Description

Model 8592 is a portable non-pressurized drain designed to safely

capture fluids drained from vehicles on service lifts.

Owner/Operator Responsibility

It is the owner/operator responsibility to properly use and maintain

this equipment. The instructions and warnings contained in this

manual shall be read and understood by the owner/operator prior to

operating this equipment. If an owner/operator does not under-

stand English, the contents of this manual shall be explained in the

owner/operator’s native language to assure that the owner/operator

comprehends. The owner/operator shall retain this manual for the

future reference to important warnings, operating and maintenance

instructions.

General Safety Standards

The Standards listed below must be observed to prevent injury to

operators and damage to the Used Fluid Drain.

•Read all Labels on the Used Fluid Drain carefully, do not cover

them and replace them immediately if damaged.

•The Used Fluid Drain must only be used by authorized personal

trained in its use.

•NEVER leave Drain unattended when operating or evacuating.

•NEVER use Drain near open flame or heat source.

•NEVER use Drain for handling highly volatile fuels and fluids.

•Do not use acid solutions which could damage the Drain and/or

injure persons.

•The Drain will remain in place up to a maximum gradient of

0.5%, before beginning to slide.

Inspection

Prior to operation or maintenance, a visual inspection shall be

made. Check for worn, damaged, loose and/or missing parts.

If the Drain is damaged, badly worn or operates abnormally, it

should be removed from service. Contact a factory authorized ser-

vice center for repair.

An annual tank/component inspection is recommended to be per-

formed by a factory authorized service center.

Tank Maintenance

The Drain does not require any special maintenance, other than

normal cleaning, which should be done with a damp cloth (water

and alcohol or normal detergent for household appliances made out

of plastic).

C AUTION

IMPORTANT! Do not use cleaning solutions that can damage

plastic containers.

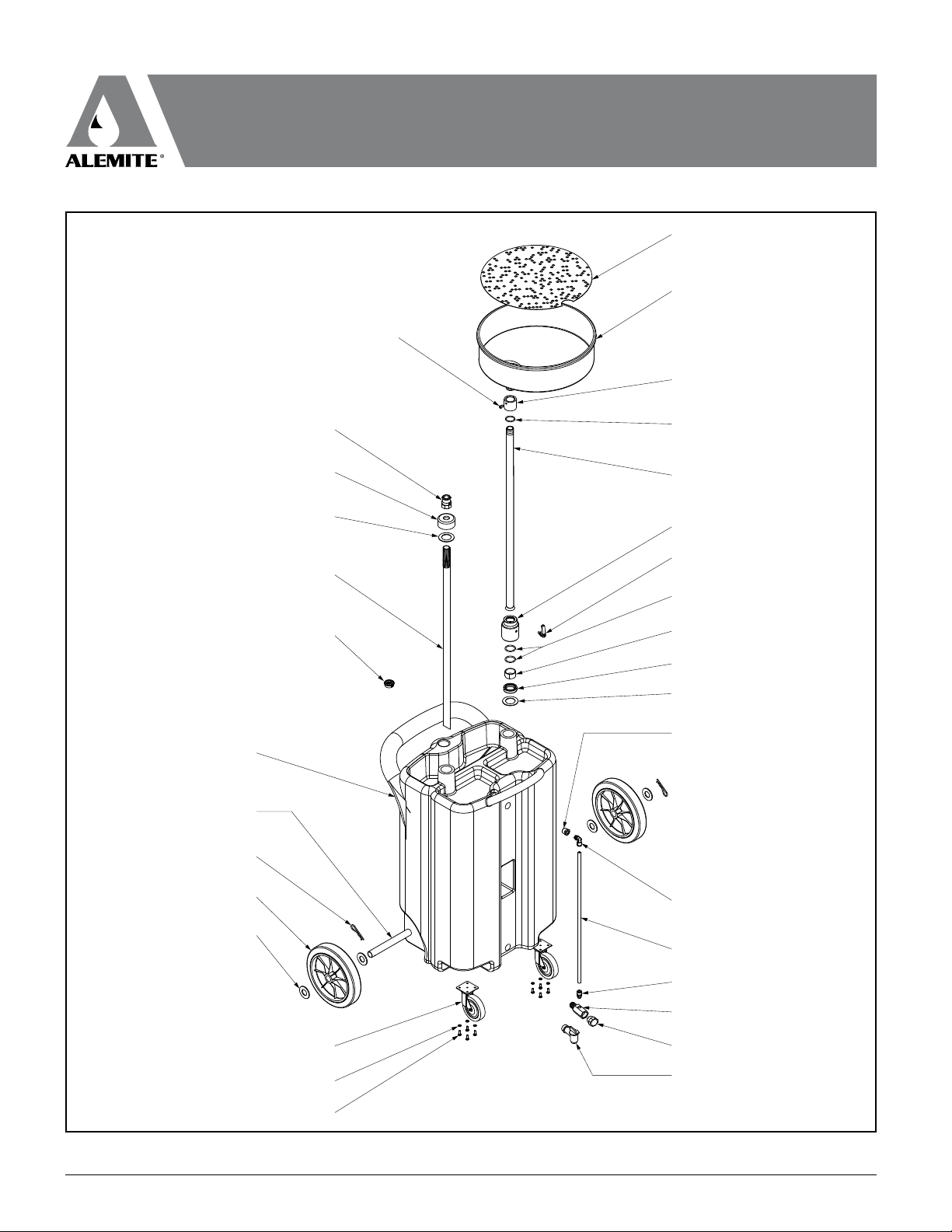

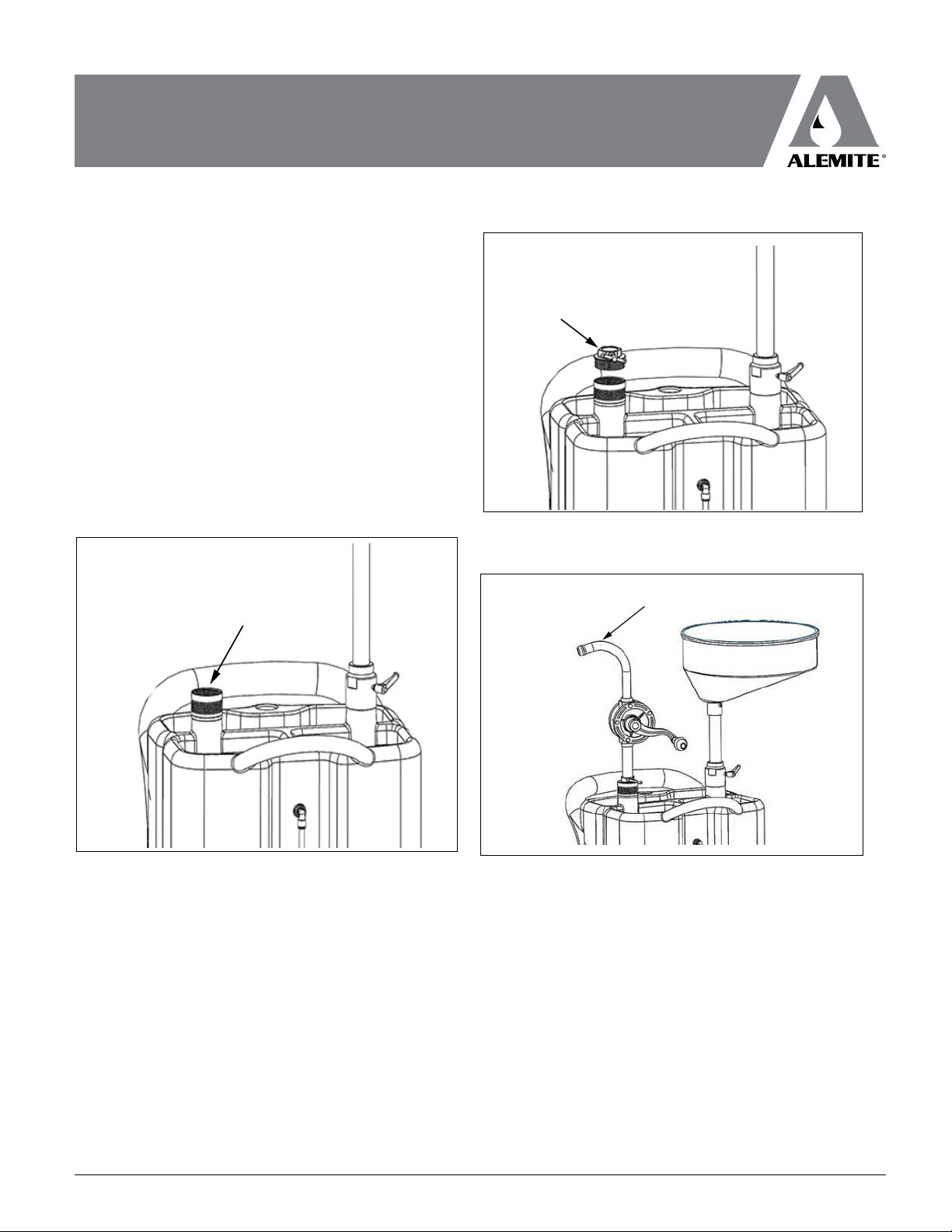

Emptying the Tank

Before the tank approaches maximum fill (as seen through the

Sight-Gauge (5) , empty the tank by connecting Camlock Fitting (20)

to an Evacuation System. The length of Suction Pipe (22) ensures

that it clears the tank bottom to prevent solids and sediments from

being sucked into and damaging the evacuation pump.

C AUTION

It is highly recommended that the tank be emptied and cleaned

of all sediments through frequently scheduled maintenance.

Sediments may build up high enough to start clogging the Suction

Pipe (22) before the next scheduled tank purge. A stop-gap feature

has been designed into the Suction Pipe (22) to enable oil evacua-

tion to proceed temporarily (See Figure 3).

1.

Apply a wrench to Camlock Fitting (20) and turn it counter

clockwise. [If necessary, secure Plug (21) with a pipe wrench to

hold it stationary.]

2.

Raise the Suction Pipe (22) to a maximum height of 1-5/8

inches (41mm).

3.

Connect Camlock Fitting (20) to an evacuation system and com-

plete emptying of the tank.

4.

Schedule a tank purge as soon as possible before the tank fills

up with more sediments and solids.

5.

Upon completion of the tank purge, turn Camlock Fitting (20)

clockwise as far down as possible to reset the Suction Tube (22)

height.

Portable Used Fluid Drain 8592

02-2020 2 Alemite, LLC

Figure 3: Raising Suction Piping