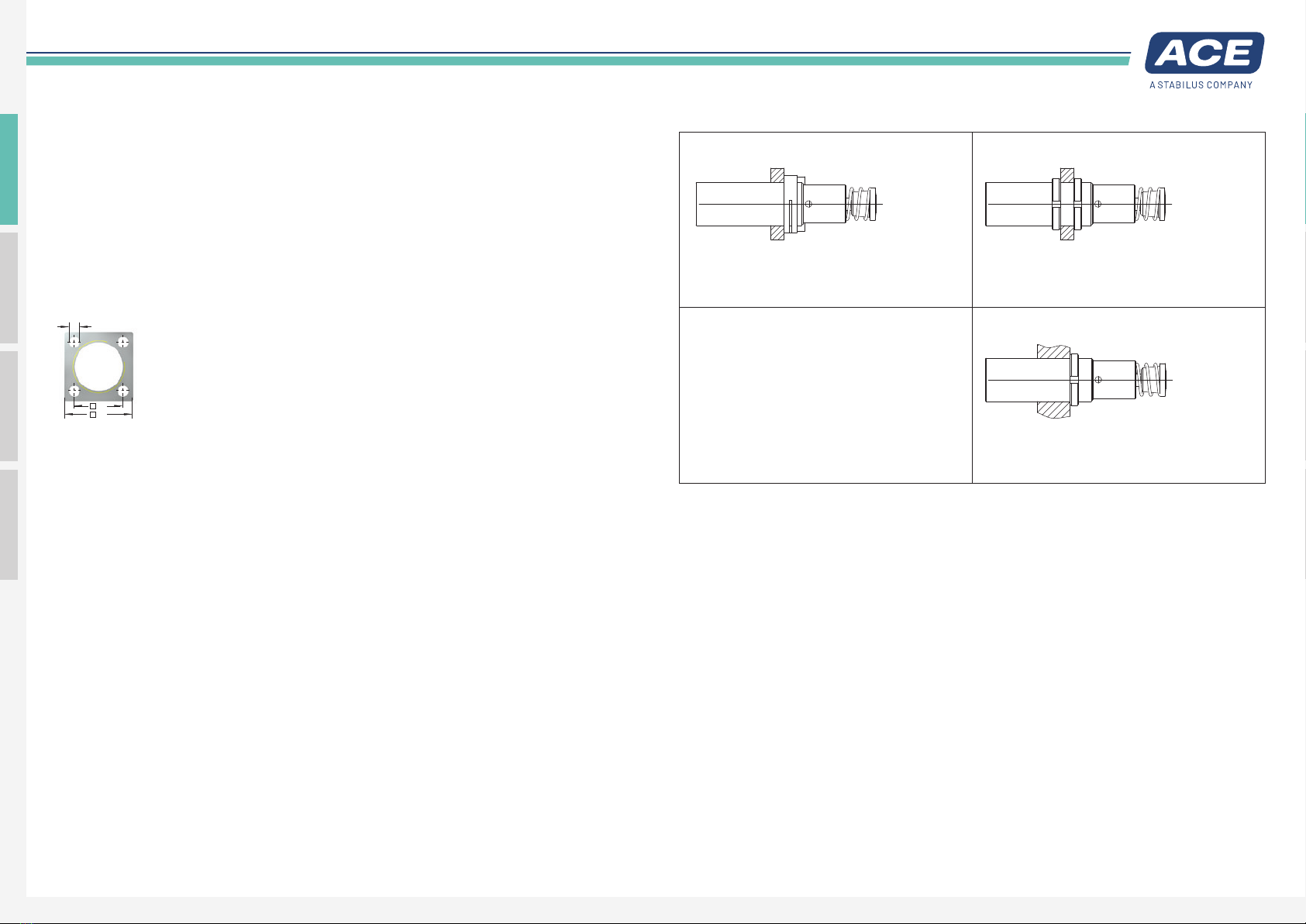

M33x1.5 mounting accessories

MC33-V4A

Before installation check whether the identification number on

the packaging matches the respective designation on the delivery

note.

Note the dimensioning for mounting when using accessory parts.

Bolts for fitting of accessories are not included.

If you have any questions, please phone +49 (0)2173 - 9226-20

for free advice.

When using accessory parts and mounting elements also note the

Mounting types

QF33-V4A

Square Flange

44

Thickness

10 mm

32

6.6

Ø

mounting instructions for accessories delivered separately.

Mounting with Square Flange QF-V4A Mounting of damper in borehole with two locking rings

Screwing the damper into a threaded hole with

additional locking ring

Torque: 80 Nm

Mount with 4 bolts

Torque max.: 11 Nm

Clamping torque: > 90 Nm

Torque: 80 Nm

Mounting instructions and mounting accessories

Industrial Shock Absorbers MC33-V4A (self-compensating, stainless steel) – mounting accessories

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

5

M

L2 Stroke

Ø

d1

Ø

d2

A max.

L1

Installation instructions

Before installation and use check whether the identification

number on the damper or on the packaging matches the respective

designation on the delivery note. Industrial shock absorbers are

maintenance-free and ready to install.

Operating temperature range: -12 °C to 66 °C

Mounting: As required but always in such a way that the entire

damper stroke is used. The dampers must always be mounted in

such a way that the forces are introduced centrally over the piston

rod. The maximum permissible side load angle (see table) must

not be exceeded. If there is a side load angle, it generally leads

to a reduction in service life. In the case of maximum permissible

values being exceeded a side load adapter must be used.

Self-compensating: The MC range of shock absorbers is

self-compensating. In a selectable range according to a table, the

different effects of power, weight, temperature and speed balance

out independently. The shock absorbers are divided into five

hardness ranges (me min. to me max.) as standard. The grading

ranges from -0 (very soft) to -4 (very hard).

WARNING

Temperature effect: The W4and me values given in the

performance table (see manual or catalogue) are valid

for room temperature. Deviating values apply to higher

temperatures.

During installation of the dampers moving masses can

lead to injuries due to inadvertent starting. Secure moving

masses against inadvertent moving.

The dampers may be unsuitable for use and have an

insufficient damping effect. Check the specific suitability

of the dampers before installation.

If operated outside of the operating temperature range,

the damper can lose its function. Operating temperature

range must be maintained. Do not paint dampers due to

heat emission.

Fluids, gases and dirt particles in the surrounding area can

attack or destroy the seal system of the damper and cause

it to fail. Protect or encapsulate piston rod and seal system

from external materials in the surrounding area.

Damage to the piston rod surface can destroy the seal

system. Do not grease, oil piston rod etc. and protect

against dirt particles.

The piston rod can be torn from the damper. Do not load

the piston rod with tensile stress.

Damper can tear off upon impact. Always lay out the

connection structure in such a way that the maximum

occurring forces can be absorbed with sufficient safety.

The maximum reacting forces listed in the calculation range

may deviate from the actually occurring reacting forces, as

these are based on theoretical values.

Commissioning

- After installation, start a test run of the moving mass at reduced

operating speed to begin with.

During the test run

- Gradually accelerate the load capacity up to the subsequent

operating speed. You can find this in the calculation for your

application. In the correct final setting, the piston rod of the

shock absorber reaches the end position (positive stop) without

a hard stop.

Mounting accessories

Information on the corresponding mounting accessories can be

found on the following pages.

Dimensions

TYPES

Stroke

mm

A max.

mm

d1

mm

d2

mm

L1

mm

L2

mm

M

MC4525EUM-V4A 23.1 164.5 42 42 19.4 95 M45x1.5

MC4550EUM-V4A 48.5 214.4 42 42 19.4 120 M45x1.5

MC4575EUM-V4A 73.9 265.4 42 42 19.4 145 M45x1.5

Performance data

Max. Energy Capacity Effective Weight

TYPES

W3

Nm/cycle

W4

Nm/h

1me min.

kg

1me max.

kg

Hardness Return Force min.

N

Return Force max.

N

Return Time

s

2Side Load Angle max.

°

Weight

kg

MC4525EUM-0-V4A 370 107,000 7 27 -0 70 100 0.03 4 1.14

MC4525EUM-1-V4A 370 107,000 20 90 -1 70 100 0.03 4 2.09

MC4525EUM-2-V4A 370 107,000 80 310 -2 70 100 0.03 4 1.14

MC4525EUM-3-V4A 370 107,000 260 1,050 -3 70 100 0.03 4 1.31

MC4525EUM-4-V4A 370 107,000 890 3,540 -4 70 100 0.03 4 1.31

MC4550EUM-0-V4A 740 112,000 13 54 -0 70 145 0.08 3 1.41

MC4550EUM-1-V4A 740 112,000 45 180 -1 70 145 0.08 3 1.36

MC4550EUM-2-V4A 740 112,000 150 620 -2 70 145 0.08 3 1.37

MC4550EUM-3-V4A 740 112,000 520 2,090 -3 70 145 0.08 3 1.41

MC4550EUM-4-V4A 740 112,000 1,800 7,100 -4 70 145 0.08 3 1.39

MC4575EUM-0-V4A 1,130 146,000 20 80 -0 50 180 0 . 11 2 1.59

MC4575EUM-1-V4A 1,130 146,000 70 270 -1 50 180 0 .11 2 1.59

MC4575EUM-2-V4A 1,130 146,000 230 930 -2 50 180 0 .11 2 1.50

MC4575EUM-3-V4A 1,130 146,000 790 3,140 -3 50 180 0 .11 2 1.59

MC4575EUM-4-V4A 1,130 146,000 2,650 10,600 -4 50 180 0 .11 2 1.59

1It is permissible to exceed the stated energy in emergency stop situations. In the event of such a case, please contact ACE.

2If side load angle is higher contact ACE.

Packaging disposal

Please dispose of the transportation packaging in an environ-

mentally-friendly manner. Recycling packaging materials saves

raw materials and reduces waste. The packaging materials do not

contain any prohibited materials.

Model type prefix

Standard types

MC: self-contained with return spring, self-compensating

Special types

MCA: not self-contained, without spring. Use only with external air/oil tank.

MCS: not self-contained, with spring. Use only with external air/oil tank.

MCN: self-contained, without spring

Mounting instructions and mounting accessories

Industrial Shock Absorbers MC45-V4A (self-compensating, stainless steel)

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

6

M45x1.5 mounting accessories

MC45-V4A

Before installation check whether the identification number on

the packaging matches the respective designation on the delivery

note.

Note the dimensioning for mounting when using accessory parts.

Bolts for fitting of accessories are not included.

If you have any questions, please phone +49 (0)2173 - 9226-20

for free advice.

When using accessory parts and mounting elements also note the

mounting instructions for accessories delivered separately. Mounting types

QF45-V4A

Square Flange

56

Thickness

12 mm

42

9

Ø

Mounting with Square Flange QF-V4A Mounting of damper in borehole with two locking rings

Screwing the damper into a threaded hole with

additional locking ring

Torque: 235 Nm

Mount with 4 bolts

Torque max.: 27 Nm

Clamping torque: > 200 Nm

Torque: 235 Nm

Mounting instructions and mounting accessories

Industrial Shock Absorbers MC45-V4A (self-compensating, stainless steel) – mounting accessories

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

7

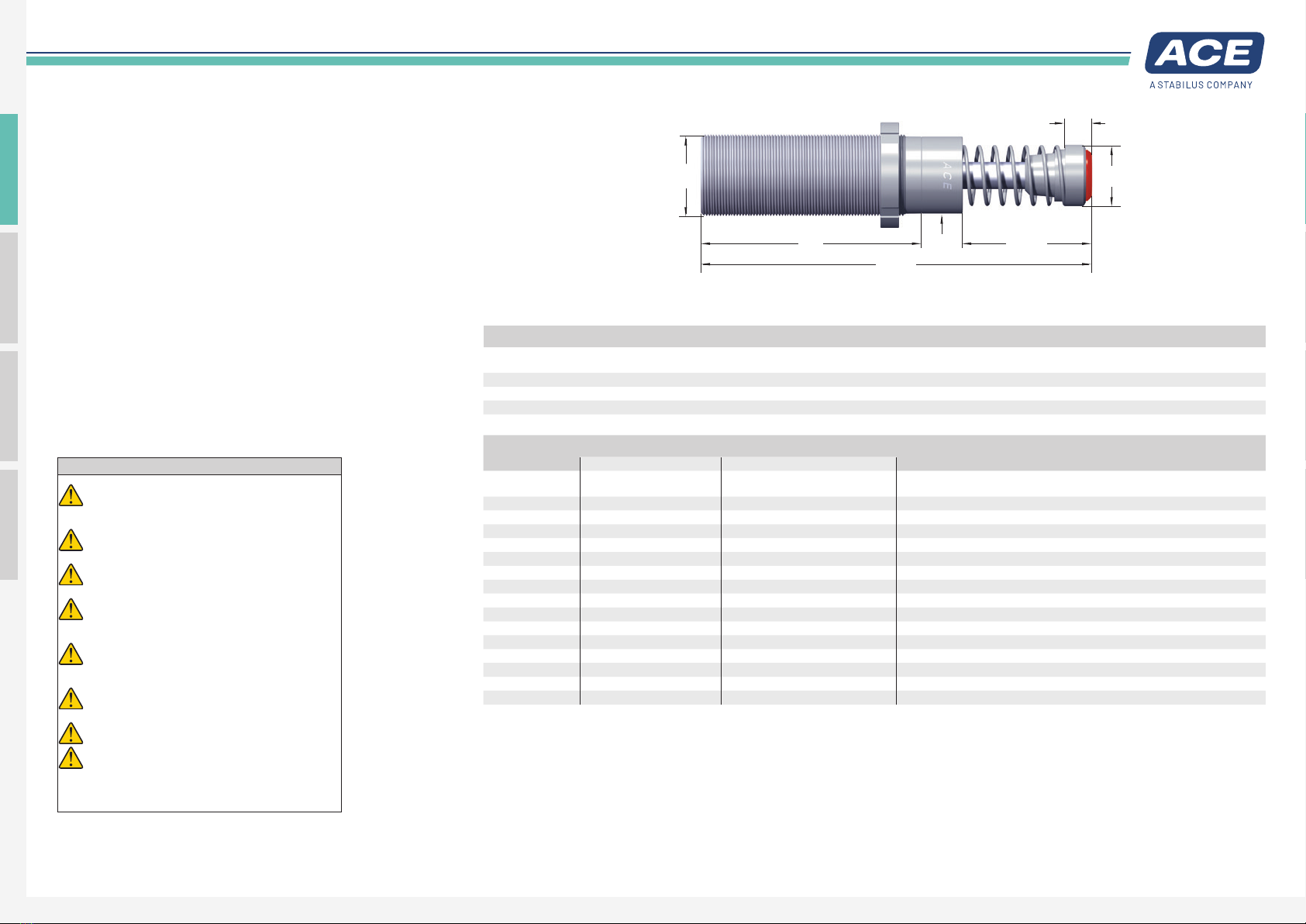

M

L2 Stroke

Ø

d1

Ø

d2

A max.

L1

Installation instructions

Before installation and use check whether the identification

number on the damper or on the packaging matches the respective

designation on the delivery note. Industrial shock absorbers are

maintenance-free and ready to install.

Operating temperature range: -12 °C to 66 °C

Mounting: As required but always in such a way that the entire

damper stroke is used. The dampers must always be mounted in

such a way that the forces are introduced centrally over the piston

rod. The maximum permissible side load angle (see table) must

not be exceeded. If there is a side load angle, it generally leads

to a reduction in service life. In the case of maximum permissible

values being exceeded a side load adapter must be used.

Self-compensating: The MC range of shock absorbers is

self-compensating. In a selectable range according to a table, the

different effects of power, weight, temperature and speed balance

out independently. The shock absorbers are divided into five

hardness ranges (me min. to me max.) as standard. The grading

ranges from -0 (very soft) to -4 (very hard).

WARNING

Temperature effect: The W4and me values given in the

performance table (see manual or catalogue) are valid

for room temperature. Deviating values apply to higher

temperatures.

During installation of the dampers moving masses can

lead to injuries due to inadvertent starting. Secure moving

masses against inadvertent moving.

The dampers may be unsuitable for use and have an

insufficient damping effect. Check the specific suitability

of the dampers before installation.

If operated outside of the operating temperature range,

the damper can lose its function. Operating temperature

range must be maintained. Do not paint dampers due to

heat emission.

Fluids, gases and dirt particles in the surrounding area can

attack or destroy the seal system of the damper and cause

it to fail. Protect or encapsulate piston rod and seal system

from external materials in the surrounding area.

Damage to the piston rod surface can destroy the seal

system. Do not grease, oil piston rod etc. and protect

against dirt particles.

The piston rod can be torn from the damper. Do not load

the piston rod with tensile stress.

Damper can tear off upon impact. Always lay out the

connection structure in such a way that the maximum

occurring forces can be absorbed with sufficient safety.

The maximum reacting forces listed in the calculation range

may deviate from the actually occurring reacting forces, as

these are based on theoretical values.

Commissioning

- After installation, start a test run of the moving mass at reduced

operating speed to begin with.

During the test run

- Gradually accelerate the load capacity up to the subsequent

operating speed. You can find this in the calculation for your

application. In the correct final setting, the piston rod of the

shock absorber reaches the end position (positive stop) without

a hard stop.

Mounting accessories

Information on the corresponding mounting accessories can be

found on the following pages.

Dimensions

TYPES

Stroke

mm

A max.

mm

d1

mm

d2

mm

L1

mm

L2

mm

M

MC6450EUM-V4A 48.6 244.1 60 60 19.1 140 M64x2

MC64100EUM-V4A 99.4 345.1 60 60 19.1 191 M64x2

Performance data

Max. Energy Capacity Effective Weight

TYPES

W3

Nm/cycle

W4

Nm/h

1me min.

kg

1me max.

kg

Hardness Return Force min.

N

Return Force max.

N

Return Time

s

2Side Load Angle max.

°

Weight

kg

MC6450EUM-0-V4A 1,870 146,000 35 140 -0 90 155 0.12 4 2.90

MC6450EUM-1-V4A 1,870 146,000 140 540 -1 90 155 0.12 4 2.90

MC6450EUM-2-V4A 1,870 146,000 460 1,850 -2 90 155 0.12 4 3.61

MC6450EUM-3-V4A 1,870 146,000 1,600 6,300 -3 90 155 0.12 4 2.90

MC6450EUM-4-V4A 1,870 146,000 5,300 21,200 -4 90 155 0.12 4 2.90

MC64100EUM-0-V4A 3,730 192,000 70 280 -0 105 270 0.34 3 4.01

MC64100EUM-1-V4A 3,730 192,000 270 11,000 -1 105 270 0.34 3 3.99

MC64100EUM-2-V4A 3,730 192,000 930 3,700 -2 105 270 0.34 3 3.99

MC64100EUM-3-V4A 3,730 192,000 3,150 12,600 -3 105 270 0.34 3 3.70

MC64100EUM-4-V4A 3,730 192,000 10,600 42,500 -4 105 270 0.34 3 3.70

1It is permissible to exceed the stated energy in emergency stop situations. In the event of such a case, please contact ACE.

2If side load angle is higher contact ACE.

Packaging disposal

Please dispose of the transportation packaging in an environ-

mentally-friendly manner. Recycling packaging materials saves

raw materials and reduces waste. The packaging materials do not

contain any prohibited materials.

Model type prefix

Standard types

MC: self-contained with return spring, self-compensating

Special types

MCA: not self-contained, without spring. Use only with external air/oil tank.

MCS: not self-contained, with spring. Use only with external air/oil tank.

MCN: self-contained, without spring

Mounting instructions and mounting accessories

Industrial Shock Absorbers MC64-V4A (self-compensating, stainless steel)

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

8

M64x2 mounting accessories

MC64-V4A

Before installation check whether the identification number on

the packaging matches the respective designation on the delivery

note.

Note the dimensioning for mounting when using accessory parts.

Bolts for fitting of accessories are not included.

If you have any questions, please phone +49 (0)2173 - 9226-20

for free advice.

When using accessory parts and mounting elements also note the

mounting instructions for accessories delivered separately. Mounting types

QF64-V4A

Square Flange

80

Thickness

16 mm

58

11

Ø

Mounting with Square Flange QF-V4A Mounting of damper in borehole with two locking rings

Screwing the damper into a threaded hole with

additional locking ring

Torque: 780 Nm

Mount with 4 bolts

Torque max.: 50 Nm

Clamping torque: > 210 Nm

Torque: 780 Nm

Mounting instructions and mounting accessories

Industrial Shock Absorbers MC64-V4A (self-compensating, stainless steel) – mounting accessories

ACE Stoßdämpfer GmbH · Postfach 1510 · D-40740 Langenfeld · T +49 (0)2173 - 9226-10 (Technik -20) · F +49 (0)2173 - 9226-19 · [email protected] · www.ace-ace.comStand 03.2021 ACE Stoßdämpfer GmbH · www.ace-ace.com21_22_0019 Issue 05.2022

9

Warranty

Fundamentally, all modifications to the product by third parties

lead to exclusion from the warranty.

Obvious defects must be reported to the vendor in writing immedi-

ately after delivery, no later than one week, but in any case before

processing or installation, otherwise the assertion of a warranty

claim is excluded. A timely dispatch is sufficient to keep the term.

The vendor is to be given an opportunity to check on site. If the

complaint is justified the vendor offers warranty by repair or re-

placement at its own discretion. If the rectification fails, the buyer

may choose to demand reduction of payment or cancellation of

the contract. If there is only a minor lack of conformity, particularly

with only minor defects, the buyer nevertheless has a right of

withdrawal.

If, after failed rectification, the buyer chooses to cancel the

contract due to a defect of title or material defect, they are not

entitled to additionally claim for damages.

If, after failed fulfilment, the buyer chooses compensation, the

goods remain with the buyer, if this is reasonable. The compen-

sation is limited to the difference between the purchase price and

the value of the defective item. This does not apply if the vendor

maliciously causes the breach of contract.

The quality of the goods is only considered as agreed upon with

the product description of the vendor. Public statements, claims

or advertising of the manufacturer do not represent an additional

contractual specification of quality of the goods.

If the buyer receives defective mounting instructions, the buyer

is only obligated to deliver defect-free mounting instructions and

only if the defect to the mounting instructions prevents proper

mounting.

The warranty period is two years and begins upon completion.

Exchange and return of custom products are fundamentally

excluded. The factory conditions of the manufacturing factory

apply to parts not manufactured and processed by the vendor,

which can be viewed by the orderer at the vendor at any time.

Construction and installation parts are delivered according to the

present standard of engineering.

Service life

In general industrial shock absorbers are machine elements that

are subject to wear. Wear parts such as seals, pressure chambers

and pistons are excluded from the general warranty. The wear of

seals is largely dependent upon the operating conditions and the

respective application and its operating parameters.

In general with this model of industrial shock absorber with

grooved ring wiper seal system an average service life of three to

five million load changes can be expected. Adverse environmental

and operating conditions can significantly reduce the expected

service life.

Technical data

Energy capacity: 170 Nm/cycle to 3,730 Nm/cycle

Impact velocity range: 0.15 m/s to 5 m/s (depending on type and calculation of effective weight). Other speeds on request.

Operating temperature range: -12 °C to +66 °C. Other temperatures on request.

Mounting: in any position

Positive stop: integrated

Material: Outer body, main bearing, accessories, locking ring: V4A (1.4404, AISI 316L)

Piston rod: Hard chrome plated steel

Piston rod seal: NBR

Rod end button: V4A (1.4404, AISI 316L) with elastomer insert

Return spring: Stainless steel

Permissible torque of locknut:

MC33-V4A: 80 Nm

MC45-V4A: 235 Nm

MC64-V4A: 780 Nm

Damping medium: Special oil NSF-H1 approved

Application field: Linear slides, Swivel units, Turntables, Food industry, Medical technology, Portal systems, Machines and plants, Tool

machines, Machining centres

Note: The damper includes a PP head for noise reduction. It is permissible to exceed the stated energy in emergency stop situations

and continuous use (with external cooling). In the event of such a case, please contact ACE.

Safety instructions: External materials in the surrounding area can attack the sealing components and lead to a shorter service life.

Please contact ACE for appropriate solution suggestions. Do not paint the shock absorbers due to heat emission.

On request: Special oils, other special options and special accessories are available on request.

Industrial Shock Absorbers MC33-V4A to MC64-V4A (self-compensating, stainless steel)

Manual

This manual suits for next models

46

Other STABILUS Industrial Equipment manuals

STABILUS

STABILUS ACE FRT-C2 Service manual

STABILUS

STABILUS ACE TUBUS TC Service manual

STABILUS

STABILUS ACE FRT-D2 Service manual

STABILUS

STABILUS ACE TUBUS TR-HD Service manual

STABILUS

STABILUS ACE TUBUS TR-L Service manual

STABILUS

STABILUS FYT-LA3 Service manual

STABILUS

STABILUS ACE FYT-H1 Service manual

STABILUS

STABILUS ACE FRT-F2 Service manual

Popular Industrial Equipment manuals by other brands

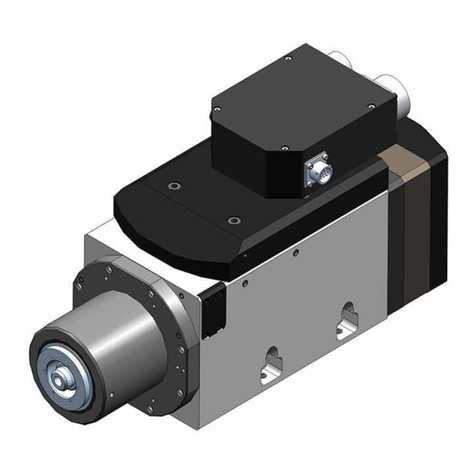

SCHUNK

SCHUNK SPG 100 Assembly and operating manual

HSD

HSD ES779 Translation of the original instructions

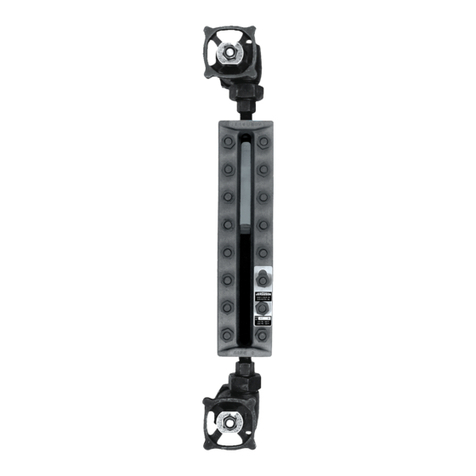

Jerguson

Jerguson 300L Series Installation, Operation & Maintenance Instruction Manual

Dynatech

Dynatech STAR Instructions for use and maintenance

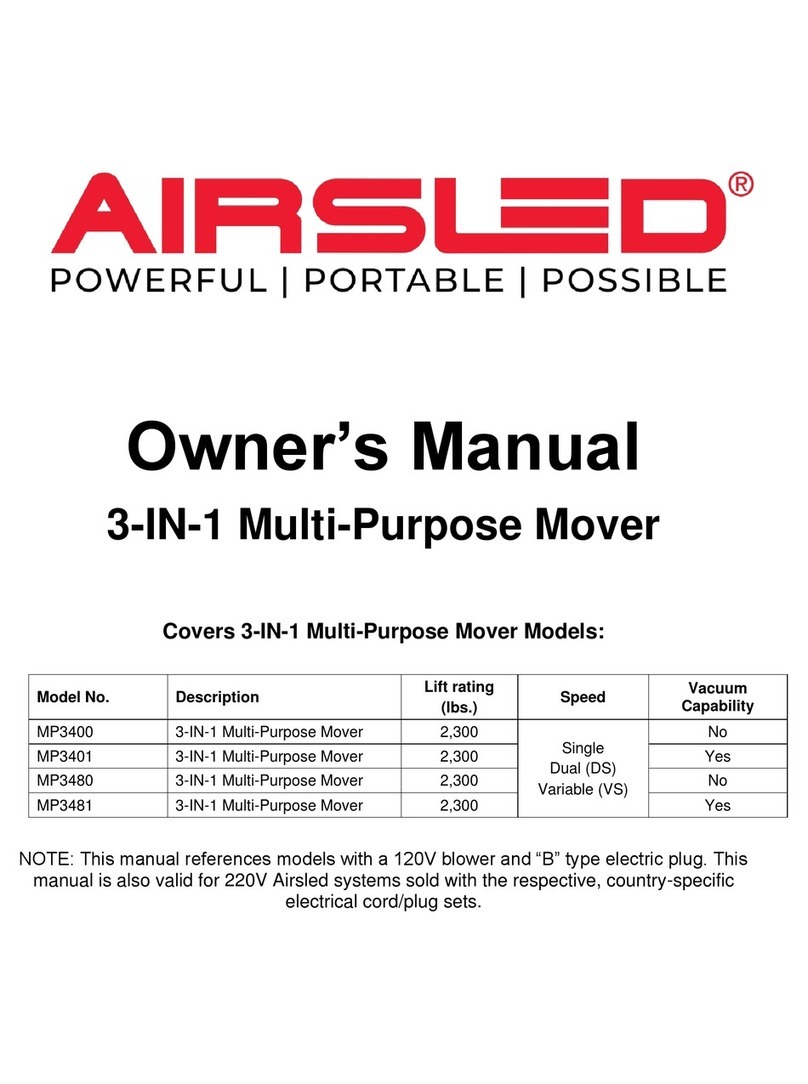

AIRSLED

AIRSLED MP3400 owner's manual

Nederman

Nederman MagnaTrack ST user manual